The heating system in private houses differs significantly from city apartments due to its complexity; it may contain several circuits of heated floors and heat exchange radiators with a large number of connections. After installation, a performance test procedure is mandatory; for this test, a technique called pressure testing of the heating system is used.

To carry out crimping work, special automatic or manual equipment is used; if it is available, the test will not cause any particular difficulties even for an unprepared homeowner. The only thing you should know when pumping water or air into the system is the pressure limits and time intervals for checking a specific heating network, which are specified in the regulations.

Fig.1 Hydraulic test process in the basement of a building

What is pressure testing of heating and water supply systems?

Heating and water supply are two systems consisting of a large number of varied equipment. As you know, the performance of any multicomponent system is determined by the weakest element - if it fails, it stops completely or partially. To identify all weak points, pressure testing of heating and water supply is carried out. In simple terms, the pressure deliberately rises much higher than the working one, pumping liquid. This is done using special equipment; the pressure is controlled using a pressure gauge. The second name for crimping is hydraulic testing. It's probably clear why.

Heating pressure testing is carried out after any repair or before the heating season

When a heating system is pressure tested, the pressure is increased by 25-80% depending on the type of pipes, radiators, and other equipment. It is clear that such a test reveals all the weak points - everything that does not have a safety margin breaks, leaks appear in worn pipes and unreliable connections. Having eliminated all identified problems, we ensure the functionality of our heating or water supply for some time.

If we are talking about centralized heating, then pressure testing is usually carried out immediately after the end of the season. In this case, there is a decent period of time for repairs. But this is not the only case when such events are held. Pressure testing still takes place after repairs or replacement of any element. In principle, this is understandable - we need to check how reliable the new equipment and connections are. For example, you soldered heating from polypropylene pipes. We need to check how high quality the connections are. This can be done using crimping.

If we talk about autonomous systems in private houses or apartments, then a new or repaired water supply is usually checked simply by turning on the water, although even here a strength test would not hurt. But it is advisable to test the heating “to its fullest”, both before commissioning and after repairs. Keep in mind that those pipelines that are hidden in walls, floors or suspended ceilings must be tested before they are closed. Otherwise, if during testing it turns out that there are leaks there, you will have to disassemble/break everything and fix the problems. Few people will be happy about this.

What is the final hydraulic test of water supply lines?

Such hydraulic checks of water supply pipelines are carried out after the installation of plumbing fixtures for hot water is completed.

- They start by pumping up the working pressure in the water supply. It must be raised to the initial level if the indicator has dropped by 0.02 MPa.

- The pressure rises ten minutes before the test readings. The system remains in this state for two hours.

Equipment and test frequency

Pressure testing of centralized systems is carried out by personnel using standard equipment, so it is hardly worth talking about. But not everyone probably knows about the costs of private heating and water supply. These are special pumps. There are two types - manual and electric (automatic). Manual pressure testing pumps are autonomous, the pressure is pumped up using a lever, and the created pressure is controlled using a pressure gauge built into the device. Such pumps can be used for small systems - pumping is quite difficult.

Manual crimping machine

Electric pumps for pressure testing are more complex and expensive equipment. They usually have the ability to create a certain pressure. It is set by the operator, and it is “caught up” automatically. Such equipment is purchased by companies engaged in professional crimping.

According to SNiP, hydraulic testing of heating systems must be carried out annually, before the start of the heating season. This applies to private houses too, but few people comply with this standard. At best, they check it once every 5-7 years. If you are not going to test your heating annually, then there is no point in buying a pressure tester. The cheapest manual one costs about $150, and a good one costs from $250. In principle, you can rent it (usually from companies that sell components for heating systems or from offices that rent equipment). The amount will be small - you need the device for several hours. So this is a good solution.

Call specialists or do it yourself

If for some purpose you require a pressure test certificate for your heating or hot water supply system, you have only one option - order this service from a specialized organization. The cost of heating pressure testing can only be quoted to you individually. It depends on the volume of the system, its structure, the presence of shut-off valves and their condition. In general, the cost is calculated based on the tariff for 1 hour of work, and it ranges from 1000 rubles/hour to 2500 rubles/hour. You will have to call different organizations and inquire with them.

Companies involved in hydraulic system testing have more serious equipment.

If you have upgraded the heating or hot water supply of your own home, and you know for sure that your pipes and equipment are in good condition, there are no salts or deposits in them, you can carry out pressure testing yourself. No one will demand hydraulic test certificates from you. Even if you see that your pipes and radiators are clogged, you can wash everything yourself and then test it again. If you just don’t want to do this, you can call specialists. They will immediately clean the system and pressure test it, and will also issue you a certificate.

Certificate of hydrostatic testing of the system (pressure testing)

Under what conditions is it necessary to carry out hydraulic testing of pipelines?

It is necessary to realize how complex the hydraulic testing of plumbing systems is. The reliability of the structure itself and its quality largely depend on the competence of this procedure. Therefore, the work is trusted only to specialists with the appropriate classification.

The requirements for the test work itself include several items. This is required by any technique.

- All points of use in the riser are switched on simultaneously to check efficiency. But the need at this stage is determined individually, at each enterprise separately.

- The condition of heated towel rails is tested when the hot water supply is checked.

- Temperature measurements take place only at the extreme sections of the system. Water is poured with predetermined characteristics.

- The liquid must be completely drained after completion of all stages of the activity.

- Filling of pipelines begins from the lower floors, gradually moving to the upper ones. Then the air will be properly forced out of the pipes. And there is no danger of air pockets appearing in the pipeline.

- The first stage in filling the water pipeline affects only the main section. Only at the next stages they move on to small local networks and individual risers.

- Outdoors or indoors during work the temperature should not fall below +5 degrees.

Crimping process

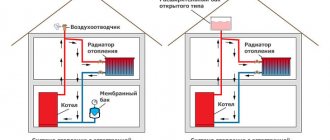

Pressure testing of heating systems in a private home begins with disconnecting the heating boiler, automatic air vents and expansion tank from the system. If there are shut-off valves leading to this equipment, you can close them, but if the valves turn out to be faulty, the expansion tank will definitely fail, and the boiler will fail, depending on the pressure that you apply to it. Therefore, it is better to remove the expansion tank, especially since this is not difficult to do, but in the case of a boiler, you will have to rely on the serviceability of the taps. If there are thermostats on the radiators, it is also advisable to remove them - they are not designed for high pressure.

Sometimes not all heating is tested, but only some part. If possible, it is cut off using shut-off valves or temporary jumpers are installed - surges.

There are two important points: pressure testing can be carried out at an air temperature not lower than +5°C, the system is filled with water with a temperature not higher than +45°C.

The following is the process:

- If the system has been in operation, the coolant is drained.

- A crimping machine is connected to the system. A hose extends from it, ending with a union nut. This hose is connected to the system in any suitable place, even in the place of the removed expansion tank or instead of the drain valve.

- Water is poured into the container of the pressure testing pump and pumped into the system using the pump.

The device is connected to any available input - on the supply or return pipeline - it doesn’t matter - Before increasing the pressure, all air must be removed from the system. To do this, you can bleed the system a little with the drain valve open or drain it through air vents on the radiators (Mayevsky valves).

- The system is brought to operating pressure and held for at least 10 minutes. During this time, all remaining air is released.

- The pressure is raised to the test pressure and maintained for a certain period of time (regulated by the Ministry of Energy standards). During the test, all devices and connections are checked. They are inspected for leaks. Moreover, even a slightly damp connection is considered a leak (fogging also needs to be eliminated).

- During crimping, the pressure level is monitored. If during the test its fall does not exceed the norm (as specified in SNiP), the system is considered to be in good working order. If the pressure drops even slightly below normal, you need to look for a leak, fix it, then start pressure testing again.

As already mentioned, the testing pressure depends on the type of equipment and system being tested (heating or hot water supply). The recommendations of the Ministry of Energy set out in the “Rules for the technical operation of thermal power plants” (clause 9.2.13) are summarized in a table for ease of use.

| Type of equipment tested | Test pressure | Test duration | Allowed pressure drop |

| Elevator units, water heaters | 1 MPa(10 kgf/cm2) | 5 minutes | 0.02 MPa (0.2 kgf/cm2) |

| Systems with cast iron radiators | 0.6 MPa (6 kgf/cm2) | 5 minutes | 0.02 MPa (0.2 kgf/cm2) |

| Systems with panel and convector radiators | 1 MPa (10 kgf/cm2) | 15 minutes | 0.01 MPa (0.1 kgf/cm2) |

| Hot water supply systems made of metal pipes | operating pressure+ 0.5 MPa (5 kgf/cm2), but not more than 1 MPa (10 kgf/cm2) | 10 minutes | 0.05 MPa (0.5 kgf/cm2) |

| Hot water supply systems made of plastic pipes | operating pressure+ 0.5 MPa (5 kgf/cm2), but not more than 1 MPa (10 kgf/cm2) | 30 minutes | 0.06 MPa (0.6 kgf/cm2), with further testing for 2 hours and a maximum drop of 0.02 MPa (0.2 kgf/cm2) |

Please note that for testing heating and plumbing made of plastic pipes, the test pressure holding time is 30 minutes. If no deviations are detected during this time, the system is considered to have successfully passed the pressure test. But the test continues for another 2 hours. And during this time, the pressure drop in the system should not exceed the norm - 0.02 MPa (0.2 kgf/cm2).

Correspondence table for different units of pressure measurement

On the other hand, SNIP 3.05.01-85 (clause 4.6) has other recommendations:

- Heating and water supply systems are tested at a pressure of 1.5 times the working pressure, but not lower than 0.2 MPa (2 kgf/cm2).

- The system is considered operational if after 5 minutes the pressure drop does not exceed 0.02 MPa (0.2 kgf/cm).

What standards to use is an interesting question. For now, both documents are valid and there is no certainty, so both are valid. It is necessary to approach each case individually, taking into account the maximum pressure for which its elements are designed. So the working pressure of cast iron radiators is no more than 6 Atm, respectively, the test pressure will be 9-10 Atm. It’s also worth deciding on all the other components in approximately the same way.

Water hammer in heating networks and its consequences

Timely tests make it possible to identify weak points in communications and prevent a possible accident. The usual operating pressure in the heating main is 12 atmospheres. A sudden increase in permissible pressure causes a situation called water hammer.

What are the consequences of water hammer in a heating network? The moment of occurrence and spread of water hammer cannot be tracked: having suddenly formed in the heating network, it is instantly transmitted to the general heating system, including intra-house communications that are not designed for this pressure. As a result, cracks and leaks occur; in the most serious cases, an accident occurs - a rupture of a weak part in the pipeline, flooding of premises with hot water, which leads to damage to valuable property, furniture, equipment, etc. Subsequently, fungus and mold may spread on the walls and ceiling. Since the pressure in heating systems is high, an area of several tens of meters around can be flooded with boiling water. If a room is flooded with boiling water, people can also be harmed. Regular hydraulic checks and professional maintenance of the heating system help to successfully avoid such unpleasant and dangerous moments.

To contents

Air crimping

Not everywhere and not always is it possible to rent a crimping machine, just as it is not possible to buy one. For example, you need to test the heating in your dacha. The equipment is specific and the chances that someone you know has it is very low. In this case, pressure testing of the heating system is carried out with air. To pump it, you can use any compressor, even a car one. The pressure is monitored using a connected pressure gauge.

This type of crimping is less convenient and not entirely correct. Heating and plumbing are designed to transport liquids, which are much denser than air. Where water will not even ooze out, air will escape. Therefore, we can say with a high degree of confidence that you will have an air leak - somewhere there will be a loose connection. Moreover, it is difficult to determine the location of the leak during such testing. For this purpose, use a soap solution, which coats all joints and connections, all places where air can escape. Bubbles appear at the leak site. Sometimes you have to search for a long time. This is precisely why such pressure testing of the heating system is not very popular.

Pressure testing of a heated floor has its own characteristics - you must first check the comb and all the devices attached to it. To do this, close all the supply and return valves of the loops, filling only the heated floor manifold, and check it by raising the pressure. Having reset it to normal, the heated floor loops are filled one by one, and only then is excess pressure created. The process is described in more detail in the video.