Many owners of country houses and apartments prefer to use autonomous heating and hot water supply systems, which require a water heater or a double-circuit boiler. Devices differ in many parameters, the most important of which is the type of fuel used for operation. A water heating boiler has its own design features and operating principle.

Why do you need a hot water boiler?

If the housing does not provide centralized heating and hot water supply, then these functions are assigned to the boiler. As a rule, this situation occurs in suburban buildings. However, heating equipment can be successfully installed in an apartment.

With the right choice of equipment, the system will effectively perform its task, creating warmth and comfort in the room, regardless of the weather outside. Water heating boilers are safe, easy-to-use devices, the heating efficiency of which depends on the specific model and a number of other factors.

Specifications

Heat exchanger of an industrial water heating boiler

The main technical characteristics of water heating equipment are as follows:

- device - fire tube, water tube;

- operating temperature - low temperature (up to + 115 ºС), high temperature (+ 115-200 ºС);

- coolant - water;

- functionality - single-circuit (heating only), double-circuit (heating, hot water supply);

- nominal pressure in the system - 0.6-0.8 MPa;

- produced power - 3-28 kW;

- types of fuel - firewood, briquettes, gas, diesel, mining, fuel oil, electricity;

- control - manual, automatic.

The choice of product is made based on its purpose, size and configuration of the facility in which it will be installed.

Design features

At the moment, several types of water heating equipment are produced, each of which has its own design. Establishing the differences between them will allow you to correctly evaluate the technology and choose the appropriate model.

Fire tube

These types of heaters are equipped with a pressurized gas-tight firebox. For their operation, automated burner devices equipped with blower fans are used. This feature allows the equipment to work without smoke exhausters, while all the necessary parameters are easily adjustable. As a result, the device is highly efficient and has an efficiency level of 92–95%.

Almost all fire tube boilers are internally equipped with a cylindrical firebox and smoke tubes. Depending on the layout, two- and three-way models are distinguished. This equipment was used back in the 19th century and has undergone many changes since then. These boilers are in demand today as they are easy to use and do not require much maintenance.

Considering the features of the equipment, first of all it is worth noting that fire tube boilers can be classified as gas appliances. Special pipes are installed on their surface through which the coolant moves.

There are two types of fire tube boilers:

- Steam. The coolant is heated by water steam, so the inside of the boiler is equipped with a special container.

- Hot water. The entire body is heated using the liquid.

The principle of operation is as follows: gas or fuel is supplied to the burner located on the front of the body, which is burned. The role of the firebox is played by pipes located in the water, where all combustible material burns.

Despite their relatively compact size, such devices are highly powerful and safe to use. In addition, they can operate in autonomous mode, but for this you will need to purchase special equipment in the form of a pressure gauge, water pressure sensor, and so on.

Water tube

In such models, water is heated by passing inside metal pipes. The working pipes located outside are heated by fuel combustion products. Due to the design features, it is possible to increase the heating surface, for which a larger number of water pipes are used.

Thanks to the convection flow in such systems, the movement of water accelerates, which means the heat transfer coefficient also increases. The upper limit of the temperature of the exiting steam reaches +550 °C.

Water tube models are more compact than fire tube models. This is a complete piece of equipment housed in a rugged housing. The operating principle of water pipe technology is natural circulation of water.

Number of circuits

At the moment, the market offers a wide variety of heating equipment. First of all, you need to understand for what purpose the boiler is being purchased: only for heating or also for preparing hot water. To solve the first problem, a single-circuit model is sufficient - they are more affordable and do not consume fuel as intensively.

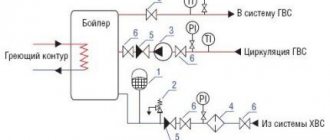

To solve the second problem, you should choose a dual-circuit device. These models, in addition to being able to heat water using a running method, are additionally equipped with a built-in boiler, the volume of which varies from 150 to 180 liters. Flowing heating is optimal if you need to wash dishes or take a shower in the country.

Types of water heaters for heating systems

Boilers, that is, water heaters, are available in a wide range. Some models are capable of preparing hot water for a bath within 20 minutes, while others immediately heat the liquid during use. Flow devices are preferred by those who do not like to wait.

Gas

As the name suggests, this system runs on gas. These boilers are also called columns; they used to be installed in almost every Khrushchev building. This was explained by the low cost of gas during the Soviet era, which was the key advantage of the units.

However, for the gas water heater to operate fully, it is necessary to equip a chimney through which combustion products are removed from the room. It is because of this that gas models are increasingly being replaced by a modern alternative. However, with proper operation, their efficiency will be higher compared to an electric boiler, which is explained by their high power. For full operation, the equipment is connected to a central gas system or cylinder.

There are flow-through and storage models. The former are capable of instantly heating the flowing water. As a rule, such a device is called a speaker and is most often found in Russian homes. A storage tank is not provided, since the system is capable of preparing any amount of water, which is heated by a gas burner.

Cumulative models are practically not used, because they are not relevant if the city has a gas supply. As a rule, they are found in places with weak highways or in areas where there is no wiring.

Advantages:

- after turning on the device, the water immediately begins to heat up;

- unlimited amount of hot liquid.

There is only one drawback - to install such equipment you must obtain special permission from the gas service. In addition, you will have to contact a specialized company that will install the system.

Solid fuel

A solid fuel boiler is the best solution for a summer house or a separate autonomous room (bathhouse, sauna). Such systems are most often installed in cases where there are difficulties with the power supply.

The following are suitable fuels for boilers:

- coal;

- logs;

- briquettes

Solid fuel equipment must be connected to the water supply system. Often, columns of this type are equipped with a mixer through which already heated water is supplied. Of course, the scope of their application is quite narrow, but due to its simplicity and efficiency, the equipment is still in demand. Such speakers have been on the heating market for about 50 years, and during this period their properties and capabilities have improved significantly.

Advantages of the equipment:

- Rapid heating of liquid. For example, to prepare water for a shower, 15 to 20 minutes and several kilograms of solid fuel are enough. If the tank is large enough, then in 1 hour the boiler will prepare water for a family of 3-4 people.

- Autonomy. If you make the right choice, you will not need to depend on electricity or gas.

- Availability. Compared to similar heating equipment, solid fuel models have a low price.

- Reliability. This is explained by the simple technology of the system, which can operate reliably for many years.

Along with advantages, solid fuel devices also have disadvantages.

The following disadvantages are highlighted:

- You need a place to store fuel. For maximum efficient combustion, certain requirements must be met.

- Inconvenience of cheap models. Such devices cause a lot of trouble during operation. They get more dirty, so they have to be cleaned more often so that the efficiency does not drop.

- Manual fuel loading. The amount of fuel loaded may vary depending on the model selected.

- Installation of auxiliary devices will be required. At a minimum, the unit will need a heat accumulator.

If we consider the operating principle of a solid fuel boiler, it can be compared to a large wood-burning samovar. At the bottom there is a firebox, waste from combustion processes is discharged through the chimney. The coolant comes into contact with the exhaust gases and heats up. The design of models may vary, therefore the speed of water preparation also varies.

Liquid fuel

Many homeowners use an energy source such as diesel fuel. Most often, this equipment is chosen if there is no gas pipeline in the area where you live, and the installation and use of electrical equipment will be very expensive. Using liquid fuel units, you can heat rooms with an area of 100 m2 or more. Devices are often found at industrial facilities: factories, warehouses, and so on.

Advantages of diesel fuel models:

- high efficiency, reaching 92%;

- Convenient operation thanks to excellent automation;

- Frequent maintenance is not required;

- installation and commissioning do not require a large number of permits and documents.

Many boilers operating on diesel fuel are capable of taking air directly from the street, for which they are equipped with a coaxial pipe. This means you don’t have to make a chimney, which can also be considered an advantage.

Such equipment cannot be called completely autonomous, since the diesel burner runs on electricity. And if difficulties arise with the supply of electricity, you will need to install a generator. In addition, you will have to prepare a place to store fuel containers. For this purpose, fire prevention measures are carried out and a high-quality ventilation system is equipped.

The operating principle is as follows: coolant moves through the boiler pipes, which can occur naturally or using a circulation pump. Diesel oil and air are supplied to the burner under pressure. This mixture ignites in the combustion chamber.

Electric boilers

Based on the name, it becomes clear that such systems require electricity to heat water. These are the most common models that are often found in apartment buildings.

Advantages:

- in many regions electricity is more affordable than gas;

- operates from a 220 V network;

- no unnecessary pressure is created in the water supply;

- hot water can be supplied to several points at the same time;

- adjusting the liquid temperature allows you to set the extreme value, after which the fuse is activated;

- affordable price.

In a word, if there are no serious requirements for the boiler, then the electric model will be optimal. Such equipment also has disadvantages.

Among the disadvantages are:

- It takes time to heat the water;

- The electricity bill increases.

The key feature of the electric boiler is that it can be installed in any room where there is a 220 V network. This could be: an apartment, a country house, an office, a store, and so on. In addition, you do not need to obtain permits to install them. During operation, no carbon monoxide is released, so there is no need to build a chimney.

Application area

Powerful models are installed at facilities where large volumes of water need to be heated.

The scope of application of water heating boilers extends to all areas of human activity. The products are used for heating residential and commercial buildings, covering almost all areas of industry:

Subject to compliance with safety requirements, heating equipment can be installed in the following places:

- apartments, dachas, cottages, private houses;

- warehouses;

- agricultural buildings;

- buildings for keeping animals and poultry;

- storage for vegetables and grain;

- hangars and closed pavilions;

- mines, drilling rigs, artels and settlements located outside populated areas;

- tourist centers and holiday homes.

When choosing a boiler, it is recommended to pay attention to the origin of the product. Priority should be given to trusted, world-famous manufacturers.

Classification of boilers by purpose

Not only residential buildings and apartments, but also industrial facilities need high-quality heating. Manufacturers take this fact into account and produce powerful units that can easily heat large areas. At the moment, there are 2 categories of boilers: domestic and industrial.

Household

This is the name given to heating equipment installed in apartments, cottages and dachas. These devices are ideal for small heated areas, but for enterprise conditions their power will not be enough. There are no special requirements for them, operation is simple and does not require special skills.

Thus, domestic boilers are used for heating and hot water supply to individual houses. These can also be public utility facilities.

Industrial

Nowadays, all enterprises producing thermal energy have industrial equipment installed. We are talking about gas, steam and solid fuel boilers, which are fully automated, safe and functional.

An industrial boiler used for heating premises and providing hot water has many advantages.

The following advantages of use are highlighted:

- ease of maintenance;

- ability to operate on multiple types of fuel;

- adjustment depending on weather conditions;

- If desired, the equipment can be built into a block-modular boiler room.

To regulate the operation of such systems, instrumentation and built-in automatic mechanisms are used, which makes the units safe and reliable. To manufacture the outer casing of the boilers, strong steel or cast iron is used, and they are delivered to the enterprise in the most complete form, which facilitates installation work.

The most popular boilers in industry are gas boilers. The fact is that this type of fuel is now the most accessible resource and emits the most heat when burned.

GOST: general requirements

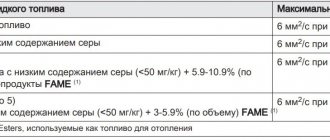

The table shows the basic requirements for the equipment in question in accordance with GOST 21563 93.

| Thermal output (MW) | Outlet water/air temperature (°C) maximum | Coolant pressure (calculated/excessive), kgf/sq.cm | Specific emission of nitrogen oxides (kg/GJ) | Notes |

| From 0.63 to 209.0 | 200/10 | 3,0/2,8 | From 0.09 to 0.21 | The value of these parameters depends on the design of the boiler, the type of fuel and environmental conditions. The tolerance for deviation from nominal values is 5% in both directions. By agreement with the customer, it is possible to manufacture equipment with outlet water temperatures up to 190 °C. |

Before you start operating the unit, you need to study the rules for operating boilers.

Types of boilers by heating and installation method

Modern boiler equipment can be classified according to many criteria. One of them is a method of heating the coolant.

There are 3 types of boilers:

- Heating elements. They are equipped with tubular electric heating elements.

- Electrode (ionic, electrolysis). If alternating voltage passes through the coolant, it will begin to heat up. For this purpose, fuel with certain characteristics is used.

- Induction. Their action is determined by the properties of ferromagnets, which heat up under the influence of induction current.

Depending on the manufacturer and specific model, each boiler has unique features, strengths and weaknesses. It is also customary to classify hot water boilers according to the installation method.

Floor-standing

Such units are installed in large premises. Due to their significant weight, they cannot be mounted on a wall. They often require their own foundation. The burners of such boilers are atmospheric and forced. The first ones are simpler, cheaper and quieter. The latter are more expensive, but their efficiency will be higher. Any boiler is equipped with an atmospheric burner, but you will have to purchase a pressurized burner.

Advantages:

- durable heat exchanger;

- if desired, heating systems with a large number of circuits are created;

- possibility of increasing power.

Along with the advantages, such equipment also has disadvantages.

Flaws:

- high price;

- large mass;

- the boiler must be installed in a separate room;

- restrictions on the use of coaxial chimneys.

Thanks to its high power, the unit effectively copes with its main task - heating a large industrial premises.

Wall mounted

These models, considering their power, are ideal for heating rooms from 100 to 350 m2. These are compact devices that are easy to install and at the same time have an attractive design. Exhaust gases are removed in two ways: through a chimney or a special coaxial pipe. The second method is forced due to the built-in fan, therefore it is more effective.

Advantages:

- compactness;

- installed in almost any room;

- availability;

- a coaxial chimney can be installed.

As for the disadvantages, there are only 2 of them: wall-mounted devices are not as powerful and reliable compared to floor-mounted ones.

Wall-mounted appliances can have piezo ignition, for which a special button or automatic electronic mechanism is provided. In a word, in the first case the launch is manual, and in the second it is automatic, the main thing is that there are no problems with the power supply.

What about the number of contours?

Most of the boilers described in the article (both fire- and water-tube) are double-circuit, but there are also quite a lot of single-circuit units. If the unit has two circuits, then the liquid heated by it will be supplied not only to the heating network, but also to the water supply (after this, of course, it can be used for domestic purposes). Note also that the design of some devices includes special circulators designed to intensify water circulation. Finally, expansion tanks (those of the membrane type) may also be present.

Other differences may relate to the possibility of using different fuels - coal, wood, gas, electric or liquid fuel. Universal units that can truly be called “omnivorous” are becoming increasingly popular today. Regardless of the type of fuel used, any boiler must be equipped with a system that supports combustion processes in automatic mode.

Review of popular models

Any manufactured boiler meets all safety standards. However, more expensive models are equipped with a complex multi-stage diagnostic system and effective automatic protection. Service life and reliability in general depend on how high-quality parts were used when assembling the unit. The most popular models, according to consumer reviews and expert opinion, are the following.

Wolf CGG-1K-24

This is a dual-circuit wall-mounted device. The boiler has a closed combustion chamber and is equipped with a forced smoke removal function. Combustion products are discharged through concentric or separate air ducts. The chimney can have different lengths, so the built-in fan automatically adjusts the speed.

This model has the following features:

- during installation it does not require making an indentation from the side wall;

- runs on both natural and liquefied (cylindered) gas;

- starts quickly and smoothly;

- has a compact size and low weight (40–42 kg).

Let's also take a look at the technical specifications.

The key parameters are:

- power - from 9.4 to 24 kW;

- the presence of two heat exchangers (copper and stainless steel);

- expansion tank volume - 8 l;

- productivity regarding hot water - up to 11.5 liters per minute.

This model is manufactured in Germany and is covered by a manufacturer’s warranty for a period of 2 years.

Wolf boiler prices

Wolf boiler

Vaillant ecoTec plus VUW INT IV 246

This gas boiler is produced by a German company. Its thermal power is 20 kW, which is enough to effectively heat a room up to 200 m2. This condensing equipment is used both for heating and for preparing hot water. To heat the coolant, the latent heat of condensation is additionally used, which allows the boiler to achieve a high efficiency rate with lower fuel consumption.

Peculiarities:

- the Aqua-Power-Plus function allows you to increase the power to 24 kW in DHW mode;

- the presence of a digital information and analytical DIA system and a built-in eBus module;

- can be used in low temperature heating systems;

- The air required for combustion can be taken both from inside and outside the room.

This is a modern model with electronic control. Thanks to the backlit display, it is easier for the user to control the work.

Vaillant boiler prices

Vaillant boiler

Viessmann Vitogas 100-F GS1D870

This low-temperature gas boiler model is equipped with a single circuit and an open combustion chamber. Thermal power indicator is 29 kW. The device is economical and efficient. Compact dimensions greatly facilitate installation work; the water heater can be installed in a small utility room.

Peculiarities:

- for the manufacture of heat transfer surfaces, special gray cast iron with flake graphite is used;

- automation takes into account weather conditions, which allows the system to consume energy more efficiently;

- Possibility of combination with storage devices.

The only drawback of this model is its high cost.

"RusNIT 208M"

This is a wall-mounted electric model produced by a domestic manufacturer. Using this compact device, you can heat residential buildings, cottages and various domestic premises with an area of up to 80 m2. Stainless steel is used to manufacture the heating element and heat exchanger.

The unit is equipped with three-stage power control - 30, 60 and 100%. The temperature range maintained in the room is from +5 to +30 °C. Water or antifreeze is used as a coolant. Connect to 220 or 380 V networks.

There is a built-in thermal switch that prevents the liquid from heating above +90 °C. If the system is not full, a special protective sensor is triggered. Thanks to its splash-proof design, the model can be installed even in the bathroom.

Peculiarities:

- availability;

- you can connect a circulation pump;

- 2 year warranty.

The only difficulty with this model is the problematic connection to the electrical network, so it is best to contact specialists.

Prices for RusNIT boilers

boiler RusNIT

ZOTA 24 Lux

Powerful electrical equipment that is capable of heating both large cottages and industrial premises with an area of no more than 240 m2. This is a domestic unit, which is compact, easy to operate and affordable. The boiler allows you to maintain the room temperature in the range from +5 to +35 °C.

The heating of the coolant is smoothly regulated, which allows you to combine the device with a “warm floor” system. The presence of an intelligent control circuit is necessary to effectively maintain temperature and save energy. The equipment is connected to a 380 V network.

Peculiarities:

- power – 24 kW;

- Efficiency – 99%;

- The device automatically diagnoses faults.

For reliable operation of ZOTA 24 Lux, it is additionally recommended to install a voltage stabilizer.

Protherm Skat 24 KR 13

This is a Czech model of a high-performance electronic boiler. Its power indicator reaches 24 kW. The unit has 1 circuit and can be connected to a “warm floor” and a hot water boiler. The laconic and compact design allows you to easily place the device.

The package includes: a 7-liter expansion tank, copper heating elements and a circulation pump. Availability of electronic control with indication and display. It is powered by a 380 V network. This is a safe model to use, equipped with many protective systems.

Peculiarities:

- Efficiency - 99.5%;

- soft start;

- the boiler is assembled in Slovakia;

- The warranty period is 2 years.

In any case, in order for the device to be as protected as possible, you will need to purchase an additional stabilizer. In operating mode, the boiler is quite noisy, so it is better if it is installed in a separate room.

Operating rules

You can avoid an accident with a hot water boiler by observing safety precautions during operation.

The service life of the boiler depends on the quality of its manufacture, the solutions used in the assembly and compliance with operating standards. Installation of the device must be carried out in strict accordance with the technical description of the product and the drawing.

Using the device requires compliance with the following rules:

- use only those types of fuel that are listed in the instructions for the device;

- when using solid fuel devices, have containers for filling extracted ash;

- the firebox door must be kept closed at all times;

- ensure that the temperature and pressure established by the regulations are maintained in the circuit;

- the room where the boiler is located must be protected from access by unauthorized persons;

- pressure gauges and thermometers must be checked at least once every 12 months;

- safety valves must be checked and purged before each boiler start-up;

- Regular cleaning of the chimney is required, even if the stove consumes natural gas;

- Having heard the indicator signal about a system malfunction, you need to act quickly, in strict accordance with the emergency stop instructions.

To fill the circuit, you must use water with the salt content and alkalinity standards established for the product in order to prevent the development of corrosion and the formation of plaque inside the circuit.

Installation features

First of all, you need to choose a frost-free room. The installation location is agreed upon with the regulatory services. When purchasing a device, you must ask the seller for a certificate, the presence of which will facilitate registration and obtaining permission for installation.

When choosing a location, you immediately need to think about how combustion products will be removed. You can install separate pipes or use a ready-made chimney. As a rule, heating equipment is already equipped with an exhaust system. During installation, you should be especially careful when connecting the device to the gas supply system.

The general requirements are as follows:

- It is allowed to install boilers only on load-bearing or permanent walls.

- The hood and chimney have similar dimensions.

- The system is freely accessible, which is necessary for maintenance.

- If the boiler is installed in a cabinet, then 5 cm should be left free to the top. It is also important to maintain access to the installation nodes.

When installing it yourself, you need to make sure that the equipment parameters correspond to the power of the heating system. If the wall-mounted appliance is connected to the “old” wiring, all pipes will need to be cleaned and flushed, which will prevent further clogging.

The installation process itself consists of the following steps:

- During installation, a special cardboard template is used to help make fastenings and holes for the chimney.

- Taking into account the free space for technological maintenance of the boiler, a template is attached to the wall. The places of fastenings and connections of wires are first marked on it. These marks must be transferred to the wall using a marker or colored pencil. The template can then be removed.

- Next, prepare the holes for the dowels using a drill of the appropriate diameter. Metal corners are inserted into them. It is important to choose the right dowels, taking into account the material and thickness of the wall.

- The top cover (front panel) is removed from the boiler. This makes it easier to hang the device on prepared mounts.

- Before installing the brackets, check the size of the fittings for the chimney.

- The brackets are securely fastened.

Please note that each wall has its own way of installing fasteners. This is explained by the operational characteristics of the materials, meaning the load that the partition can withstand. Electric heating convectors with wall-mounted thermostat, you will find the answer in the link.

DIY making

It’s easy to make a simple hot water boiler yourself. Here's what you need to consider:

- The choice of firebox material should take into account what type of fuel you plan to use. Coal is characterized by a much higher combustion temperature than wood, so sheets for making a coal boiler firebox should be thicker - thin steel will quickly burn out.

- The ideal material is special heat-resistant boiler steel. In second place is alloyed heat-resistant steel with additions of chromium and molybdenum, for example, grades 12ХМ or 12Х1МФ. If you plan to use ordinary steel, then it should have a grade lower than steel 35. In steels of higher grades, when heated, a hardening effect occurs, as a result of which they become brittle.

Kits consisting of a fan, a temperature sensor and a controller are available for sale (for example, from the Polish company KG Elektronik), with the help of which it is easy to organize forced air supply into the firebox (see above for the description of the operation of a boiler with a fan).