Gas water heater water reducer: principle of operation, equipment and maintenance

A geyser is a water heating device that comes with many different devices.

Let us note the operation of the water reducer of the gas water heater. It is also called a water block or knot. It is installed in the device in front of the heat exchanger. According to the material of manufacture, water reducers are divided into those made of:

- Brass;

- Plastic;

- Polyamide.

It should be noted that brass is copper and zinc, that is, an alloy of these metals; this material is often used for the manufacture of plumbing fixtures. Plastic units (Fig. 1) are durable and practical. Polyamide is a material that is very similar in composition to plastic, but its durability can be explained by the presence of glass fiber in the composition.

Rice. 1 Plastic membrane water unit

The functioning of this device in a gas water heater is no different from other gas water heaters. That is, the main difference lies in the material of manufacture.

Membrane reducers for gas water heaters can withstand fairly high pressures, as for household appliances. Namely, it is from 0.5 to 3 m3/hour.

Required water pressure

The minimum pressure required to turn on the selected column is indicated in the equipment documentation

Paying attention to this parameter is especially important when installing a heater in old houses built in the 60-70s, since the pressure in their pipes is often insufficient for the heater to operate. If the manufacturer states that the minimum requirement is a pressure of more than 0.15 bar, then in an old building there may be problems with the functioning of this column

Another point is the ability of the column to withstand the hydraulic shock that periodically appears during water supply. This is the name for a short-term increase in pressure in pipes, which can cause leaks and damage to connections. With a value in the range of 11-12 bar, the column is able to withstand such changes.

Types of water blocks and operating principle

The water block of a geyser can be made of different materials:

- brass - an alloy of copper and zinc;

- plastic - practicality and long service life;

- polyamide - long service life is ensured through the use of fiberglass.

The design of the water block of a geyser implies the presence of the following components:

- base and cover with screws;

- diaphragm with a disk mounted on the rod;

- flow regulator;

- nozzles;

- flow regulator;

- temperature selector;

- hot water filter.

The water block is divided into two parts by a rubber membrane, one of which is connected to the cold water supply, and the other is equipped with a rod connected to the gas valve. On the metal rod of automatic devices there are “wings” connected to the electric ignition unit.

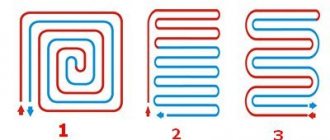

The principle of operation of the “frog” is as follows:

- when you open a cold water tap, one of the cavities of the block is filled;

- the water pressure puts pressure on the membrane, which in turn bends and puts pressure on the rod located in the second part of the “frog”;

- the rod begins to press on the valve, thereby opening the gas supply;

- in automatic dispensers there are “ears” on the stem that send a signal to the ignition unit;

- a spark is produced that ignites the flame;

- after closing the hot water tap, the internal parts begin to move in reverse, the rod returns to its original position using a spring and closes the gas supply.

The equipment of automatic and semi-automatic geysers may differ slightly, but the operating principle itself remains unchanged.

How to repair a “frog” with your own hands?

Hard water, exposure to high temperatures and other factors gradually cause the elements of the water block to wear out. If any damage is detected, it is necessary to urgently repair the problematic part.

If desired, you can repair the water block of a geyser yourself, since its design is quite simple. Before doing this, it is important not to forget to turn off the fuel and water supplies.

If you need to adjust the pressure of the device, you need to twist the special bolts located on the back of the block. Then the water is drained from the heat exchanger; for this purpose, a tap located below the water heater is used. Disconnect the gas and water supply pipelines. Now the “frog” can be removed. The design of the water block may vary slightly depending on the model. In order for the removal of the water unit to be successful, all pipes and wires should be disconnected from it.

Possible malfunctions of the water unit

There are malfunctions and malfunctions in the operation of a flow-through water heater, which clearly indicate failure of the structural elements of the gearbox. These include:

- refusal to turn on the column;

Malfunctions indicate the following possible breakdowns and malfunctions in the “frog”:

- The membrane has broken - the average service life of the diaphragm is 5-7 years. Over time, due to constant mechanical stress and hard water, the rubber breaks through. A sign of membrane failure is that water drips from the gearbox.

Dismantling the water unit

To carry out repairs, the unit must be removed from its seat. This is only possible together with the dismantling of the gas unit.

- Turn off the gas supply valve.

- Disconnect the cold water hose.

- Using a wrench, disconnect the assembly from the pipe.

- Disconnect the wiring from the gas valve and microswitch.

- Use a screwdriver to unscrew the flange bolts.

- Remove the water-gas block.

Now you need to disassemble it and replace the broken parts:

- To disconnect the gas part from the water part, unscrew the two screws. One is on top, the other is on bottom. You can not unscrew it completely, but slightly loosen the fastening. It happens that the bolts stick. Spray these areas with WD-40.

- Separate the blocks.

- Now unscrew the frog screws on top.

- The body will split into two parts and the diaphragm will become accessible.

- Remove the rubber part (if it is faulty, prepare a new one).

- Pull out the disc with the stem. Behind them is a spring.

- Remove the spring and check the seal located behind it. It requires periodic cleaning and lubrication.

- Install new parts and reassemble the unit in reverse order. The oil seal can be lubricated before installation.

- When tightening the frog bolts, lubricate them with graphite lubricant.

To avoid running the column into a faulty state, check its components every six months and clean them of scale and dirt.

Removing the water unit

In order to repair this unit, the unit must be removed from its seat. This is only feasible in conjunction with dismantling the gas unit:

- you need to turn off the gas supply valve;

- then disconnect the cold water hose;

- after this, the assembly is disconnected from the pipe using a key;

- Next, you need to disconnect the wiring from the gas valve and microswitch;

- Use a screwdriver to unscrew the flange bolts and remove the water-gas block.

In order not to bring the gas water heater to a critical state, check all its components every 6-8 months and clean them of scale and dirt.

If you follow the installation instructions, maintenance of the device is kept to a minimum. However, hard water and regular temperature changes gradually lead to failure of one or another part of the instantaneous water heater. Usually the breakdown is associated with the gearbox and it is necessary to be able to remove it for comfortable maintenance and to identify the exact cause of the malfunction.

To do this, you need to shut off the water and gas supplies. Next, you need to drain all the water from the heat exchanger using a special faucet or faucet located much lower than the device itself. The next step will be to disconnect the pipes supplying gas and water. To do this you will need a gas key. The work must be carried out carefully, especially when the system operates thanks to a centralized gas supply.

Then you can easily remove the gearbox if the installation was done correctly. It's worth noting that the outer metal casing comes off easily and is just as easy to reinstall. In different speaker models, the appearance of the water unit may differ, but not significantly. The Lviv gearbox is considered the easiest to repair.

Cleaning the gearbox

Experts recommend cleaning the water unit at least once a year. This will help extend the service life of the geyser. It should be removed in the usual way without significant effort. There are bolts on the cover of the part that must be carefully unscrewed, being careful not to damage the threads.

Documentation

In order to install a gas water heater in an apartment or private house, you will need the following documents:

- Technical passport of the purchased dispenser or indication of the model in case of subsequent purchase of the unit.

- A report on the technical condition of the hood or chimney, drawn up by the exhaust and chimney duct inspection service.

- Project for placing new water heating equipment and connecting it to the gas and water mains in accordance with the technical specifications.

- An application submitted by the owner for the reconstruction of a premises with a water pump must additionally provide proof of ownership and a technical passport for the apartment.

- An application for installation work sent to the gas supply organization (Gorgaz) with a project attached.

The company engaged in the maintenance of the purchased gas water heater or specialists from the gas supply organization are required to perform the following actions when installing the equipment:

- Make a connection into the gas pipeline with the installation of metering devices and a shut-off valve.

- Hang the column with the flammable surface of the wall lined with insulating materials (tin in combination with asbestos or basalt sheets), connect a flexible gas supply to the unit.

- Connect the column to the chimney or exhaust system using a pipeline.

- Connect flexible hoses from the unit to the cold water main and hot water supply pipes.

- Upon completion of the work, the Gorgaz specialist must set up and start the dispenser, seal the gas meter and draw up a report on putting the unit into operation.

The cost of installing a gas water heater at home by private specialists will cost about 3,000 rubles; gas supply companies, depending on the region, carry out the connection at their own prices.

Rice. 10 Recommended spacing and placement of insulation

2

Operating principle

Having become familiar with the design of geysers, it will be easier to understand the operating principle of these units. When fuel burns, thermal energy is released, heating the heat exchanger. Most often, this part of the burner is made of copper or special alloys with high thermal conductivity.

Around the heat exchanger there is a coil, which is also made of materials with high thermal conductivity. As a result, it heats up and transfers thermal energy to the water. After this, the hot liquid enters the pipeline. To remove combustion products, the unit is equipped with a chimney.

It is worth considering separately the operating principle and design of the gas water heater reducer. This is one of the most important design elements, since its main task is to start the column and supply water. The node works as follows:

- 1. When the tap is open, water flows into the water reducer of the gas water heater.

- 2. In one of the chambers of the device, pressure begins to increase, which sets the membrane in motion, which, bending, pushes out the plate.

- 3. The plate acts on the water rod, which moves the gas block pusher.

- 4. This triggers the switch, which starts the control unit, and it gives the command to ignite the unit.

- 5. At the same time, the gas valve is released, opening the fuel supply.

If a flame appears, a special sensor turns off the spark plug. When the hot water tap closes, the pressure in the two chambers of the reducer is equalized and the gas valve shuts off the fuel supply. The principle of operation of a battery-powered geyser is no different from units powered from the mains.

Depending on the ignition method, the columns are divided into three types:

- 1.

Manual. First you need to open the fuel supply, then manually light the fire using matches or a lighter. - 2. With piezo ignition. Unlike the first type, the burner is ignited using a button that activates the piezoelectric element.

- 3. Automatic machines. These units are fully automated and designed as efficiently as possible.

The structure of a gas boiler and the principle of its operation

3

Recommendations for maintenance and repair

All elements of the column structure are subject to destruction due to various factors. Any gas equipment requires regular maintenance. If defects are identified during maintenance work, they must be eliminated as quickly as possible. Of course, some repair work should be entrusted to a professional, but some can be done independently.

The principle of operation of a double-circuit gas boiler

3.1

Dismantling and adjusting the gearbox

You must first turn off the fuel and water supplies. Only after this can you begin to carry out preventive or repair work. To remove the gearbox, you need to perform several steps:

- Water is drained from the heat exchanger;

- using an adjustable wrench, the gas and water pipelines are disconnected from the column;

- If no mistakes were made at the previous stages, the gearbox can be easily dismantled.

Depending on the model of the unit, changes may be made to its design. To avoid problems when dismantling the water reducer, you must first disconnect all pipes and parts that make the work difficult. The housing should be easy to remove; no physical effort is required.

To adjust the gearbox, you must use special bolts located on the back side of the unit. Most often, the unit is already prepared for operation at the factory and does not require additional configuration. It is not advisable to adjust the unit unless absolutely necessary.

3.2

Cleaning the water unit

This event must be held at least once every 12 calendar months. When unscrewing the fastening bolts located on the unit cover, you must be careful not to damage the folds. When the cover is removed, it is necessary not only to clean the internal space of the gearbox, but also to perform the following procedures:

- 1. All solid residues must be removed from the bottom of the part, and the coarse water filter must also be rinsed.

- 2. It is advisable to lubricate the rod with grease or castor oil.

- 3. If you suspect that the gasket has lost its former elasticity, it also needs to be lubricated.

With regular maintenance of the unit, its service life can be significantly extended. Most often, the rod seal and membrane fail. The first element must be replaced once every 3 years, and the second - after the appearance of ruptures or microcracks. In addition, during intensive work the spring for returning the rod to its original position may break.

Having carefully studied the design and principle of operation of the gas water heater, you can carry out all preventive measures yourself. If you don’t have confidence in your own abilities, then you should turn to professionals for help. When working with the unit, you must strictly follow the instructions.

This is interesting: What wire cross-section is needed for 15 kW 3 phase to enter the house

Design and principle of operation of a geyser

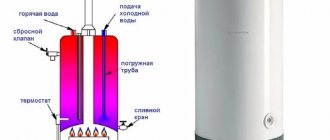

A water geyser works on the following principle: water and gas enter the system when the hot water tap is opened. The ignition system is turned on, the gas in the combustion chamber is converted into thermal energy. The thermal energy then enters the heat exchanger.

A water geyser has a complex structure and consists of an outer casing, a combustion chamber, a water reducer, a heat exchanger, an ignition system, pipes, and a locking system.

- The device housing is designed to protect the water unit and other built-in parts. The body gives the device a beautiful appearance, and it is made of steel or cast iron metal or metal-plastic. It also contains toggle switches that regulate the temperature and water pressure, and a display.

- The main part of the gas water heater is the water block, another name for it is “frog”, water unit or water reducer. A water unit is installed inside the device in front of the heat exchanger and regulates the operation of the column depending on the volume of water entering the device. The water block of the geyser regulates the water supply to the system, directs it for heating through the heat exchanger and other elements, supplying users with hot water. The water reducer is made of brass, plastic and polyamide and consists of a base, a cover, a membrane, a Venturi nozzle, a temperature switch, a water flow and flow device, and a filter.

- The column heat exchanger contains thermal energy that heats the cold water circulating through the tubes. In a Junkers water column, the heat exchanger and the water unit cover are directly connected to each other. A little further from the heat exchanger is the water unit of the Ariston gas water heater.

- The combustion chamber can be closed or open. Its task is to convert gas into thermal energy.

- The ignition system consists of electric or piezo ignition.

- The pipes supply cold water and gas; they also have a valve for hot water outlet and a discharge valve.

- Some models are equipped with an emergency device shutdown system and system locking.

Combustion chamber type

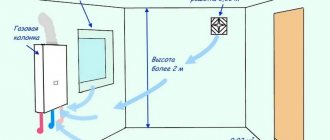

Regardless of the method of gas ignition, in all columns the combustion chambers can be of two types: open or closed.

If the design of the combustion chamber is open, then air enters it directly from the room, and all combustion products are removed using an ordinary hood. Such devices have several advantages:

- simple design;

- makes virtually no noise during operation;

- Most often they do not need electricity.

However, such cameras have one significant drawback. When the hood does not work properly, air pollution in the room can occur.

Closed combustion chambers are typical for gas water heaters with a turbine. The design of such chambers, with the exception of pipes for air supply and exhaust, is completely sealed. Air is supplied using built-in fans and removed through a chimney.

The closed combustion chamber in the column is completely sealed

The closed design of the combustion chamber is characteristic of more modern models of dispensers with automatic operation. Due to the presence of various sensors, such models are considered the safest.