In the process of choosing thermal insulation materials, structures and products, a number of important questions inevitably arise, which can only be answered correctly by performing the appropriate calculations, because other methods (analog method, etc.) do not in all cases give an acceptable result. A simple example: in the case of channelless pipeline laying with a nominal bore of 200 mm, just a change in soil characteristics and laying depth can change the minimum possible thickness of thermal insulation by 40%, all other things being equal. And the value of heat losses with a fixed thickness of the thermal insulation layer can increase by 24%. It follows from this that even with constant parameters of pipelines and coolants, it is necessary to perform an individual calculation of heat losses, taking into account the specific installation conditions.

House heat loss diagram.

reference Information

Documents • Laws • Notices • Document approvals • Contracts • Requests for proposals • Technical specifications • Development plans • Document management • Analytics • Events • Competitions • Results • City administrations • Orders • Contracts • Work execution • Protocols for consideration of applications • Auctions • Projects • Protocols • Budgetary organizations Municipalities • Districts • Education • Programs Reports

: • by references • Documentary base • Securities

Regulations

: • Financial documents

Resolutions

: • Categories by topic • Finance • cities of the Russian Federation • regions • by exact dates Regulations

Terms

: • Scientific terminology • Financial • Economic

Time

: • Dates • 2015 • 2016 Documents in the financial sector • in the investment sector • Financial documents - programs

General information about the methodology for calculating heat losses

The purpose for which the calculation of heat losses is carried out is to determine the actual losses of heat energy through the thermal insulation of pipelines of water heating networks of centralized heating.

Calculation of heat losses is carried out for the entire heating network connected to a common energy source. Calculation of actual thermal energy losses for some individual sections of the network is not performed.

Calculation of heat losses presupposes the presence of certified thermal energy metering units both at thermal energy consumers and at the thermal energy source. The number of consumers with metering devices must be at least 20% of the total number of consumers of the heating network in question.

Heat loss calculation table.

Instruments that will be used to calculate heat losses of heating pipelines must be equipped with an archive with hourly and daily recording of values. The depth of the hourly archive must be at least 720 hours, and the daily archive must be at least 30 days.

The main thing when calculating heat losses of heating pipelines is the hourly archive. The daily archive is used in the absence of hourly data for some reason.

Calculation of actual heat losses is carried out based on measurements of the temperature and flow rate of network water in the supply pipeline for network consumers who have metering devices, as well as the temperature of network water at the energy source. Calculation of heat losses for consumers without measuring instruments is performed using a slightly different methodology.

Consumers and sources of thermal energy are:

- in the absence of metering devices directly in the buildings: thermal energy consumers - individual or central heating points; sources of thermal energy - boiler houses, thermal power plants, etc.;

- If there are metering devices directly in buildings, the buildings themselves are considered consumers of thermal energy, and central heating points are considered sources.

Standards for thermal energy consumption for the boiler house’s own needs.

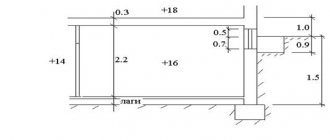

For the convenience of calculating thermal energy losses through thermal insulation, supply pipelines are divided into: main pipelines and branches from the main pipelines.

The main pipeline should be understood as part of the supply pipeline between the source of thermal energy and the thermal chamber, from which there is a branch to consumers of thermal energy.

Branches from the main pipelines are parts of supply pipelines from the corresponding thermal chambers to consumers of thermal energy.

Calculation of actual heat losses is carried out using standard loss values, which are determined according to the norms of thermal energy losses for networks, the thermal insulation of which was carried out in accordance with design standards (the standards should be clarified according to the design and as-built documentation).

Education and science

Science

: Tests • Scientific and technological progress • Pedagogy • Work programs • Faculties • Methodological recommendations • School • Vocational education • Student motivation

Subjects

: Biology • Geography • Geology • History • Literature • Literary genres • Literary characters • Mathematics • Medicine • Music • Law • Housing Law • Land Law • Criminal Law • Codes • Psychology (Logic) • Russian Language • Sociology • Physics • Philology • Philosophy • Chemistry • Jurisprudence

Conditions for calculation

It is necessary that the measurement period satisfy a number of conditions, namely:

- the value of the average temperature of the network water in the supply pipeline at the heat source for the time before the start of the measurement period and the value of the average water temperature in the supply pipeline at the heat source for the time at the end of the measurements should differ by no more than 5 degrees;

- measurements must be carried out continuously for at least 240 hours;

- The measurement period must be completely contained within the data availability period.

Calculating heat loss at home.

If such a period cannot be selected due to the lack of data from one or several consumers, then the data from the metering devices of such consumers is not used in further calculations.

The number of consumers who have data from metering devices must be at least 20% of the total number of consumers of the heating network in question. If the number of consumers with metering devices decreases to less than 20%, you need to select another period for data collection and repeat the verification procedure.

For the parameters obtained at the heat source, it is necessary to determine the average temperature of the network water in the supply pipeline over the measurement period and the average temperature of the network water in the return pipeline over the measurement period.

For the measuring period, it is necessary to determine the average air temperature and average soil temperature at the average depth of the pipeline axis.

Business and finance

Business

: • Banks • Wealth and prosperity • Corruption • (Crime) • Marketing • Management • Investments • Securities: • Management • Open Joint Stock Companies • Projects • Documents • Securities - control • Securities - valuations • Bonds • Debts • Currency • Real estate • (Rent) • Professions • Work • Trade • Services • Finance • Insurance • Budget • Financial services • Loans • Companies • State enterprises • Economics • Macroeconomics • Microeconomics • Taxes • Audit Industry

:

• Metallurgy • Oil • Agriculture • Energy

Construction

• Architecture • Interior • Floors and ceilings • Construction process • Building materials • Thermal insulation • Exterior • Organization and production management

Photo blogs

Art

• Children's creativity • Paintings • Art • Congratulations • Film review • Musical world • Russian rock

World

• People of the world • The world around us • My homeland is the USSR • Nature Channel • Stones and minerals • Cooking, food • Construction and architecture • Under construction • Transport • Weapons • Military transport

beauty

• Fashion Pandia.ru • Girls and Girls

School

• Tests for the Unified State Exam • Solver books • Unified State Examination • 10th and 11th grades • Various textbooks • 4th grade • Russian language grades 5-9 • 5th grade • 6th grade • 7th grade • 8th grade

Wisdom

• Cliparts • Quotes

Author Directory (private accounts)

AutoAuto service • Auto parts • Products for auto • Auto repair centers • Auto accessories • auto parts for foreign cars • Body repair • Auto repair and maintenance • Car chassis repair • Auto chemicals • oils • technical centers • Gasoline engine repair • auto electrical repair • Automatic transmission repair • Tire fitting BusinessAutomation of business processes • Online stores • Construction • Telephone communications • Wholesale companies LeisureLeisure • Entertainment • Creativity • Catering • Restaurants • Bars • Cafes • Coffee shops • Night clubs • Literature TechnologiesAutomation of production processes • Internet • Internet providers • Communications • Information technologies • IT companies • WEB studios • Website promotion • Software sales • Switching equipment • IP telephony | InfrastructureCity • Authority • District administrations • Courts • Utilities • Teen clubs • Public organizations • City information sites The sciencePedagogy • Education • Schools • Training • Teachers GoodsTrading companies • Trade and service companies • Mobile phones • Accessories for mobile phones • Navigation equipment |

The procedure for processing the initial data of metering devices

The main task of processing data from metering devices is to convert the source files, which are read directly from heat meters, into a single format that allows further verification of the reliability of the measured heat consumption parameters and the necessary calculations.

Heat meter design.

For different types of heat meters, data is read in different formats and requires appropriate processing procedures. Thus, for one type of heat meters for different consumers, the parameters stored in the archive may require the use of different coefficients for converting the initial data to common physical quantities. The difference in these coefficients is determined by the characteristics of the pulse inputs of the computer and the diameter of the flow converter. In view of this, the initial processing of the received data requires an individual approach for source data files. Hourly and daily parameters of the coolant are used to confirm the reliability of the measured values. When performing this procedure, main attention should be paid to the following indicators:

- the values of coolant flow rates and temperatures should not exceed physically justified boundaries;

- the daily file should not contain sudden changes in coolant flow;

- the change in the average daily temperature of the carrier in the supply pipeline at the thermal energy source must correspond to the change in the average daily temperature in the supply pipeline and consumers;

- The average daily temperature of the coolant in the supply pipeline at consumers should not be higher than the average daily temperature in the supply pipeline at the source.

Heat meter design.

In accordance with the results of verification of the initial metering data, a table should be compiled in which for all heat energy consumers who have metering devices and for the energy source, the period of time is given when the reliability of the initial data is beyond doubt. Based on this table, you should select the general period during which reliable change data is available for all consumers in the network and at the heat source (the so-called data availability period).

Based on the hourly data file obtained at the heat source, the number of hours in the measurement period is determined, the data for which will be used for further processing. Before determining the measurement period, you should calculate the time required to fill all supply pipes with coolant.

Fuel consumption calculations

To understand how many fuel resources a boiler room needs to produce a given amount of energy, take into account:

thermal power per hour (Gcal/hour);

performance maps (according to performance testing), SNiP tables.

heat load on DHW in one hour;

daily system operation in hours;

heating season time;

own temperatures of unheated water in winter/summer.

If there are no ready-made regime maps, the efficiency of the boiler unit is calculated according to its condition, technical parameters, features and duration of operation. Calculations of fuel volumes are made in accordance with the instructions of the Ministry of Energy of the Russian Federation, which substantiates the standards for fuel supply to obtain the required amount of heat.

Fuel demand can be determined as follows:

otp is the average fuel consumption rate, and Qotp is the volume of heat in Gcal that goes to the heating network.

Methodology for calculating the characteristics of thermal insulation

Calculation of the minimum permissible thickness of thermal insulation of pipelines and equipment is carried out on the basis of heat flux density standards, which are fixed in SNiP 41-30-2003. The algorithm and calculation formulas are given in SP 41-103-2000. Using the same document, you can calculate actual heat losses.

However, the problem is that, depending on the option of laying the heating main, the number of formulas used for calculations will be from 8 to 23. The number of variables and coefficients included in them is from 20 to 29. So even if you have special knowledge and experience in calculating the minimum permissible thickness of thermal insulation (as well as calculating actual heat losses) is a very labor-intensive job.