Often a metal stove is installed to heat steam rooms and other bath rooms. The design is compact, but quickly warms up the rooms. Not every owner can buy a good factory unit, so many owners with minimal skills in working with an angle grinder and a welding machine have learned to assemble such a stove themselves.

A furnace made from a large-diameter pipe is characterized by good reliability and a long service life. We’ll look at how to make it at home in our article.

Types of tube furnaces

According to the design and shape of the firebox, they can be horizontal or vertical. We will describe the differences, advantages, and application of each type in more detail.

Horizontal

This is an oblong-shaped sauna stove with a recessed firebox that runs horizontally, which allows you to immediately load a large volume of firewood and quickly warm up the steam room. And provided that part of the firebox is removed to the dressing room, this room will also be removed. It is convenient to use in conjunction with a hanging water tank. A larger firebox length heats a larger number of stones at the same time, due to which the convection of warm air in the steam room improves.

A horizontal stove is perfect for spacious baths. For ease of cleaning, kindling, and loading fuel, it is recommended to move the firebox to the dressing room.

The finished structure has a complex assembly process, but is durable and has high heat transfer rates.

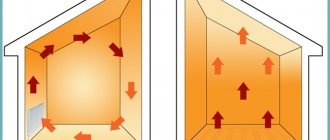

The main advantage of the horizontal type is uniform heating of all corners of the room, which a vertical stove cannot boast of.

Vertical

This type is an economical option for a small bathhouse. It looks very similar to a standard potbelly stove. Such a stove is installed not only in the bathhouse, but also in the garage and summer kitchen. It doesn't take up much space. Firewood is loaded vertically. The entire structure of the stove is located in the steam room, which causes inconvenience when lighting and cleaning the ash pan.

The diameter of the vertical furnace is equal to the diameter of the pipe used for its manufacture. Immediately under the heater there are grate bars, on top of the heater there is a platform for laying stones, it is possible to attach a tank for heating water. This kind of homemade product is much easier to make than a horizontal one, and it will take less time.

The disadvantage of the vertical type is that the walls of the room are well heated, but the floor and air at the top of the steam room are poorly heated.

But this drawback does not apply to the original “rocket stove”. The design has nothing in common with a combat missile other than appearance. It is characterized by high efficiency, economical consumption of firewood and good heat dissipation. Available with open and closed firebox. For a bathhouse, the second option is preferable.

In the “rocket”, firewood is loaded into the horizontal compartment and set on fire in the vertical section. It is only suitable for a small seasonal bathhouse.

Useful tips

To make the stove not only functional, but also pleasing to the eye, you can paint it with fire-resistant paint - heat-resistant paint will not only give it the desired color, but will also help protect the metal from corrosion.

You can also cover it with brick, which not only has a decorative function, but also saves you from excessive infrared radiation carried by heated metal. This type of rays does not soar, but burns.

What metal is suitable

When selecting and inspecting metal pipes for a future furnace, it is important to pay attention to the following details:

- strength of the metal workpiece;

- pipe thickness;

- no defects or severe metal corrosion.

To eliminate defects, you need to weld patches of a suitable size in problem areas with a small margin.

As for the composition of the metal, it is not recommended to use alloy steel or steel with a high carbon content. The permissible carbon content in steel should not exceed 2%.

You can determine whether a metal is high-carbon or not by the appearance of sparks when grinding with sandpaper or an attachment on a grinder or drill. A high carbon content is indicated by white sparks like stars that pour in different directions. Low carbon content is indicated by yellow sparks that fall in a straight line. Alloy steel produces orange, bright red sparks.

The stove can be made either from a round pipe for a bath or from sheet metal. If in the first case the shape will be close to cylindrical, then in the second the furnace unit will be rectangular.

By choosing a round pipe as a blank, bathhouse owners receive a number of advantages:

- The pipe is easier to work with. Essentially, you have a ready-made firebox at your disposal that does not need to be cut.

- Economical material consumption allows you to reduce money expenses.

- In a round oven, the process of heat and air exchange is many times more efficient.

- The service life of a round stove is longer than a rectangular one made of sheet metal.

In addition to selecting the material, it is important to develop a drawing, a diagram of the future product, indicate the location and method of fastening all structural elements. This will simplify the assembly process of the unit.

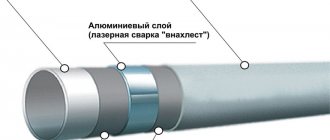

Polypropylene

Polypropylene

Polypropylene pipes are excellent for installation in heating system structures.

In addition, they have an attractive advantage - an affordable price.

However, when choosing, you should pay attention to the possibility of operating such pipelines with hot coolant, since not all types of polypropylene pipes fit this category.

Polypropylene has many advantages, in addition to the already mentioned reasonable cost.

These include:

- Lightness of the design, as a result of which after installation there will not be a significant load on the walls of your house;

- Smooth inner surface. Thus, even after many years, there will be no lime deposits or rust in them;

- Durability. The service life of polypropylene pipes is approximately 20 years, and all their qualities will remain unchanged during this period;

- Low temperature resistance. They are ideal for country houses, because the owners do not live there permanently, but come only for a short period of time, and naturally, in their absence, the heating system will be turned off;

- Comparatively better appearance. Polypropylene pipes do not need to be painted every year and do not change color.

- Possibility of installation inside walls. The closed method of pipeline installation will save you from constantly observing the pipes with the naked eye. However, it will be necessary to take into account that the linear expansion of a segment 5 m long will be about 4-5 mm. It is also advisable to install compensators to prevent damage to wallpaper or wall decoration.

However, despite a sufficient number of advantages, polypropylene also has disadvantages:

- Soldering required. However, in the case of polypropylene pipes, you do not have to hire a professional welder and pay for his services, unlike the installation of steel pipes. You can install them yourself, and for this you will need a little time to master the soldering technique itself and the soldering machine itself, which can be easily purchased or rented at any specialized store in your city.

- Not elasticity of the material. To make the necessary turns of the pipeline, it will be necessary to purchase special adapters, angles and couplings, and this can lead to various difficulties in cases where the heating system is non-standard. However, there is also a plus - the price of fittings is low and affordable for everyone. To cut pipes, you will have to purchase special scissors for plastic.

- Only in exceptional cases will you be able to repair your pipes. Most often, you will have to completely replace the faulty section of the pipeline with a completely new one.

- Reduced rigidity. This is fraught with sagging pipes as a result of prolonged exposure to high coolant temperatures. To fix this problem, you will need to purchase special clips that will be attached directly to the wall.

- Inability to work with high temperatures. The permissible coolant temperature in polypropylene pipes is 70 degrees Celsius. An indicator of 90 degrees is possible only for a short time. This is not entirely convenient, because when the temperature outside is below zero, more heat will be needed to heat residential premises, and the best solution would be to increase the temperature, which is unacceptable in this case.

Suitable pipe sizes

Steel pipe as the main raw material for the furnace has a number of advantages. Among them:

- resistance to damage;

- good level of heat transfer;

- rapid heating of the room;

- minimal expansion when heated;

- use of any type of fuel;

- minimum number of welds.

The disadvantages of a metal stove are the same rapid cooling of the room as heating, uneven distribution of heat in the room. To eliminate them, the stove is often lined with bricks.

530 mm

For a steam room of standard sizes, a pipe measuring 530 millimeters is good. A stove made from it will be quite powerful; the wood will burn for a long time, providing good performance. Available in horizontal and vertical versions.

640 mm

A good material option for a large steam room in a bath complex. The large firebox allows you to place a lot of firewood at once, increasing the break between loads to 8 hours.

426 mm

This diameter is enough for a small steam room in a seasonal building, where bathing procedures are combined with washing or dousing with cold water in one room.

It is important to note that cast pipes without seams are an excellent option for small furnace parts; their diameter does not exceed 250 mm. To make the main part of the furnace, it is better to take pieces of spiral pipes - they are reliable and will cost the same as scrap metal. If you can’t find these, you should take straight-seam ones.

Copper

If you are still wondering which heating pipes are best to take, and the price does not play a special role for you, then you should undoubtedly pay attention to copper pipes.

Among the most important points in the use of copper, one can highlight only one - they have a very wide range of operating temperatures. Coolant with a temperature exceeding 470 degrees can pass through them, and they are not afraid of frost.

Even if the coolant freezes in the pipes, nothing will happen to them, your system will be intact and will not leak. Copper is also resistant to pneumatic and hydraulic shocks.

You are unlikely to install copper heating with your own hands, because... The connection is made using high-temperature soldering using solders containing silver.

Yes, and capillary fittings are used, so it’s better to contact professionals who understand this.

Pipes are resistant to corrosion, and the average service life under normal loads reaches 100 years. Quite a lot, isn't it?

But there is also a limitation - it is better not to use them outside the house, because... they have high thermal conductivity and the coolant will cool quickly in winter.

Stainless steel pipes

Stainless steel

Steel has always been the strongest and most durable material.

It has no equal in quality, even in comparison with copper.

Heating pipes made of stainless steel are not subject to corrosion and various temporary defects. The service life is from 100 years, and in price they are almost equivalent to copper ones.

They can be divided into 2 main types:

- Welded;

- Seamless.

Welded ones are produced by welding a sheet of steel, but this method increases the likelihood of leakage. No, the seams will not come apart even after 10 years, but if this happens, the repairs will not be cheap.

For this case, there are seamless pipes, which cost an order of magnitude more than welded ones, but are also much more durable.

Stainless steel pipes are divided into 2 subtypes:

- Thick-walled;

- Thin-walled.

Thick-walled ones are often used in pipeline sections that are subject to heavy loads and are under high pressure. They are not used when heating in a private house.

Thin-walled ones are used specifically in private homes.

Important:

Let us remind you that the installation of stainless steel pipelines is best carried out by specialists. Don't try this yourself.

When starting to plan the heating of an apartment or private house, we are faced with a large number of tasks that require a professional solution. Such tasks include: preparation of permits, installation work.

If previously there were only two options - cast iron radiators and steel pipes for heating, now the consumer is offered various types of heating devices. Having studied information about the types and features of pipelines, you can not only get an answer to the question of which pipes are best to install, but also install them yourself.

Choosing the optimal oven size

The first step is to calculate the volume of the heated room. Therefore, we measure the width, length, height of the steam room and multiply between each other. The result must be divided by two. The resulting figure is the approximate number of kilowatts that will be required to heat the room. But you need to take into account that there will still be stones on top that will have to be heated, and water to wash yourself. That is, we multiply the number of kilowatts by another 3. The resulting figure is suitable for an insulated steam room in which the shower is located separately. For an uninsulated bathhouse, this value is multiplied by another 1.5.

To understand how much furnace volume is needed, the final power is divided by 0.5 – 0.6. The result is obtained in liters. To calculate the linear dimensions, the volume of the firebox is raised to the cube root.

In the dimensions of the sauna stove, it is important to adhere to the following proportions:

- The volume of the firebox to the cross-section of the chimney pipe should be in a ratio of 1 to 10.

- The dimensions of the firebox to the area of the room are 1:50, 1:70.

- The depth of the firebox to the overall dimensions of the furnace is 1:2, 2:3.

The most popular oven sizes are:

- The size of the combustion part is 55*55 cm. The height of the furnace is 90–143 cm. The average power is 16 kW. Can accommodate from 60 to 150 kg of lying stones. Enough to heat a room up to 22 cubic meters. m in volume.

- The dimensions of the firebox are 63*63 cm. The height of the stove is from 98 to 158 cm. It will be possible to load stones of 70–170 kg. To heat a steam room in an hour, a volume of 35 cubic meters is enough. m. Average power 28 kW.

- The large firebox 73*73 cm has a capacity of up to 250 kg of stones. As a rule, when fully loaded, such a stove will provide enough heat for at least 6 hours in a room with a volume of up to 50 cubic meters. m.

If difficulties arise in determining the dimensions of the stove, then it is better to consult an experienced stove maker or find designs for stoves made from pipes of suitable sizes on the Internet.

Household

Finally, the third area of application where pipe stoves find their place is heating poultry houses and barnyards; except sparrowhawks, etc. for keeping heat-loving species. Heater stoves like Buleryan are not suitable here. They are good for heating greenhouses with greenhouses, but greenhouse conditions are contraindicated for commercial domestic animals kept in winter: the animals will catch a cold from drafts and die. In bullers, convectors are turned on only when the fire is sufficiently intense; If the heater stove is heated with wood chips, it will not heat at all.

The best option in this case is a cast iron stove. With a low- or medium-intensity firebox, its efficiency turns out to be quite acceptable even without a special chimney. But, due to the rather high demand and archaic nature of the technology (parts are poured into the ground, as under the Demidovs, and assembled into the product by hand), cast iron potbelly stoves are quite expensive. Moreover, manufacturers play tricks on the design and, of course, charge money for an elegant modern look, like Mercedes does for an asterisk.

Lining a potbelly stove from a pipe to increase efficiency

In this case, it is possible, and not difficult, to make a potbelly stove yourself from a pipe (500...530)x(10...12), thanks to the thick walls it will be quite durable and in a chemically rather aggressive atmosphere. True, due to the lower heat capacity than cast iron and the greater thermal conductivity of steel, the efficiency of the furnace will drop, but this can be dealt with.

The easiest way out is to wall up the lower third of the stove in brick, see fig. on the right, extending the blower (profile pipe 130x60x2). The lining will provide heating of the air entering the firebox and, to some extent, optimize the temperature regime in it. Chimney – pipe 100…120 mm.

Those who prefer metal to stone and are not afraid to put their hands to the stove can make a potbelly stove from the same 530 pipe with an efficiency almost like that of a buller, yes, yes! How? By supplying secondary air to the furnace for afterburning. In rectangular potbelly stoves made from sheet metal, this trick does not work; proper internal circulation will not be achieved due to the corners. And in a round one - please.

Drawings of such a stove made from a pipe are shown in Fig. below. Among other things, it is also mobile, because... not walled up. The opening for laying the grate bars is formed by 2 circular segments made of 4-8 mm sheet steel, see the inset at the bottom right of Fig. In addition to wood and coal, this stove can also be heated with pellets. True, when not burned in a special burner, they produce a lot of ash, but they are cheap, and the ash is suitable for fertilizer. Household potbelly stoves made from pipes have one more advantage compared to cast iron ones: on their cooking surface you can quickly heat up food with swill even with a low firebox.

Potbelly stove made from pipe 530 with secondary air supply

Note: the chimney of a heating stove in a chicken coop must be a vertical monopipe. Stupid birds will definitely sit on the horizontal knee, which is useful for a “human” potbelly stove, and burn their legs. Turkeys, geese and even ducks seem to be smarter.

Schemes and drawings of homemade stoves

A correctly drawn up drawing reduces installation time and minimizes errors. On paper it is important to depict not just the detailed design of the stove from different angles, but also the method of fastening the parts and the dimensions of each element.

The photo above is a clear example of a horizontal stove. The diagram of the firebox with a remote water tank is shown separately. A foundation is provided for the finished product. You need to make a distance of 20 cm from the wall.

Here the operation of a horizontal furnace, the flow of fire and flue gases is schematically shown. The water tank is connected and fixed to the top of the wall.

Here is a drawing of a pipe stove from different angles with the chimney pipe exposed. In the part of the ceiling, the wall where the chimney will go out onto the street, you need to make a thickening of 12 cm. The protrusion of the pipe above the roof is at least 50 cm.

Here is a stove with horizontal fuel loading. Total height - 800 mm, length - 900 mm, width - 600 mm. For a stable position, metal legs are welded at the bottom. The stones are placed on top of the grate. It is permissible to connect a heat exchanger to such a design.

Here is a schematic principle of operation of a vertical stove made of a metal pipe with an attached oil (exhaust) tank. Quite a complex option to make at home. You shouldn't start assembling it without experience.

Option for a sauna boiler with horizontal loading of firewood. The arrows show the direction of movement of hot gases. To increase heat transfer, craftsmen recommend covering the unit with brick. In this case, the heating of the room will be more uniform.

Tube stove made of thick steel. The diagram shows the general dimensions of the device, the key elements and the principle of their connection are shown separately.

Frequent errors and problems during installation

The most important mistake is installation without testing. To do this, the finished heater is installed on the street, stones are loaded, and it is heated strongly. If there are leaks in the body, smoke will be visible - these places should be cooked. Stones may emit gases with unpleasant odors - in this case the stones should be replaced, especially if the smell is hydrogen sulfide.

The basic safety requirements for a bathhouse are fire safety and protection from burns. A very serious mistake is the lack of a non-combustible base under the body and the lack of thermal insulation of the wall - this is a direct road to fire.

You cannot install shelves close to the body, much less so that the wood comes into contact with hot metal.

Do-it-yourself pipe stove: step-by-step instructions

Below we will analyze step by step how to make a stove yourself at home, how to weld its individual parts together, how to install and finish it.

Required materials and tools

During the work you will need the following set:

- For the firebox, water tank - a piece of pipe 500-550 mm in diameter, 8-15 mm thick, 1.5 m long.

- For a heater - a piece of pipe up to 8 mm thick, with a diameter of 310-340 mm.

- For the chimney - a piece of pipe 2-5 mm thick, with a diameter of 150 mm.

- A piece of sheet steel up to 12 mm thick.

- Factory grate or reinforcement bars to weld yourself.

- Doors for firebox, ash pan, hinges.

- Arc welding machine with electrodes or semi-automatic.

- Grinder with metal wheels and grinding attachments.

- Electric drill, other plumbing tools.

After preparing the tools, you can begin the main part of the work.

Assembly and welding

Vertical and horizontal furnaces have differences when connecting parts. Therefore, we will analyze the creation of each type separately.

Vertical ovens

For a small stove, pieces of pipe 1.5 m long are enough.

The procedure is as follows:

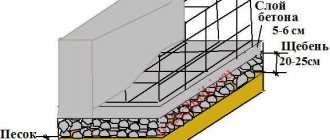

- We are laying out the foundation for the furnace. It must be larger than the size of the stove on each side by at least 20-30 cm. Reinforcement with reinforcement is required. The recommended height of the foundation above the floor is 20 cm (more is possible). We lay bricks on top.

- We take a piece of pipe 1 m long. At the bottom, carefully cut out a hole 50*200 mm with a grinder. The bottom should be completely flat. This part will serve as a ash pit.

- Now we need to strengthen the bottom of the firebox, which will be above the ash door. We cut a circle from a sheet of metal with a thickness of at least 12 mm. There will be a grate in the center.

- We make an indent of 50 mm from the bottom of the oven. We cut the opening for the firebox. The average door dimensions are 250*300 mm. It’s easier to buy a ready-made one and weld the hinges.

- We weld a rectangular piece of metal at the corners on top of the firebox. You will get a kind of cut-off device. The hot air that will pass between the walls of the pipe and the cut-off valve better warms up the walls of the stove.

- We place a heater on top of the firebox. The bottom will be a lattice of rods. The thickness of the rods is from 12 to 16 mm. We make an indent of up to 1 m and weld the heater to the firebox. The door for it can also be bought ready-made.

- We cover the top of the heater with an iron water tank. It can be welded from a piece of metal that is left over. A length of 1.5 m is enough. We leave a hole for the pipe, make a lid, and attach the tap.

Experts recommend not to take up a welding machine or grinder without having the skills to work with them.

Video description

An example of a vertical stove with a closed, insulated heater is shown in the video:

Above the heater, a water compartment is fenced off with another horizontal spacer and equipped with a tap. Since the water in the “blackie” pipe quickly becomes red from rust, it is often replaced with a stainless steel tank.

Without special electrodes and skills in such work, it is difficult to qualitatively weld ferrous metal with stainless steel. It is better to buy a ready-made tank with a section of the chimney already installed in it and place it on the heater.

Tank for installation on a stove Source prom.st

If space allows, the water tank can be installed separately, connecting it to the firebox with a piece of pipe. One end of it is welded to the wall of the firebox, and the second open end is inserted into the tank, into the lower part of the side wall.

Water heating from a stove: ensuring an optimal temperature microclimate

Wooden houses in the classic version with stove heating warm up very unevenly. Heated air is constantly near the stove, and distant corners are cool. Using multiple ovens is quite expensive. It is better to combine heating - stove and water, as many of our compatriots do, who strive to achieve the warmth and comfort of their existence.

The solution is to equip a conventional brick oven with a heat exchanger shaped like a coil. It is installed in fuel rooms or at the base of chimneys. The heat from the stove warms up the water in it, which then goes to the radiators located in the rooms. Buildings are heated evenly.

The advantages of such systems include:

- Efficient and uniform heating - batteries are installed in different rooms and provide constant heat.

Complete independence - such heating systems are not affected by gas or gas pipelines. The only dependence is on the owner, who determines when and how much to heat.

- There is no need to attract specialists to service heating systems. It is quite within the capabilities of consumers themselves.

The disadvantage of such heating using stoves is its rather high fire hazard, which requires compliance with building protection measures. This option cannot be considered mobile, since movement is excluded. Not used in two-story houses. It is necessary to resort to the construction of an additional furnace, which entails considerable costs.

Despite the need to start heating daily from a water-heated stove, significant fuel savings are felt. Another disadvantage is the need for constant monitoring of the functioning of the system.