Today we will talk to you about induction heating. Many are trying to present induction boilers as something innovative that will supposedly save us money and ensure the existence of our heating system. But what really?

In fact, induction boilers are units that are very expensive, bulky, inconvenient to use and not endowed with a sufficient number of properties and qualities that are necessary for the normal operation of a modern electric heating boiler.

Those people who invent these boilers and try to sell them to you do not tell the consumer anything about these aspects of their products, but only highlight positive qualities. Here we will display all the pros and cons of induction heating at home

Features of induction boilers

For many, the choice mainly comes down to one of the two most rational options:

- Application for heating boilers powered by gas;

- Electric analogues.

However, there is one indisputable fact that both gas fuel and electricity are constantly increasing in price. So the cost of heating a home does not become much cheaper.

As an alternative proposal, it is worth taking a closer look at using an induction boiler for heating a private home for these purposes and familiarizing yourself with its technical parameters.

- One of the main advantages, according to reviews of induction boilers, is that maintenance is not required for its normal operation, as is the case with other types.

- The vibration of the built-in element prevents the fixation of the resulting fractions, thereby allowing them to be freely washed out of the pipe.

- Therefore, it is precisely this equipment that allows residents of rural areas to feel calm in this regard.

- In addition, the boiler is resistant to voltage fluctuations, which is important for private owners.

The only thing that confuses buyers is that the price of induction boilers is almost twice as high as that of gas boilers.

Improving the heat exchanger

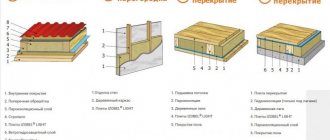

Of course, a theoretical saucepan is only an intermediate version of a heat exchanger. In practice, it must be reliable, cheap and compact, because we are talking about heating an apartment (small area - up to 50 sq. m). The amount of agent should not exceed 40 liters. A flat metal tank with dimensions of approximately 500x600x50 mm is most suitable for all of the above requirements. Such a container can be welded from a 50x50 profile pipe.

- Cut the pipe 50x50 to 600 mm - only 9-10 pieces.

- Weld the sections together wall to wall to form a row of tubes.

- Cut a length of transverse length lengthwise and remove one wall from the pipe.

- Install and weld the transverse section in the manner of a comb manifold.

- Install the opposite wall in the same way.

- Weld 1-1.5 inches of fittings into diagonally opposite planes.

- Carefully scald the structure - it must be airtight and all chambers must communicate freely.

Classification of induction boilers

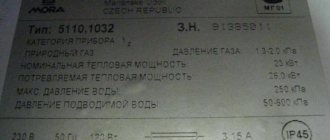

Power separation is the main characteristic according to which they can be distinguished:

- From two and a half to ten kilowatts of power, with a current frequency of fifty hertz and a supply voltage of two hundred twenty to three hundred eighty volts;

- From fifteen to sixty kilowatts with a power at a voltage of three hundred and eighty volts and a current frequency of fifty hertz.

An electrical network with three phases is required for normal power supply of equipment, starting with a power indicator of five or seven kilowatts. Its voltage should be three hundred eighty plus or minus three percent volts.

If we talk about the dimensions of induction-type boilers, then, for example, SAV equipment with a power of ten kilowatts has the following dimensions. The height is one thousand millimeters, and the diameter is one hundred and twenty-one millimeters. Without taking into account the weight of the control system, its mass is equal to seventy kilograms.

Based on the dimensions, it is already clear that in appearance the design of the equipment resembles one large cylinder with a metal body or can be represented by several smaller cylinders.

Safety Tips

Installations of this type are widely used not only for space heating, but also for smelting operations. The main problem with home-made induction devices is the lack of components that provide temperature and pressure control and explosion protection. Therefore, when operating such units, care and caution must be exercised.

Before starting the induction boiler, it is necessary to fill the system with coolant

Before starting the boiler, check that the cavity is filled with coolant. A case made of polymers will begin to melt without regular cooling with liquid. This entails deformation changes and complete failure of the installation. Also dangerous can be the fall of hot metal from the melting body. In the event of such an incident, it will be necessary to replace a number of installation components.

The device is connected to electricity through a separate wire, which is led from the switchboard. The contacts must be covered with insulating material. If the design involves a welding machine, its inverter must be grounded. The wire used for this operation should be 4-6 mm in diameter. To prevent excessive heating of the installation in the absence of water, it is advisable to install an excess pressure valve in the inlet.

How does an induction boiler work?

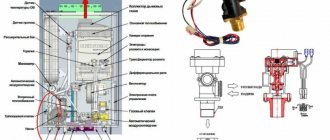

The device includes:

- Inductor element with two windings;

- An inverter that converts incoming energy into high-frequency current;

- Heating element – metal pipe;

- Two pipes. One conducts the coolant, the second supplies water to the system.

The equipment works as follows:

- The flow of water is ensured by a pipe;

- When the inverter is turned on, high frequency current is supplied;

- The core is heated thanks to vortex flows along with the entire heating element;

- Heat enters the coolant, and from there into the heating system thanks to the outlet pipe;

The coolant can be water, oil, antifreeze, etc.

Thus, the simple operation scheme is quite suitable for independently designing and connecting such equipment.

Application

Heating based on eddy currents created by electromagnetic fields can find its application in:

- heating a residential property, house, bathhouse, garage, industrial or administrative building;

- in the hot water supply system;

- heating of buildings and structures that have certain requirements for heat sources (for safety).

What to build a boiler from

When designing you will need:

- Plastic pipe as a body part;

- Stainless steel wire as a heating element;

- A piece of copper wire for an inductor;

- Adapters plus ball valves when connecting the boiler to a common system;

- Pliers with wire cutters.

Having prepared everything you need, you can start assembling.

Debunking myths

Sometimes in stores selling equipment for induction heating at home, you can hear simply unrealistic characteristics assigned to it. And, unfortunately, such properties are not always true. There are several basic points that you should know the truth about:

- Novelty of the principle. Many argue that these are innovative technologies that are built on the principles of physics. In reality, the situation is like this: the phenomenon of electromagnetic induction was discovered by Michael Faraday back in 1831. And since the twentieth century, the induction heating system has been widely used in industry to melt steel. As you can see, this is not a new technology, but just a well-known principle that has found application in modern times for everyday purposes.

Heating water in an induction boiler

- Economical. A common statement is that an induction heater for heating uses 20-30% less energy than other electric analogues. In reality, everything is like this: any heating device converts 100 percent of the energy it uses into heat - of course, if it does not do mechanical work. The efficiency may be lower. It all depends on how the heat is dissipated around the heating device. The time it takes for the coolant to heat up to the desired temperature directly depends on how efficient the heating element is. Therefore, lofty speeches about revolutionary economy are just tricks. After all, no one has canceled the law of conservation of energy. To get 1 kW of heat, you need to spend at least 1 kW of electricity. In addition, some of the heat will be wasted just like that. For example, the coil itself heats up, since the conductor resistance is not zero.

Economic effect of using an induction boiler

- Durability. Another common statement is that heating with an induction stove will work for you for at least 25 years, and that it is the most durable option for heating with electricity. Mechanical wear of boilers of this type is impossible, since they have no moving elements. Copper winding is highly durable and, if used with proper cooling, will last a long time. In any case, the core will gradually deteriorate - since it can be affected by aggressive impurities, and constant heating and cooling will not impart strength. But we note that even this process is very long. The control circuit contains several transistors. They will determine the service life of all equipment without failure. Typically a 10 year warranty is provided. Although there are cases where the equipment worked for 30 years. The conclusion from all this is the following: induction water heaters for heating will work much longer than their analogues - heating elements.

- Irreplaceable properties. Many people say that induction boilers retain their original characteristics for decades due to the fact that scale does not appear here. First of all, let's say that the influence of scale is slightly exaggerated. The lime layer does not have high thermal insulation properties, and in a closed system many deposits will not appear. But the same cannot be said about the core - scale is a common occurrence here. So, heating using an induction cooker is really not subject to scale.

- Quiet operation. In fact, if you study the reviews, you can say that any electric boiler will not make noise when heating water, since there are no acoustic vibrations. Noise can only come from pumps. So the judgment is correct.

- Compactness. Induction equipment can be installed in any room. This statement is true: this device is a piece of pipe that does not require any special space.

Induction boiler

- Induction heating of water for heating is safe. If a coolant leak occurs, the electromagnetic field will not disappear automatically. The core will continue to heat up; if the power supply is not interrupted, the housing and mount will melt in a matter of seconds. That is why during installation it is necessary to provide for automatic shutdown of the induction boiler in such situations.

Assembly order

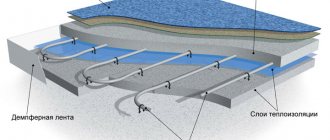

A do-it-yourself induction boiler is assembled in several stages:

- First you have to cut the stainless steel into pieces of three or seven centimeters;

- Fill the void with plastic pipe with these pieces so tightly that there is no void;

- The tube ends are reinforced with mesh, which will prevent the segments from falling out;

- In the upper part of the pipe, as well as in the lower part, both pipes must be cut in. Through one, the coolant will enter the unit, and through the other it will be transferred to the heating system;

- Copper wire must be wound onto the pipe so that the resulting number of turns is ninety;

- Both ends are connected to the inverter;

- Connect the boiler to the heating system using ball valves with adapters;

- Install a circulation pump if it was not originally provided for in the heating circuit.

The high-frequency current should be supplied no earlier than the circulation pump is turned on and the equipment is fully filled with coolant.

Saving on electricity consumption

Consumption of 2.5 kW instead of 4–5 is an excellent result. But it turned out to be not enough for ambitious and thrifty home craftsmen. But where can I get cheap electricity for the stove? It turns out that the answer has been known for a long time. This device is called an inverter, and it converts direct current into alternating current. With its help, you can reduce current consumption for heating to almost zero.

To reduce energy consumption we need the following:

- Two batteries of at least 190 Ah (preferably 250 Ah).

- 4 kW inverter.

- Battery charger (24 V).

- The main pipes must be made of non-magnetic material (plastic, aluminum, copper).

We connect the batteries in parallel and put them on constant “charging”. The process that occurs in an electrical circuit:

- The batteries generate direct current, which is supplied to the inverter.

- The inverter converts direct current into alternating current 220 V.

- Current from the inverter is supplied to the induction furnace, which operates in normal mode (flow).

- The charger continuously recharges the batteries.

Thus, heating the apartment costs the consumption of a 24-volt charger, not counting the cost of operating the circulation pump, which will be used in any option.

Advantages and disadvantages

A boiler device that was made independently has many advantages, for example, an induction electric boiler:

- Provides rapid heating of the coolant within three to five minutes;

- The lowest temperature required for heating is no more than thirty-five degrees;

- Scale practically does not form due to the imperceptible work of vibration created by thermal energy;

- An almost 100% efficiency factor is ensured, that is, almost all incoming electrical energy is converted into heat;

- The operation of the unit is in no way connected with the release of harmful toxins, so there is absolutely no need to remove the chimney outside, as well as to carry out maintenance;

Such an aggregate device can function quietly for up to thirty years, because there is simply no mechanical movement of the parts, which means there is no damage to the component elements or wear.

What is

Induction vortex heaters are suitable for heating a house, garage, apartment, bathhouse, in general, any square meters where there is insufficient heat or no heat at all. Induction heaters operate using eddy currents (Foucault currents) created by a magnetic field. They heat the surrounding area. To generate such a field, an inductor is required, which is a multi-turn coil in the form of a cylinder. An alternating electric current passing through this very coil creates a magnetic field. Next, the eddy currents are converted into thermal energy.

Heating to high temperatures (70 degrees) using such a device occurs quite quickly, in about 5 minutes.