Years go by, science and technology move forward, and solid fuels still remain in demand. Burning wood in a traditional stove or potbelly stove is not very effective, but pyrolysis heating boilers have changed the situation - the units are characterized by high efficiency and relatively simple operation.

Agree, these are quite significant arguments when arranging autonomous heating. If you are looking for an efficient boiler for your home, then you should take a closer look at pyrolysis boilers.

We will tell you how long-burning units are designed and operate, what their technical and operational features are, and also provide an overview of the most rated models from domestic and foreign manufacturers.

Pyrolysis boiler - what is special?

This device is equipment for processing solid fuel with its subsequent use for heating private houses or utility rooms for various purposes.

- The pyrolysis boiler does not require a constant source of oxygen; the system is automated.

- Here the main role is played by the water circuit, which retains gases and mixes them with oxygen.

- All this burns in a special chamber, releasing thermal energy through radiators.

- It is gas energy that is used to heat rooms.

- At the same time, the combustion temperature of pyrolysis is a hundred times higher than a conventional wood-burning device.

The equipment is made of cast iron or sheet material. The second option is more popular than heavy cast iron. Boilers are installed in one way - floor mounting.

Commissioning works

After the assembly of the pyrolysis boiler is completed, it is necessary to check the tightness of the welded joints. The water jacket is filled with water, then air is pumped into it, creating excess pressure. Poorly welded seams will make themselves felt by leaks. Now you can carry out tests, it is better to do this outside, supplying running water from a hose. If a safety group is installed on the unit, then you can fill the boiler tank with water and check its operation at a critical pressure of 2-2.5 Bar. The test order is as follows:

- Attach a temporary chimney, load fuel into the chamber and open the direct draft damper.

- Stop the flow of running water by providing a temporary tap.

- Ignite and start the pyrolysis boiler. As soon as the firewood flares up, the direct draft damper must be closed so that the pyrolysis process can begin.

- Open the secondary chamber door and make sure there is a flame. This requires adjustment of the pyrolysis boiler; you need to achieve an even and stable flame by opening or closing the air damper.

- Close the door and observe the readings of the thermometer and pressure gauge. In a closed water jacket, the process of vaporization can begin when the pressure reaches 1.5 Bar, at which time the temperature must be carefully monitored.

- High-quality welded pyrolysis heating boilers can withstand pressures of up to 3 Bar, but there is no need to set records. It is enough if the safety valve set to a pressure of 2 or 2.5 Bar begins to release steam, then you can open the tap and resume water circulation. The air supply damper must be closed for the fuel to begin to fade.

Be careful when carrying out such tests, there is a danger of scalding with boiling water due to negligence or if the water jacket ruptures.

How does a pyrolysis boiler work?

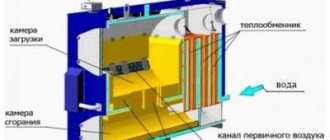

The boiler is represented by a rectangular furnace, which has a built-in two-chamber sealed firebox. The chamber is equipped with a fan and a tight door. Fuel is loaded into this container and set on fire.

Wait until the fuel ignites and close the equipment door. The device differs from a traditional open furnace in that the pyrolysis boiler does not require constant oxygen during the combustion of fuel substances, and therefore does not require a high chimney.

On the contrary, the device will generate heat longer if the flow of oxygen in the combustion chamber is limited.

- The second section of the boiler is responsible for the air duct and is the basis of the chimney. The movement of gases occurs due to a fan or damper.

- At the same time, the firewood in the device is completely processed, without emitting harmful substances and perfectly transferring heat to the room.

- Waste (ash) from the combustion of wood is minimal, which makes maintaining the equipment an easy process.

- And if there is any unburnt wood left in the boiler, then it is removed using a rotary retort, which is a round part of the stove container.

Important! When fuel is burned, the efficiency increases to 90%. This is quite a lot compared to analogues of wood heating.

Reviews of domestic gas generator boilers: advantages and disadvantages

The world community's concern about the problem of environmental pollution has strengthened the position of pyrolysis boilers in the market of long-burning heating units. According to operating practice and reviews from owners, when this type of boiler operates correctly, a small amount of carbon dioxide and steam enters the atmosphere. When burning any organic fuel, such a unit emits a minimum of unburnt substances from the chimney without burning, without smoke, odor and color. The result is also manifested in emissions into the boiler room, for example, when reloading fuel, and especially in the contamination of the boiler itself and the frequency of its cleaning.

| Advantages | Flaws |

| Due to the afterburning of pyrolysis gases, the efficiency can reach 95%. | The cost of equipment is 1.5-2 times higher, although it pays off relatively quickly |

| An enlarged loading chamber allows you to work longer from one load (1.5-3 times) than with conventional units | High costs for fuel moisture treatment. It should not exceed 20%, otherwise the pyrolysis process will not take place |

| The fuel burns out with almost no residue and the design of the combustion chambers makes cleaning and maintenance less frequent and easier. | Most industrial and domestic units with high automation use blower fans and smoke exhausters, which makes them dependent on power supply |

| High temperatures require the construction of a heat exchanger made of heat-resistant steel, which makes it possible to heat the building faster | If the temperature of the coolant in the return pipe is low, the boiler may go out; it is necessary to add hot water through a three-way valve or bypass. |

| Emissions of combustion products are minimal | Overall dimensions and weight are significantly higher than those of other types of boilers |

| The units can operate on any organic fuel without significant modification, but with different efficiencies | At low loads (less than 50%) it is difficult to obtain stable combustion |

| High efficiency implies economical fuel consumption and reduces fuel costs | |

| A high level of automation of the boiler operation allows for less frequent monitoring of the combustion process |

What is used for fuel?

A long-burning pyrolysis boiler is a universal and unpretentious device for processing various types of fuel. Even tires are used to generate heat.

But still, for greater benefit, both for human health and to avoid environmental air pollution, it is recommended to use the following types of fuel energy:

- Firewood. Firewood up to 40 cm is suitable for the boiler. In this case, birch and also coniferous wood are used for heating the premises. Oak panels warm households well, but are expensive, which is not very suitable for the family budget. At the same time, alder and aspen help clean the chimney and are beneficial raw materials in all aspects;

- Pellets. Pressed material of plant origin. It is made from straw, sunflower husks, wood chips, bark, branches, shavings and even peat. All this gives excellent combustion results in the furnace firebox, and therefore good heat transfer through the radiator system;

- Coal. The natural resource is used in two ways. The first is the formation of volatile substances and the second is the way of converting it into a solid residue. Therefore, a coal-fired pyrolysis furnace is ideal for heating industrial premises;

- Fuel braces. They are an analogue of pellets, but the material is compressed with a large volume of raw materials (up to 45 cm).

Important! The range of fuel for pyrolysis furnaces depends on the type of equipment. All information is indicated in the instructions for using the boiler.

Combustion air supply methods

Increased requirements are placed on the height and diameter of the chimney when the air supply circuit in the pyrolysis boiler involves the use of conventional draft. It should be enough to overcome the resistance of the gas-air path of the installation and the chimney pipe, as well as to create a vacuum in the firebox of 16-20 Pa. You can select the diameter according to the outlet pipe, and the height should be at least 5-6 m.

Forced air supply to both chambers can be carried out in three ways:

Typically, the design of a pyrolysis boiler involves installing a fan in pressure mode. This is explained by the fact that a conventional blower is more affordable than a smoke exhauster, since the latter must extract exhaust gases at high temperatures. For this reason, its structural elements are more expensive.

Leading manufacturers of pyrolysis boilers install smoke exhausters on their products at the exit of combustion products. The reason is to ensure safety for the person who opens the firebox door in operating mode. The smoke exhauster creates a vacuum, so the flame will not blaze through the open opening into a person’s face.

For high-power installations, manufacturers use fans for both types of boilers, at the inlet and outlet of the gas-air duct.

In order to understand how a pyrolysis boiler works, we recommend watching the following video.

Species affiliation

Pyrolysis boilers are produced in two types, each of which has its own specific operation.

Boiler

The equipment is equipped with a mechanical damper. The furnace is fully loaded, otherwise there will be no desired effect from fuel combustion. At the same time, make sure that the firewood is dry.

Otherwise, all the energy of the thermal chamber will be spent on drying the material, and over time the oven will simply stop working.

- Firewood or other material is loaded into the upper chamber and the fan is turned on.

- It serves to combine flammable gases with oxygen, transferring energy to the adjacent chamber.

It is located under the upper container, separated by a grille. In this chamber, the main combustion occurs at temperatures above 1000 C, while in the loading chamber the fuel is processed at temperatures up to 600 degrees.

Top combustion boiler

This type of device is represented by a wood-burning boiler for water heating. The device is produced in a cylindrical shape with two chambers equipped with a movable pipe for supplying oxygen with a disk.

Before adding fuel, the movable element is lifted up using the outer torso. Firewood is loaded through the door and set on fire.

- Next, the disk is lowered onto the fuel, pumping oxygen into the chamber.

- The fuel does not burn quickly, which gives an advantage in air distribution.

- Combustible materials rise, bypassing the disk and entering the upper chamber, in which combustion of the substance occurs.

- In this case, the periodicity of gas substances is controlled by an automatic boiler system, which monitors the temperature of the liquid in the heat exchanger.

These devices are not particularly popular, although they are ideal for disposing of household waste.

How to make it yourself

Today, many craftsmen make a pyrolysis boiler with their own hands. Their approaches and design options differ from each other. Some craftsmen make their own calculations and drawings, others order professional diagrams. Which path to choose depends on the level of training and skills of each master.

Self-production is a complex and time-consuming process. It will be necessary to prepare a certain minimum of materials, tools and equipment, perform step-by-step assembly and check the operation of the unit.

Approximate boiler manufacturing diagram.

Required tools and materials

Heat-resistant metal or cast iron can be used as a material for the manufacture of the body and chambers, but in order to save money, simple carbon steel 5 mm thick is most often used. The consumption for the specified scheme will be 7.5–8 square meters.

In addition to the basic material, you will also need:

- metal pipe for the manufacture of a heat exchanger (diameter - 57 mm, wall thickness - 3.5 mm, length - 7–8 m);

- metal pipe for making a chimney (diameter - 159 mm, wall thickness - 4.5 mm, and also diameter - 32 mm, thickness - 3.2 mm, both lengths - 1 m);

- profile pipe for air ducts (size - 60 x 30, wall thickness - 2 mm, length - 1.5 m, as well as 1 m each size 80 x 40 and 20 x 20 mm);

- fireclay bricks for lining chambers (12–15 pcs);

- steel strips: 20 x 4 (7.5-8 m), 30 x 4 (1.5 m), 80 x 5 (1 m);

- temperature sensor.

The amount of material required to manufacture the boiler will depend on the chosen implementation option, its design and dimensions.

Basic tools you will need for self-assembly:

- electric welding machine;

- angle grinder;

- electric drill;

- set of locksmith tools.

Assembly of internal parts

For high-quality assembly, precise cutting of sheet metal to specified dimensions is necessary. It is difficult to do this yourself using an angle grinder, so it is better to entrust this stage of work to specialists who will do the work using professional equipment. If the cut is perfectly even, then the seams will be neat.

The assembly of prepared materials can be divided into the following main stages.

Metal sheets are connected and welded in accordance with the diagram. The result is a two-chamber design.

Inside the fuel loading compartment, a wall and air ducts are welded to the back of the chambers, which are made from a 60 x 30 mm profile pipe. Holes are pre-drilled along its entire perimeter to ensure uniform distribution of the supplied air.

A metal pipe is cut into the wall of the combustion chamber for secondary air supply. A pipe is welded to it. It must be connected to the boiler with a professional pipe measuring 20 x 20.

Next, the heat exchanger is made. Cut the pipe into 10 pieces of equal length. Take two flat metal sheets and cut round holes in them to fit the diameter of the workpieces. The pipes are inserted into the plates and welded.

The heat exchanger is fastened to the inner body of the boiler, a throttle valve is made, then the rear wall is welded.

The inside of the chambers is lined with fireclay bricks. To do this, it needs to be cut, sharpened and adjusted to the installation location. The greater the boiler power, the longer the nozzle gas gap should be - from 140 (15 kW) to 280 mm (50 kW), width - 34 mm.

A wall with pre-cut holes for the outgoing and incoming air pipes is welded to the front panel of the fuel chamber.

Then the lid is welded, and a hog is welded in place of the damper.

The entire boiler structure is framed by external metal panels. For the manufacture of the casing, 4 mm thick sheets and corners are used.

To secure them well, holes are made on the workpiece and welded.

The doors are reinforced with fireclay bricks and installed on the front panel. For their manufacture it is better to use cast iron plates.

After assembly is completed, the welding seams are processed. It is advisable to cover the top cover of the boiler with a primer and thermal insulation material.

Threaded rods will be needed to regulate the operation of the air dampers.

The boiler is completely covered with an outer casing. An air duct is made from a professional pipe. To create forced draft, a fan is welded onto it. To optimize the combustion process, the lower chamber is also lined with brick.

It is imperative to install a safety group on the boiler: an air vent, an emergency pressure relief valve, and a pressure gauge.

Examination

Before starting operation, the assembled structure must be checked.

A well-functioning system has the following qualities:

- the heat exchanger is sealed;

- a pyrolysis torch appears in the combustion chamber 15–20 minutes after ignition;

- the temperature of the gases in the chimney does not exceed 60 ° C;

- Only carbon dioxide and steam should come out of the chimney.

After successfully testing the equipment, you can proceed to installation and operation of the homemade system.

Pros and cons of a pyrolysis boiler

Reviews about pyrolysis boilers are completely different. Here the choice is entirely up to the buyer. Before purchasing this device, professionals advise you to take a closer look at the following positive and negative qualities of the equipment.

Advantages of a pyrolysis boiler

- High heat transfer;

- Saving money on fuel;

- Long-term combustion of fuel material (up to 5 days);

- Easy care.

Minuses

- Use only dry firewood;

- Additional area for storing firewood;

- Floor installation of the device;

- Heavy weight of the equipment and it takes up sufficient space in the room;

- The need for a fan and a smoke exhauster;

- Expensive installation of the device.

Connecting the boiler to the heating system

The last stage is connecting the pyrolysis boiler and piping it. As with all solid fuel installations, it is necessary to prevent the formation of condensation on the internal walls of the firebox during heating. This phenomenon shortens the service life of the furnace body, since the condensate contains sulfur inclusions and will cause intense corrosion of the metal. For this reason, the piping of the heating boiler must be done according to a scheme that does not allow cold water to enter the jacket during heating.

Below is a classic diagram for connecting a pyrolysis boiler to a heating system with a balancing valve between the supply and return pipelines.

The jumper forms a small circuit in which the coolant is driven by a circulation pump. The piping of a pyrolysis heating boiler shown in the diagram allows water to circulate through a small circuit, warming up along with the unit. The thermostatic three-way valve will begin to add cold water from the system at the moment when the water temperature in the small circuit reaches the set value, usually 45-50 ºС.

The operating temperature in the heating system is in the range of 60-80 ºС; it is rarely necessary to raise it higher. If your home is cool when operating in this temperature range, then you need to look for the reason in the system itself. It makes no sense to increase the temperature; this will only increase the consumption of firewood in the pyrolysis boiler.

Price

Prices for pyrolysis boilers are quite high. Here, buyers need to compare the characteristics of this equipment in terms of power and manufacturing class.

It may turn out that a pyrolysis boiler will cost a couple of times more than a classic product of the same type.

- A manufacturer may offer a long-term combustion pyrolysis furnace for 150 thousand rubles, but a boiler of the same power, but of a classic type, will cost the customer 50 thousand rubles.

- The same can happen with foreign-made and Russian-made devices, where the cost may differ by either 75 thousand rubles or 35 thousand rubles.

Therefore, before purchasing, it is very important to compare prices for pyrolysis boilers from different companies. It may turn out that there is no need to overpay for a device of the same power and functionality.

Advice! You can make a pyrolysis boiler yourself. The material listed below is used for this.

How to choose the right one

Today, many manufacturers produce gas generating equipment, so choosing a model becomes quite a difficult task. For pyrolysis solid fuel boilers, the price varies from 30 to 300 thousand rubles, depending on power, configuration, dimensions and other indicators.

When purchasing, you should focus on the following characteristics:

- Efficiency The higher this indicator, the less fuel will be spent heating the house.

- The power of the device must correspond to the area of the heated room.

- Types of combustible materials that can be used.

- Dimensions, appearance of the boiler, quality of welding seams.

- The thickness of the metal walls must be at least 4–5 mm.

- Service life of the boiler itself and warranty period.

- Price. It should be noted that domestic models are 2–3 times cheaper than imported ones.

Photos of the best models of pyrolysis boiler

Prices

And one more important factor: with equal characteristics, cast iron boilers are much more expensive than steel ones. But it must be said that the average warranty period for them is 5 years. However, the warranty does not apply to cases of cracks due to mechanical stress or temperature changes. These are the consequences of improper operation. In principle, if you are able to ensure proper operation, such equipment can last 30 years or more. Many museums still have cast iron stoves, many of which are several hundred years old. In some European countries, old stoves from the second half of the last century still operate in old houses. These are ordinary direct combustion boilers, however, they are still in use.

Top combustion boilers

These units are called classic long-burning boilers. Both cast iron and steel models are available. They are distinguished by high autonomy, which is achieved due to a special design:

- There is no grate and ash pan.

- At the bottom there is a blind tray.

- The firebox also has a specific design – oval shape.

- The design of such a heating boiler includes a movable air distributor. When adding fuel, it must be raised. Then, under its own weight, it sinks onto the fuel, and as it burns out, it sinks lower and lower. This achieves air supply specifically to the top layer of fuel.

- The ash, along with other combustion products, is carried into the upper chamber, where further combustion of gases occurs.

- The draft is adjusted automatically depending on the temperature of the coolant.

The advantages of such a system

- The operating time without adding fuel is limited only by the size of the firebox itself.

- Due to the absence of complex automation, such heating units turned out to be very reliable.

- All the main advantages of pyrolysis boilers, such as high efficiency and complete combustion of fuel, have been preserved.

It is worth noting that initially such long-burning boilers operated exclusively on wood. But then models appeared that ran on all types of solid fuel.

Disadvantages of classic boilers

- Greater sensitivity to coolant temperature. High circulation speed leads to condensation on the heat exchanger.

- The blower often fails to carry the ash into the chimney. This leads to a drop in heat transfer.

- It is not advisable to use raw and coarse fuel (not chopped wood).

- The large size of the firebox makes it difficult to ignite the boiler.

It is worth noting that cast iron solid fuel boilers perform much better during operation than steel ones. They are less susceptible to corrosion and more durable.

Advice! When installing a long-burning heating boiler, it is necessary to adhere to fire safety measures. The base on which the cast iron boiler is mounted must be approximately 20 cm larger than the boiler itself. Fuel must be stored at a distance of at least 40 cm from the boiler.

When choosing a solid fuel boiler, you should decide in advance in what capacity it will be used. If it is used as the main heating, you should choose a reliable and automated model. For rare use as a backup, there is no need to fork out money for an expensive unit; a simple option is quite suitable.

Model selection

Termico pyrolysis 12 kW

One of the most popular models. It has one circuit, a power of 12 kW and can heat up to 120 square meters of room area. Open combustion chamber type. The heat exchanger is steel, the control panel is electronic. The thickness of the metal from which the boiler is made is 5 mm.

Can work with almost any type of solid fuel and firewood with humidity up to 40%. The depth of the firebox allows you to place bars up to 37 cm long. The time to enter the pyrolysis mode is about 10 minutes. Installation type: floor-standing, dimensions 478*1126*981 mm, weight 170 kg.

Pyrolysis boiler Termico

Bourgeois-K MODERN-12

Domestic Bourgeois-K devices are produced in Kharkov and have proven themselves in operation. Power 12 kW, has one circuit, capable of heating up to 120 sq. m. at home. Non-volatile with mechanical control panel. Large firebox with a volume of 30 liters and a depth of 40 cm, which allows you to load long bars.

The grate is made of cast iron. Fuel consumption 1.2 kg per hour. It has the ability to additionally connect a heating element to maintain the coolant temperature in the event of the end of solid fuel. Installed on the floor, dimensions 718*459*560 mm, weight 87 kg.

Boiler Burzhuy-K MODERN-12

WATTEK PYROTEK 30

Pyrolysis boiler WATTEK PYROTEK 30 with a thermal power of 30 kW and one circuit. Has a closed combustion chamber. Electronic control with display in Russian. It has several operating modes: standard, summer, with DHW priority. The primary heat exchanger is steel. Works only with wood fuel. Dimensions 530*1145*915 mm.

Boiler WATTEK PYROTEK 30

You will find more information about popular models of pyrolysis boilers in the article at the link: https://boilervdom.ru/kotly/po-tipu-topliva/populyarnye-modeli-piroliznyx-kotlov-i-otzyvy-vladelcev.html