Popular models of hydrogen units for heating systems

Chinese generator Kingkar3000

Producing “Brown gas” - a mixture of oxygen and hydrogen in a ratio of 2 to 1. Moreover, the user can adjust the temperature of the torch in the range from 800 to 3200 degrees Celsius, changing the percentage of components in the fuel mixture.

Installation characteristics:

- Water consumption – 1.6 liters per hour.

- Fuel generation – 3 m3/hour.

- Energy consumption – up to 9 kW.

- Cost – 8000 US dollars.

Combustible mixture generators for heating with hydrogen

STAR 1000 and STAR 2000

Demonstrate the following characteristics:

- Water consumption is from 0.7 to 1.1 liters per hour or 5.5 liters per day.

- Fuel generation – from 1.2 to 2.0 m3/hour.

- The estimated period of operation is at least 15 years.

- Energy consumption – from 1.2 to 3 kW.

- Heated area – up to 250 square meters.

- Price – up to 230,000 rubles.

Hydrogen boiler STAR-1.1

Working in tandem with the STAR 2000 generator:

- Thermal power – 27 kW

- Energy consumption – 300 W/hour.

- The number of circuits is one heating + one hot water, installed for an additional fee.

- Cost – 63 -73 thousand rubles.

Main nuances of hydrogen boilers

The power of hydrogen-based boilers is selected depending on the area of the structure that needs to be heated.

Using this type of technology, you can solve many heating-related problems. This occurs due to the simultaneous functioning of several channels designed to generate hydrogen energy (there can be a maximum of 6).

The modular system inherent in hydrogen boilers ensures independent operation of the channels, without in any way affecting the efficiency of the installation. Each individual channel contains its own catalyst.

Advantages of hydrogen heating

A hydrogen-powered boiler is in demand for many reasons:

- The inexhaustibility of hydrogen, as well as the ability to obtain it in any quantity.

- Producing hydrogen is considered more economically profitable than the constant extraction of minerals with flammable properties (gas, coal, oil, etc.).

- The heating system operates without emissions harmful to people and the atmosphere, emitting ordinary water vapor.

- There is no need for a flame (hydrogen heating works based on chemical reactions).

- The boiler has the highest possible efficiency.

- The device operates completely silently.

- There is no need to build and operate a chimney.

- Safety requirements for hydrogen heating are lower than for gas-based installations.

Disadvantages of hydrogen boilers

Despite the many advantages, it is important to know about the disadvantages of such units:

- the need to constantly replenish the catalyst;

- explosion hazard of the element if strict requirements are not met;

- inconvenient transportation of hydrogen;

- lack of specialists in installation and maintenance of such equipment in Russia;

- insufficient number of necessary spare parts due to the underdeveloped market for hydrogen heating.

Reviews of household hydrogen installations: advantages and disadvantages

There is so little information about the actual use of hydrogen boilers that it has to be collected “bit by bit”, but the main points can be identified (including based on reviews from real users of hydrogen boilers for heating).

| pros | Minuses |

| “quiet combustion” – heating of the coolant is carried out due to catalytic reactions, which means there is no open flame | dangerous operation - when the normal pressure increases, there is a high risk of depressurization of seams and explosion of the boiler |

| high environmental friendliness - during operation no carbon monoxide, no fumes, or other substances harmful to health are produced | low energy efficiency - as already mentioned, the energy costs for the production of HHO are higher than its heat transfer |

| absence of a chimney - from the previous paragraph it also follows that such units do not need to remove exhaust gases | lack of specialists - in the regions there are no certified organizations involved in the repair of such boilers |

| availability of resources - formally, to refuel they only need electricity and water (+ replacement of the catalyst once a year) | searching for cylinders - if you buy pure hydrogen, you need to take into account that they are also unlikely to be found nearby |

It is worth noting that the above qualities apply to factory models, since reworking units often makes no economic sense at all.

Hydrogen boilers, which “craftsmen” create with their own hands on the basis of solid fuel or gas predecessors, are, of course, cheaper than branded equipment, but without knowledge of physics, chemistry and calculations, it is almost impossible to assemble a properly functioning boiler. In addition, no one is responsible for security.

Pros and cons of heating

- Absolutely environmentally friendly - water breakdown products (hydrogen, oxygen and steam) do not affect health even during combustion.

- The maximum efficiency level, reaching 96%, is much higher than the same coal, diesel or natural gas.

- The use of hydrogen as an alternative source of energy resources can significantly save reserves of exhaustible natural resources, reducing their production several times.

- Low cost - for heating residential buildings, the cost of the system is insignificant, and the simplicity of operation, based on the primitive chemical reaction of electrolysis, allows you to assemble the system yourself.

Negative aspects of generators

True, there are certain disadvantages of using such generators. The technology for extracting heat from hydrogen is currently at the development stage, so some disadvantages cannot be avoided. First of all, it is difficult to access; not every store has generators. Accordingly, even if it breaks, you will have to search carefully for a replacement part.

Cylinders with this substance are not very convenient to transport; it should also be noted that at room temperature hydrogen is a light volatile gas and is difficult to work with. It is not easy to buy such an alternative fuel in Russia today, and not everyone can handle the construction of electrolysis with their own hands. Also, when using homemade structures, one must take into account that they may be unsafe, because it is impossible to guarantee complete control of the reaction.

But all these disadvantages will only exist for a while; soon scientists will find a way to quickly produce and conveniently transport hydrogen, and then it can be used to heat a house on an ongoing basis. The popularity of generators of this type is constantly growing, and they are moving from the category of exotic devices to “innovative”.

Independent construction

Due to the fact that there is currently no mass production of such units, purchasing them is not an easy process. Most likely, you will have to place an individual order or negotiate the supply of equipment from Italy, where such devices were first developed and put into operation.

But not all consumers can afford such a solution to the problem. In this case, it is worth considering the possibility of building a boiler with your own hands.

How does a homemade hydrogen heating boiler work?

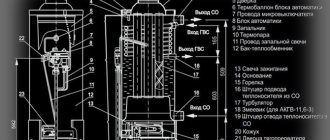

The hydrogen heating system consists of a generator, burner and boiler.

At the moment, no source can provide accurate and success-guaranteing instructions for constructing a hydrogen boiler. But according to the skills and experience of practicing chemists and technicians, such a unit should consist of the following components:

- Heat exchanger.

- Electrolyzer.

- The combustion chamber.

- Safety block protecting against “return” (with 2 stages).

- Container with electrolyte and produced hydrogen. It should be made of alloy or stainless steel, and also be equipped with a valve with which you can relieve pressure in the system.

Operating principle of the boiler

Hydrogen begins to be produced after the electrolytic solution enters the electrolyzer. Under the influence of a catalyst with O2, the element is divided into heat and water. The resulting heat, which has a temperature of about 40 degrees, goes into the heating system, first passing through a heat exchanger. Very often, this temperature is enough to fully heat the house using heated floors.

The water released as a result of the chemical reaction enters the tank (with the electrolyte), and then a certain part of the solution undergoes spontaneous ignition due to the recirculation process.

Manufacturing instructions

First stage. To begin, take a sheet of steel and place it on a flat surface. From a sheet of the dimensions indicated above (0.5x0.5 m) you should get 16 rectangles for the future hydrogen burner, cut them out with a grinder.

Second phase. On the back side of the plates we drill holes for the bolt. If we planned to make a “dry” electrolyzer, we would drill holes from the bottom, but in this case this is not necessary. The fact is that the “dry” design is much more complicated, and the useful area of the plates in it would not be used 100%. We will make a “wet” electrolyzer - the plates will be completely immersed in the electrolyte, and their entire area will participate in the reaction.

Water energy

Third stage. The principle of operation of the described burner is based on the following: an electric current passing through the plates immersed in the electrolyte will cause water (it should be part of the electrolyte) to decompose into oxygen (O) and hydrogen (H). Therefore, we must have two plates at the same time - the cathode and the anode.

As the area of these plates increases, the volume of gas increases, so in this case we use eight pieces per cathode and anode, respectively.

Each water molecule consists of two hydrogen atoms and one atom

Fourth stage. Next, we have to install the plates in a plastic container so that they alternate: plus, minus, plus, minus, etc. To insulate the plates, we use pieces of transparent tube (we bought a whole 10 m of it, so there is a supply).

We cut small rings from the tube, cut them and get strips approximately 1 mm thick. This is the ideal distance for hydrogen to be generated efficiently in the structure.

Fifth stage. We attach the plates to each other using washers. We do this as follows: we put a washer on the bolt, then a plate, after it three washers, another plate, again three washers, etc. We hang eight pieces on the cathode, eight on the anode.

Next, tighten the nuts and insulate the plates using previously cut strips.

Sixth stage. We look where exactly the bolts rest in the container, and drill holes in that place. If suddenly the bolts do not fit into the container, then we cut them down to the required length. Then we insert the bolts into the holes, put washers on them and tighten them with nuts - for better tightness.

Next, we make a hole in the cover for the fitting, screw in the fitting itself (preferably by covering the joint with silicone sealant). Blow into the fitting to check the tightness of the lid. If air still comes out from under it, then we coat this connection with sealant.

Seventh stage. Upon completion of assembly, we test the finished generator. To do this, connect any source to it, fill the container with water and close the lid. Next, we put a hose on the fitting and lower it into a container of water (to see air bubbles). If the source is not powerful enough, then they will not be in the tank, but they will definitely appear in the electrolyzer.

Next, we need to increase the intensity of gas output by increasing the voltage in the electrolyte. It is worth noting here that water in its pure form is not a conductor - current passes through it due to the impurities and salt present in it. We will dilute a little alkali in water (for example, sodium hydroxide is excellent - it is sold in stores in the form of the “Mole” cleaning agent).

Principle of operation

Under the influence of an electric charge, water breaks down into hydrogen and oxygen. Then, when hydrogen and oxygen molecules interact, a reaction occurs, as a result of which the so-called Brown gas is formed and the process of heat release occurs. The heat, in turn, will heat the water and ensure a normal temperature in the room.

Elements of a heating system using hydrogen

Structure of hydrogen boilers:

- An electrolyser is a special hydrogen generator for home heating that produces a reaction between oxygen and hydrogen.

- A heating burner that creates a flame.

- A boiler that acts as a heat exchanger.

Electrolysis process to produce hydrogen

For successful operation of a hydrogen plant, it is important to observe the following:

- Possibility of water supply, most often it is water from the tap.

- Fluid consumption parameters directly depend on the power of the device.

- Provide access to the electricity needed to carry out the electrolysis reaction.

- Replace the catalyst in accordance with a certain frequency, which depends on the modification and power of the boiler.

It is important to note that a hydrogen boiler created industrially is characterized by a high level of safety. This unit is safer in operation than gas and solid fuel boilers.

Brief theoretical part

Hydrogen, also known as hydrogen, the first element of the periodic table, is the lightest gaseous substance with high chemical activity. During oxidation (that is, combustion), it releases a huge amount of heat, forming ordinary water. Let us characterize the properties of the element, formatting them in the form of theses:

- The combustion of hydrogen is an environmentally friendly process; no harmful substances are released.

- Due to chemical activity, the gas does not occur in free form on Earth. But its reserves in water are inexhaustible.

- The element is extracted in industrial production by a chemical method, for example, in the process of gasification (pyrolysis) of coal. Often a by-product.

- Another way to produce hydrogen gas is by electrolysis of water in the presence of catalysts - platinum and other expensive alloys.

- A simple mixture of hydrogen + oxygen gases explodes from the slightest spark, instantly releasing a large amount of energy.

From the above, the following conclusion suggests itself: 2 hydrogen atoms easily combine with 1 oxygen atom, but they part very reluctantly. The chemical oxidation reaction proceeds with the direct release of thermal energy in accordance with the formula:

2H2 + O2 → 2H2O + Q (energy)

Here lies an important point that will be useful to us in further debriefing: hydrogen reacts spontaneously from combustion, and heat is released directly. To split a water molecule, energy will have to be expended:

2H2O → 2H2 + O2 – Q

This is the formula for an electrolytic reaction that characterizes the process of splitting water by supplying electricity. How to implement this in practice and make a hydrogen generator with your own hands, we will consider further.

Installation of a hydrogen boiler

To install the structure, you should purchase the following components:

- 12-Volt power supply;

- 30 Amp PWM regulator;

- tubes of different diameters made of stainless steel;

- capacity.

Water in ideally sealed conditions is supplied inside the container with the dialectic. There are stainless steel plates located there, the adjoining of which to each other is ensured by an insulator. The plates receive 12 Volt voltage. The result will be the decomposition of water into gases.

Using a PWM regulator allows you to convert direct current into pulsed or alternating current, which increases the overall efficiency of the system.

Feasibility of the technique

The reason for installing a hydrogen heating system in a private home may be the lack of natural gas and the availability of electricity. At the same time, the costs of providing the building with heat are lower compared to the use of electric heating devices.

In addition, there is no need for pipes to remove combustion products. It turns out that a hydrogen installation can be used in country houses as an independent or additional heating equipment.

Materials used

The heating system usually uses distilled water, to which sodium hydroxide is added in a proportion of 10 liters of liquid per 1 tbsp. l substances. If it is unavailable or difficult to obtain the required amount of distillate, the use of ordinary tap water is also permitted, but only if it does not contain heavy metals.

As the metals from which hydrogen boilers are made, it is permissible to use any type of stainless steel - ferrimagnetic steel, to which excess particles are not attracted, would be an excellent option. Although the main criterion for choosing a material should still be resistance to corrosion and rust.

To assemble the apparatus, tubes with a diameter of 1 or 1.25 inches are usually used. The burner can be purchased at the appropriate store or online service.

If you choose the right materials and carefully study the heating circuit, manufacturing the installation and connecting it to the boiler is not difficult.

Features of operation

An important feature of the use of hydrogen fuel is the danger of its explosion when in contact with air. Therefore, it is important to adhere to the following operating rules:

- it is necessary to periodically monitor the temperature of the sensors installed on the heat exchangers and prevent the coolant from overheating above permissible standards;

- it is prohibited to operate the boiler in modes that are not provided by the manufacturer or that may cause a chain reaction;

- when the gas pressure in the combustion chamber increases, it is necessary to take measures to stabilize it and find out the reasons for such changes;

- for continuous operation of the boiler, you need to take care of a stabilized power supply;

- It is important to periodically change the electrolyzer and monitor the water supply.

Is self-assembly of a hydrogen boiler justified?

The feasibility of assembling a hydrogen unit with your own hands raises a lot of questions that have not yet been sufficiently researched, therefore, before making such a decision, you should carefully weigh the pros and cons, and also take into account important points.

By constructing a unit from the above elements and supplementing it with standard automatic and mechanical components, you can obtain a prototype of a hydrogen unit. In order for it to work fully, a lot of tests and trials should be carried out.

Why is it still not drowned with water?

Intermolecular water bonds arise and break much more easily than intramolecular ones. Therefore, it was decided to use them in heat transfer processes. Chemists have experimentally found that the energy of intermolecular bonds of water ranges from 0.26 to 0.5 eV (electron volts).

The problem is that to obtain fuel from water, it must be broken down into its components. In simple words, it needs to be decomposed into oxygen and hydrogen, then burn the hydrogen and get water again. Cleavage is achieved by passing an electric current through the liquid.

When boiling, water does not break into individual molecules, but only evaporates. Heating from normal combustion does not cause any other reactions in the liquid. Moreover, this process also requires a lot of energy, which could be used usefully. Eg:

- burning 1 kg of dry wood with a moisture content of no more than 20% gives about 3.9 kW;

- if the wood moisture level rises to 50%, then only 2.2 kW is released from 1 kg.

The decomposition of water to produce actual combustion requires significant energy expenditure. Much more of it is needed than will be released when the recovered elements are used again as fuel. An approximate ratio can be given:

- 100% of energy is for splitting;

- 75% of energy comes from burning recovered components.

It is the fact that the reverse reaction of released hydrogen and oxygen releases less energy that is the reason why water is still not used as a fuel for cars and other things. Economically, this method turned out to be unprofitable. It is more feasible to make fuel from garbage. It can be liquid, gaseous and solid.

Is there a "water" car?

In 2008, in Japan, a “water” car was presented by Genepax at an exhibition in Osaka. The fuel could be a glass of tap or river water, or even regular soda.

The device split the liquid into hydrogen and oxygen molecules, which began to burn and give the car energy to drive. Today it is known that the Genepax company went bankrupt and closed within a year.

Prospects for hydrogen in the heating industry

Many scientists call hydrogen the most promising fuel, and this is only confirmed by the following facts:

Hydrogen is the most abundant fuel element in the Universe, and the tenth most abundant of all chemical elements on our planet. To put it simply, there will definitely be no problems with hydrogen reserves;

- Despite the fact that it is a gas, it is absolutely harmless and non-toxic, so people, animals and even plants will not feel any harmful effects;

- In heating equipment that runs on hydrogen, the combustion product is ordinary water, so there is no point in talking about harmful emissions;

- The combustion degree of hydrogen is 6000, this confirms the high heat capacity of this chemical element;

- By weight, this fuel is even lighter than air (14 times), so in the event of a leak, the fuel choice will evaporate on its own and very quickly;

- A kilogram of hydrogen today costs only 2-7 US dollars. But a kilogram is a lot, because the density of the substance is only 0.008987 kg/m3;

- The calorific value of 1 cubic meter of hydrogen is 13,000 kJ. Of course, this figure is approximately three times lower than that of natural gas, but the price of hydrogen is tens of times lower.

From this we can conclude that heating houses with hydrogen will cost no more than using conventional gas boilers. Also, the owner of such unique equipment will not pay crazy markups into the pockets of the owners of oil and gas companies; there is no need to equip an expensive gas pipeline. At the same time, the owner will also save himself from going through tedious and lengthy bureaucratic procedures for approving various projects.

In general, hydrogen can truly be considered the most promising fuel. All the benefits of this element have already been experienced by employees of aerospace enterprises that use hydrogen as rocket fuel.

Some good advice

Next, let's talk about other components of the hydrogen burner - the filter for the washing machine and the valve. Both are for protection. The valve will not allow ignited hydrogen to penetrate back into the structure and explode the gas accumulated under the lid of the electrolyzer (even if there is only a little of it there). If we do not install the valve, the container will be damaged and the alkali will leak out.

A filter will be required to make a water seal, which will act as a barrier preventing an explosion. Craftsmen who are familiar firsthand with the design of a homemade hydrogen burner call this valve a “bulbulator.” Indeed, it essentially only creates air bubbles in the water. For the burner itself we use the same transparent hose. That's it, the hydrogen burner is ready!

All that remains is to connect it to the input of the “warm floor” system, seal the connection and begin direct operation.

Is it profitable to heat a house with hydrogen?

The average selling price of natural gas for the population for heating and electricity generation is 4.76 rubles/m3. 1 m3 contains 0.712 kg. Accordingly, 1 kg of natural gas costs 6.68 rubles. The average calorific value of natural gas is 50,000 kJ/kg. For hydrogen it is much higher, 140,000 kJ/kg. That is, in order to obtain an amount of thermal energy equal to that generated by the combustion of 1 kg of hydrogen, 2.8 kg of natural gas will be required. Its cost is 13.32 rubles. Now let’s compare the cost of thermal energy obtained from burning 1 kg of hydrogen obtained in a good factory electrolyzer and from 2.8 kg of natural gas: 420 rubles versus 13.32. The difference is truly monstrous, 31.5 times! Even compared to the most expensive of traditional types of heating - electric, hydrogen cannot even come close to competing, it costs 4 times more! The electricity that will be spent on the operation of the electrolyzer is better used to operate heating electrical appliances; there will be much more benefit.

It is precisely these advertising technologies and methods of persuasion that sellers of installations for heating a home with hydrogen use in order to sell their useless goods at exorbitant prices.

As for the prospects for hydrogen energy, they exist, but success is associated with promising industrial technologies that have not yet been invented. Household hydrogen generators and hydrogen vehicles are definitely unprofitable at least for the next decades. Their very limited use in some countries is only possible thanks to significant government subsidies as part of experimental environmental programs.

========

Educational and scientific organizations of Russia, members of the consortium for the development of hydrogen technologies, presented their developments at the First Conference “Hydrogen. Technologies. Future" on the platform of Tomsk Polytechnic University.

In Tomsk, fundamental and applied research is being carried out in the field of producing pure hydrogen, its safe storage, transportation, and use as an energy carrier in autonomous power supply systems. Among the developments of TPU scientists are technologies for producing hydrogen from natural gas and by processing biomass; a material that generates hydrogen from water when exposed to sunlight; materials – hydrogen storage; hydrogen fuel cells based on polymer membranes.

The head of the IPCP RAS, Sergei Aldoshin, said that the institute is actively developing three areas in the field of hydrogen energy: production, storage and transportation, as well as the use of hydrogen. Scientists at the Institute of Chemical Physics of the Russian Academy of Sciences are developing approaches to producing hydrogen from hydrocarbon gases and low-grade fuels, and developing components and materials for hydrogen fuel cell batteries. The institute operates an NTI Competence Center for technologies of new and mobile energy sources and a test site for testing the safety of gas technologies.

Director of the IC SB RAS Valery Bukhtiyarov said that the institute has been conducting research in the field of producing synthesis gas and hydrogen-containing gas in compact reformers for more than 20 years. They provide hydrogen in “hydrogen refueling” or “on demand” formats to power electrochemical generators. Traditional fuels (natural and liquefied gas, gasoline, diesel), synthetic products (methanol, dimethyl ether, ammonia), and promising renewable carriers (dimethoxymethane, bioethanol, biodiesel) can be used as raw materials. Approaches have been developed for the generation and use of hydrogen in conjunction with gas piston, gas diesel and gas turbine power plants, as well as for the creation of reducing atmospheres for metallurgy. Scientists are working on producing methane-hydrogen mixtures, processing natural gas to produce hydrogen and carbon nanomaterials, and conducting fundamental research on producing hydrogen from water under the influence of sunlight.

Director of the Institute of Chemical Chemistry of the Russian Academy of Sciences Anton Maksimov noted that among the breakthrough areas of the institute are a one-stage technology for producing synthesis gas by gas-phase partial oxidation in a reactor based on rocket technology, the development of the scientific foundations of plasma-chemical processes for processing natural gas into hydrogen and carbon black, as well as the conversion of methane into acetlinides metals and hydrogen in plasma, membrane technologies for hydrogen separation/purification and other projects.

SamSTU Vice-Rector for International Cooperation Andrey Pimenov presented several projects being implemented jointly with PJSC Gazprom, including those related to the pyrolysis of natural gas in molten metals and the adiabatic conversion of natural gas. Also in Samara, an approach to assessing the relative efficiency of hydrogen and MHS production technologies based on the DEA method has been developed. Scientists are also working on liquid organic carriers of hydrogen, materials for hydrogen fuel cells, and the creation of multifunctional materials and new generation catalysts.

Deputy Minister of Digital and Technological Development of the Sakhalin Region Evgeniy Getz spoke about measures to support scientific, scientific, technical and innovative projects in the region. In particular, he shared the concept of creating a hydrogen cluster on Sakhalin.

In addition to scientific organizations, presentations were made by the industrial partners of the consortium - representatives of the Rosatom State Corporation, Gazprom PJSC, Russian Railways JSC, Severstal PJSC, Gazprom Neft PJSC and SIBUR LLC.

Review of manufacturers

There is no fundamental difference among hydrogen generators for heating. The only criterion on the basis of which they can be differentiated is the power indicator of devices made from different materials.

Hydrogen boiler STAR-3.0

As an example, consider the characteristics of two similar American-made boilers, “HHO” and “Star 1000”:

- In one hour, such a generator consumes 1.5-3 kW.

- Water consumption - 5.5 liters per 24 hours.

- Generates from 1.2 to 2 liters of fuel during the day.

- Can be used to heat air in buildings with an area of up to 250 square meters.

- The minimum operational service life is 15 years.

- The approximate cost on the domestic market is 3000-3500 USD.

| Model | Characteristics |

| STAR 1000 and STAR 2000 |

|

| Hydrogen boiler STAR-1.1 |

|

| Chinese generator Kingkar 3000 |

|