Hot water supply to a private home is an important engineering system, the arrangement of which always remains a pressing issue. This is a necessary condition in order to fill the house with coziness and make it comfortable for living. The installation of modern water heaters successfully solves the problems of hot water supply and heating in a private home, and for this it is no longer necessary to have powerful electrical wiring, gas or a chimney. All you need is to familiarize yourself with the operating principles of various systems, select a suitable scheme, and, if desired, you can carry out the installation yourself.

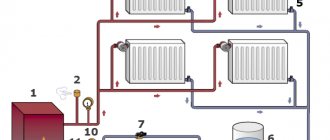

Scheme of hot water supply with instantaneous water heater

The following can be used as an instantaneous water heater:

- DHW gas water heater;

- DHW heating circuit of a double-circuit heating boiler;

- electric instantaneous water heater.

- plate heat exchanger connected to the heating circuit.

The instantaneous water heater begins to heat the water at the moment the water is drawn

when the hot water tap is opened.

All energy spent on heating passes from the heater to the water almost instantly , in a very short time of water movement through the heater. In order to obtain water at the required temperature in a short period of time, the design of an instantaneous water heater provides for limiting the speed of water flow. The water temperature at the outlet of the flow-through heater very much depends on the water flow -

the size of the stream of hot water flowing from the tap.

To properly supply hot water to only one shower head, the power of the instantaneous water heater must be at least 10 kW. You can fill a bathroom in a reasonable time using a heater with a power of more than 18 kW

.

And if, when filling the bathtub or running the shower, you also open the hot water tap in the kitchen, then for comfortable use of hot water you will need a flow heater power of at least 28

kW. To heat an economy class home, a lower power boiler is usually sufficient. Therefore, the power of a double-circuit boiler is chosen

based on the need for hot water.

A DHW circuit with an instantaneous water heater cannot provide comfortable and economical use of hot water in the house for the following reasons:

- The temperature and pressure of water in the pipes very much depend on the amount of water flow. For this reason When you open another tap, the water temperature and pressure in the hot water system changes greatly.

It is very uncomfortable to use water even in two places at the same time.

- When the flow of hot water is low, the instantaneous water heater does not turn on at all and does not heat the water.

To obtain water at the required temperature, it is often necessary to use more water than necessary. - Each time the water tap is opened, the instantaneous water heater starts again. It constantly turns on and off, which reduces its service life . Each time, hot water appears with a delay, only after the heating mode has stabilized. Frequently restarting the heater reduces efficiency and increases energy consumption. Some of the water goes down the drain uselessly.

- It is impossible to recirculate water in the distribution pipes throughout the house. Hot water from the tap appears with some delay.

The waiting time increases as the length of the pipes from the water heater to the water collection point increases.

Some of the water at the very beginning has to be drained uselessly into the sewer.

Moreover, this is water that has already been heated, but has managed to cool down in the pipes. - Scale deposits quickly accumulate

on a small surface inside the heating chamber of an instantaneous water heater. Hard water will require frequent descaling.

Ultimately, the use of an instantaneous water heater in a domestic hot water system leads to an unreasonable increase in water consumption and the volume of sewerage , to an increase in energy consumption for heating, as well as to insufficiently comfortable use of hot water in the house.

The DHW system with instantaneous water heater is used, despite its disadvantages, due to the relatively low cost and small size of the equipment

.

The system works better if a separate individual instantaneous water heater is installed near each water collection point.

In this case, it is convenient to install electric flow heaters. However, such heaters, when drawing water simultaneously in several places, can consume significant power from the electrical network (up to 20 - 30 kW). Typically, the electrical network of a private home is not designed for this, and the cost of electricity is high.

Useful tips

When constructing a new building, it makes sense to immediately install a storage boiler with a capacity of over 100 liters. It will provide comfortable living without the need for alterations in the future.

If the house is used infrequently, for example a summer house, then there is no point in installing a storage system; a flow-through heater is sufficient. At the same time, the compact arrangement of flow points in such buildings will ensure convenience during operation.

If you have a large family, you can install additional capacity in the storage water supply system. A 30-liter tank with additional electric heating, which serves to compensate for heat loss, will allow you to compensate for changes in water consumption with a large number of household members.

When purchasing a gas boiler, preference should be given to ready-made boiler-boiler kits. Their parameters have already been selected for each other, such a combination will optimally consume heat.

When heating a house with solid fuel, it makes sense to use a heat storage tank to create a secondary hot water supply circuit. This will significantly reduce energy costs.

At temperatures of 55 degrees and above, salts begin to actively precipitate from the water. They clog the pipes and impair the flow of water. This is especially important for flow-through heaters that heat large volumes over a short length of pipe. If the water contains more than 140 mg of impurities per liter of water, then instantaneous water heaters cannot be used - they break down too quickly and stop heating the water.

How to choose an instantaneous water heater

The main parameter for choosing an instantaneous water heater is the amount of water flow that it can heat.

For comfortable use, it is recommended to focus on the following volumes of hot water consumption at a temperature of 55 ° C at the points of analysis:

- from the sink faucet or washbasin 4.2 l/min (0.07 l/sec);

- from the bath or shower tap 9 l/min (0.15 l/sec).

For example.

Three points of disassembly are connected to one instantaneous water heater - a sink in the kitchen, a washbasin and a bathtub (shower). To fill only the bathtub, you must select a heater that is capable of delivering at least 9 l/min. water with a temperature of 55 oC. Such a water heater will also provide the use of hot water simultaneously from two taps - in the sink and washbasin.

It will be comfortable to use hot water in the shower and washbasin at the same time if the heater capacity is no less than 9 l/min + 4.2 l/min = 13.2 l/min.

Manufacturers in the technical specifications usually indicate the maximum performance of an instantaneous water heater, based on heating water at a certain temperature difference, dT, for example, 25 °C, 35 °C or 45 °C. This means that if the water temperature in the water supply is +10 °C, then at maximum performance, water with a temperature of +35 °C, 45 °C or +55 °C will flow from the tap.

Be careful. Some sellers in advertising indicate the maximum performance of the device, but “forget” to write for what temperature difference it is determined . You can buy a geyser with a capacity of 10 l/min, but it turns out that at this flow rate it will only heat the water by 25 °C, i.e. up to 35 oC. Using hot water with such a column may not be very comfortable.

For our example, a gas water heater or a double-circuit boiler with a maximum productivity of at least 13.2 l/min at dT=45 °C is suitable. The power of the gas appliance with these hot water parameters will be about 32 kW.

When choosing an instantaneous water heater, pay attention to one more parameter - the minimum performance, the flow rate l/min at which heating is turned on.

If the water flow in the pipe is less than the value specified in the technical characteristics of the device, the water heater will not turn on. For this reason, it is often necessary to use more water than necessary. Try to choose a device with the minimum minimum capacity as low as possible, for example, no more than 1.1 l/min.

Electric instantaneous water heaters intended for domestic use have a maximum heater power of about 5.5 - 6.5 kW. At a maximum productivity of 3.1 - 3.7 l/min, water is heated at dT = 25 °C. One such water heater is installed to serve one water point - a shower, washbasin or sink.

Heating system water temperature

- In the corner room +20°C;

- In the kitchen +18°C;

- In the bathroom +25°C;

- In corridors and stairwells +16°C;

- In the elevator +5°C;

- In the basement +4°C;

- In the attic +4°C.

It should be taken into account that these temperature standards refer to the heating season and do not apply to the rest of the time. Also, it will be useful information that hot water should be from +50°C to +70°C, according to SNiP-u 2.08.01.89 “Residential buildings”. There are several types of heating systems: Contents

- 1 With natural circulation

- 2 With forced circulation

- 3 Calculation of the optimal temperature of the heating device 3.1 Cast iron radiators

- 3.2 Aluminum radiators

- 3.3 Steel radiators

- 3.4 Warm floor

With natural circulation The coolant circulates without interruption.

DHW circuit with storage heater (boiler) and water circulation

A storage water heater (boiler) is a heat-insulated metal tank of a fairly large volume.

Most often, two heaters are built into the lower part of the water heater tank at once - an electric heating element and a tubular heat exchanger connected to the heating boiler (diagram for connecting the boiler to the boiler). The water in the tank is heated by the boiler most of the time.

The electric heater is turned on as needed when the boiler is stopped. Such a boiler is often called an indirect heating boiler.

Hot water in an indirect heating boiler is consumed from the top of the tank. In its place, cold water from the water supply immediately enters the lower part of the tank, is heated by a heat exchanger and rises upward.

In the European Union, hot water systems in new houses are required to be equipped with a solar heater - a collector. To connect the solar collector, another heat exchanger is installed in the lower part of the indirect heating boiler .

The water in the boiler is heated by a solar collector. If there is not enough heat from the collector, then the boiler or electric heater is switched on. Read: “DHW system with solar collector” .

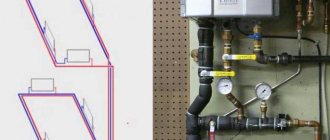

Coordination of coolant and boiler temperatures

Regulators help coordinate the temperature of the coolant and the boiler.

These are devices that create automatic control and adjustment of return and supply temperatures. The return temperature depends on the amount of liquid passing through it. Regulators cover the liquid supply and increase the difference between the return and supply to the level required, and the necessary indicators are installed on the sensor.

If the flow needs to be increased, a boost pump can be added to the network, which is controlled by a regulator. To reduce the heating of the supply, a “cold start” is used: that part of the liquid that has passed through the network is again transported from the return to the inlet.

The regulator redistributes the supply and return flows according to the data collected by the sensor, and ensures strict temperature standards for the heating network.

DHW diagram with layer-by-layer heating boiler

| DHW diagram with layer-by-layer heating boiler and instantaneous water heater |

Recently, a hot water supply system with a layer-by-layer heating boiler has been gaining popularity,

the water in which is heated by a flow-through water heater. This boiler does not have a heat exchanger, which reduces its cost.

Hot water is drawn from the top of the tank. In its place, cold water from the water supply immediately flows into the lower part of the tank. The pump drives water from the tank through a flow-through heater and supplies it directly to the top of the tank. Due to this, the consumer gets hot water very quickly

— you don’t need to wait until almost the entire volume of water warms up, as happens in an indirect heating boiler.

Rapid heating of the top layer of water allows you to install a smaller boiler in the house, as well as reduce the power of the flow-through heater,

without sacrificing comfort.

The Galmet SG (S) Fusion 100 L layer-by-layer heating boiler is connected to the DHW circuit of a double-circuit boiler or to a gas water heater.

The boiler has a built-in three-speed circulation pump. Boiler height 90 cm, diameter 60 cm. Manufacturers produce double-circuit boilers with a built-in or remote layer-by-layer heating boiler. As a result, the cost and dimensions of the DHW system equipment are somewhat smaller,

than with an indirect heating boiler.

The water in the boiler is heated in advance,

regardless of whether it is spent or not. The hot water reserve in the tank allows you to use hot water in the house for several hours.

Thanks to this, the water in the tank can be heated for quite a long time, gradually accumulating thermal energy in the hot water. Hence another name for the boiler - storage water heater.

The long duration of water heating allows the use of a relatively low power heater.

Adjustment

Automatic control is provided by the heating regulator.

It includes the following parts:

- Computing and matching panel.

- Actuating device on the water supply section.

- An actuator that performs the function of mixing liquid from the returned liquid (return).

- Boost pump and sensor on the water supply line.

- Three sensors (on the return line, on the street, inside the building). There may be several of them in the room.

The regulator closes the liquid supply, thereby increasing the value between return and supply to the value specified by the sensors.

To increase the flow, there is a boost pump and a corresponding command from the regulator. The incoming flow is controlled by a "cold bypass". That is, the temperature decreases. Some of the liquid that has circulated along the circuit is sent to the supply.

Sensors collect information and transmit it to control units, resulting in a redistribution of flows that provide a rigid temperature scheme for the heating system.

Sometimes, a computing device is used that combines hot water and heating regulators.

The hot water regulator has a simpler control scheme. The hot water sensor regulates the flow of water with a stable value of 50°C.

Advantages of the regulator:

- The temperature scheme is strictly maintained.

- Elimination of overheating of the liquid.

- Fuel and energy efficiency.

- The consumer, regardless of the distance, receives heat equally.

Storage gas water heater - boiler

Storage boilers, the water in which is heated by a gas burner, are less popular in domestic hot water systems. Installing heating and hot water systems in a house with two gas appliances - a gas boiler and a gas boiler - turns out to be noticeably more expensive.

Storage gas water heater - boiler

It can be advantageous to install gas boilers in apartments with central heating or in private houses with heating by a solid fuel boiler and heating of water in the hot water system with liquefied gas.

Gas water heaters, like boilers, are available with an open combustion chamber and a closed one, with forced removal of flue gases and with natural draft in the chimney.

There are storage gas boilers on sale that do not require connection to a chimney . (Household gas stoves also operate without a chimney.) The power of the gas burners of such devices is small.

Gas boilers with a capacity of up to 100 liters are designed for wall mounting. Large volume water heaters are installed on the floor.

Water heaters use different methods of gas ignition - with a pilot wick, electronic with batteries or hydrodynamic ignition.

In devices with a pilot wick, a small flame is constantly burning, which is first ignited manually. A certain amount of gas burns uselessly in this torch.

Electronic ignition operates from the mains or a battery.

Hydrodynamic ignition is started by rotating a turbine, which is driven by the flow of water when the tap is opened.

Dependence of coolant temperature on outside air temperature

The specific table of the relationship between outdoor temperature and coolant depends on factors such as climate, boiler room equipment, and technical and economic indicators. Reasons for using a temperature schedule The basis for the operation of each boiler house serving residential, administrative and other buildings during the heating season is a temperature schedule, which indicates the standards for coolant indicators depending on what the actual outside temperature is.

- Drawing up a schedule makes it possible to prepare the heating for a drop in outside temperature.

- It also saves energy resources.

ATTENTION! In order to control the temperature of the coolant and have the right to recalculate due to non-compliance with the thermal regime, a heat sensor must be installed in the centralized heating system

How to choose the volume of a storage water heater - boiler

The larger the volume of the storage water heater, the higher the comfort of using hot water in the house. But on the other hand, the larger the boiler, the more expensive it is, the higher the costs of its repair and maintenance, and the more space it takes up.

The size of the boiler is selected based on the following considerations.

It is generally accepted that the boiler volume, selected at the rate of 20-30 liters per person, will provide the minimum necessary comfort for using hot water in the house.

Increased comfort will be provided by a boiler, the volume of which is selected at the rate of 30 - 60 liters per user of water.

A high level of comfort will be provided by a water heater with a volume of 60-100 liters per person living in the house.

To fill the bathtub, it is necessary to use up almost all the water from the boiler with a volume of 80 - 100 liters.

Actions after receiving the act

After you have completed all the documents and received an act of violation of the quality of public services for the delivery of hot water, your further actions are to submit a request for recalculation of payment. You can find out the time for which the recalculation must be made from the information provided above.

The period of violation of the temperature schedule is considered:

- From the time of bringing information about the violation to the dispatcher;

- Until the time of testing to restore parameters.

If during this time the correct DHW has not been resumed, then the services with a violation of quality are considered incomplete, which means you have the right to submit a second claim.

How to choose boiler power for a DHW boiler

When choosing a boiler, you need to pay attention to the power of the heating element that is installed in it. For example, to heat 100 liters of water to a temperature of 55 oC in 15 minutes, a heater (heat exchanger for the boiler, built-in gas burner or heating element) with a power of about 20 kW must be installed in the boiler.

In real operating conditions, the temperature of the water in the boiler is equal to the temperature of the water in the water supply only when the heating is first turned on. In the future, the boiler almost always contains water that has already been heated to a certain temperature. To heat water to the required temperature in an acceptable time, heating devices of lower power are used.

But it’s still better to check how long it will take to heat the water in the boiler. This can be done using the formula:

t = m•cw•(t2 – t1)/Q , in which: t – water heating time, seconds (s); m – mass of water in the boiler, kg (mass of water in kilograms equals the volume of the boiler in liters); cw is the specific heat capacity of water, equal to 4.2 kJ/(kg•K); t2 – temperature to which the water should be heated; t1 – initial water temperature in the boiler; Q – boiler power, kW.

Example: The time for heating water by a 15 kW boiler in a 200-liter boiler from a temperature of 10°C (we assume that the water entering the boiler has this temperature) to 50°C will be: 200 x 4.2 x (50 – 10) /15 = 2240 s, that is, about 37 minutes.

Household products

⇆

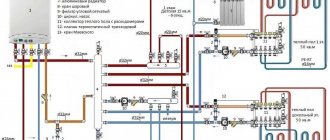

DHW scheme with water recirculation in the system

The use of a storage water heater in a domestic hot water system allows for the recirculation of hot water in pipelines. All hot water collection points are connected to a ring pipeline through which hot water constantly circulates.

The length of the pipe section from each point of hot water consumption to the ring pipeline should not be more than 2 meters.

The circulation pump of the DHW hot water recirculation system is small in size and has low power.

Water recirculation in the DHW system is ensured by a circulation pump. The pump power is small, several tens of watts.

Pumps for DHW, unlike heating pumps, must have a maximum operating pressure of at least 10 bar. Heating pumps are often designed for a maximum pressure of no more than 6 bar. Another difference is that the DHW pump must have a hygienic certificate allowing use in drinking water supply systems.

The water in hot water supply systems is constantly renewed and the oxygen content in it remains quite high. Hot water is highly corrosive. In addition, hot water must meet sanitary requirements for drinking water. Therefore, for the manufacture of DHW pumps, corrosion-resistant non-ferrous metals or stainless steel are used. For these reasons, circulation pumps for hot water supply are noticeably more expensive than similar pumps for heating systems.

In some DHW pipeline designs, it is possible to create natural water recirculation, without a pump.

As a result of water circulation in the hot water supply system, hot water is constantly supplied to the sampling points.

In a DHW system with a storage heater and water recirculation, the water supply mode is more stable:

- Hot water is always present at the sampling points.

- Water can be collected simultaneously in several places. The temperature and pressure of water change slightly when the flow rate changes.

- You can take any, no matter how small, amount of hot water from the tap.

The recirculation circuit allows not only to increase the comfort of water supply in remote points of the house, but also makes it possible to connect heated floor circuits to it in individual rooms. For example, in a bathroom, a water-heated floor will be comfortable all year round.

A DHW system with water recirculation constantly consumes energy

for the operation of the circulation pump, as well as to compensate for heat losses in the boiler itself and in the pipes with circulating water. To reduce energy consumption, it is recommended to install a circulation pump with a built-in programmable timer that turns off water circulation during hours when it is not needed. The boiler and hot water pipes are insulated.

Materials

The hot water supply system for Soviet-built residential buildings was installed with steel pipes (black and galvanized) using welding and threaded fittings. However, now, excuse me, it’s the twenty-first century, and steel (at least black) in no way meets the regulatory requirements for the durability of water pipes.

What materials are in use now?

| Image | Description |

| A copper pipe is incomparably more durable than a steel pipe (copper water pipes from a century ago still work perfectly) and is not inferior to it in strength (the breaking pressure for a 15 mm pipe with a millimeter wall is 240 atmospheres). Not only that: copper helps disinfect water due to its bactericidal properties. To connect pipes, socket soldering, crimp and compression fittings are used. |

| Hot water supply in the house, installed with a corrugated stainless pipe, will be resistant to water hammer and significant overheating. With a wall thickness of only 0.3 mm, stainless steel is almost as strong as a copper pipe, outperforming it in terms of flexibility and manufacturability of installation on compression fittings. |

| Polypropylene pipes are designed for pressures up to 25 atmospheres and temperatures up to 90 degrees. The advantage of this material is the minimal cost of the pipes themselves (from 20 rubles/m) and welding fittings (from 3 rubles). To connect them, a soldering iron with Teflon tips is used. |

| Heat-resistant and cross-linked polyethylene is used mainly for hidden collector distribution of hot water supply. Heat resistance is from 70 to 110 degrees, it is determined by the amount of copolymers and PERT and the degree of cross-linking of PEX. Installation - on compression fittings, fittings and (for PERT) coupling fittings for welding. |

| A metal-polymer pipe with compression fittings is ideal if you want to install a hot water supply for your dacha yourself with a minimum set of tools. To install the fitting, you only need two wrenches (open-end or adjustable), an inexpensive calibrator and a pipe cutter. The inner lining of the pipe is made of PEX or PERT and provides quite acceptable temperature resistance. |

Disadvantages of a hot water supply system with a double-circuit gas boiler or water heater

Clocking of a double-circuit boiler in heating mode

As you know, a double-circuit gas boiler can provide a house with hot water and be a source of heat in the heating system. Hot water is prepared in a flow-through heat exchanger of the boiler. Read about the general disadvantages of a DHW system with a flow-through heater at the beginning of this article. But gas appliances with a flow-through heater have another problem - the difficulty of choosing the maximum power of a double-circuit boiler or hot water heater.

Most often it turns out that the required boiler power for preparing hot water is significantly greater than the power required to heat all rooms in the house.

As already mentioned in the article above, in order to obtain hot water at the required temperature and its maximum consumption, double-circuit gas boilers and water heating geysers have a fairly large maximum power, about 24 kW . or more. Boilers and heaters are equipped with automatic equipment, which can, by modulating the burner flame, reduce their power to a minimum, equal to approximately 30% of the maximum. The minimum power of a double-circuit gas boiler or water heater is usually about 8 kW. or more. This is the minimum boiler power, both in DHW and heating modes.

Due to design features, the gas burner of a double-circuit boiler or water heater cannot operate stably with a power less than the minimum (less than 8 kW). At the same time, to work with the heating system of a private house or autonomous heating of an apartment, the boiler in heating mode very often must produce a power of less than 8 kW.

For example, power 8 kW. enough to provide heat to the premises of a house or apartment with an area of 80 - 110 m2, and during the coldest five-day period of the heating season. In warmer periods, the productivity and power of the boiler should be significantly less.

Due to the fact that the boiler cannot operate with power below the minimum, problems arise with the adaptation (coordination) of the double-circuit boiler and the heating system.

In small facilities with low heat consumption for heating, the boiler produces more heat than the heating system can accept. As a result of inconsistency between the parameters of the boiler and the system, the double-circuit boiler begins to operate in pulse mode, “clocking” - as people say.

Operating in the “clocking” mode significantly reduces the service life of boiler parts and significantly reduces efficiency.

Read more: “Setting the power of a double-circuit gas boiler”

Clocking a gas boiler or water heater in DHW mode

Diagram of heating tap water with a double-circuit gas boiler or hot water column, depending on the temperature ( T oC) and flow rate ( Q l/min) of hot water. The thick line shows the boundaries of the Working Area. Gray zone, position 1 - clock zone of the boiler or dispenser (switching between ON/OFF).

For normal heating of water by a boiler or column, in the diagram the point of intersection of the temperature and hot water flow lines (operating point) must always be located inside the working zone, the boundaries of which are shown in the diagram with a thick line. If the hot water consumption mode is selected so that the operating point is in the gray zone, pos. 1 on the diagram, then the boiler and column will clock. In this zone, with a small water flow, the power of the boiler or dispenser turns out to be excessive, the boiler, dispenser turns off due to overheating, and then turns on again. Either hot or cold water comes out of the tap.

Read more: “Alternately cold and then hot water comes from the boiler.”

Low efficiency of double-circuit gas boilers and water heaters

Double-circuit gas boilers, when operating at maximum power, have an efficiency of more than 93%, and less than 80% when operating at minimum power. Imagine how the efficiency will further decrease if such a boiler has to operate in pulse mode, with the gas burner constantly re-igniting.

Please note that a double-circuit boiler operates at minimum power most of the time throughout the year. At least 1/4 of the spent gas will literally fly uselessly down the pipe. Add to this the cost of replacing prematurely worn-out boiler parts. This will be the price to pay for installing cheap heating and hot water equipment in your home.

What do you want - choose

If the power of a double-circuit gas boiler is more than 20 kW. , is selected based on heating the maximum required flow of hot water, then the boiler cannot provide economical and comfortable operation in low heating power mode and when heating water at low flow rates. The same can be said about the operation of a hot water column.

Most often, there is no need to prepare large flows of hot water in the house. For many people, it is much more important to ensure comfortable and economical use of hot water with low consumption.

For such economical owners, many manufacturers produce double-circuit gas boilers and water heaters with a maximum power of about 12 kW. and the minimum is less than 4 kW. Such boilers and heaters will provide more economical and comfortable heating and the use of hot water in quantities sufficient for taking a shower or washing dishes.

Before purchasing a double-circuit boiler or water heater, owners need to decide which mode of hot water consumption is more profitable and comfortable - with a large water flow or with a small one. Based on this decision, choose the power of the boiler or dispenser. If you want both, you will have to choose a hot water system with a boiler.

For shower lovers, for preparing hot water and heating houses and apartments with a heated area of up to 140 m2, with one bathroom , I recommend installing double-circuit gas boilers with a maximum power of 12 kW. They best suit the needs of heating and hot water systems of small private houses and apartments.

For those who like to take a bath, as well as for large houses and apartments with an area of more than 140 m2, I highly recommend using a hot water system with a stratified heating boiler and a double-circuit boiler, or with an indirect heating boiler and a single-circuit boiler.

Many manufacturers of heating equipment produce special kits, a boiler plus a built-in or remote boiler, just for such cases. Such a set of equipment will be more expensive, but will provide an increased service life of the equipment, gas savings and more comfortable use of hot water.

Factors affecting boiler operation

They are:

- Design. The equipment may have 1 or 2 circuits. It can be mounted on a wall or on the floor.

- Normative and actual efficiency.

- Proper heating arrangement. The power of the equipment is comparable to the area that needs to be heated.

- Technical conditions of the boiler.

- Gas quality.

Question about the design.

The device may have 1 or 2 circuits. The first option is complemented by an indirect heating boiler. The second one already has everything you need. And the key mode in it is the provision of hot water. When water is supplied, heating ends.

Models mounted on the wall have less power than those placed on the floor. And they can heat a maximum of 300 sq.m. If your living space is larger, you will need a floor-mounted unit.

P.2 efficiency factors.

The document for each boiler reflects the standard parameter: 92-95%. For condensation modifications it is approximately 108%. But the actual parameter is usually 9-10% lower. It decreases even more due to heat losses. Their list:

- Physical underburning. The reason is excess air in the apparatus when gas is burned, and the temperature of the exhaust gases. The larger they are, the more modest the efficiency of the boiler.

- Chemical underburning. What is important here is the volume of CO2 oxide produced when carbon is burned. Heat is lost through the walls of the apparatus.

Methods for increasing the actual efficiency of a boiler:

- Removing soot from pipelines.

- Elimination of scale from the water circuit.

- Limit chimney draft.

- Adjust the position of the blower door so that the coolant reaches its maximum temperature.

- Removing soot from the combustion compartment.

- Installation of a coaxial chimney.

P.3 Questions about heating. As already noted, the power of the device necessarily correlates with the heating area. A competent calculation is needed. The specifics of the structure and potential heat losses are taken into account. It is better to entrust the calculation to a professional.

If the house is built according to building codes, the formula works: 100 W per 1 sq.m. This results in a table like this:

| Area (sq.m.) | Power. | ||

| Minimum | Maximum | Minimum | Maximum |

| 60 | 200 | 25 | |

| 200 | 300 | 25 | 35 |

| 300 | 600 | 35 | 60 |

| 600 | 1200 | 60 | 100 |

It is better to purchase foreign-made boilers. Also in advanced versions there are many useful options that help you achieve the optimal mode. One way or another, the optimal power of the device is in the spectrum of 70-75% of the highest value.

The optimal operating mode of a gas boiler to save gas is achieved by eliminating clocking. That is, you need to set the gas supply to the lowest value. The attached instructions will help with this.

DHW circuit with sewerage heat recuperator

In Western Europe and around the world, various ways to save energy when operating a private home are popular.

After use, hot water from the house flows into the sewer and takes with it a significant part of the thermal energy that was spent on heating it.

Scheme for the recovery of thermal energy from sewerage wastewater into the hot water supply system

To reduce energy losses in the house, a scheme is used to recover (return) heat from sewage into the domestic hot water system of a private house.

Cold water passes through a heat exchanger before entering the DHW boiler. The wastewater from sanitary equipment is sent to the heat exchanger.

In the heat exchanger, two streams, cold water from the water supply and hot water from the wastewater, meet but do not mix. Some of the heat from hot water is transferred to cold water. The hot water boiler receives already heated water.

In the diagram shown in the figure, only those sanitary fixtures that operate with hot water flow are sent to the heat exchanger. This recovery scheme is advantageous to use with any method of heating water - both with a boiler and with a flow-through heater.

To recover heat from the drains of sanitary appliances, which first accumulate hot water and then discharge it into the sewer system (bathtub, swimming pool, washing machine and dishwasher), a more complex scheme is used with water circulation between the boiler and the heat exchanger while these devices are emptying.

Tips for the developer

For houses and apartments with permanent residence, I highly recommend using a hot water system with a stratified heating boiler and a double-circuit boiler, or with an indirect heating boiler and a single-circuit boiler. The boiler volume is at least 100 liters. The system will provide good comfort in using hot water, economical consumption of gas and water, as well as a smaller volume of waste into the sewer. The only disadvantage of such a system is the higher cost of the equipment.

With a limited construction budget, in small country houses for seasonal living, you can install a hot water system with a flow-through heater.

It is advisable to use a DHW circuit with a flow-through heater in houses with a kitchen and one bathroom, where the heating source and hot water collection points are located compactly , at a short distance from each other. It is recommended to connect no more than three water taps to one instantaneous water heater.

The cost of such a system is relatively low,

and the disadvantages of operation in this case are less pronounced. A double-circuit gas boiler or gas water heater takes up little space. Almost all the necessary equipment is mounted in the device body. To install a boiler with a power of up to 30 kW or a gas water heater, a separate room is not required.

To prepare hot water and heat houses and apartments with a heated area of up to 140 m2, with one shower in the bathroom , I recommend installing double-circuit gas boilers with a maximum power of 12 kW.

In a DHW system with a gas water heater or a double-circuit boiler

The stability of the water supply mode will increase significantly if

a buffer tank is installed in the circuit between the heater and the water collection points

- a conventional storage electric water heater. It is especially recommended to install such a buffer storage electric water heater near distribution points remote from the gas appliance.

Read more: Connecting an electric hot water boiler to a double-circuit gas boiler or water heater

In a scheme with a buffer tank, hot water from a gas water heater or double-circuit boiler first enters the tank of the electric boiler - water heater

. Thus, the tank always contains a supply of hot water. The electric heater in the tank only compensates for heat loss and maintains the required temperature of hot water during the period when there is no water supply. An electric water heater with a small capacity tank is enough - even 30 liters, and using hot water will become much more comfortable.

DHW system with instantaneous water heater and built-in boiler or remote stratified heating boiler

will be somewhat more expensive. But here you will not need to spend expensive electricity to maintain the water temperature, and the comfort of using water will be the same as with an indirect heating boiler.

In houses with an extensive DHW network, implement a scheme with a storage water heater (boiler) and water recirculation. Only such a scheme will provide the necessary comfort and economical operation of the hot water system. True, the initial costs of its creation are the highest. It is recommended to buy boilers that are sold complete with a boiler.

In this case, the parameters of the boiler and boiler have already been correctly selected by the manufacturer, and most of the additional equipment is built into the boiler body.

If the heating in the house is carried out with a solid fuel boiler , then it is beneficial to install a buffer tank - a heat accumulator, to which you can connect a hot water supply system with water circulation.

Otherwise, to heat water in the house, an indirect heating boiler, additionally equipped with an electric heater, is connected to the solid fuel boiler.

It is beneficial to use an electric hot water boiler in a house with a solid fuel boiler

Often, only electricity is used to heat water in a house with a solid fuel boiler. For hot water supply in the house, near the water collection points, an electric storage boiler - a water heater - is installed. There is no hot water circulation system in this option. It is more profitable to install your own separate storage heater near remote water collection points. In this case, electricity is spent more economically on heating water.

When water is heated above 54 °C, hardness salts are released from the water. To reduce scale formation

If possible, heat the water to a temperature lower than specified.

Instantaneous water heaters are especially sensitive to scale formation. If the water is hard, contains more than 140 mg

CaCO3 in 1 liter, then

the use of instantaneous water heaters, including those with stratified heating boilers, for heating water is not recommended.

Even small scale deposits clog the channels in the instantaneous heater, which leads to the cessation of water flow through it.

It is recommended to supply water to the instantaneous water heater through an anti-scale filter, which reduces water hardness. The filter has a replaceable cartridge that will have to be changed regularly.

To heat hard water, it is better to choose a hot water storage system with an indirect heating boiler.

Salt deposits on the heating element of the boiler do not impede the flow of water, but only reduce the performance of the boiler. The boiler is easier to clean from scale.

It should be remembered that prolonged heating of water to a temperature of less than 60 ° C can lead to the appearance of Legionella bacteria harmful to human health in the storage tank (boiler) with hot water. It is recommended to periodically perform thermal disinfection of the hot water supply system , increasing the water temperature to 70 ° C for some time.

More articles on this topic:

⇒ Connecting a layer-by-layer heating boiler to a double-circuit boiler ⇒ Why there is either cold or hot water from the boiler ⇒ Descaling the DHW heat exchanger of a boiler or column ⇒ Solar collector - water heater for a home, pool

More articles on this topic

- Dew point, vapor barrier and ventilated wall gap

- How to make a house warm. Energy saving house

- Installation of plastic windows at the dacha

- We are building a house, walls made of concrete blocks

- The procedure and stages of construction of a private country house, cottage

- Lessons from the Maidan for Russia.

- Should I build a house on one floor or two?

- Films and membranes for water vapor barrier and wind protection at home

Optimal values in an individual heating system

Autonomous heating helps to avoid many problems that arise with a centralized network, and the optimal temperature of the coolant can be adjusted according to the season.

In the case of individual heating, the concept of standards includes the heat transfer of a heating device per unit area of the room where this device is located. The thermal regime in this situation is ensured by the design features of the heating devices. It is important to ensure that the coolant in the network does not cool below 70 °C. 80 °C is considered optimal

With a gas boiler, it is easier to control heating, because manufacturers limit the ability to heat the coolant to 90 °C. Using sensors to regulate the gas supply, the heating of the coolant can be adjusted.

It is a little more difficult with solid fuel devices; they do not regulate the heating of the liquid, and can easily turn it into steam. And it is impossible to reduce the heat from coal or wood by turning the knob in such a situation. Control of heating of the coolant is quite conditional with high errors and is carried out by rotary thermostats and mechanical dampers.

Electric boilers allow you to smoothly regulate the heating of the coolant from 30 to 90 °C. They are equipped with an excellent overheat protection system.