Autonomous heating systems are relevant if it is not technically possible to connect an apartment or house to a centralized system. Gas boilers Zhitomir are quite popular among residents of our country. The products have excellent technical characteristics, are of high quality, and adapted to Russian conditions of use. In addition, if you look at reviews on the global network, you can understand that many users are attracted by the reasonable price.

Under the brand in question, heating boilers were born 27 years ago. Since then, the products have undergone many upgrades. In order to meet modern requirements and not lose its leading position, the manufacturer is constantly improving and finalizing its product.

About the boiler

Chimney boilers that are characterized by very high operating efficiency combined with time-tested design reliability and an attractive price. Thanks to successful design solutions and many years of experience of engineers, Zhytomyr-3 boilers have long been the most popular series of boilers among buyers. During the production of the series, these boilers have already been chosen by more than 1,000,000 customers.

The lineup

The price range largely characterizes the model range of gas boilers in Zhytomyr. The boiler names contain alphanumeric designations. The letters indicate the main features of the boilers. The numbers give a characteristic of thermal power.

Floor standing boilers

Floor-standing boilers have a wider range of models. Their price depends on the power of the boiler. Thus, the most powerful boiler ZHITOMIR-3 KS-G-080SN has a thermal power of 80 kW. A floor-standing gas boiler is capable of heating a building with a heated area of up to 800 sq.m.

Floor-standing gas unit Zhytomyr

The presence of an additional letter “B” in the name, for example, ZHITOMIR-3 KS-GV-080SN, indicates a double-circuit gas boiler “Atem Zhitomir-3”, which can not only heat the room, but also heat water.

The amount of hot water produced is proportional to the thermal output of the boiler. This dependence is due to the presence of a copper coil inside the heat exchanger. Boilers with a higher heat transfer value also have a larger surface area of the coils. This explains the high hot water output.

Wall boilers

Wall-mounted boilers have a smaller range of sizes. They are less often installed inside private houses. The main purpose of ATEM ZHITOMIR wall-mounted boilers is heating apartments in multi-storey buildings. Wall-mounted boilers are much lighter in weight. They have a lower heat exchanger area. The maximum area of such devices allows heating up to 150 sq.m of housing area.

Gas wall boiler Zhytomyr

Wall-mounted boilers have a peculiarity - they are connected to coaxial chimneys that exit through the wall.

Turbulent heat exchanger "Atem" - maximum heat

The process of transferring heat from gas combustion to the heating system occurs precisely in the boiler heat exchanger, so how it copes with this task directly affects the gas consumption and efficiency of the boiler. In boilers of an outdated design, developed when no one was thinking about saving yet, the heat exchangers are built in such a way that half of the heat simply flies out into the chimney, practically without lingering in the boiler. Unlike boilers of outdated design, the heat exchanger of the Atem boiler is built in such a way as to ensure maximum operating efficiency combined with reduced gas consumption. The efficiency of Zhytomyr-3 boilers reaches 94%, which is a very high indicator belonging to the premium segment boilers.

The design of the Atem heat exchanger provides two operating modes: calm and turbulent. In “quiet” mode, with relatively warm weather outside, hot gases smoothly pass all the way through the heat exchanger and manage to transfer heat to the heating system. When the temperature outside begins to drop below, the draft in the chimney increases significantly, which leads to an increase in the rate of extraction of hot flue gases and then the heat exchanger goes into a “turbulent” operating mode, in which the hot gases begin to actively mix, ensuring efficient heat transfer to the heating system. While in boilers with a conventional heat exchanger, as the draft increases, the efficiency can drop sharply, the efficiency of the Atem boiler with a turbulent heat exchanger remains very high in any operating mode.

Specifications

The Atem-Frank private enterprise, located in Zhitomir, produces two types of gas heating systems:

- in floor version;

- in a suspended version (so-called parapet boilers).

Floor-standing units are produced as single- and double-circuit, the latter can supply hot water to 2-3 consumers at low costs. General technical characteristics of the Zhytomyr gas boiler for the entire range of floor heaters are presented in Table 1.

The DHW capacity of double-circuit floor-mounted installations is from 175 to 1400 l/h with a heated water temperature difference of 35 ºС. The product can be equipped with a circulation pump, installed as an option. The characteristics of the model range of parapet units can be seen in Table 2.

Double-circuit parapet boilers provide hot water consumption from 160 to 345 l/h with a water temperature difference of 35 ºС.

As can be seen from the tables, the suspended and floor-mounted single-circuit boilers Zhitomir are adapted to the conditions of low gas pressure in main pipelines, which is their advantage. A significant drawback is that the maximum permissible coolant pressure in the heat exchanger of the unit is quite low, for floor-standing versions - up to 2 kgf/m2, and for suspended ones - up to 0.7 kgf/m2. At the same time, foreign analogues can operate with system pressure up to 3 kgf/m2. This suggests that ATEM gas installations are more adapted to gravity systems and small houses with 1-2 floors. It is not recommended to purchase suspended models for two-story cottages, since there is simply not enough pressure for normal operation of the system.

Flue with floating damper retains heat

Unlike simple “open” draft compensators, which are still used in boilers of many brands, Atem boilers are equipped with a floating flue damper, which, on the one hand, prevents the loss of warm air from the premises, and on the other, ensures stable operation of the boiler safety sensors. This design solution made it possible to reduce gas consumption, especially at low external temperatures, when the draft increases and the air flow speed increases.

Design features

The general structure of the Zhytomyr floor-mounted gas boiler is shown below:

The design of the water heating installation is simple and ensures energy independence for all models of the manufacturer. The gas burner is an atmospheric, single-stage type from the Italian brand POLIDORO, of simple design, whose reliability has been tested by time. The automation systems for gas boilers Zhitomir, made in Italy, are equally reliable in operation. The automatic non-volatile gas valve of the EURO SIT brand is the most popular among all manufacturers of boiler equipment; leading foreign and domestic brands install it in their products.

To transfer thermal energy to the heating system, the installation uses a fire-tube-type steel heat exchanger. This means that high-temperature flue gases pass through several pipes immersed in the water jacket of the boiler. They transfer their heat to the water and come out at a temperature of 110-150 ºС. The pipes have a rectangular cross-section, which increases the exchange surface area and makes the unit more efficient. In double-circuit versions of boilers, coils of a copper coil are located around the heat exchanger pipes to heat water for household needs.

To slow down the movement of gas combustion products in smoke pipes and make it multi-pass, turbulators are used in the heat exchangers of floor- and wall-mounted gas boilers. Their additional function is to absorb soot deposits. The latter settle on the planes of these parts located perpendicular to the gas flows, and soot practically does not linger on the walls of the pipes.

Subsequently, soot deposits can be easily removed from the turbulators, since when disassembling the unit they are removed from the smoke pipes. This technical solution allows the internal surfaces of smoke pipes to remain clean for a long time and effectively transfer heat to the water jacket. Otherwise, a layer of soot deposited on the walls can significantly impair their thermal conductivity, then the temperature of the gases at the outlet will increase and the heat will be released outside.

Household gas boilers Zhytomyr are adapted to chimneys with insufficient draft. For this purpose, the unit is equipped with a direct damper, which opens the way for flue gases to the outside, bypassing the heat exchanger. It works like this:

- The damper must be opened before ignition. By default, the chimney has insufficient draft force.

- The valve adjustment wheel and the piezo ignition button are pressed sequentially, and the igniter lights up.

- The wheel turns a couple of notches, gas is supplied to the burner and it ignites.

- High-temperature gases (up to 200 ºС) begin to flow directly into the chimney. Due to the temperature difference in the chimney pipe, the draft increases and the boiler enters operating mode.

- After 5-7 minutes, the damper closes and heating of the coolant begins, the improved traction force is maintained.

The Zhitomir parapet chimneyless boiler largely repeats the design of its floor-standing “brother”. The difference is in the design of the chimney pipe; in suspended models it is coaxial. This is a double-walled pipe, inside which combustion products move, and air from the street moves towards them between the walls of the outer and inner pipes. Accordingly, the gas burner device does not use air from the room for its operation, but takes it from outside, while the combustion chamber is closed. In foreign analogues, a fan is used to suck in air; in Zhytomyr units, the entire process is energy-independent and operates with natural draft.

Easy start in any conditions thanks to Atem-Start

Any turbocharged boiler can be difficult to start after a long stop in operation, when the chimney has time to cool down. Start-up is also complicated due to unfavorable weather or simply a poor-quality chimney. The Atem-Start system helps solve this problem. When starting the boiler, the Atem-Start system allows you to increase the temperature of the flue gases in the chimney in order to “break through” the air lock and quickly warm up the chimney to stabilize the draft. Models with power from 7 to 16 kW are equipped with the Atem-Start system.

Make your boiler electric with Atem Electroreserve

Now, when you buy an Atem gas or solid fuel boiler, you have the opportunity to make it electric at any time. The boilers provide a place for installing a heating element, which you can purchase in a store in your city. Atem boilers are compatible with heating elements, or others that correspond to the installation dimensions. Read more about installing the electric heating element in the instruction manual.

The boiler will last longer thanks to Atem Protect

Anti-corrosion coating with liquid aluminum is a proprietary Atem technology, which reliably protects the most vulnerable parts of the boiler - the firebox and the lower part of the heat exchanger. Molten aluminum, upon contact with the heated surface of the boiler, forms a super-strong Interalloy, which in its properties is very close to stainless steel. This reliably protects the boiler from corrosion even in the most unfavorable operating conditions and significantly increases the service life of the boiler. The boiler is supplied with a flue distribution pipe, which ensures compliance with building regulations when installing the boiler.

Combination boiler ATEM Zhitomir-9 KS-GV-020SN/AOTV-15 - 20/15 kW

Combination boiler ATEM Zhitomir-9 DHW 20/15 kW

Manufacturer

A country

Find out about payment and delivery

ATEM Zhytomyr 9 is a high-quality factory-made combined boiler running on natural gas and solid fuel for systems with natural and forced coolant circulation. Separate combustion chambers, high-quality steel heat exchanger, spacious firebox for wood and coal, hot water production, non-volatile automation.

Attention! Free delivery means payment of the cost of transporting the product to the Nova Poshta warehouse chosen by the customer at the expense of the Thermocouple store, subject to partial prepayment! Check with the managers of our online store for details.

Attention! The cost of cash on delivery, as a separate service of Nova Poshta, is not included in the delivery amount and is paid by the buyer in full.

Attention! According to the terms of the promotion, the ATEM Zhitomir-9 combination boiler is equipped with a mechanical thermostat for the Regulus RT4 solid fuel boiler!

Purpose:

The KS-GV-020SN/AOTV-15 double-circuit boiler is designed for heating residential, utility or industrial premises - up to 200 m2 - with an autonomous open or closed heating system and the production of hot water for domestic needs. This device can work either independently or in combination with other heating devices that use other types of fuel. The heating device ATEM Zhytomyr-9 fully complies with the requirements of DSTU EN 297:2005, DSTU EN 265:2002 and DSTU 3075-95.

Certificates, awards, documentation:

The universal gas/wood boiler Zhytomyr-9 with two circuits is equipped with:

- durable fire-tube heat exchanger made of steel up to 4 mm thick, coated with special heat-resistant paint;

- separate combustion chambers for solid fuel and natural gas with one common wall;

- turbulators in the natural gas combustion chamber;

- gas burner device with Polidoro microflare burners controlled by a Sitgroup Eurosit 630 gas valve;

- spacious loading chamber for solid fuel;

- a copper DHW coil located in the water jacket of the unit, with connections to the water supply system;

- two doors for the solid fuel part of the boiler, which are lined with a non-flammable seal up to 2 cm thick;

- two outlets for a round chimney for separate removal of combustion products of different fuels;

- a damper on the chimney of the solid fuel part of the device;

- removable top cover for cleaning the heat exchanger;

- non-burnable cast iron grate with a special thickening in the center;

- coolant supply and return pipes;

- a bonnet for connecting a chain thermostat;

- dial thermometer on the front panel of the device;

- ash chamber;

- a layer of high-quality thermal insulation;

- boiler cleaning accessories;

- aesthetically pleasing casing made of 1.5 mm steel, painted with heat-resistant ivory enamel, with two reinforced doors.

Design of the KS-GV-020SN/AOTV-15 boiler:

The Zhytomyr-9 model compares favorably:

- relatively small dimensions;

- low price with impeccable workmanship;

- full adaptation to domestic operating conditions;

- the presence of separate chambers for solid fuel and a gas burner;

- long-term operation and corrosion resistance of the heat exchanger;

- the ability to work on the main types of solid fuel and natural gas, both alternately and simultaneously;

- high efficiency: on solid fuel - up to 78%, on gas - up to 92%;

- burning duration on one tab is from 4 to 8 hours, depending on the calorie content of solid fuel;

- the presence of a circuit that heats water for household needs;

- the presence of a removable cover for high-quality cleaning of the heat exchanger;

- round section of chimneys;

- the presence of a door for servicing the grate and bottom ignition of the boiler;

- availability of reliable non-volatile gas automatic equipment Eurosit 630 (Italy);

- the presence of a dial indicator for visual control of the coolant temperature;

- possibility of connecting a mechanical thermostat;

- saving space and consumables, which are usually used when installing two separate heating devices in parallel;

- a three-year quality guarantee for the boiler from the manufacturer from the date of commissioning of the device;

- ease of transportation and installation.

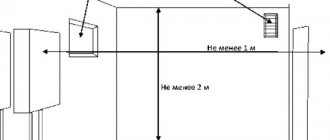

Connection diagrams:

Features of operation of the ATEM KS-GV-020SN/AOTV-15 boiler:

Attention! In order to avoid irreversible damage to the thermal bellows of gas automation, we strongly recommend that you do not allow the coolant in the solid fuel part of the device to overheat above 90° C!

A number of typical problems with the device can be resolved independently, without contacting a service center.

- If combustion is normal, but the water in the system does not warm up well, bleed off excess air. If the amount of coolant is not enough, add it to the system. In the event of a coolant leak, find the problem area and eliminate the leak, then refuel the heating system.

- If excessive fuel consumption is observed, check the heat exchanger for excess soot and clean it. Perhaps the heating system needs to be cleaned of scale deposits, or the amount of coolant is significantly higher than recommended.

- In case of condensation on the heat exchanger, the temperature of the coolant should be increased.

- The reason for the attenuation of the main and pilot burners, as well as unstable combustion of solid fuel, may be poor draft or insufficient ventilation of the room.

Attention! In case of more serious malfunctions, especially those related to the gas part of the heating device, we strongly recommend that you seek help from specialists from the service center.

Latest design changes:

In May 2016, the manufacturer made several changes in order to increase the structural strength of the heating device.

- the front doors of the boiler received additional stiffening ribs;

- The wires of the front part of the device were equipped with a reinforcing coating.

Recommended articles from the Thermocouple store blog:

termopara.net.ua