NAKS-TPA » Articles about pipeline fittings » Articles about pipes

Articles about pipes

Nax-TPA Supply of pipeline fittings, plumbing fixtures, pumps, heating equipment. 10/13/2021

168 Views

Guidelines for technical equipment and modernization of thermal units

- Principles of constructing ITP

- The principle of operation of the node.

- ITP modernization options

- Legend:

- Conclusions and recommendations

- Appendix A

- Appendix B

Principles of constructing ITP

Due to historical reasons, in the vast majority of regions of the Russian Federation, a centralized system of generation and distribution of thermal energy for the needs of heating and hot water supply (DHW) has been formed.

Thermal networks of cities have a large extent and heterogeneous topology, as a result of which consumers of thermal energy are located at various distances from the source of thermal energy. In addition, the heat loads of consumers also differ from each other. As a result, the main parameters of the coolant (pressure and temperature) cannot be standardized for all network subscribers.

The task of connecting various subscribers to a single heating network and converting coolant parameters for the specific needs of heat consumption facilities is solved in individual heating points (IHP).

The function of converting coolant parameters (pressure and temperature) on a large number of IHPs is still performed by the elevator.

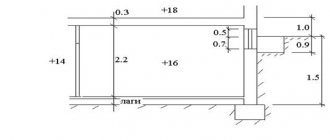

A diagram of the elevator mixing unit is presented below.

The water jet elevator is designed to lower the temperature of the network coolant coming from the heating plant networks due to partial mixing with water coming from the return pipeline and organizing the circulation of the coolant in the heating system of the house.

Elevator Bias System

Installation of thermal units

A modern heating unit is the most important element of a heating network, which is subject to the highest requirements. Proper installation of thermal units makes it possible to maintain their functionality for a long time and increase reliability.

Nowadays, in addition to the distribution function, thermal units monitor the consumption of thermal energy, so professional and high-quality installation of the ITP (heating unit) allows for uninterrupted and efficient operation of the equipment, and also ensures accurate accounting and saving of energy resources.

The principle of operation of the node.

Coolant under pressure P1 is supplied to the nozzle body (glass).

After the nozzle, the coolant stream enters the mixing chamber.

the elevator body, carrying with it part of the cooled coolant from the heating system (P2,t2).

Due to the pressure difference (P1>P2), the coolant stream enters further into the expanded

As a result of mixing, a coolant with parameters P3,t3 is obtained, which is supplied to the heating system of the building. In this case, the following inequalities are observed: P1>P3>P2 and t1>t3>t2

Advantages of a water jet elevator:

- simplicity and low cost;

- reliability;

- independence from power supply.

Flaws:

- the operating mode (mixing coefficient) is adjusted by selecting the diameter of the nozzle and the throttle device (limiting washer) in front of the elevator;

- the operating point of the mixing characteristic of the elevator depends on the inlet pressure; when it changes, the operating mode changes;

- the fundamental impossibility of deep adjustment of the coolant parameters according to weather conditions and the needs of the subscriber.

The elevator unit is the main, but not the only element of the ITP. Below is a schematic drawing of the simplest ITP with an elevator mixing unit without hot water supply (DHW) lines, ventilation, etc.

Elevator unit kit

Legend:

- P1 - directly indicating pressure gauge;

- T1, T2, T4, T5 - ball valves;

- T3 - gate valve;

- F1 - mud filter.

The coolant flow from the heating network through valve 1 and the throttle device (between flanges T1 and F1) enters the elevator. The flow rate (and its pressure P1) is controlled by the gate valve T3.

Initial setting of the elevator operating mode (throttle diameter

devices and nozzles) is performed in the middle position of the gate valve. Its controls have a locking mode and a position scale.

If necessary, increase the heat flow entering the building,

is done by opening valve T3 in proportion to the decrease in ambient temperature.

In this case, it is necessary to clearly understand that an increase in pressure P1 in front of the elevator leads to an increase in coolant circulation in the heating system and, as a result, to an increase in the coolant temperature in the return pipeline. This indicator is significant for the resource supply organization and, as a rule, is fixed in the heat supply agreement.

For many regions of the Russian Federation, the most characteristic periods are the so-called “flooding”. They occur mainly in the spring, when the outside air temperature during the day is above average, and increased thermal radiation from the sun provides additional heating of the building envelopes and window openings. The heat energy supplier is objectively unable to reduce the temperature of the coolant at the outlet of the boiler room below 70ºС. As a result, we get increased and uncomfortable indoor temperatures, for which we also pay extra through personal and budgetary funds.

During this period, common sense dictates limiting the flow of coolant into the heating system by partially closing the T3 gate valve.

Pressure P1 in front of the elevator will decrease, which will lead to an increase in the mixing coefficient, a decrease in the circulation of coolant through the heating system and, as a result, an increase in the temperature difference between the initial and final bottling points. In other words, in buildings with overhead bottling, the temperature of heating devices on the upper floors will be significantly higher than the temperature of devices on the lower floors.

However, the average consumption of thermal energy for heating will decrease.

The “overflow” effect will be neutralized.

Maintenance and repair of the heating unit

Maintenance of a heating unit (maintenance of ITP) is a set of measures that ensures uninterrupted operation of equipment, monitoring the functioning of units and elements of the facility during operation, carrying out seasonal and commissioning work, organizational and legal support of technical work, carrying out minor repair work, and checking instrumentation and control equipment.

All work on servicing heating units is carried out in accordance with current regulatory documents (PTE TE). Repair of thermal units with replacement of failed units is usually carried out by a specialized organization in accordance with an additional agreement.

Conclusions and recommendations

Based on the presented information, statistical and information materials, the following conclusions can be drawn:

- The main reasons for excess consumption of thermal energy for heating needs are the discrepancy between the operating modes of the heating point and the contractual heat load.

- Operating individual heating points using elevator mixing units are morally and technologically outdated and cannot ensure rational and efficient consumption of thermal energy.

- Attempts to introduce automated schemes for controlling coolant parameters in elevator mixing units do not currently lead to effective weather control.

- The most effective solution for rational consumption of thermal energy is full-fledged automated heating units with weather regulation.

- The most rational solution, combining the technical advantages of automated heating points and the relatively low cost of implementation, is the use of control systems.

Design of thermal units

Design of thermal units is one of the initial stages of construction. The development of a heating unit project is necessary for coordination with the heat supply organization. At this stage, the necessary calculations are made, equipment is selected, and the scope of installation work is determined.

A correctly and competently drawn up design of a heating unit allows you to calculate construction costs, avoid unjustified costs, and solve many problems during further operation. This process is described in more detail in the material designing heating points.

Appendix B

List of sources used

- Federal Law of November 23, 2009 N 261-FZ (as amended on December 29, 2014) “On energy saving and increasing energy efficiency and on introducing amendments to certain legislative acts of the Russian Federation”

- Rules for the technical operation of thermal power plants (approved by order of the Ministry of Energy of the Russian Federation dated March 24, 2003 N 115)

- Federal Law of July 27, 2010 N 190-FZ (as amended on December 29, 2014) “On Heat Supply” (as amended and supplemented, entered into force on March 3, 2015).

- Presentation of the report at the meeting of the City Non-Departmental Commission on March 27, 2015. “Results of monitoring the equipping of apartment buildings in St. Petersburg with metering units as of March 27, 2015”

- JSC "SHAD-International" Description of a water jet with an adjustable nozzle (VARS). Patent No. 2151918. https://www.shad-in.ru.

- Methodology for determining the need for fuel, electrical energy and water in the production and transmission of thermal energy and coolants in municipal heating systems. (approved by the State Construction Committee of the Russian Federation on August 12, 2003)

Cost of the heating unit project

The cost of designing a heating unit is usually determined individually in each specific case and depends on many factors: the type of heating unit being built; type of heating system; types, brands, types and quantities of equipment; the required power of the heating unit, volume and complexity of work and other indicators.

However, it is rightly noted that savings begin precisely at the stage of drawing up the project. With professional and high-quality design, the high price of modern, efficient equipment, the cost of the heating unit project, the cost of installation work and other expenses are recouped in the shortest possible time.

Repair or modernization of a heat metering unit

- Work on completion, additional equipment, and modernization includes work caused by a change in the technological or service purpose of equipment, a building, structure or other object of depreciable fixed assets, increased loads and (or) other new qualities.

- Reconstruction includes the reconstruction of existing fixed assets, associated with the improvement of production and increasing its technical and economic indicators and carried out under the project for the reconstruction of fixed assets in order to increase production capacity, improve quality and change the range of products.

- Technical re-equipment includes a set of measures to improve the technical and economic indicators of fixed assets or their individual parts based on the introduction of advanced equipment and technology, mechanization and automation of production, modernization and replacement of obsolete and physically worn-out equipment with new, more productive ones.

However, there is no clear concept of repair in the legislation.

- According to paragraph 16 of the letter of the Goskomstat of Russia dated 04/09/2001 No. MS-1-23/1480 (hereinafter referred to as the letter of the Goskomstat), repair means work to maintain fixed assets in working condition during their useful life, which does not lead to an improvement in the original regulatory performance indicators .

- According to clause 14.2 of Art. 1 of the Town Planning Code of the Russian Federation (Civil Code of the Russian Federation), major repairs of capital construction projects (except for linear objects) include such work as: - replacement and (or) restoration of building structures of capital construction projects or elements of such structures, with the exception of load-bearing building structures; — replacement and (or) restoration of engineering support systems and networks of engineering support for capital construction projects or their elements; — replacement of individual elements of load-bearing building structures with similar or other elements that improve the performance of such structures and (or) restoration of these elements.

Fable

So, the owner of the heat energy source claims that he repaired the commercial heat metering unit, while changes were made to the design documentation and the work carried out was in the nature of modernization. The owner of the heat energy source claims that, according to the Rules for Commercial Accounting of Thermal Energy, approval of changes to the design documentation is not required. At the same time, at the unit for commercial metering of thermal energy, say, the type of heat meter was replaced, which led to a change in the formula for calculating thermal energy in accordance with the Methodology for commercial metering of thermal energy and coolant (Order of the Ministry of Construction No. 99/pr).

What really happened and what was required from the owner of the thermal energy source

For thermal energy and coolant metering devices, a short name has been adopted - heat meters.

The heat meter consists of two main functionally independent parts: a heat calculator (TV) and sensors (flow, temperature and pressure of the coolant).

A heat calculator is a specialized microprocessor device designed for processing signals (analog, pulse or digital - depending on the type of sensor used) from sensors, converting them into digital form, calculating the amount of thermal energy in accordance with the adopted algorithm (determined by the heat supply circuit), indicating and storage (archiving) of heat consumption parameters in the non-volatile memory of the device.

Requirements for design documentation are established by GOST 2.106-96 Unified System of Design Documentation (ESKD). Calculations must be performed in accordance with sections 10 and 13 of the ESKD. The procedure for making changes to design documentation is regulated by GOST R 21.1101-2013.

According to clause 7.1.2. GOST R21.1101-2013, a change to a document previously transferred to the customer is any correction, exclusion or addition of any data to it without changing the designation of this document. Changes to calculations are not permitted.

In accordance with paragraph 7.1.3 of GOST R21.1101-2013, if a change to a document is unacceptable, then a new document with a new designation must be issued.

Thus, the owner of the thermal energy source in the case under consideration had to release a new design for the metering system of the metering unit

And according to paragraph 38 of the Rules for commercial metering of thermal energy for a heat energy source, the design of a metering system for a metering unit is developed on the basis of a technical specification prepared by the owner of the thermal energy source and agreed upon with the adjacent heat supply (heating network) organization in terms of compliance with the requirements of the Rules for commercial metering of thermal energy, coolant, terms of the contract and conditions for connecting the heat source to the heat supply system.

Conclusion

That is, before upgrading the commercial heat energy metering unit, its owner was required to agree on the terms of reference with the adjacent heating network organization and agree on the design of the metering unit for compliance with the requirements of the Rules for commercial metering of heat energy and coolant.

The cost of installing a heating unit

The construction (installation) of a heating unit (heating station) consists of several stages.

- Installation, welding and plumbing work, including installation of fittings, pumps, heat exchangers, metering unit, laying pipelines.

- Electrical installation work - laying power cables, connecting electrical loads (metering, automation and control devices, pumps and other electrical equipment).

- Commissioning works.

- Commissioning of the heating unit.

The total cost of installation work depends on the volume of these operations.

Comprehensive information on the cost of installing a heating unit (point), its repair and other data can be found on the page “Cost of ITP”. Get an offer