The most popular way to maintain heat in the rooms of a private house is heating associated with the movement of water through pipes. There are many types of structures that allow you to conduct and install heating in a house. Practical owners choose a double-circuit heating system for a private home. It fully pays for the money spent on it and effectively heats the premises.

In our article we will analyze in detail what two-pipe heating is, why people install this system, what heating installation schemes exist. We will also touch on the topic of installing a double-circuit boiler that runs on gas.

What is dual-circuit heating?

Double-circuit heating (two-pipe) is the most popular pipe layout for heating a house. A double-circuit heating system is better than a single-circuit heating system due to the rational and efficient distribution of the coolant.

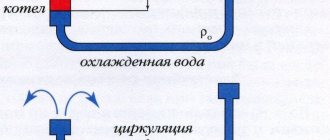

The two pipes connected to the radiator perform different functions. Water heated by the boiler to the required temperature flows through one pipe. On the other, the cooled coolant is discharged. Then it goes back into the boiler for further heating, but does not flow into the next radiator. The water in both pipes often moves in the same direction, although with a certain installation design it can move in opposite directions.

A double-circuit heating system requires more pipes than a single-circuit heating system, but it is more efficient and much more practical.

Thanks to the two-pipe system, you can maintain a comfortable temperature in a specific room, and not in the entire house at once. It's also more economical. A two-circuit system can be automated so that it can heat a room to a certain temperature, turn itself off, and then turn on again when the temperature drops to a certain point. These are not the only advantages of such heating.

Forced circulation

The method has become most widespread, since the pump intensively pumps coolant through the system and heating efficiency increases by 30%.

Advantages also include the ability to regulate temperature and low pipe consumption during installation. The system will still cost significantly more, since it is more complex and requires more devices. Installed elements require balancing, and the entire system requires regular maintenance. In addition, a source of electricity is required.

If you install a combined system, it will combine the advantages of both previous ones.

It can be switched to any mode using a bypass installed with the pump. In this case, the heating operation will not depend on the supply of electricity to the house. Date: September 25, 2022

Why do people choose a dual-circuit system?

This type of wiring has advantages that need to be mentioned in order to understand why home owners choose it. These include:

- Parallel connection of radiators. This allows you to maintain different temperatures in a single room. This allows the system to be used in multi-storey buildings. Plus, if one or more radiators break down, the system will continue to function. With a single-circuit system this is impossible.

- Possibility of connecting a large number of radiators. The temperature of the water entering each radiator will be the same, regardless of how far it is located from the boiler.

- Possibility of installing a thermostat. The system monitors the temperature itself and automatically turns on when needed. The owner only needs to set the temperature range.

- Low heat loss. Almost all the heat generated is not lost, but is used to heat the room. In single-circuit systems it is wasted.

Of the minuses: many note the long length of pipes and the high cost of installing double-circuit heating in a private house. In fact, a double-circuit system is not more expensive than its single-pipe counterpart due to the small diameter of the pipes themselves. And there are much more benefits from it.

Dual-circuit heating schemes

An example of a two-pipe heating scheme for a house

A double-circuit heating system can be installed in different ways. The choice depends entirely on the decision of the home owner. In order not to miscalculate and understand which of them is necessary in a given situation, we will dwell on them in more detail. The most common of them will be:

- Open wiring.

- Closed wiring.

- Upper wiring.

- Bottom wiring

- Dead end.

So, let's start in order.

Comments

March 11, 2021

Posted by HowardDep

I bought it here Construction » Heating systems tovaromania.rf/index.php?cat=40700 delivered free of charge

Answer

May 05, 2021

Author: CharlieBap

I bought here Garden and vegetable garden » Bathhouse and sauna » Stoves and accessories » Chimneys and ventilation » Chimney-convectors, heaters, heat exchangers tovaromania.rf/index.php?cat=193650 delivered free of charge

Answer

May 05, 2021

Author: Robertower

I bought here Auto » Auto parts » Heating and air conditioning system tovaromania.rf/index.php?cat=201631 delivered free of charge

Answer

Open wiring

This implies the presence of an expansion tank that is not sealed. It has a lid, but it does not close the tank tightly, which allows the liquid in it to communicate with the atmosphere.

Install it at the highest point of the system. It is located in attics or directly under the ceiling of a building. In the first case, it is necessary to maintain heat in the attic, otherwise the coolant may freeze, and in the second, such a design looks untidy. Installation at this point in the house is necessary to ensure that water does not overflow from it.

The tank can only be filled with water. Other coolant fluids will not work. The system communicates with the atmosphere and some of the water regularly evaporates. Owners of such heating systems must monitor the water level in open wiring. If there is insufficient coolant, the entire heating system will fail.

The system is the easiest to install, does not pose any particular threat to humans and does not require additional components.

Features of the wall-mounted model

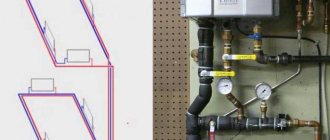

First you need to make connections to the heating system, water supply and electrical network, if the device has control and regulation elements. Connection to the gas main is carried out by an employee of the relevant service or a licensed company. The home owner only needs to buy a meter and a gas filter.

The device has 5 connection pipes: heating system supply and return, cold water inlet and hot water outlet plus gas supply. It is convenient to screw all the fittings before hanging the device on the wall. The handles that interfere with rotation can be removed by unscrewing the nut on the rod. Installation of a gas valve cannot be done without a dielectric gasket

What products and materials will be needed during the work process:

- 3 ball valves with American sizes 1/2″ and 4 of the same size 3/4″;

- 2 mud traps (mechanical or self-flushing) - installed on the cold water supply and return of the heating pipe;

- gas filter;

- expansion tank (if its volume is not enough for a large pipeline network, a membrane tank is also needed);

- fittings for pipelines - elbows, tees;

- three-core cable (brand VVG, cross-section 2.5 mm2);

- automatic two-pole switch 20 A.

This list is suitable for heat generators of simple design with an open combustion chamber. Expensive models are equipped with an expansion tank and a gas filter.

If the water pressure is less than 1 atm, it is worth installing a pressure booster station. It is useless if the water pressure is constant within 2-3 atm.

Additionally, the system may include: a third fine cartridge filter, pressure gauges for monitoring pressure in different places of the circuit, an automatic air vent, a circulation pump, a voltage stabilizer

In the case of a separate boiler room, you will need a heating radiator, which will ensure normal temperature conditions for the boiler to operate and protect it from the formation of condensation

Next, we hang the boiler on the wall, determining the optimal height. You shouldn’t hang it from the ceiling - ease of use is important. The minimum distance from the ceiling to the outlet pipe is 15 cm, from the floor - 80 cm, from the wall - 20 cm.

To mount the device you will need two special brackets, which are supplied in the kit. They are attached to the wall with plastic dowels and screws. To set them correctly, it is recommended to use a level and plumb line.

Stage #1 - connection to the heating system

All ball valves for shutting off the pipeline are installed more for servicing the system than taking into account its possible cutting and dismantling during operation. Heating equipment is characterized by reliability. Example: a shut-off valve on the heating return is designed to clean the filter without draining the coolant.

The standard connection diagram is in the passport of any double-circuit boiler. This is what you should use to navigate when tying up the device.

Recommendations for connection:

- Half-inch taps are installed on water fittings and gas supply. And DN20 are mounted on pipes with coolant.

- The fittings must be screwed with the pipes down.

- The filters are attached horizontally, with the “spouts” facing the floor. In this position it is convenient to clean them.

- The external expansion tank is connected to the return line using additional fittings.

- The drain pipe is installed at the lowest point of the system.

If you plan to fill the system with non-freezing antifreeze as a coolant, to be on the safe side, additional valves for supply and return should be added to the circuit. This makes it possible to dismantle the boiler without draining the antifreeze.

Stage #2 - connecting the boiler to the electrical network

There are usually no difficulties with supplying electricity - just plug the device into an outlet. But there are also rules and safety requirements.

If the boiler is heavily dependent on electricity and its supply is often turned off in the region of installation, the circuit is supplemented with an uninterruptible power supply

The main requirement when connecting the device to the network is grounding and the presence of a circuit breaker. The latter is located so that in case of an emergency water does not get on it.

Primary requirements:

- You need a wire connected to the ground loop. If such a cord is not included in the kit, the conductor is connected to the body of the device itself.

- It is prohibited to use steel pipes of the hot water supply system as grounding conductors.

- The cable is laid in a protective “corrugation”.

When connecting turbocharged boilers from European manufacturers, it is important not to confuse phase with zero . Otherwise, the electronic unit will not start the system.

Stage #3 - connecting the unit to the chimney

In 95% of modern houses, wall-mounted boilers with closed combustion chambers and a coaxial chimney are installed. It is discharged horizontally through the wall with a slope of 3-5% towards the street to allow condensation to escape.

Pipe sections of several elements are mounted inside each other in the direction of the flow of combustion products. In a vertical channel, joints must be sealed

For a high-power floor-mounted unit, only a vertical design is suitable, which can cope with a large volume of combustion products. It should have as few turns as possible and protrude beyond the boundaries of the roof at a distance of 0.5 m.

Closed wiring

The system is based on an expansion tank. Inside it is divided transversely into two parts by an elastic partition, which is called a membrane. The required pressure is maintained in the upper part, and the volume of water is maintained in the lower part. The lower part is connected to the heating system through a pipe.

Water and any ethylene glycol-based liquid are suitable for filling a closed dual-circuit system. The advantage of the latter is that it does not freeze even at fairly low temperatures. Disadvantage: it is not egological and requires disposal. And there are problems with this in the CIS countries.

An expansion tank with a membrane can be installed anywhere in your home, not necessarily at the highest point.

A sealed tank is more dangerous than a leaking one. The pressure can increase greatly, and gases, having no outlet, accumulate. Therefore, a closed system must be carefully monitored and air vents installed.

Upper wiring

Pipes supplying coolant are installed at the top of the room. Most often closer to the ceiling, above the windows. This contributes to the appearance of high pressure in them. The pipes supplying coolant back to the boiler run along the bottom of the room, as close to the floor as possible.

A two-pipe heating system for a private house with overhead wiring requires an expansion tank. Sealed or not is the owner's choice.

The disadvantage of the top wiring is that some of the heat goes up. It is not intended for heating large areas. But the coolant is transferred at high speed.

Bottom wiring

Here the coolant-conducting pipe is installed directly under the window sill, and the return pipe is installed near the floor.

The pressure in the pipes is not very high, so pumps have to be used. Airing is possible. To avoid this drawback, Mayevsky cranes should be installed on the floor. If the house is multi-story, then this tap should be located on each floor.

The wiring can be laid only to the doorway or two heating systems independent of each other can be installed on both sides of the door.

The expansion tank is easy to install anywhere. If it is closed, then it can be placed in rooms rather than in the attic, which is convenient. The lower wiring is not noticeable. This is important if you care about the wiring fitting into the decor of your room.

Heating the house with a double-circuit gas boiler

If you are looking for a universal way to provide your home with heat, then you should think about purchasing a double-circuit gas boiler. It can not only heat the room, but also heat water for domestic needs.

It is worth keeping in mind that boilers are not entirely suitable for large houses. The heating capacity of hot water in double-circuit boilers allows servicing only one point. If you plan to have several bathrooms, then the power will not be enough. In such cases, you should resort to indirect heating boilers or conventional heating element tanks.

One of the leaders in popularity is Lemax. Description of the boiler Premium 16N V

When choosing equipment for heating and hot water supply, you should pay attention to models from. Among the company’s other offers, “Premium 16N B” should be highlighted

This device has an acceptable cost - about 25,000 rubles. The boiler is equipped with a durable casing made of 2 mm steel. The equipment can be used for autonomous heating.

The heat exchanger is reliably protected from corrosion by an enamel coating. Inhibiting compounds provide protection against aggressive factors. Such double-circuit floor-standing gas boilers for home heating provide the consumer with the ability to connect equipment to liquefied gas. You can use the soft start option. The control panel consists of a thermometer and temperature controller. Using the first one, you can monitor the heating temperature of the coolant.

This device has a power of 16 kW. The maximum natural gas flow rate is 0.95 m3/h. Heating temperature – 90 °C. These double-circuit Lemax floor-standing boilers weigh 60 kg. They have many advantages, for example:

- ease of maintenance;

- advanced security protection system;

- increase in primary and secondary air flow;

- boiler compliance with all environmental and safety requirements;

- the ability to connect a room thermometer, with which the consumer will be able to adjust the temperature of the unit taking into account the temperature inside the room.

Double-circuit heating combined with heated floors

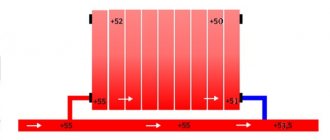

Closed options for double-circuit heating of a private house can be easily combined with a water heated floor system. It is important to consider that underfloor heating is a low-temperature system, and radiators are a high-temperature system. Therefore, it is necessary to provide underfloor heating so that the temperature drops from 60-80 degrees to a more comfortable 45-50.

If you want to heat all one room with a water floor, then this module will be useful to you:

The module has a thermal head, which, depending on the temperature, opens or closes the coolant supply to the system. The module is connected to the return of the dual-circuit system.

If you want to implement a solution: one floor has floors, another has radiators, then it’s worth distributing the coolant in the boiler room.

Conclusions and recommendations

The two-circuit system is suitable for most houses of different heights and sizes. The main thing is to choose the right design and make calculations. Then the rooms will be warm, and all elements of the heating system will last a long time.

- When purchasing components, do not buy cheap Chinese models. Otherwise, all the heating will have to be redone in a couple of years.

- If you plan to add antifreeze to the system, when purchasing radiators and components, pay attention to compatibility with such solutions.

- It is often easier to install such a heating system than to achieve its stable operation. Therefore, if you are unable to balance all the elements yourself, do not be afraid to contact specialists.