Thermal load of a residential area

Calculation of heat loads for all blocks of a residential area is carried out using aggregated indicators.

Maximum heat flow, W, for heating residential and public buildings in the block:

Q0max. = q0(1 + kl) A,

where q0

— aggregated indicator of the maximum heat flow for heating per 1 m2 of total area, W/(m2C), taken according to [2] depending on the number of storeys of the building and the design temperature tо

q0 = kt0 + b,

where

k

and

b

are coefficients, the values of which depend on the number of storeys of the building, are taken according to [5];

kl

— the coefficient taking into account the heat flow for heating public buildings is assumed to be

kl

= 0.25;

A

— total area of residential buildings, m2,

A = fm,

where

f

is the housing supply rate, m2/person, adopted according to [6],

f

= 18 m2/person.

M is the number of residents, people, determined by the formula

m = NF,

where F

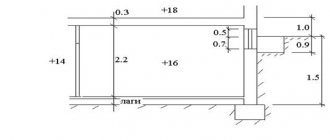

— area of the block, hectares, is determined according to the general plan, taking into account the scale;

N

— the number of residents per 1 hectare (population density) is taken depending on the number of floors of the block.

Maximum heat flow, W, for ventilation of public buildings in the block

Qvmax. = klk2q0А,

where k2

— coefficient taking into account the share of heat flow for ventilation of public buildings,

k2

= 0.6 for buildings built after 1985.

Average heat flow, W, for hot water supply of residential and public buildings in the block:

Qhm = qhm,

where qh

— the aggregated indicator of the average heat flow for hot water supply per one resident of the block, taking into account public buildings, W/person, is taken according to [2].

As an example, let us give the calculation of heat loads on one of the blocks of a residential area. The heat load of quarter No. 1 is calculated.

The area of the quarter is F = 5.41 hectares. A block of one- or two-story buildings. Depending on the number of floors in the block, according to [5], the population density of the block is assumed to be: N = 163 people/ha.

Number of residents of the block

m = NF = 1635.41 =882 people.

The housing supply standard for the current construction period according to [6]:

f = 18 m2/person

The total area of residential buildings will then be equal to

A = 18882 =15876 m2.

Taking into account the number of floors of the block, the coefficients are determined according to [6]: k = -1.2; b = 140. We calculate the aggregated indicator of the maximum heat flow for heating per 1 m2 of total area

q

'

0 = -1.2(-28)+140 =173.6 W/m30C.

Heat flow for heating residential and public buildings:

Q`omax = q'0(1+k1) A =173.6(1+0.25)15876 = 3445 kW.

We determine the maximum heat flow for ventilation of public buildings in the block, taking into account the coefficient k2 = 0.6 for buildings built after 1985

Qvmax = k1k2q'0A = 0.250.6173.615876 = 413 kW.

To calculate the average heat flow for hot water supply, the aggregated indicator of the average heat flow for hot water supply is determined per one resident of the block, taking into account public buildings according to [2]. With the rate of hot water consumption per inhabitant qh = 115 l/day, it is equal to qh = 407 W/person. Then

Qhm = 407882 =359 kW

The results of calculating the heat loads of the quarter are given in Table 2.

table 2

| Quarter number | Area of block F, ha | Number of storeys | Number of inhabitants m, people. | Total area of residential buildings, A, m2 | Thermal loads, kW |

| Qo(max) | Qv(max), | Qhm | Qh(max) | Q?wed | |

| 5,41 | 1h2 | ||||

| 3,24 | |||||

| 1,98 | |||||

| 3,23 | |||||

| 4,37 | |||||

| 1,87 | |||||

| 1,25 | |||||

| 1,25 | |||||

| 2,48 | |||||

| 2,25 | |||||

| 2,04 | |||||

| 1,25 | |||||

| 1,25 | |||||

| 1,98 | |||||

| 4,04 | |||||

| 3,04 | |||||

| 1,65 | |||||

| Sum |

Calculation of thermal energy losses in heating networks with thermal insulation made of foam polyethylene

The example shows calculations for three sections.

| Plot number | Length of the section, m | Purpose of the pipeline | Outer diameter of water pipelines, mm | Wall thickness, mm | Coef. Thermal conductivity of steel, W/m*degree | Insulation thickness, mm |

| 1 | 41,2 | from | 426 | 9 | 55 | 50 |

| 41,2 | from | 426 | 9 | 55 | 50 | |

| 41,2 | guards | 108 | 4 | 55 | 50 | |

| 2 | 152 | from | 426 | 9 | 55 | 50 |

| 152 | from | 426 | 9 | 55 | 50 | |

| 3 | 274,3 | from | 426 | 9 | 55 | 50 |

| 274,3 | from | 426 | 9 | 55 | 50 |

Table continuation:

| Plot number | Coef. Thermal conductivity of insulation, W/m*degree | Coolant temperature, °C | Temperature on the surface of the insulated pipe, °C | Specific heat loss per 1 m, W | Total heat loss, W |

| 1 | 0,05 | 68 | 6 | 83,1 | 3 425 |

| 0,05 | 53 | 6 | 63,0 | 2 596 | |

| 0,05 | 73 | 6 | 28,9 | 1 191 | |

| 2 | 0,05 | 68 | 6 | 83,1 | 12 634 |

| 0,05 | 53 | 6 | 63,0 | 9 578 | |

| 3 | 0,05 | 68 | 6 | 83,1 | 22 800 |

| 0,05 | 53 | 6 | 63,0 | 17 284 |

In total, the heating network consists of 56 sections.

Based on the results of calculations, the total heat losses in heating networks with insulation made of foamed polyethylene are 864,687 W, from thermoplex 730,602 W, from glass wool 864,687 W.

How to choose a circulation pump

You can’t call your home cozy if it’s cold inside.

And it doesn’t matter what furniture, decoration or overall appearance is in the house. It all starts with heat, and it is impossible without creating a heating system.

It is not enough to buy a “sophisticated” heating unit and modern expensive radiators - first you need to think through and plan in detail a system that will maintain the optimal temperature in the room

And it doesn’t matter whether this refers to a house where people constantly live, or whether it’s a large country house, a small dacha. Without heat, the living space will not be habitable and it will not be comfortable to be in it.

To achieve a good result, you need to understand what and how to do, what nuances there are in the heating system, and how they will affect the quality of heating.

When installing an individual heating system, it is necessary to provide for all possible details of its operation. It should look like a single balanced organism, requiring a minimum of human intervention. There are no small details here - the parameter of each device is important. This may be the power of the boiler or the diameter and type of pipeline, the type and connection diagram of heating devices.

Today, not a single modern heating system can do without a circulation pump.

There are two parameters by which this device is selected:

- Q is the coolant flow rate for 60 minutes, expressed in cubic meters.

- N is the pressure indicator, which is expressed in meters.

Many technical articles and regulations, as well as device manufacturers, use the designation Q.

Methods for determining load

First, let's explain the meaning of the term. Thermal load is the total amount of heat consumed by the heating system to heat the premises to the standard temperature in the coldest period. The value is calculated in energy units - kilowatts, kilocalories (less often - kilojoules) and is denoted in formulas by the Latin letter Q.

Knowing the heating load of a private house in general and the needs of each room in particular, it is not difficult to select a boiler, heaters and batteries of the water system according to power. How can you calculate this parameter:

- If the ceiling height does not reach 3 m, a larger calculation is made based on the area of heated rooms.

- For ceiling heights of 3 m or more, heat consumption is calculated based on the volume of the premises.

- Determination of heat loss through external fences and the cost of heating ventilation air in accordance with SNiP.

Note. In recent years, online calculators posted on the pages of various Internet resources have gained wide popularity. With their help, determining the amount of thermal energy is carried out quickly and does not require additional instructions. The downside is that the reliability of the results needs to be checked, because the programs are written by people who are not heating engineers.

Photo of the building taken with a thermal imager.

The first two calculation methods are based on the use of specific thermal characteristics in relation to the heated area or volume of the building. The algorithm is simple, used everywhere, but gives very approximate results and does not take into account the degree of insulation of the cottage.

Calculating thermal energy consumption according to SNiP, as design engineers do, is much more difficult. You will have to collect a lot of reference data and work hard on calculations, but the final numbers will reflect the real picture with 95% accuracy. We will try to simplify the methodology and make the calculation of the heating load as easy to understand as possible.

Total heat losses in heating networks

As a result of the inspection of the heating network, it was established that

- 60% of heating network pipelines are insulated with glass wool with 70% wear,

- 30% extruded polystyrene foam type TERMOPLEX and

- 10% polyethylene foam.

| Thermal insulation | Total losses of thermal energy in heating networks, taking into account the percentage of coverage and wear, kW | Calculation of heat losses in heating networks, taking into account the percentage of coverage and wear, Gcal/hour |

| Glass wool | 803,589 | 0,69092 |

| TERMOPLEX | 219,180 | 0,18845 |

| Foamed polyethylene | 86,468 | 0,07434 |

| Total: | 1109,238 | 0,95372 |

Thermal imaging inspection of the heating network

The calculation of heat losses in heating networks was supplemented by thermal imaging examination.

Thermal imaging inspection of the heating network helps to detect local defects in pipelines and thermal insulation for subsequent repair or replacement.

The thermal insulation of the pipelines containing the coolant is damaged. The maximum temperature in open areas was 59.3 °C

Partial destruction of thermal insulation of pipelines with coolant. The maximum temperature in open areas was 54.5 °C

Partial destruction of thermal insulation of pipelines with coolant. The maximum temperature in open areas was 56.2 °C

The thermal insulation of the pipelines containing the coolant is damaged. The maximum temperature in open areas was 66.3 °C

Open sections of pipelines without insulation.

Open sections of pipelines without insulation.

Partial destruction of thermal insulation of pipelines with coolant.

Partial destruction of thermal insulation of pipelines with coolant. The maximum temperature in open areas was 62.5 °C

Partial destruction of thermal insulation of pipelines with coolant. The maximum temperature in open areas was 63.2 °C

Partial destruction of thermal insulation of pipelines with coolant. The maximum temperature in open areas was 63.8 °C

Partial destruction of thermal insulation of pipelines with coolant. The maximum temperature in open areas was 66.5 °C

Partial destruction of thermal insulation of pipelines with coolant. The maximum temperature in open areas was 63.5 °C

Partial destruction of thermal insulation of pipelines with coolant. The maximum temperature in open areas was 69.5 °C

Partial destruction of thermal insulation of pipelines with coolant. The maximum temperature in open areas was 62.2 °C

Partial destruction of thermal insulation of pipelines with coolant. The maximum temperature in open areas was 52.0 °C

Open sections of pipelines without insulation. The maximum temperature in open areas was 62.4 °C

Partial destruction of the thermal insulation of pipelines with coolant under the influence of the environment.

Learn about inspection of water supply systems.

Partial destruction of the thermal insulation of pipelines with coolant under the influence of the environment.

Partial destruction of thermal insulation of pipelines with coolant. The maximum temperature in open areas was 67.6 °C

Partial destruction of thermal insulation of pipelines with coolant. The maximum temperature in open areas was 58.8 °C

Partial destruction of the thermal insulation of pipelines with coolant under the influence of the environment.

Calculation of pipeline wear

The average age of heating network pipelines is 36.5 years.

During a physical examination, it was found that the residual service life for it is assumed to be 15 years, while the standard service life is 25 years. Pipeline wear is determined as follows:

36.5/(36.5+20) x (100-15) = 54.9115%

Look at an example of a survey before upgrading a boiler house and heating network.