The steel hot water heating boiler Zhytomyr-3 Atem KS-G is designed for heating residential buildings and public utility buildings equipped with continuous heating systems with natural or forced circulation of coolant.

The coolant is water. The device is designed to operate on low pressure natural gas and discharge combustion products into the chimney.

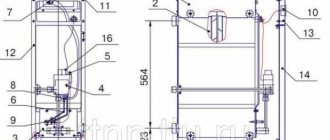

Construction of a gas boiler Zhytomyr-3 Atem

The Zhytomyr-3 gas boiler is made in the form of a rectangular floor cabinet, the front side of which is closed by a door that provides access to start and control its operation.

The apparatus consists of the following main parts: boiler body 1 (Fig. 1), which consists of a firebox and a heat exchanger. Turbulators 18 are installed in the heat exchanger for the most complete selection of heat when burning natural gas and transferring it to the coolant; flue 2; burners: main 5 and pilot 4; safety automatics with gas valve 6; inlet pipes 13 and coolant outlet 14.

The Zhitomir-3 Atem KS-G boilers with a built-in water heater are equipped with 12 connecting pipes. On the front part of the housing there is an inspection window 3 to monitor the ignition and operation of the unit. A thermal indicator cylinder 17 and a thermal cylinder 9 of the gas valve are installed in the cup 7, which serves to control its operation. Thermostat (draft sensor) 10 serves to ensure its safe operation.

For the most complete heat extraction from the outside, the unit body is covered with thermal insulation and a decorative steel casing coated with powder enamel. A temperature indicator is installed in the upper part of the casing to control the water temperature.

When the boiler is ignited, the pilot burner is first lit, which heats the thermocouple and gives a signal to open the gas valve for supplying gas to the main burner.

All boilers are equipped with piezo ignition 16, which greatly simplifies its ignition.

The gas valve installed on the device is a multifunctional gas control device that has:

— thermoelectric protective device for automatic shutdown;

— safety device to protect against incorrect operations;

— a combined thermostat that provides a quick increase (decrease) in gas supply with modulated control from maximum to minimum gas supply;

— adjusting screw for gas supply to the ignition burner;

— gas pressure regulator;

— control points of inlet and outlet gas pressure;

Rice. 1. Design diagram of the gas boiler Zhitomir-3

1 - boiler body; 2 - gas duct; 3 - viewing window; 4 — pilot burner; 5 — main burner; 6 — automatic safety system with gas valve “630 EUROSIT”; 7 — cup of the boiler body for installing thermal cylinders; 8 — machine oil; 9 — thermal cylinder; 10 — traction sensor; 11 — traction sensor wire; 12 — outlet pipe of the water heater; 13 — coolant (water) supply pipe; 14 - coolant (water) outlet pipe; 15 — gas valve control knob; 16 — piezo ignition button; 17 — temperature indicator cylinder; 18 — turbulator; 19 — overheating sensor; 20 - thermal insulation; 21 - flue pipe (manufactured in two versions - vertical and horizontal)

An ignition burner is installed on the body of the Zhitomir-3 KS-G boiler, which serves to ignite it and ensure safe operation.

— Water heater 12 operates on the “water-to-water” principle, i.e. The temperature of the water used for household needs depends on the temperature of the water in the unit.

— Therefore, to obtain the maximum amount of hot water, it is necessary to maintain a temperature of 90°C; for this, when installing the boiler, it is necessary to install an overflow pipe with a valve that connects the inlet and outlet of water from the heating device.

— Using valves, the temperature of the water in the boiler and the temperature of the water supplied for household needs are regulated.

— When operating the device for heating water in the summer, it is necessary to close the valve installed at the inlet completely, and the valve installed on the overflow pipe to open completely.

— A correctly installed unit makes it possible to obtain hot water with a temperature difference of 35°C.

Boiler safety devices Zhytomyr-3

Protection in case of sudden gas shutdown

If the gas suddenly turns off or the pilot burner flame blows out, the heating of the thermosensitive element of the thermocouple stops: the decreasing emf of the thermocouple will turn off the magnetic block of the gas valve, which will shut off the gas supply.

Protection in the absence of draft in the chimney

To protect the KS-G boiler in the absence of draft, a draft sensor is connected to the gas valve.

The traction sensor is a thermal relay that opens the contacts when the temperature exceeds a preset one.

In the absence of traction, the thermal relay placed on the gas duct heats up and opens the circuit connecting the thermocouple to the gas valve. In this case, the magnetic block of the gas valve will shut off the gas supply.

overheat protection

A shutdown sensor is installed on the body of the unit, which, if the temperature of the coolant in the boiler rises above 95°C, opens the circuit connecting the thermocouple to the gas valve.

In this case, the magnetic block of the gas valve closes the valve and the gas supply stops.

FAULTS AND REPAIRS

REPAIR OF GAS HEATTER

BOILER SPARE PARTS

Gas water heaters Atem Zhytomyr - technical properties of floor models

What attracts most domestic consumers when purchasing heating equipment is that the price is not expensive. Most owners of privatized houses will be able to afford devices from common foreign brands due to their high cost. But everyone wants to buy themselves a simple and at the same time reliable boiler at the best prices. Such equipment can be found under the Atem brand, under which they are made and supplied to the market. The more common and common name for the heater is gas boiler Zhitomir .

A gas boiler

floor Zhitomir 3 KS-G-025 SN

The lineup

The price range largely characterizes the model range of gas boilers in Zhytomyr. The boiler names contain alphanumeric designations. The letters indicate the main features of the boilers. The numbers give a characteristic of thermal power.

Floor standing boilers

Floor-standing boilers have a wider range of models. Their price depends on the power of the boiler. Thus, the most powerful boiler ZHITOMIR-3 KS-G-080SN has a thermal power of 80 kW. A floor-standing gas boiler is capable of heating a building with a heated area of up to 800 sq.m.

Floor-standing gas unit Zhytomyr

The presence of an additional letter “B” in the name, for example, ZHITOMIR-3 KS-GV-080SN, indicates a double-circuit gas boiler “Atem Zhitomir-3”, which can not only heat the room, but also heat water.

The amount of hot water produced is proportional to the thermal output of the boiler. This dependence is due to the presence of a copper coil inside the heat exchanger. Boilers with a higher heat transfer value also have a larger surface area of the coils. This explains the high hot water output.

Wall boilers

Wall-mounted boilers have a smaller range of sizes. They are less often installed inside private houses. The main purpose of ATEM ZHITOMIR wall-mounted boilers is heating apartments in multi-storey buildings. Wall-mounted boilers are much lighter in weight. They have a lower heat exchanger area. The maximum area of such devices allows heating up to 150 sq.m of housing area.

Gas wall boiler Zhytomyr

Wall-mounted boilers have a peculiarity - they are connected to coaxial chimneys that exit through the wall.

About the manufacturer and its products

The Atem brand and its Zhytomyr gas water heaters have been known and available to customers for more than 27 years. Undoubtedly, from the beginning of production to the present time, the products have changed a lot. The company's manufacturers are constantly improving units to satisfy all the needs and desires of consumers. This is precisely why Atem is considered a leader in the field of heating equipment in the market of our country.

High quality and durability are key indicators related to boilers of this brand.

Atem products have been repeatedly awarded with various awards. Let’s say, “European quality level”, “Golden Mark”. The units are marked with the “Highest Standard” quality mark.

Gas water heaters Atem Zhytomyr are intended for houses equipped with chimneys. The assortment range is the widest, and this provides a possible buyer with a chance to choose a good model.

Why Zhytomyr boilers?

The Zhytomyr boiler has been known among consumers for more than twenty years. The choice of these products is often due to several reasons

:

- the design of the products uses EUROSIT automation devices made in Italy, which has long been known as a supplier of the most reliable equipment for boiler houses;

- these devices for automatic combustion mode control can turn the gas supply on and off at a certain coolant temperature within 0.08 s;

- when the enhanced gas supply is turned off, the control equipment leaves the pilot burner on, its combustion is always stable, which is a guarantee of successful operation;

- POLIDORO burners are of high quality, they almost never break down;

- The stable flame never breaks away from the edges, which does not lead to malfunction of the combustion process of gaseous fuel.

The boiler is in an open state.

The company has service centers that always have spare parts and components for heating equipment produced there. Representatives ensure that point-of-sale sales managers can provide clear product information.

The media conducts regular surveys of the population about the quality of operation of equipment produced by Atem-Frank. Constant modernization of manufactured products is carried out in order to improve their quality and attractiveness for the population.

Video on the topic:

Boiler specifications

Looking at the owners' reviews of gas water heaters Zhitomir

, it becomes clear why this manufacturer’s equipment stands out so much, why it is so in demand and important.

The equipment is distinguished by a large number of characteristic positive properties when compared with similar competitors. Yes, like any other devices, boilers of this brand also have disadvantages, but in comparison with the large number of advantages, any inaccuracies are insignificant.

Let us note the main positive qualities that Atem gas water heaters have:

- A heat exchanger made of steel, which makes it possible to transfer to water the maximum heat energy that is generated when fuel is burned.

- Full compliance with all Western standards.

- Good and reliable burner design. Thanks to it, the heating unit is considered highly efficient and emits a minimum of substances that are harmful to health during gas combustion.

- Using good automation from a foreign manufacturer. This makes it possible to achieve better technical parameters.

- Simple and convenient control and operation.

- Beautiful design.

- Small design dimensions.

The device has a variety of settings that allow you to adjust the required temperature level. There are installed sensors that monitor the constant operation of the heating structure.

Technical parameters of Atem gas water heaters

Atem company produces:

- gas boilers for floor Zhytomyr ;

- wall devices (parapet).

Units installed on the floor are also divided into single-circuit and double-circuit. Devices with 2 circuits heat water for two or three consumers at low costs. See the technical properties of all Zhytomyr floor-mounted gas water heaters all together.

The productivity of the hot water circuit for floor-standing installations with 2 lines is from 175 to 1400 l/h with a temperature difference of the heated liquid of 35 °C. The device can be equipped with a circulation pump, which is mounted as a function. Parameters of a number of models of double-circuit Zhytomyr parapet type in the table.

Parapet 2-circuit units provide warm water flow from 160 to 345 l/h with a liquid temperature difference of 35 °C.

From the tables we conclude and make sure that the wall-mounted and floor-standing boilers of this manufacturer are adapted to the conditions of low gas pressure in pipelines, and this is their big advantage. A significant disadvantage is the maximum coolant pressure in the heat exchanger, which is possibly very low. For boilers installed on the floor, this is up to 2 kgf/m2, and for suspended boilers, up to 0.7 kgf/m2. Then how can foreign analogues operate at a system pressure of up to 3 kgf/m? Thanks to this, you can make sure that Atem gas equipment is more suitable for gravity systems and small houses with one or two floors.

Professionals do not recommend purchasing wall devices for two-story cottage buildings, since the pressure simply will not be enough for the system to work well.

When, in addition to heating, you also want to receive warm water, it is better to choose models with 2 circuits.

Design features

You can take a look at the general structure of the Zhytomyr unit.

Installation of a gas boiler Atem Zhytomyr

The design features of the heat generator provide independence from electrical energy for absolutely all models of the company. The burner is atmospheric and single-stage, with a simple system, brand POLIDORO, bought in Italy, very reliable and durable.

The automation for Zhytomyr gas water heaters is also reliable; it is also manufactured in Italy. The EUROSIT valve is considered automated, does not depend on energy, is more common among manufacturers of heat-generating equipment; production leaders in domestic and foreign countries install it in their devices.

To transfer heat energy in the heating system of the boiler, a fire-tube heat exchanger made of steel is used. This means that high-temperature smoke gases pass through several pipes immersed in a water jacket. They transfer their heat to the liquid and come out at a temperature of 110-150 °C. The pipes have a cross-section with right angles, and this creates a larger exchange surface area and makes the boiler work more effectively. In models with 2 circuits, there are copper coils around the heat exchanger pipes to heat water for domestic needs.

Movement of smoke gases

To slow down the movement of smoke gases in flame tubes, in pipe coils of mounted and floor-mounted units, turbulators are used. Their backup function is to collect soot deposits remaining on the planes of these parts, which are placed perpendicular to the gas flows, and soot deposits almost do not stop on the walls of the pipes.

In the future, soot can be easily removed from the turbulators, just as when dismantling a heating device, they are removed from the flame tubes. A similar characteristic provides a chance for the surfaces of the flame tubes inside to remain clean and transfer heat energy well to the water jacket. Otherwise, the soot layer that settles on the walls can greatly reduce their thermal conductivity, and the temperature of the outlet gases will become higher, and the heat will go outside.

Gas water heaters Atem Zhytomyr will work well with chimneys with low draft. For this purpose, the equipment has a direct damper, which opens the way for smoke gases to escape without affecting the heat exchanger.

It works like this:

- Before ignition, the damper is opened. There is insufficient draft in the chimney.

- The valve adjustment wheel and the piezo ignition button are pressed in stages, the ignition wick lights up.

- The wheel is turned a couple of times, gas is supplied to the burner and it lights up.

- High temperature gases (up to 200 °C) begin to flow directly into the chimney. Due to the temperature difference in the chimney, the draft increases and the boiler enters operating mode.

- After approximately 6 minutes, the damper is closed and the liquid begins to heat up, but the high traction force remains.

A mounted gas Zhytomyr boiler without a chimney is almost similar to the design of floor-standing equipment. The difference is in the design of the chimney; in suspended units it is coaxial. This is a double-walled pipe through which gaseous, liquid and solid substances move, and street air moves towards them between the walls of the inner and outer pipes.

The burner takes oxygen for its operation not from the room, but from the street, and the combustion chamber is of a closed type. In similar foreign units, a ventilation device is built in for air circulation; in Atem boilers, the overall process is independent of energy and operates with natural draft.

Owner's review of the Zhytomyr heating boiler

Boiler repair and adjustments Zhitomir

A floor-standing boiler Zhitomir-3 KSGV-10 sn was installed, the first year everything was fine, but this year, when the main burner ignites, a crackling sound (and a strong one) and the sound of boiling water can be heard from the device, what is the reason and how to eliminate it? The radiators all heat up well, and how dangerous is this? Will the unit burst? Condensation drips onto the burner. Warm up the boiler and heating system well - the sound should disappear. I checked with an electronic thermometer on 1st 84-85 degrees, on 3rd at 90 degrees it did not work, turned it off manually, the oil was filled. The thermostat may need to be replaced. There is no way to take the device back to the store. Most likely, the gas valve has failed, and the 95-degree overheating sensor is also responsible for the safe operation of the boiler. The gas boiler Zhitomir-3 KS-GV-10 SN with Eurosit 630 automation is in operation. A heating area of 80 sq.m. was installed a couple of months ago. 1 - the first room, which is closer to the device, heats perfectly, the second is very bad, and this is if it is with a pump. If you turn off the pump, it barely heats up at all. 2 - water is constantly dripping onto the burner, and this despite the fact that it heats at 60 degrees. 3 - it’s impossible to get rid of the air pocket in the last battery in a distant room. Two sections of the last battery are cold, the pump was installed on top. He works constantly on one. What are we doing wrong, what is the problem? Before this, there was an apparatus, it heated all the rooms perfectly, heated all the radiators, they were hot and heated up very quickly, but this was a real problem. We have already spent a lot of water because we are constantly adding water, please help! This is clearly not a matter of the boiler. You need to look at the heating system. If the device heats water, it should circulate even without a pump. Be sure to check all hydraulics. I tried to turn on the device, but it didn't work. Explain what a throttle valve is and how it should be in order to open the Zhytomyr 3 boiler. The throttle valve allows you to temporarily increase the temperature of the exhaust gases, due to which the chimney warms up faster and, accordingly, good draft occurs, which makes the initial start-up of the device much easier. The principle of operation is this: before igniting the boiler, you must fully pull the damper handle towards you. After the chimney has warmed up, the handle must be pushed back. A more detailed description of the operation is in the insert to the instruction manual. A floor-standing boiler Zhitomir-3 was installed for 120 sq. m., it is difficult to light the wick. What could be the reason? Does not light well due to a clogged pilot burner (wick). I have 250 sq.m., please tell me whether it is worth installing an Atem boiler, could there be problems with it and which one should be installed on such an area? If you install the boiler correctly there will be no problems. According to the calculation, 1 kW of the device per 10 sq.m. with a ceiling height of 2.5 m, and also pay attention to the amount of water. Malfunction of the Zhytomyr parapet boiler with Eurosit 630 automation, shuts down above 60 degrees, help. The traction sensor is the one that triggers the most. Check the chimney. The Zhitomir gas boiler has been in operation for 5 years, a week ago it froze at 45 degrees and is not adjustable, it is constantly on. What could be the reason? It is possible that the gas supply pipe from the automatic control system to the burners and the burner nozzle are clogged. Tell me, is it possible that due to low gas pressure the Atem Zhytomyr boiler goes out, a click occurs and goes out. What is the problem? Is it possible to temporarily disable automation and how? It is forbidden to turn off the automation. It's not safe for life. Regarding low gas pressure, contact a service center. It is quite possible that the problem is not the pressure, but a clogged gas supply pipe or poor draft. A Zhitomir-3 floor-standing boiler has been installed, tell me how to switch it so that there is no heating in the summer, but there is hot water? Close the supply tap (if there is one naturally). The Atem Zhitomir-M 12 CH gas boiler with Eurosit 630 automation is in operation. Installed this year. The first heating season is coming soon. Tell me: what temperature to set the numbers to take a shower. And one more thing: what temperature corresponds to each indicator from 1 to 7. For example: what temperature will it be when set to 2. The numbers on the control knob are not strictly tied to the temperature. They serve for ease of use of the device. And the temperature depends on the individual operating conditions (thermal insulation of the room, amount of water in the system, heated area, etc.). For orientation - “1” - 40 C, and “7” - 90 C. Gas boiler Zhitomir-M AOGV-12 SN. The technician installed it and did not say that the expansion tank was set to 0.9 atm. How many atmospheres can I pump cold water into the system when starting the boiler? I pumped 1.2 atm according to the pressure gauge. The pressure dropped all the time, there were no leaks anywhere. And on the second day the device leaked. And all the water is under him, on the floor. How can I fix it? What could have caused the breakdown? Tell me how to take it apart? The maximum pressure, according to the instruction manual, is 0.7 atm. You put 1.2 atm into the system. cold water and “crushed” the expansion tank, practically eliminating it from the heating system. After heating the boiler, the pressure, accordingly, increased further, and most likely because of this, the tightness of the heat exchanger was broken. For repairs, it is best to contact the service department and there you will see whether it is possible to fix it on site, or to completely replace the unit housing. Here’s a question: a house of 210 sq.m., 2 floors, so that there are no problems with gas workers, the boiler power should not exceed 23 kW. In operation Atem 20 by 220 sq.m. Will it be enough? It depends on the height of the ceilings. 220 sq. m is the estimated area for a ceiling height of 2.5 m. If it is higher, the volume of air is correspondingly larger and the device is needed more powerful. But, on the other hand, if the house is well insulated and heat loss is kept to a minimum, then it is quite possible to install. Malfunction of the boiler Zhitomir 10. When heating, there is a strong knocking sound in it, as if it is boiling. What is the reason? Won't it be torn apart? The unit is not leveled correctly or the heating system is clogged. The device has nothing to do with it. A floor-standing boiler Zhitomir 3 Atem KS-GV-12 SN (12.5 kW, 630 Eurosit) was installed; after 8 years of operation, it stopped turning off when heated and began to work continuously, raising the temperature to over 80 degrees. What could be the reason? This is your problem with automation, i.e. The thermostat does not work, you will have to change the automation completely. I turn on the Zhytomyr parapet boiler (new). Everything is working. I turned it on in the evening, everything worked until night. We woke up in the morning and the boiler had gone out. And already three times. Before this, they turned it on once, everything was fine, and then it got warmer, and they turned it off, and the second time there were such problems. There is a craving. He worked for at least exactly three hours. This is most likely due to oxidation of the traction sensor, it does not see the contact and because of this it quickly goes out. It is necessary to clean the connections until they are shiny and the boiler is working. The Atem Zhitomir-3 KSGV-10 SN gas boiler with Eurosit 630 automatic switches off. It began to go out on low and medium gas. From 1 to 5 it will work and the gas supply will be turned off. It works fine on 6 and 7. The second season has worked, the circulation pump is installed. It even happened that the igniter did not light up, cleaned the terminals, worked normally for about a day and began to turn off again. In principle, it’s already spring and I don’t want to call an unfamiliar gas worker. Yes, maybe I can figure it out on my own. Can anyone tell me what the problem might be and its solution? The igniter flame - the root third is bluish, the middle and top are yellow, fluctuates quite strongly. The main thing for me is to know whether there is a problem with the automation or whether everything just needs to be cleaned? In general, in the fall there was a strange symptom: if you turn on the igniter and immediately turn on the burner, the gas supply turns off after a minute or two. And if the igniter burns for five minutes, the gas supply does not turn off. We had a similar situation. During assembly, the thermal breaker was not fully screwed into the magnetic valve. Apparently the contact between them was not initially the strongest, and over the two seasons of work the contact worsened. And apparently, at 1-5 there was not enough contact, but at 6-7 there was enough. We tightened it a little more and everything became normal. I had the following problem: my gas boiler Zhitomir-M (parapet), installed in 2006, began to go out. The most interesting thing is that it goes out in position 2 and 1 in position 3 lights up without problems. This happened just yesterday, before that everything was normal. The house is heated by a gas boiler Zhitomir-3. Atmospheric gas burner with igniter. Is it possible to install an electric ignition so that the device ignites without an igniter? My igniter goes out and, interestingly, at a certain wind direction. I do not know what to do. If the pilot burner goes out while the main burner is running, try reducing the gas pressure to the main burner. When starting the boiler, while gas is supplied to the igniter, the following happens: I press the gas supply “key”, gas flows to the igniter, I release the gas “key” - it still “goes”. The metal plate does not heat up as before; gas has to be supplied to the main burner immediately. This phenomenon began gradually, from year to year it was necessary to hold down the “key” less and less, now it is not necessary at all. And to top it all off, the boiler began to go out, up to 5 times a day. It used to happen that it would go out once a season. I checked the traction - the traction is excellent. Can you see something wrong with the equipment? I advise you to switch to automatic Sit. Atem boiler malfunction. Installed automatic 710 minisit. 2 days already problems. 2 times, after much torment, I managed to turn it on, but it turned off spontaneously. Now when you press the ignition button, gas flows and ignites from the button. According to the instructions, you need to hold it for 10 seconds, but it turns off. The traction is normal, I replaced it with a new one. 3 meters higher than the roof, not blown by the wind. The thermocouple is ok, I checked it with a tester, when heating the current reaches 22-23 mVolt. I also cleaned the contacts. What could be the reason? How does the operation of the safety magnetic valve installed in the automation depend on the presence of air in the expansion tank? Last year I bleed the expansion tank by mistake and it worked until the end of the season. This year I worked for a month. On the advice of specialists, I decided to pump it with air and drained all the water from the system the day before yesterday and at the same time change the exhaust pipe. It was not possible to pump in air, there was a problem with the pump, and the pipe was changed. And from then on the problems began. To light the igniter, neither draft nor water is needed in the system. If the thermocouple is ok, then look for a bad connection somewhere or an open in the draft sensor. Can be short-circuited temporarily. And then - more, in the automation itself, for example, EHR. The parapet boiler goes out, I light it with a piezo ignition, the wick burns as long as I hold the button, as soon as I release the button it goes out. What could be the reason? Boiler Zhitomir, automatic 630 Eurosit Italy. We unscrew the nut that goes into the valve, and pull out the copper tube (thermocouple tail, not gas!). Then, using the tester, in the ohm-kilo-ohm resistance measurement mode, we measure between the center and the tube. If the readings of the device do not change, then the thermocouple has burned out, if they change, you can torture it further - we light the wick, set the tester to millivolt mode, and measure the voltage after 10 seconds. About 20 mV is normal, more is better. If it is less, then perhaps the flame is barely reaching the sensor - then we unscrew the igniter and clean it (in the picture in the center). That's it with a thermocouple. Now the valve. Resistance tester, one contact on the metal of the valve, the second in the center of the hole, from where the tail of the thermocouple was pulled out, without touching the edges of the thread with the probe. If it's about 0 ohm, then it's normal. If you want, then look further - the battery with one pole (no difference) on the metal, the second in the center of the valve (insulated wiring). We press the button, light it and immediately release it (no need to wait). If it continues to light, the valve is normal. If the contacts have been oxidized, they will be cleaned after unscrewing and tightening. If there is a draft sensor (in the chimney area, with two wires), we close its contacts (you can use a paper clip in place, or you can insert one into the other). A gas boiler Atem-10 was installed (Zhitomir 3). This year I made myself a closed heating system using polypropylene pipes with aluminum radiators, it worked fine for two months, and then suddenly the pressure in the system began to drop. I checked everything, there are no leaks anywhere, I tried pumping water into the system and pumping pressure into the expansion tank, it helps, but for a while, after about a day, the pressure gradually begins to drop. Tell me what to do? The pipes are all open (i.e. visible and easy to access), my highest point is the protection group, which is located immediately behind the boiler, the pressure was previously maintained at 2 atm. I checked the expansion diaphragm - normal. Your boiler is sectional (made up of separate sections), I would start by checking it. Fill with air (no need for water - it expands much more when the temperature rises) to the maximum pressure (look in the passport) and leave for a day. After this, you can check the entire system in the same way (if necessary). But these are things for the month of May. Now you can lower the pressure in the system to 1 Atm. and (if the leak stops) sleep peacefully. In your case, the pressure in the system is only needed to reliably close the automatic air vent. Pay attention to the membrane tank. Personally, I had a case with a pumping station: I bought (for installation) a 50 liter hydraulic accumulator, immediately after purchase I checked the air pressure of 1.2 atm, installed it because... it was supposed to work with a water pressure of 6 atm. pumped up the air to 2 atm. After 2 weeks they called - “the pump twitches” (i.e. it constantly turns on and off), pumped up the air - after 2 weeks the same thing, after a very long search they found 2 microscopic pores in the weld seam of the air cavity of the tank. We brewed it with argon - everything was fine for 2 years. We installed the Atem boiler with Eurosit 630 automation. We connected it, pressurized it, everything was fine. We lit the igniter according to the instructions, it burns normally. Then we turn on the main burner, 15 seconds pass, and the entire burner turns off (both the igniter and the main burner). Because It’s impossible to find a specialist, I’m asking for help - what can I try to check first? I began to understand the automation device of Eurosit 630. As far as I understand, there are two sensors that cause an emergency shutdown of the gas valve - a reverse draft sensor (thermistor?). And a thermocouple next to the igniter is a flame absence sensor. I checked the draft - it sucks in smoke from burning paper well. I removed both connectors from the traction sensor contacts and shorted them together. As a result, the valve began to turn off after about a minute (initially it turned off after 15 seconds). So it's not the traction sensor? I assume that the malfunction may be caused by a weak igniter flame; turning on the main burner may deflect the pilot flame away from the thermocouple. Please advise on replacing the draft sensor on the Zhitomir-3 boiler. It began to go out, I found out the fault - apparently the draft sensor is faulty, it is marked 75 C. Question - I will buy a sensor on the market, I couldn’t find one for 75 C, they suggested I buy 95 C. Will this be normal for the boiler? Or should I still look for a 75 C sensor? 95 is a lot. When the outside temperature is above zero degrees, the automation turns off after a minute. You can run it a hundred times and it shuts down a hundred times. Parapet boiler Zhytomyr. Where and what needs to be adjusted so that the boiler works at any outside temperature? There is no need to twist anything anywhere! Due to the fact that when the outside temperature rises, the draft from the igniter “blows out” the flame. Tell me, the difference in characteristics, filling of thermal cylinders for Eurosit 630 automatic boilers. For boilers, 42-82 degrees. Malfunction of the Atem parapet boiler, automatic 630 Eurosit. The size of the wick torch has decreased; the device does not turn on again after the temperature drops, as the wick goes out. The filter in front of the boiler is clean, the tube on the wick is also not clogged. I enlarged the hole in the wick nozzle - the wick torch increased, and the work returned to normal. A week later, the size of the wick plume decreased again and the problem returned. I checked everything that I checked before - everything is clean. They advised to increase the size of the wick torch in the boiler automation with an adjusting screw; I twisted and increased the torch slightly and this did not help. I also checked the chimney, it is clean. Does the amount of gas at the wick nozzle (pilot burner) produce a sufficiently large amount of gas? Is the injector clogged with debris? The tube to the pilot burner from the valve is intact - are there any gas leaks? Are the air suction holes for the pilot burner not closed? Is the pilot burner itself clogged with debris? The wick does not burn with a yellow flame? Does the wick go around the edge of the thermocouple? Is the thermocouple intact - does it produce the required voltage? Are the draft and overheat sensors (if equipped) normal? Is there any current leakage or voltage loss on the wires leading to the sensors? Is the pilot burner wick not being blown out by through air? How to check the draft of a boiler and not a chimney? Zhitomir-3 KS-GV-12 SN was installed (chimney outlet up). The instructions don't say anything specifically, just a drawing from which you can't understand anything. Like, put a sheet of paper on top of the device. I can’t figure out where exactly to place the sheet of paper. The installer didn't understand it either. The instructions say that you definitely need to check. I don't know, no one has pointed out how to check the traction. They always only brought a match to the window. And it’s not clear why they should be brought up. The boiler is working anyway. The only question is the length of the pipe. And the fact is that its internal diameter is not much larger than the total diameter of all outlet holes.

Model Atem Zhytomyr 3

Undoubtedly, the company’s assortment includes many models with different parameters. However, the sales driver is considered to be gas boiler Zhytomyr

3, so we need to analyze it in more detail.

The model stands out not only for its good price, but also for its excellent technical parameters.

The power of the unit is 10 kW. It can heat an area of more than 100 m2, and this is enough for a house outside the city. As for gas use, it must be stated decisively that the equipment is economical.

Efficiency - 92%. Owner reviews of the boiler

on

gas Zhitomir 3 are usually good. Almost all customers note the small size, convenient operation and reasonable price.

How to light a gas boiler Zhytomyr

There is a regulator with divisions on the boiler, which must be set to zero. Then open the gas supply on the pipe in front of the boiler and press the regulator like a button and light the wick with a match. After the wick is lit, you need to hold it for 10 seconds and slowly release it. Then set the regulator to the desired compartment (approximately 2).

If you are unsure of your own actions, call the gas service. They will tell you in detail and explain how to turn on a gas boiler in Zhytomyr.

Breakdowns

Let's consider the possible breakdowns of gas water heaters in Zhytomyr, which may appear during use, and options for solving them.

All breakdowns of gas communications and gas boiler valves must be repaired only by authorized professionals.

Disruption of water movement

If the movement of water along a closed circuit is difficult or there is no water in the heating system at all, the reason may be hidden in:

- insufficient amount of fluid in the system;

- presence of air in the heating system;

- water leakage from the heating system;

- significant scale deposits.

This damage can be removed by taking the following steps:

- Refill the heating system with water.

- Release the air by filling the heating system with coolant from below.

- Identify and clean up fluid leaks.

- Clean and flush the system.

Reduced heating efficiency and increased gas consumption

If such a problem occurs, then the reason is most likely the following:

- the heating system is installed incorrectly;

- a lot of scale was deposited.

To get the system working, you need to:

- Correctly install the heating system.

- Clean and flush the boiler.

Condensation forms

If drops of water appear and flow onto the key burner, then most likely the reason is the low temperature of the coolant. To remove this nuisance, you need to warm up the boiler.

The burner goes out

Gas boiler Zhytomyr

does not ignite, and this means the acceptable reasons are:

- not overheating the thermocouple;

- low gas pressure in the system;

- damage to the safety automatics or gas valve;

- loosening of the thermocouple.

This breakdown can only be resolved by calling a gas service professional.

Cotton when igniting

If a pop is heard when the boiler is ignited, then most likely this indicates a poor fire connection between the ignition and key burners. Gas pressure is too low.

In this case, only a master can help.

Burner extinction

If the boiler is on gas Zhytomyr

If both the main and pilot burners go out, then the reason is poor draft. How to fix this problem? Insulate the chimney and remove air suction.

These are the main reasons why breakdowns may occur with a domestic unit.

Now gas water heaters Atem Zhytomyr

are top sellers in their own position. Good technical parameters, excellent quality and budget price make the brand’s products extremely popular. Having decided to purchase a Zhytomyr device, the consumer remains satisfied with the purchase. Due to the fact that such equipment makes it possible to organize reliable and stable heating of the house.

Solid fuel boiler Zhitomir-9 KS-G-016SN/AOTV-12

| Type of fuel | Natural gas according to GOST 5542-87/Solid fuel - anthracite JSC DSTU 3472-96 |

| Fuel combustion efficiency (COP), not less than % (gas/solid fuel) | 92/78 |

| Gas pressure, Pa (mm water column), nom./min./max. | 1274/635/1764 |

| Coolant | Water pH7 |

| Maximum water temperature at the boiler outlet, no more than °C | 90 |

| Recommended coolant temperature, °C | 60-80 |

| Coolant operating pressure, no more than, MPa (kg/cm2) | 0,1 (1) |

| Maximum pressure in the hot water supply system, MPa (kg/cm2) | 0,6 (6) |

| Vacuum behind the boiler, Pa, no less - no more (gas/solid fuel) | 2/25 — 8/10 |

| Temperature of combustion products at the boiler outlet, not less, °C (gas/solid fuel) | 110/140 |

| Rated thermal power, kW (gas/solid fuel) | 16/12 |

| Heated area, m2, up to (gas/solid fuel) | 160/120 |

| Volume of water in the boiler, l | 44 |

| Water consumption for hot water supply with a temperature difference Δ t 35°С, not less than kg/year (at a coolant temperature in the boiler of 90°С) | — |

| Nominal gas consumption, normalized. conditions, m3/hour | 1,58 |

| Anthracite consumption, kg/hour | 1,8 |

| Overall dimensions of the firebox, mm | 300x315x500 |

| Conditional diameter of connecting pipes to the heating system, mm | 50 |

| to the gas supply system, mm | 15 |

| to the water supply system, mm | — |

| Overall dimensions, mm, no more (height/width/depth) | 1135x595x580 |

| Boiler weight, no more, kg, net/gross | 131/134 |

kotly.zhitomir.ua

How to start a gas water heater for the first time

When arranging a heating structure, many homeowners prefer installing double-circuits. These heating units, when installing the newest models, are distinguished by their reliability, they are economical and allow you to provide hot water in the house, but you need to know how to start a gas water heater correctly the first time.

In order for the device to work for a long time and without repairs, it is necessary to properly organize the first start-up of the gas boiler, during which the system is filled with water and the air that has entered them is removed from the pump and heating radiators. To facilitate this process, specialized devices - air vents - are used for heating devices. They should be unscrewed until water comes out of them. To prevent air from remaining in the pump, first remove the front panel of the unit and make the necessary adjustments. Air pockets are quickly removed, and the equipment is put into operation on its own.

Design Features

The main elements of the Zhitomir boiler are

:

- a housing in which the main components and equipment are installed;

- gas burner unit located in the firebox. Here gas combustion occurs and heat flow is released;

- recuperative heat exchanger, in which heat exchange occurs between combustion products and coolant;

- gas exhaust system, its responsibilities include removing combustion products outside the boiler and releasing them into the chimney.

Construction of the Zhitomir boiler

In order to increase the efficiency of heat transfer, the gas boiler Atem Zhitomir 3 has the following design features.

- The heat exchanger pipes made of heat-resistant steel have a rectangular cross-section; this device allows you to increase the contact area of the flue gas and the coolant.

- The counter movement of coolants was organized, this solution made it possible to increase the efficiency of the heat exchange device to 92%;

- To increase the area of interaction between combustion products and the coolant, as well as to prevent the accumulation of soot on the surface of the steel pipes of the ATEM boiler heat exchanger, turbulators are installed. Soot accumulates on the lower surface of the turbolizers, while the pipe walls remain clean. To remove soot, you need to periodically remove the turbolizers and clean them of soot.

- Gas double-circuit turbocharged boilers in Zhitomir have a coil of copper pipelines around the heat exchange heating pipes.

Double-circuit gas unit Zhytomyr Atem

To organize a stable gas combustion process, a POLIDORO gas burner device is used. Its distinctive feature is a single-stage atmospheric burner. The edges of the burners themselves are made of heat-resistant steel, which allows you to maintain the combustion mode at different gas supplies to the firebox. Even at low gas consumption, the heating of the edges is sufficient to maintain stable combustion.

The gas supply mode is regulated by the EUROSIT gas valve. This device automatically switches the gas supply to the burners depending on the temperature of the coolant. The user independently sets the temperature of the coolant, focusing on the temperature in the open air. As the ambient temperature decreases, the temperature of the coolant increases.

How to start a gas water heater: preparation

There are simple instructions explaining how to start a gas water heater , which is shown in the photo. The initial start-up is performed when the installation and wiring of all components of the heating equipment is completed, and the accuracy of the work has been verified by the relevant authorities.

The location of the heating unit must be selected in accordance with safety standards and regulations that do not allow the occurrence of fires. Boiler

must be at a certain distance from the wall surface, which depends on the manufacturer’s advice. By the way, for certain models of gas appliances this requirement is not considered important. You also need to make sure that there are no flammable materials or objects nearby.

Plus, it is not allowed to place boilers near windows, because their operation is disrupted. The even placement of the device body is of great importance - even slight distortions are not allowed. After installation is completed, they begin to connect the equipment to a source of cold water: remove the plugs from the pipes, and place a filter with a tap with a round hole at the entrance. Such a device protects the heating structure from a variety of contaminants that cause problems. Valves with a spherical shut-off element must be built into all pipe sections used for piping.

Solving the problem of how to start a gas

water heater, great attention should be paid to the pipe connections from the gas main. These installation works are not carried out with one’s own hands, but rather involve professionals from the relevant services who are involved in connecting, sealing and, if necessary, installing a gas meter.

Before turning on the gas water heater , a separate power line should be installed specifically for the heating unit. The equipment must be equipped with an electrical cable and plug, and a socket must be installed next to the device, separating it from the rest. After which the boiler is connected to the chimney pipe, in which the draft and its performance are checked. She should go outside. The installation work to install a chimney depends on the type of heating device.

Having completed preparations for startup, the boiler is disconnected from the electrical supply to fill it and the heating system with cold water. Then they check that there are no leaks, turn on the thermostat to the maximum value so that the operating mode toggle switch lights up in automatic mode.

Rules for filling the system with water before turning on the gas water heater

Before lighting a gas water heater

, and turn on the heating system, first of all it is filled with cold coolant, which, after heating, will circulate through the pipes and heating devices. When performing the first launch, everything is carefully checked so that subsequent work is trouble-free and the equipment does not require repairs.

In the body of the unit there is a specialized tap, located near the pipe section, to supply coolant into the system. During the filling process, the system pressure is monitored due to the presence of sensors and instruments for determining the pressure value. Modern boilers already have them, and there is no need to buy them additionally. When the device is filled with water, the mark on the meter rises. When it reaches 1.5-2 atmospheres, the water supply is shut off and filling is completed.

These pressure parameters can be changed because they depend on the manufacturer's requirements for the operating pressure in the heating system. But filling with cold water does not end there entirely, because replenishment will be needed after the structure is freed from air pockets.

Installation and installation of boilers Zhytomyr-3 Atem

___________________________________________________________________________

Recommendations for installation and assembly of the Zhytomyr-3 Atem boiler

Installation of the Atem KSG boiler and installation of the heating system are carried out by a specialized organization and gas service in accordance with the project approved in the prescribed manner.

The room in which the device is installed must have supply and exhaust ventilation.

The chimney into which combustion products are discharged must be commissioned by an act of a specialized organization.

The installed boiler is put into operation by the local gas service with mandatory instruction from the owner and a mark in the passport of the tear-off coupon for its commissioning.

The boiler must be installed in accordance with this operating manual.

When connecting the Zhitomir-3 boiler, first perform a pneumohydraulic flushing of the heating system.

The selection of heating devices and pipeline diameters in the heating system in each individual case is made on the basis of calculations and is indicated in the project.

When installing the unit in a heating system with an open expansion vessel, the installation of an overheating sensor is not required, provided that failure of the control thermostat does not cause a dangerous situation for the user or damage to the device.

When installing the Zhitomir-3 KS-G boiler in a heating system with a closed expansion vessel, installing an overheating sensor is mandatory!

Connections to water and gas communications must be checked for leaks.

The device must be connected to the chimney using roofing steel pipes. The diameter of the pipe must be at least the size of the flue.

The pipes must overlap one another along the direction of removal of combustion products by at least 0.5 of their diameter and be sealed.

It is possible to connect the device to the chimney with a flexible corrugated metal pipe in agreement with the gas service, but the manufacturer does not recommend using a corrugated pipe, as draft problems may arise.

The connection between the flue pipe and the chimney must be sealed. It is not allowed to connect other heating devices to the boiler chimney and install a damper on it.

The gas boiler Zhitomir-3 Atem KS-G operates with natural draft created by the chimney, so it must meet the following requirements:

— The chimney to which the Atem KSG boiler is connected, as a rule, should be located in the internal main wall of the building.

— When making a chimney from metal or asbestos-cement pipes, they must be thermally insulated.

The design of the chimney must ensure that the temperature of the combustion products at the exit from it is not less than 400 C. This protects it from the formation of condensation in it and subsequent destruction;

— The cross-sectional area of the chimney channel must be no less than the cross-sectional area of the chimney pipe of the apparatus, but not more than 1.3 times;

— The chimney channel must be vertical, smooth, even, without protrusions, turns, narrowings and cracks;

— The height of the smoke channel from the level of the main burner must be at least 5 m.

— In the lower part of the chimney channel below the entrance of the boiler flue pipe there must be a “pocket” at least 250 mm deep with a hatch for cleaning the chimney. Air leaks through the hatch are not allowed;

— It is prohibited to block the chimney section of the Zhitomir-3 boiler with the chimney pipe. The chimney must be installed above the wind pressure zone.

The height of the chimney above the roof of the house is set depending on its horizontal distance from the ridge and should be:

- at least 0.5 m above the ridge, if the pipe is located at a distance of up to 1.5 m from the ridge;

- not below the ridge level line, if the pipe is located at a distance from 1.5 m to 3 m from the ridge;

- not lower than a straight line drawn from the ridge down at an angle of 100 to the horizontal when placing pipes at a distance of more than 3 m from the ridge of the roof.

The connection of the Zhytomyr-3 KS-G boiler to the gas pipeline is carried out only by gas industry workers.

Fill the heating system with clean water with pH7+0.3. When filling the system with hard water with a pH greater than 7, scale deposits on the walls of the unit and heating system significantly increase, as a result of which efficiency decreases and gas consumption increases!

The expansion tank is located at the highest point of the system. Monitor the filling of the system with water through the overflow pipe. The volume of the tank must be at least 8% of the volume of the heating system.

Boilers Zhytomyr-3 Atem with automatic safety and gas valve 630 EUROSIT

The initial position of the round control handle is in the “off” position.

Turn the control handle counterclockwise to the ignition position. Press the control handle all the way and, without releasing it, press the piezo ignition button (a flame should appear on the pilot burner). Do not release the control handle for 20-30 s.

Release the control handle and check for flame at the pilot burner. If there is no flame, repeat this operation, increasing the time the control handle is held down.

To turn on the main gas burner, smoothly turn the control knob counterclockwise to position 1…7. The maximum coolant temperature corresponds to number 7 on the control handle.

Control the temperature with a thermal indicator; the temperature of the coolant (water) is adjusted by the gas valve thermostat through a thermal cylinder inserted into the cup of the Zhitomir-3 Atem KSG boiler body.

Turning off the main burner: To turn off the main gas burner, smoothly turn the control knob clockwise to position (*), while the torch will burn on the pilot burner;

Turning off the boiler: To turn off the boiler completely, turn the control knob clockwise to the “off” position. When turning off the device for a period of less than 24 hours, it is recommended to leave the pilot burner on.

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

wssm.ru

Removing air pockets before lighting a gas water heater

Before lighting a gas water heater

, it is necessary to fill the heating structure with liquid cold coolant. But just filling with water is not enough. It will either not work, or the degree of heating of the room will be insufficient. A real first start is impossible without releasing the air accumulated in the system. Often modern gas water heaters have a specialized system that automatically releases air when filled. However, its effectiveness is often insufficient: you will still need to manually reset the air jams. Only after this can you launch.

Remove air pockets before turning on the gas water heater

, it is necessary not only from the heating unit, the circulation pump, but also from all heating radiators. The process must begin with batteries - for this, as mentioned above, they are equipped with air vents. They are opened by placing a container underneath. First of all, a light whistle will be heard, which means that air is gradually leaving the system. After removing the plugs, water begins to flow. Then the taps are closed. A similar operation should be done with each of the heating devices.

Valuable advice

To start the boiler , power must be supplied and the heating regulator must be set to the desired operating position. The presence of a weak hum indicates that the circulation pump has started working. Using a screwdriver, you should lightly unscrew the cover of the detected part. However, this must be done before the water starts flowing. If the liquid begins to break through, screw the cap into place. These actions are done a couple of times and after which the air pockets will be completely removed from the system. The gurgling sounds will also disappear and the pump will run quietly.

Specifics

The ATEM brand has invested all its efforts in the development and production of a good device for individual heating. For more than 27 years, the company has been providing heat to its own consumers in the form of gas water heaters “ Zhitomir ”. Since the inception of the first boiler, a very large rebranding has been carried out, the device has received changes from the internal base of spare parts to the external design. Nowadays, the Zhitomir boiler

"is a neat, small-sized block with switching instructions that even a child can handle. The main quality characteristic of boilers of this brand is the reliability and quality of the device. The technical properties of products have also changed with the emergence of recent technologies. Not only these components, but also other facts made it possible for the ATEM brand to acquire the “European Quality Level” award.

But the company did not stop there, the Zhitomir received the “Golden Mark” and “Highest Standard” awards, proving to everyone that they occupy first place in the world market.

Characteristics

Nowadays, products represented by Zhitomir are recognized as the most modern and popular. To understand why this brand itself has gained consumer recognition, we should consider a number of models in more detail. Each individual equipment has a great advantage in comparison with similar devices from other manufacturers. There are disadvantages in Zhitomir boilers, as in any product, but the presence of advantages outweighs the importance, showing that the equipment has many more good qualities.

Gas water heaters “Zhitomir” have a number of advantages, thanks to them they are in great demand on the market.

- The heat exchanger of the device is made of steel. Because of this, the water receives the maximum heat that is generated when the gas burns.

- The design of the burner is thought out to very small details. Actually, this characteristic helps to increase the productivity of the device, and the level of release of bad impurities is minimal.

- Imported automation of each boiler makes it possible to achieve the best characteristics.

- Ease of device management. There are no unnecessary buttons or toggle switches.

- The design of the equipment is developed according to the latest fashion. The boiler

does not take up much space, and in appearance it is similar to a small bedside table, which fits into any setting. - During the manufacturing process, each individual model goes through several stages of testing according to Western standards. And after completing all tests, he receives a quality document.

Many settings in the Zhytomyr boiler system make it possible to choose a suitable and convenient state for yourself. Specialized sensors, which are also equipped in the system, monitor the device’s safety and trouble-free operation. Taking into account all the positive qualities described above, we can safely say that Zhytomyr

» are perfect for heating privatized houses, and will cope well with their own work in the apartment and in other rooms. It should be noted that not only the bright design and ease of use attract consumers, but also the price issue.

Cost of the boiler " Zhitomir"

"meets the condition "price - quality", and this quality will not hurt your pocket.

General information

The modern gas heating boiler ATEM Zhytomyr has high performance and compact dimensions. The use of foreign automation allows us to achieve optimal performance.

The user has access to many settings, which allows him to maintain the desired temperature in the room. Sensors will ensure that everything works without interruption. Consumers love Zhytomyr boilers, and reviews emphasize the optimal price-quality ratio.

Advice! The cost of a Zhitomir boiler today is 12-45 thousand rubles. Moreover, products at the upper price range have high performance and are capable of heating large areas of premises, suitable for heating multi-storey private houses. For heating a small house or apartment, a modification in the middle price range, up to 20,000 rubles, is suitable.

Varieties

Nowadays, several types are used Zhitomir For their part, floor products also have divisions into single-circuit and double-circuit.

If a gas water heater

needed only for heating purposes, you need to pay attention to single-circuit models.

They are undemanding, convenient and economical. Equipping a single-stage boiler " Zhitomir " first of all involves foreign components.

Thanks to them, the device can be turned on and off if necessary. And if there is a need, in addition to heating, to have hot water in direct access, you will need to select from dual-circuit options. Due to price demand, double-circuit units are a little more expensive, but they also provide double pleasure to the consumer in their work.

According to their own characteristics, floor-standing boilers mostly have the following similarities:

- the highest temperature limit is +90 degrees;

- Efficiency is 92%;

- gas pressure – 635 Pa.

However, when selecting exactly the model you like, you need to consider its specific characteristics and capabilities.

The same zoning as for floor-mounted boilers is also found in wall-mounted boiler models. They can also be single-circuit or double-circuit. The efficiency of all devices is similar. The same applies to gas pressure.

But it is still necessary to consider their characteristics in more detail:

- the power of chimneyless boilers must be at least 5 kW and less than 20 kW;

- the thermal fluid in the device is no more than 17.5 liters;

- depending on the model that was selected, the network gas consumption is considered; standard – 0.56–1.67 cubic meters per hour;

- economy due to imported automation.

For its part, the manufacturer provides a wide range of boilers to choose from, but the Zhitomir -3 KS-G-020 SN model is still in incredible demand. This device differs from its counterparts not only in terms of affordability, but also has clear technical data. The design of the device is designed in a minimalist style; the outside of the boiler looks like a cabinet. It must be placed exclusively on the floor. On the front of the model there is a small flap, behind which the button for turning on and adjusting the device settings is hidden. In this part there is a control window, thanks to which you have to monitor the boiler productivity indicators.

The key package includes a housing, which also includes parts of the heat exchanger. On the outside it is covered with thermal insulation material and a casing made of steel. There are two burners shown: one is the main burner, and the second is the pilot burner. The kit includes a gas duct and an automated gas valve; it is responsible for safety during operation.

If the temperature becomes more than +95 degrees, the shutdown meter breaks the circuit to the valve, and the valve itself automatically closes the gas supply.

Passport for Atem boilers (Zhitomir) ⋆ SIVtermo

Do you need to quickly find a passport for the Zhytomyr Atem boiler? Then come to Us! The website contains passports for gas and combined equipment of the Zhitomir-3, Zhitomir-M, Zhitomir-10, Zhitomir-9, Zhitomir-5 models

Operating manual Gas and combined boilers Atem produced in Zhitomir differ in their design from similar gas boilers of other brands, this can be seen both at first glance and upon careful examination of the product passport. Developers of boilers and AOGV Zhitomir try to bring a zest to each of their devices, as well as bring to the market models that are radically different from their analogues. For example, in 2016–2017, combined boilers appeared in the Atem boiler model range, which combine a gas and solid fuel boiler or a gas boiler and a gas water heater.

In 2022, a completely new type of parapet boiler appeared, equipped with two pipes instead of one coaxial one.

To make it easier to understand the features of these boilers and accurately understand whether they are suitable for you, below are the passports, or rather the operating manuals for this equipment.

You can also download a passport for the gas convector Zhitomir -5. It indicates not only the dimensions of the convector, but also all its technical data, as well as the operating instructions.

You can always buy Zhytomyr brand products, whether gas or solid fuel boilers, gas convectors, etc. in the online store sivtermo.com.ua

If you have any questions please call:

073–17–04–754

067–17–04–754

099–17–04–754

to your website.

www.sivtermo.kh.ua

Operating instructions

at the beginning of using the Zhitomir equipment, you need to make a high-quality installation of the product, check the pipes, especially if the boiler is a double-circuit one. Next, the first launch is performed. And then the boiler

part of normal operating procedures. According to the typical scheme, you need to turn on the device, light the wick, then adjust the heat supply. After these steps, you can change the settings to decrease the heating or, conversely, increase it.

At the end of the cold season, the boiler must be turned off for the warm period , because there is no need for it, which will make it possible to eliminate additional waste of the device’s potential. In most cases, after a warm period during the connection period, it is not possible to light the boiler

, the ignition fuse goes out. This may be due to weakened draft, weak gas pressure, or breakdown of the valve responsible for the gas supply.

To correct equipment errors and put the system in order, you should insulate the chimney, check the gas pressure and change the gas valve.

It’s not often that the gas valve fails to start during use. The reasons for this may be broken contacts, poor quality of the pilot burner, or an incorrectly installed thermocouple. Removing damage is simple - you just need to check the contacts. It is worth paying attention to the height of the flame. It must be at least 2.5 cm. You can try reinstalling the thermocouple or changing it completely. After this, check and light the boiler the first time.

As for a number of boiler models “ Zhitomir

", in general, you can hear only the best reviews. Excellent heating and the ability to regulate temperature conditions make it possible to feel comfortable during all cold weather. The simplest mechanism for switching on and setting is just a few knobs and pointers that tell you what needs to be done.

Another special quality that is mentioned in all reviews is the safety of the boilers. If the gas is unexpectedly turned off or the burner goes out, the magnetic block of the gas valve device closes the supply.

Moreover, Zhitomir boilers have a protective system against lack of draft in the chimney system, as well as protection against overheating of the device. In any situation, the gas supply is shut off, which is considered a big difference in the process of troubleshooting. Otherwise, gas water heaters " Zhitomir " are an excellent example of quality and reliability. They are in incredible demand on the world market. Technical properties of boilers " Zhitomir"

“They allow you to make a connection in almost any designated place.

Boilers “ Zhytomyr

” are, first of all, a concern with which you don’t have to think about the costs of heating your home using electric heating devices, and also excellent quality at a price that is affordable for everyone.

Gas boiler review “ Zhytomyr”

" - in the next video.

How to light a gas boiler with automatic Eurosit630

Why does the gas boiler Zhitomir 3 go out?

boiler shutdown

is the lack of traction, but if we talk about the technical part, the following is most likely: 1. the thermocouple-valve cable connection has oxidized;

2. The thermocouple is incorrectly set relative to the pilot burner; 3

. the pilot burner or tube is clogged (dirt, spider?); N 4.

Interesting materials:

How to insert a check mark in Word? How to insert a picture into a picture in Word? How to align text in a table in Word? How to get to the root in Word? How to replace a line break with a space in Word? How to replace all characters with others in Word? How to see everyone at the same time on Zoom? How to Vectorize a raster? How to return sheets in Excel? How to return a post from an Instagram archive?