The quality of the chimney can be easily assessed while the fireplace is operating. If there is no smell of smoke in the room with the fireplace, and the wood ignites immediately, the chimney for the fireplace was correctly designed and installed. Let's figure out what materials a chimney system can be assembled from and how to calculate the parameters of the chimney duct so that it fulfills its purpose.

Chimney parameters are determined at the design stage Source mypropertyadvice.com

Characteristics important for a chimney

The main requirement for the chimney system of any device, stove, fireplace or boiler is to ensure high-quality ventilation of the combustion chamber. The draft, which removes the products of fuel combustion outside, is formed due to the temperature difference when hot air rises through the chimney channel and cold air comes in its place.

The removal of flue gases can be organized in different ways, so chimneys are constructed from different materials, the shape and size also differ. At the same time, all the variety of structures is designed according to certain rules and is subject to strict laws.

Chimneys made of different materials have design differences, but all fireplace pipes are designed based on the following considerations:

- The draft must be sufficient to prevent combustion products from entering the room.

- In a properly selected design, a minimum of soot is deposited on the walls.

- The material is selected taking into account the temperature of the flue gases. The maximum temperature is maintained in the firebox; at the exit from the pipe it drops slightly, but can reach +100°C.

Steel has excellent performance characteristics Source superdom.ua

- Critical indicators of the chimney are its height and internal diameter; they are necessarily taken into account in the calculations.

- During the operation of the fireplace, soot settles in the chimney. Its excessive accumulation is undesirable, as it makes it difficult for gases to escape, and the rate of accumulation increases all the time. The design should provide for the possibility of convenient cleaning (this is carried out when the fireplace is not in use).

- Provisions must be made to monitor the integrity of the internal surface and connections of the structure. Cracks and irregularities that arise impede the calculated circulation of hot air.

Stainless steel smoke exhaust structures

Chimneys for fireplaces of this type are stacked structures. The length and diameter of a stainless steel fireplace pipe can be very different. Such products are often produced complete with ceramic ones and placed inside steel ones.

Chimneys made from galvanized stainless steel have the following advantages:

- they can be installed without a foundation, since they are light in weight;

- assembly and installation of the structure is permitted after completion of construction;

- they are cheaper in cost than block and ceramic systems;

- If necessary, replacing individual elements will be easy.

The disadvantage of steel chimneys is the need for a design solution in the case of interior design, if such a structure is installed indoors.

SNiP about the installation of a fireplace

The construction of fireplaces is regulated by SNiP rules; they contain all the information needed when independently designing a chimney system for a fireplace. The rules draw attention to the fact that the ventilation duct and chimney have different purposes, and they cannot be combined into one system.

Installation of a fireplace must comply with SNiP 41-01-2003 Source tinkoffjournal.ru

In a private house with a fireplace, it is necessary to provide forced exhaust ventilation and, separately from it, forced supply ventilation. Only in this way can a constant and sufficient level of draft be ensured, as well as avoid the entry of flue gases into the room.

The internal size of the chimney for a fireplace is a parameter for which the minimum acceptable values are specified in SNiP. They depend on the pipe material and the power of the heating device. For concrete and brick pipes the ratios are as follows:

- If the device power does not exceed 3.5 kW, the minimum permissible cross-section is 140x140 mm (round cross-section from 160 mm).

- For power in the range of 3.5-5.2 kW: cross-section from 140x200 mm.

- Power from 5.2 kW: from 140-270 mm (for round from 220 mm).

With the same power parameters for steel and ceramic structures, the minimum sections are increased to, respectively, 160, 190 and 220 mm.

The height of the chimney is an important detail for organizing good draft, so it is described in detail using the following conditions:

- The minimum permissible length of the structure is 5 m (meaning the distance from the grate to the pipe outlet).

Determining the height of the chimney Source s-proms.ru

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

- Longer structures are possible, which depends on external parameters (for example, on the characteristics of the roof, the location and height of neighboring buildings).

- For a flat roof, a chimney with a height above it of at least 0.5 m is calculated.

- Closely located obstacles impair traction. Such an obstacle can be the ridge or parapet of a pitched roof. If the distance to them is less than one and a half meters, the fireplace chimney is designed above the obstacles by at least 50 cm.

- If the chimney is located on a pitched roof far from obstacles (more than 3 m), its height is calculated from a conventional line drawn from the ridge down at an angle of 10º.

SNiP pays a lot of attention to brick structures, which are especially often chosen for decorating a fireplace in a private home. If you want your fireplace to have a brick chimney, it must comply with the following conditions:

- The wall thickness is at least 120 mm (concrete walls, for example, can only be 60 mm).

- In a brick (and concrete) chimney system, inspection openings with doors for cleaning are designed.

- To reduce the accumulation of soot in the channel, it is preferable to make it vertical throughout its entire length, without protrusions or slopes.

Fireplaces with open fireboxes require increased safety standards Source pinimg.com

- If it is impossible to make the structure vertical (for example, you need to bypass the beam), organize a tilt. It cannot be longer than 1 m, the angle of inclination should not exceed 30° or change the specified diameter of the chimney.

Separate rules relate to ensuring fire safety when operating a wood-burning fireplace:

- The device is placed against the wall to properly install the pipe.

- The walls and ceiling around the structure are protected with fire-resistant materials (sheet metal, plaster, asbestos). The wall through which the chimney passes is insulated from the outside. There should be no wooden elements (beams) in the floor structure.

- It is extremely important to maintain a gap between the brick wall and the ceiling: at least 13 mm (including thermal insulation). For example, for ceramics the gap increases to 25 cm.

- Before the firebox, a sheet of steel (or brass) measuring 50x70 cm is laid on the floor. The firebox sheet not only protects the floor, but also simplifies cleaning.

- The minimum distance from the firebox door to the opposite wall is 125 cm.

- The door for the firebox can be made of metal or glass, but always made of fire-resistant glass.

The door glass must be heat resistant Source amazon.com

Disadvantages of brick structures

A smoke exhaust pipe for a brick fireplace has disadvantages, the main one being the short service life of such structures, which does not exceed 7 - 10 years. The fact is that frequent and significant temperature changes during the cold season lead to the appearance of condensation, and it either freezes or thaws. As a result, over time, the brickwork begins to collapse.

To reduce the impact of negative aspects you can:

- expand the cross-section of the external chimney walls to 25 centimeters in those places where they are above the roof surface;

- insulate these sections of the chimney with mineral slabs.

The chimney pipe will last longer if you install a cap on top of it, which will protect it from precipitation.

One of the significant disadvantages of brick chimney structures is the presence of a rough inner surface, since this circumstance leads to a decrease in draft efficiency compared to smooth pipe walls.

Designing smoke drainage through a chimney that has a certain reserve cross-sectional area can help cope with this problem. The installation of galvanized steel pipes inside the smoke exhaust system will also increase the service life.

Materials

When choosing material for a fireplace and chimney, owners are guided by regulatory requirements, the size of the construction budget, the size of the chimney and their own tastes. In private homes there are fireplaces with chimneys made of the following materials:

- Ceramics . Ceramic chimneys are ideal for wood-burning fireplaces. They are compact and durable, are not afraid of overheating, are not destroyed by condensation, and have smooth inner walls. The disadvantages include their high cost, heavy weight (you will have to take care of reinforcing the floor), and complicated installation.

Ceramic components for chimney systems Source strojdvor.ru

- Brick . A traditional, time-tested material, which means a wide choice of masonry technology and pipe construction method. Problems with operation may arise if the seams between the bricks are not sealed and irregularities remain inside the pipe. Consequently, the skill of the performer comes first, and this is a parameter that is difficult to assess in advance.

- Steel . For the manufacture of pipes, heat-resistant anti-corrosion steel is used; steel products are chosen if the gas temperature does not rise above 400°C. The design is light, the floor does not need to be reinforced, and installation takes little time. More expensive steel pipes are equipped with thermal insulation (sandwich pipes) and are sold in ready-made kits, convenient for self-assembly.

Components for sandwich pipes Source strojdvor.ru

- Glass . The stylish design is made of heat-resistant glass, inert to the corrosive effects of smoke. Advantage of glass: soot settles more slowly on a smooth surface, which means less frequent cleaning. Due to its unusual appearance, high price tag and complex assembly, this option is rarely in demand, although its performance is comparable to its ceramic counterparts.

What is it and what is it for?

A chimney is a system of pipe channels designed to discharge smoke and gases generated during fuel combustion into the atmosphere.

Basic requirements for chimneys:

- resistance to high temperatures (over 500⁰C);

- formation of sufficient traction force;

- complete tightness;

- resistance to moisture formed inside the system as a result of condensation;

- resistance to the effects of carbon and sulfuric acid formed inside the circuit as a result of the chemical reaction of water vapor and exhaust gases (soot);

- ensuring structural stability;

- compliance with fire safety standards.

Diameter calculation principle

Diameter and height parameters are important for the functioning of the fireplace. If you select them incorrectly, you may encounter backdraft, and this already makes the operation of such a device dangerous for home owners.

In SNiP, the diameter of the pipes is determined by the power of the device (through the consumption of solid fuel and the volume of exhaust gases), but it is often necessary to calculate a more accurate pipe size. There are several methods for such calculations:

- According to formulas. The most accurate method, but it involves not only calculations, but also the determination of quite specific parameters (for example, the solid fuel combustion rate coefficient is pre-selected from table No. 10 of GOST 2127).

The volume of the firebox determines the amount of smoke Source pinimg.com

- According to schedule (Swedish method for open fireplaces). The diameter of the chimney for a fireplace is determined by the area of the combustion compartment, since the graph establishes the relationship between these values.

- Approximate. For a chimney with a round cross-section and an open firebox, a diameter ratio of 1:10 is used. For example, for a firebox measuring 40x50 cm, the permissible diameter will be: (40+50)x2/10=18 cm.

- For a chimney with a square cross-section, a ratio of 1:1.5 is used (this is due to the occurrence of smoke turbulence), and the minimum cross-sectional size will be 12x12 cm.

Installation of a steel chimney with a round cross-section Source maximuscentr.com.ua

Serious engineering solution

Calculating chimneys for a house or bathhouse is a complex engineering task. If you are not a specialist and you have a question about how to calculate a chimney for your home, use special programs that make it easier for you to make the correct calculation - be it the height, cross-section or length of the chimney.

In order to make correct calculations, it is necessary to know the structure and physical properties of materials, thermodynamics, and aerodynamics.

If you do not plan to further connect your life with the construction and design of chimneys, contact specialists. After all, the comfort of your home, safety and, most importantly, health, and sometimes life - yours and your loved ones - depend on the correct operation of the chimney.

Old school stove makers considered the ratio of the dimensions of the fireplace portal to the chimney to be 1:10 or 1:13. Depending on the operating conditions of the fireplace and weather conditions. Tabular fireplace calculation data are considered more accurate.

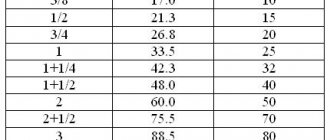

Table 6.1. Correlation of fireplace parameters (according to Sh. K. Afanasyev)

Pipes for fireplaces (three types of sections)

Flow section in bricks No.tr

Flow section in bricks No. tr

How to use table 6.1.

A is the width of the firebox,

B – height of the fireplace firebox,

column 3 – round standard chimney pipes, 4 – height of chimney pipes, 5 – dimensions of the firebox of the fireplace, 6 – height of the chimney pipes, 7 – dimensions of the firebox, 8 – height of the chimney pipes.

The ratio of the mirror of the fireplace portal, the cross-section and height of the chimney are directly dependent. Suppose you need to calculate a chimney based on the mirror of the fireplace portal with sides 1020x770. We search according to the table and find: diameter 300 mm, pipe height 9.5 meters.

Diagram 1.

Rice. 6.5 (A). Diagram for calculating the fireplace portal and pipe cross-section, where H is the height of the pipe in meters, F is the area of the fireplace portal (dimensions A and B in cm2; f is the cross-sectional area of the pipe (flow area in cm2; (f/ F) X100 is the percentage of area f from area F.

The configuration of the pipe sections is shown above.

How to use the diagram. Rice. 6.5(A). The horizontal numbers indicate (as a percentage) the area of the chimney pipe (f) to the area of the fireplace portal (F).

For example. The fireplace portal is 77 cm x 63 cm, therefore, the portal area is F = 4851 cm2. The dimensions of the square chimney pipe are 25cm x 25cm, therefore the cross-sectional area of the pipe is f = 625 cm2.

(f/ F) X100= 625/4851x100=12.8%.

Using a horizontal scale, we find the straight line until it intersects with the curve of the diagram (the middle line of a square chimney) and find the height of the chimney. The height of the chimney is 5 meters.

Let's consider other options for the ratios and dimensions of the fireplace. If you compare these tables, they are all approximately the same. There are small adjustments for: the roughness and cleanliness of the surface of the chimney walls, the angle of inclination of the outlet, the height of the pipe, the presence of nearby trees and buildings.

To determine the parameters and dimensions of the portal and chimney pipe of the fireplace, various factors are taken into account: the temperature of the flue gases, the speed of the exhaust gas-air mixtures (0.25 m/sec), the cleanliness of the channels, air pressure, etc. A round cross-section is considered better than a square cross-section, and a square cross-section is considered better than a rectangular cross-section. The air supply to the firebox of the fireplace is the main criterion in ensuring reliable operation of the fireplace. Most often, this is achieved by balanced supply and exhaust ventilation in a cottage, where the windows and doors are made of sealed double-glazed windows. Ventilation should be excessive with air pressure of 12-14%. If there is no supply and exhaust ventilation in the room, then sometimes it is enough to open the window, or slightly open the transom of the window.

Rice. 6.6. Facade, section and plan of the fireplace with letter designation for calculating various fireplace options according to table 6.2

Table 6.2. The ratio of the cross-section of the fireplace portal and the chimney.

Fig.6.6(A). The ratio of the cross-section of the fireplace portal and the chimney.

Errors or even the slightest inaccuracies made at the chimney construction stage will ultimately lead to serious consequences

In view of this, it is extremely important to do everything in accordance with the requirements and standards. An incorrectly designed chimney for a fireplace with your own hands can cause serious financial losses, which will manifest itself along with the need to redo everything

Among the consequences may be fire or poisoning of people in the room by products of improper combustion. Correct calculation of the chimney for the fireplace will allow you to avoid these accidents and enjoy a pleasant pastime in a cozy home.

Diagram of an English fireplace with a straight chimney.

Impact on the strength of structures

Fluctuations in the groundwater level under already erected buildings can cause deformation not only of the foundation, but also of the walls. This may be due to the following factors:

- saturation of the soil with readily soluble minerals. Over time, the soil changes its structure, and substances dissolved in groundwater disappear from it. Under the pressure of the walls, the soil that has lost its density sags and the building falls. To avoid this, before starting construction, a chemical analysis of the soil is carried out to determine the concentration of easily soluble substances;

- location of the building on the so-called quicksand - fine sandy soils that begin to slide when flooded by groundwater. If there are places where groundwater comes to the surface on the construction site, the risk that the building will “float away” along with the soil increases significantly. To prevent this phenomenon, when designing buildings on quicksand, the direction and speed of movement of groundwater, the nature of the relief, etc. are taken into account;

- location of the building on clay soils. As in the case of quicksand, when flooded with groundwater, such soils greatly lose their stability. Considering the distribution of clay soils in our country, the construction of high-rise buildings on them is possible if measures are taken to drain the aquifer before starting work.

There are also so-called aggressive groundwater, characterized by a high concentration of alkalis and acids dissolved in them.

Such waters destroy the concrete foundations of buildings much faster than ordinary ones.

Installation features

Installing a fireplace and future installation of a chimney is quite a troublesome task for one person, take care of helpers. Let's look at some features that are identical for absolutely any type of duct, regardless of stoves or fireplaces.

So, important installation aspects:

- The distance from the combustion part to the nearest wall is at least 150 mm.

- Calculate the angle of inclination correctly.

- Provide the ability to adjust the combustion level, regardless of the chimney.

- Pipe installation should begin only after measuring all planes.

- Remember to apply a double coat of sealing compound.

- Remember, the upper contour of the next section of pipe must fit into the lower one. This is the only way to achieve protection against moisture ingress.

- Use special clamps and rivets to securely secure the connections.

- Provide for technological expansion depending on temperature; in other words, there needs to be some play at the bottom where the pipe enters the firebox. This will avoid depressurization when heated. You need to use a special adapter.

Fuel options

On the heating equipment market, consumers are offered a variety of fireboxes operating on alternative fuels - they can be installed without a chimney structure in premises for any purpose.

Depending on the type of fuel used, a fireplace in a house made of timber or logs can be:

- Solid fuel, classic. The fireboxes of such units are intended for firewood or coal. They are equipped with standard smoke exhaust structures. In this case, installing a fireplace in a wooden house requires laying a foundation separate from the building, insulating surfaces and ceilings adjacent to the unit.

- Electric. Such devices are the most reliable from a fire safety point of view. They do not have an open fire, and the air is heated by consuming electrical energy. An imitation of a burning hearth is created by illuminating the decoration located inside the fireplace. Electrical appliances are easy to install because they do not require a foundation or a chimney. Such units are an ideal solution for placement on the upper floors of buildings and in attics. The main thing that is required for their installation is proper electrical wiring and its reliable insulation that can withstand the loads.

- Biofireplace. This heating equipment is a relatively new type. This fireplace in a log house runs on ethanol. Inside its combustion chamber there is a ceramic burner and a container intended for fuel. The advantage of the device is the absence of soot, ash and other substances harmful to health. To fully provide heat to a room, such a fireplace will not be enough, since its main function is decorative. Biofireplaces are produced in wall-mounted, floor-standing, hanging and tabletop versions. The peculiarity of the devices is the release of steam during the combustion process, which humidifies the air in the room. There is no need to make a chimney.

- Gas. In such a unit there is a burner inside the chamber. The fuel is natural or liquefied gas. In this case, installing a fireplace in a wooden house requires certain measures, as is the case with classic models of equipment. It is necessary to create a chimney.