Home / Solid fuel boilers

Back

Published: 07/02/2019

Reading time: 7 min

0

6315

The KChM boiler is a reliable, simple and popular piece of equipment. This equipment can operate on different fuels. The design feature allows for quick repairs - the damaged section is replaced with a new one. This is the main difference from steel boilers, which can be difficult to repair.

- 1 Who is the manufacturer

- 2 Decoding

- 3 Construction of KChM boilers

- 4 Pros and cons

- 5 Basic parameters

- 6 Installation and operation rules

- 7 Malfunctions

Device and technical characteristics

The peculiarity of the KChM-5 boiler is that its heat exchanger is not solid, like most heating devices, but consists of cast iron sections. The number of sections increases with increasing power.

Photo 1: Hot-water solid fuel household boiler KCHM-5

The next feature of KChM heating devices is their versatility. If necessary, a solid fuel boiler can be easily converted to operate on gas, diesel fuel, fuel oil, or exhaust gas. If you install a pellet burner and a hopper with a feed auger, the KChM-5 easily turns into an automatic long-burning pellet boiler. You just need to slightly modify it, install a burner for the appropriate fuel, and now it’s gas or diesel. This versatility can be very useful if main gas is still being installed, but a heating device is needed now. Then everything is simple, install a solid fuel boiler KChM-5, and then switch it to gas with a minimum of costs.

Photo 2: Heating boiler KChM-5 with Baxi gas burner

Let's take a closer look at what parts the KChM-5 boiler consists of:

- We have already mentioned that the heat exchanger consists of sections. At the bottom of the near section there is a pipe for connecting the return line of the heating system, and at the top of the far section there is a pipe for connecting the direct line.

- There are three doors on the front panel: the loading door, the scooping door and the ash pan door. The loading chamber has holes for access of secondary air. By adjusting the amount of opening of the ash pan door, you can regulate the intensity of combustion. This process is performed either manually using an adjusting screw or using a draft regulator.

- On the rear wall of the boiler there is a chimney pipe with a smoke damper. Thanks to it, you can regulate the output of combustion products.

- The entire body of the KChM-5 is insulated with a special material to prevent heat loss and increase operating efficiency. The outside of the body is coated with wear-resistant paint.

- To prevent boiling and control the water temperature in the heating system, a thermometer is provided. It measures the water temperature in the middle section and displays the readings on the front panel.

Let's look at the main technical characteristics from the manufacturer's official website:

Number of sections3456789

| power, kWt | 21 | 30 | 40 | 50 | 60 | 70 | 80 |

| Room area, m² | 210 | 300 | 400 | 500 | 600 | 700 | 800 |

| Efficiency no less, % | 78 | ||||||

| Coal consumption, kg/h | 3,3 | 4,6 | 6,1 | 7,6 | 9,1 | 10,6 | 12,0 |

| Price, rub | 42 900 | 50 600 | 57 200 | 73 700 | 86 900 | 96 800 | 107 250 |

As you can see, KChM-5 stands out from the general mass of solid fuel boilers. Let's move on to analyzing its advantages and disadvantages.

What is special about the equipment?

Before purchasing this or that heating equipment, it is necessary not only to read reviews, but also to get acquainted with the features of the product. Heating units are universal, as they can operate on different types of fuel. Can be used:

- firewood;

- loose and briquette coal;

- peat;

- wood waste - wood chips, sawdust, shavings, pellets.

Advice! If necessary, you can install a special burner in the boiler. This will allow you to use gas or diesel fuel for heating.

This unpretentiousness to the type and quality of fuel is very convenient. Especially if the house is built in a remote area and the supply of a certain type of fuel is difficult.

Advice! If you have to use very low quality fuel, the manufacturer recommends equipping the boiler with a fan for forced air supply.

With such undemanding quality of fuel, KChM heat generators have high efficiency, which allows you to save on heating.

Device

Heat exchangers in KChM boilers are made of cast iron. Why was this material chosen? The fact is that cast iron has excellent heat capacity and at the same time it lasts a long time, since it is resistant to corrosion and does not burn out even at high temperatures.

Advice! Cast iron heat exchanger sections can last up to 50 years. However, under certain conditions, the qualities of the material change. For example, cast iron does not tolerate sudden temperature fluctuations; such exposure makes the material brittle.

Model range of boilers KChM-5

KChM-5-K solid fuel 03M1: coal, firewood from 21 to 80 kW

KChM-5-K Gas 17M1: from 27 to 96 kW

Universal-RT Solid fuel version with rated thermal power from 120 to 240 kW.

KChM-7 GNOM Pure gas boiler. From 48 to 96 kW.

Structure and appearance of the KChM

The package of sections of the KChM-5 boiler is assembled from 3 types of sections: front, rear and middle sections. A cover for cleaning the chimney, a door for loading fuel, and an ash door are attached to the front section. Also, through the nipple hole plug on the front section, a temperature sensor from the automation is attached. Thanks to the temperature sensor, the KChM-5 Combi boiler automatically maintains the set temperature of the coolant in the boiler. Through a special rod, the temperature sensor lever is connected to a damper on a hinge and, by changing the angle of coverage, it regulates the amount of air supplied to the boiler (Honeywell VR). The rear section has holes for the chimney, a flange for discharging heated water into the heating system and a flange for supplying return water. The middle sections of the KChM-5 boiler in the lower part have specially shaped castings. When sections are connected into a single package, a firebox (the main convective part) is formed, and these castings form a grate. On the outside, the seams between the sections of the KChM boiler are puttied with heat-resistant mastic. The boiler package is insulated with modern mineral insulation, which reduces heat losses. It is harmless to health. Under the insulation, the seams are formed by connecting successive sections of putty with heat-insulating mastic, forming a stable gas tightness. The outside of the boiler, the KChM-5 combi boiler, is covered with metal casing, which is coated with high-quality powder paint of bright red color.

Main settings

The technical characteristics of the KChM depending on the heat output are as follows:

| No. | Name | Characteristics | Note | ||||||

| 1 | Number of sections | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

| 2 | power, kWt | 21 | 30 | 40 | 50 | 60 | 70 | 80 | |

| 3 | Area of heated premises, sq.m. | 210 | 300 | 400 | 500 | 600 | 700 | 800 | For ceiling heights up to 2.8 m |

| 4 | Efficiency, % of | 77,6 | 78,3 | 78,8 | 79,2 | 79,6 | 79,8 | 80 | |

| 5 | Coal consumption, kg/h up to | 3,3 | 4,6 | 6,1 | 7,6 | 9,1 | 10,6 | 12 | At rated power |

| 6 | Flue gas temperature,˚С to | 250 |

Design features

The KChM has a structure in the form of sections, which, depending on the model, can be from 3 to 9. According to the number of sections, the technical characteristics of the device change - its power, boiler length, volume and size of the firebox, volume of the water tank, fuel consumption.

Thus, in the configuration for 3 sections, the KChM 5 boiler has the following technical characteristics: dimensions 1150x500x715 mm, diameter of the hole for the pipe - 15.3 cm, volume of the combustion tank - 35 l, size of the combustion tank 320x210 mm, volume of the water boiler 35 l, heating capacity - 21 kW, heated area - 210 m2, anthracite consumption 3.3 kg/hour.

Equipment design

The KChM-5 boiler, as noted above, is made of cast iron sections. A chimney is attached to the rear section, in its upper part. There is also a flange for water used for heating. On the front part there is a hatch for cleaning the chimney, as well as several doors (ash pan, scoop, loading). Fuel is added through them and the ash pan is cleaned.

Mineral wool is used as a heat insulator that protects the housing from heat loss. This material can withstand high temperatures and is safe for humans. Next comes the metal casing. It is painted with paint. The draft in the boiler is adjusted manually using the handles of the slide valves.

Special devices are installed on the furnace body to monitor the operation of the device. Thus, a capillary thermometer is installed in the water heating zone. It is used to measure the temperature of the coolant.

What is a KChM boiler and what are its positive aspects?

A cast iron solid fuel boiler is deciphered quite simply. “K” - boiler, “Ch” - cast iron, “M” - modernized. The number 5 indicates the number of sections if we are talking about a solid fuel boiler KCHM-5. Many consumers choose solid fuel cast iron boilers due to their qualities that stand out among other competing models of units.

This may include:

- High quality cast iron heat exchanger;

- Long service life;

- Carefully thought out design and its technical characteristics;

- Easy equipment care and maintenance;

- Checking the unit before assembly;

- With increasing sections, the power of the device increases;

- No need for additional traction;

- Switching to another fuel without damaging the system;

- Affordable price unlike other competing brands.

Date: September 25, 2022

Comparison with analogues

Solid fuel boilers KChM-5 can be considered universal in their design. Their heat exchangers are cast iron sections. This distinguishes the model from its analogues. Moreover, the greater the power of the unit, the more sections are included in its design.

A feature of the boiler is its ability to be converted to work with other fuel. A long-burning pellet boiler operating in automatic mode can be assembled. To do this, you just need to install a pellet burner and a hopper with an auger supplying fuel. You can get a KChM gas boiler through a simple modification. You just need to replace the fuel burner.

In terms of its technical characteristics, the KChM differs from its analogues. A comparison of the main indicators for models with a power of 40 kW is shown in the table below.

Getting to know the manufacturer and its products

The founder of the plant is considered to be Catherine the Second, who gave permission for its construction. It is worth saying that this is one of the oldest enterprises in the Russian Federation, its history dates back to the eighteenth century. Currently, this enterprise is a representative of a diversified holding company, which produces up to ninety percent of the cast iron battery market. Iron casting is the hallmark of the Santo holding.

Solid fuel heating boilers KChM are just a small part of the production at the Kirov plant. But, despite this, such heat sources have gained great popularity not only in our country, but also abroad.

Heat generator device

Why is it worth buying KChM boilers?

It must be said that solid fuel heat generators are in great demand among owners of cottages, dachas and private houses. Such equipment works equally well on:

- Wood processing waste;

- Peat briquettes;

- Fuel pellets;

- Coal;

- Firewood.

Unfortunately, not all citizens of our country have the opportunity to connect to main gas pipelines. This can be difficult technically and economically. The use of liquid fuel and electric boilers is not economically profitable, because electricity and diesel fuel are becoming more expensive all the time.

For an autonomous heating system, the factor of independence from the supply of additional energy sources and reliability is very important. If you want to improve your heating quality, then purchase a KChM 5 heating boiler.

View inside the heating device

Heating equipment KChM

Heat generators of this type are made of cast iron components - sections. Cast iron was chosen because it has good strength and is resistant to burning and corrosion. It also has a high heat capacity, and, therefore, its heat-accumulating functions are much higher.

The very name solid fuel boiler is arbitrary, because such generators can be converted to both diesel fuel and natural gas.

How to choose a solid fuel boiler? Experts advise choosing the following generators, as they stand out the most from the total:

- KChM Micro;

- heating boiler KChM 5.

Representatives of this series include the best cast iron models for designing individual heating systems. In the store you can purchase any equipment with a power from fourteen to one hundred kilowatts.

If we talk about heating areas, the most productive boiler is capable of providing heat to a building with an area of up to eight hundred square meters. Heat sources of this series have a draft regulator, which regulates the air flow into the firebox. Due to this, the generator becomes more economical, stable and has a long fuel burning time.

Such equipment is not inferior to its competitors from “abroad” in:

- Design;

- reliability;

- power.

In addition, they have the opportunity to switch to other types of fuel. In order to switch to natural gas, you only need to buy a burner and SABC automation. In addition, diesel burners can be purchased for such equipment. It will take no more than half an hour to switch the boiler to another type of fuel with your own hands.

Generator installed in a ready-made building heating system

All engineering plans that were embodied in these boilers are related to the design features and arrangement of the gas duct. The efficiency of units of about seventy-seven percent is achieved due to the presence of a front gate and a bumper. This figure for solid fuel boilers for heating private houses is a decent level that helps save money.

Various channels are used to build smoke removal systems for generators. To create “sandwich” chimneys, double-circuit chimneys are well suited. The instructions for the generator contain the required diameters and cross-sections of chimneys; they must be taken into account to create a reliable heating system.

A few words about automation

In order for the work process to occur automatically, KChM units are equipped with:

- “HONEYWELL” thermostats, it is installed in models with code 03;

- control panel and blower fan – equipment 05.

The boiler 05 configuration is volatile, so a two hundred and twenty volt power source is required for operation.

Cast iron heat exchanger of the unit in question

Installation features and connection

When installing KChM 5 yourself, a number of specific requirements must be met. If you follow all these rules, you will be able to significantly extend the life of the boiler, and will also make its use safe and convenient. Let's take a closer look at all the installation requirements:

- The boiler should be installed in such a way that the distance from the rear wall of the boiler to the wall of the boiler room is at least 0.25 meters. The distance between the side walls and the walls of the boiler must be at least 0.1 meter. In order to provide access to the rear, a passage should be made on one of the sides, and the minimum permissible width in this case is 0.4 meters. There should be at least 1 m2 of free space near the front of the unit to make stowing and cleaning convenient.

- Installation is carried out only on a floor made of non-combustible material or on a special plinth. Under no circumstances should there be flammable materials around at a distance of at least 0.4 meters. It is also prohibited to store fuel nearby; the minimum permissible distance is 0.4 meters from the boiler.

- Only clean water, free from various impurities, should be used in the heating system. When using a liquid with high hardness, scale will begin to form, and this will significantly reduce the service life of the heating boiler and the heating system itself.

According to reviews of the solid fuel boiler KChM 5, the installation procedure is as follows:

- First, you should install the boiler on a stand made of non-flammable material, possibly on a plinth.

- The device must be connected to the heating system and chimney.

- The system can be filled with water and then checked for leaks. Also, KChM 5 can be used for systems with forced and natural circulation.

By following the simple rules described below, you will be able to protect your loved ones and yourself, as well as make using the device convenient and enjoyable.

About the manufacturer

KChM is the oldest brand of domestic equipment.

The Kirov plant for the production of sanitary, technical and heating equipment was founded in 1745 by the Zolotarev and Faleev brothers. Merchants and industrialists founded the first workshops of a hammer plant on the river in the Kaluga province.

The small enterprise gradually developed into a large company, using advanced technologies in conjunction with the time-tested features of iron casting. Modernization of assembly lines and the use of highly qualified specialists brings the quality of units to a high level. Since 2006, the company has been a member of OJSC Santo Holding.

Pros and cons of solid fuel boilers

The use of solid fuel boilers is due to the many advantages of this equipment. These include:

- Long service life. A high-quality cast iron body guarantees at least 25 years of boiler service. At the same time, the device does not lose its consumer properties.

- Easy to maintain. The design of the equipment does not cause problems in terms of independent maintenance. An ordinary user can replace the energy carrier used at will.

- Versatility. When purchasing a boiler, additional parts are included in the kit, so you can convert the device to any type of fuel.

- High efficiency. High-quality thermal insulation of the body and other engineering solutions contribute to high heating efficiency, which is at least 78%.

- Possibility of modernization. The power and amount of heat depends on the number of sections in the heat exchanger. The power limits of the equipment range from 20 to 80 kW, which makes it the most flexible solution when using solid fuel in an individual heating network.

Note! High efficiency indicators are achieved through high-quality fuel. The most suitable type of coal for this boiler is anthracite with a fraction of up to 60 mm. When using wood, its moisture content should not exceed 20%.

Among the disadvantages of solid fuel boilers KChM-5, the most important is high fuel consumption and short time of continuous operation without human intervention. In addition, in comparison with gas generator devices, these devices are much inferior in efficiency. Also, this equipment requires constant cleaning due to the large amount of ash and ash that remains after burning wood or coal.

Types of equipment

The types and principles of operation of ventilation with recovery may differ from each other. There are five types of recuperators.

- Plate ones are the simplest option, characterized by easy installation, affordable price and ease of operation. Such ventilation systems have metal or plastic plates in their design that separate the incoming and outgoing air flows and cool and heat them. This type of recuperative unit has no moving parts in its design, so it can boast reliability and a long service life.

- Rotary - in the body of such exhaust systems there is a cylindrical rotor, which is responsible for heat transfer. Such systems are characterized by the ability to adjust the rotation speed. The only significant drawback is that when passing through such a ventilation system, the incoming and outgoing flows are partially mixed, so it is not recommended to install it in hospitals and other premises where complete filtration of the air flow is required. Also, this variety cannot boast of compact dimensions, it is more difficult to maintain than the previous version, and it does not remove unpleasant odors from the room.

- With an intermediate coolant - such ventilation is characterized by the presence in the heat exchanger of a liquid through which heat exchanges between warm and cold air. This type of ventilation is quite compact and wear-resistant, but condensation often forms inside it, and the efficiency does not exceed 60%.

- Chamber - air flows are separated from each other by a damper, which opens, mixing the air flows. Such exhaust ventilation cannot be called hermetically sealed; the efficiency of such a project is low, so it has not been particularly popular lately.

- Heat pipes are compact and efficient pipes containing freon or other easily evaporating substance. Thanks to the warm exhaust air, it heats up, turns into a gaseous state, rises through the pipes, giving off heat to the supply air, cools down and falls again. The fundamental difference between this model and the previous ones is that the two air flows cannot mix in any way. In addition, the tubes are very reliable, and the efficiency when using them is up to 70%.

Ventilation with intermediate coolant

Features of choosing a recuperator

Once you have learned what heat recovery is, you can begin choosing a model for your private house or apartment

When choosing home ventilation with recuperators, you need to pay attention to some points

- The thickness of the body of the air handling unit with heat recovery, as well as the material from which it is made. There should be no so-called cold bridges in the housing. And he himself should be able to withstand temperatures dropping down to -30 degrees Celsius. For example, in the case of an aluminum system, it will have to be additionally insulated, since this material does not tolerate sub-zero temperatures very well.

- Fan free pressure indicator - it should be as high as possible to ensure maximum system efficiency.

- The presence in the system design of the ability to connect additional automatic components that will save energy by turning equipment on and off when necessary.

- Type of ventilation control – remote or using controls located directly on the device.

- Power and performance are determined at the design stage of the room and should provide 60 cubic meters of air per person.

In order to ensure the most efficient air recovery, you need to take into account all these parameters, and also pay attention to the manufacturer. Regenerative devices from trusted companies last longer and work more efficiently.

Experience in supplying equipment and spare parts. Our portfolio!

Spare parts for KChM-7 GNOM Middle and outer sections in Omsk

Spare parts for KChM-5-K Front section of a new model in Tyumen

Universal-RT delivery to Kaluga KChM-7 GNOM Delivered to a regular customer in Yelnya Two boilers KChM-5-K Monastery in Belgorod

Gas KChM-5 School in Lipetsk Spare parts Universal-RT 2 middle sections in Kaliningrad

Spare parts KChM-5-K Front section with loading hole in a semicircle in Moscow

Advantages and disadvantages

So, what advantages does the KChM-5 boiler have in comparison with its solid fuel counterparts? Let's look at them in order:

- Thanks to the use of cast iron, proven design and quality of workmanship, the KChM-5 will serve you for at least 25 years.

- One of the main advantages over other solid fuel boilers is its versatility. With the help of easily installed additional equipment, it can be converted to another type of fuel, such as gas, diesel, fuel pellets.

- The simplicity of the design of the KChM-5 boiler greatly simplifies its maintenance. The device is easy to clean and eliminate minor problems that inevitably arise during the operation of any unit.

- The use of a sectional heat exchanger made it possible to create an impressive range of different capacities from 20 to 80 kW.

- Design features, as well as the presence of thermal insulation, made it possible to achieve an efficiency of at least 78 percent when working with wood and coal.

Advice: The most preferred fuel for which the best efficiency is achieved is anthrocyte coal with a diameter of 40-60 mm. Firewood should be used with a humidity of at least 20%. With wetter fuel, the boiler efficiency will decrease significantly.

Photo 3: Loading chamber of a domestic boiler KChM-5

The disadvantages of KChM models include high fuel consumption and short operating time on one load, as well as low efficiency compared to long-burning pyrolysis solid fuel boilers. Low operating efficiency entails another significant drawback - the boiler requires frequent cleaning and the organization of a competent chimney system.

Boiler features

Photo of the KChM boiler

The KChM boiler is a device produced by the Kirov plant, which has been specializing in iron casting for more than 250 years.

The manufacturer's range includes:

- Solid fuel boilers;

- Gas heating systems;

- Liquid fuel devices;

- Fireplaces;

- Furnaces;

- Various cast iron products.

But since we are interested in boilers specifically, let’s try to understand their key features.

- Solid fuel boiler models from KChM belong to the category of universal ones, since they can operate on various types of fuel.

- KChM units operating on solid fuel are able to “feed” on peat, sawdust, coal, and traditional firewood.

- By making minor changes to the design, a solid fuel boiler can switch to working with liquefied gas, diesel fuel, or special liquid fuel stove compositions.

- KChM perfectly adapted to the peculiarities of the Russian climate and the conditions of populated areas. Main gas is not installed everywhere, and many cities and villages have constant problems with electricity. In this situation, a solid fuel universal boiler from KChM becomes objectively the best solution to the problem.

- KChM are unpretentious in terms of the quality of burned fuel. Therefore, for its operation, you can purchase cheap fuel options.

- To ensure efficient combustion of low-grade fuel, a fan is provided. It allows you to force air in, thereby maintaining the temperature and burning fuel. The traction control actively helps with this.

- The efficiency indicators are quite solid, although they may be inferior to more advanced imported analogues. However, the difference in cost is significant. Paying almost twice as much for a few percent efficiency is not always reasonable.

- The Kirov plant is a true virtuoso in working with cast iron. Many years of experience and the availability of highly efficient equipment allows us to assemble boilers using excellent cast iron. The material itself is reliable and durable, and in combination with a competent approach to its casting, the result is enviable boiler equipment.

- The only thing you should be wary of when operating a cast iron unit is sudden temperature changes. They can cause cast iron to crack. By following basic operating rules, the device will serve you for many years.

Installation and operation rules

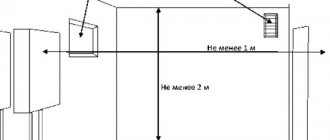

When installing a boiler, it is necessary to fulfill certain requirements related to fire safety. This will increase the service life of the solid fuel boiler and ensure safety and comfort. When installing the boiler in a suitable room, it is important to maintain the distance from the unit to the walls: from the back surface to the wall at least 250 mm, to the side surfaces at least 100 mm.

To ensure access to the rear surface of the boiler during installation and maintenance, it is necessary to maintain a distance of at least 400 mm from one side. A free space of about 1 sq.m. is provided in front of the boiler to ensure easy loading of fuel and cleaning of the ash pan.

The heating installation is placed on a reliable base, finished with fire-resistant materials, or on a platform. The fuel is placed at a distance of 400 mm from the boiler. The coolant is used prepared, without impurities, to avoid the formation of deposits, which can reduce the service life. The equipment is suitable for operation in systems with both natural and forced coolant circulation.

It is important to protect the boiler from overheating when the water temperature has reached the maximum value and the fuel continues to burn.

This phenomenon can be avoided by using: a thermostatic draft regulator, using a cooling heat exchanger, a switching valve or installing a heat storage tank.

Tying using the method of primary and secondary rings

There is another way to combine a solid fuel boiler with an electric one to supply a large number of consumers. This is a method of primary and secondary circulation rings, which provides for hydraulic separation of flows, but without the use of a hydraulic needle. Also, for reliable operation of the system, a minimum of electronics is required, and a controller is not needed at all, despite the apparent complexity of the circuit:

The trick is that all consumers and boilers are connected to one primary circulation ring by both the supply and return pipelines. Due to the small distance between connections (up to 300 mm), the pressure drop is minimal compared to the pressure of the main circuit pump. Due to this, the movement of water in the primary ring does not depend on the operation of the secondary ring pumps. Only the temperature of the coolant changes.

Theoretically, any number of heat sources and secondary rings can be included in the main circuit. The main thing is to choose the right pipe diameters and the performance of the pumping units. The actual performance of the main ring pump must exceed the flow rate in the most “gluttonous” secondary circuit.

To achieve this, it is necessary to perform a hydraulic calculation and only then will it be possible to select the right pumps, so an ordinary homeowner cannot do without the help of specialists. In addition, it is necessary to link the operation of solid fuel and electric boilers by installing shut-off thermostats, as described in the following video:

Security measures

It is necessary to operate KChM-5 boilers in compliance with safety regulations. Failure to follow these instructions will result in damage to the device, which may result in a health hazard.

Only adults who have undergone special training are allowed to service ovens. Leaving children near the boiler unattended is strictly prohibited. In situations that could result in a fire, the stove must be turned off immediately.

It is prohibited to light KChM-5 boilers using flammable liquids. It is necessary to ensure that explosive objects do not get into the firebox.

It is prohibited to change the design of the boiler, carry out repairs during operation, and do not operate it with the heating system not fully charged or with the cord door open.

Prices and some characteristics

| Boiler type | Power | Dimensions Height* Width*Depth (+ chimney) | Weight, kg |

| KChM -5 K 21-03(17) (3 sections) - 133,000 rubles / 156,000 rubles | 21/27 kW | 1150 x 500 x 350(+153) | 244 |

| KChM -5 K 30-03(17) (4 sections) - 133,000 rubles / 156,000 rubles | 30/38 kW | 1150 x 500 x 470(+153) | 310 |

| KChM -5 K 40-03(17) (5 sections) - 133,000 rubles / 156,000 rubles | 40/50 kW | 1150 x 500 x 590(+153) | 376 |

| KChM -5 K 50-03(17) (6 sections) - 169,000 rubles / 201,800 rubles | 50/61 kW | 1150 x 500 x 710(+205) | 442 |

| KChM -5 K 60-03(17) (7 sections) — 183,000 rubles / 213,000 rubles | 60/73 kW | 1150 x 500 x 830(+205) | 508 |

| KChM -5 K 70-03(17) (8 sections) - 204,000 rubles / 235,000 rubles | 70/84 kW | 1150 x 500 x 950(+205) | 574 |

| KChM -5 K 80-03(17) (9 sections) - 225,000 rubles / 261,000 rubles | 80/96 kW | 1150 x 500 x 1080 (+205) | 640 |

Version 03 is a model for working on solid fuel. Version 17 presented in the title is a model for working on gas fuel. All prices are current at the time of publication. June 2022.

We are waiting for YOU

Cast iron hot water heating boilers KChM 5 combi with a power from 20 to 100 kW operate on various types of fuel. The power of the KChM boiler is determined by the number of sections. Cast iron boilers KChM 5 combi are not afraid of untreated water and are very reliable in operation. The efficiency of KChM cast-iron gas boilers is no less than 90%; for solid fuels, the efficiency of KChM boilers is up to 80%. It’s easy to buy KChM heating boilers! Place your order directly on the website or call us by phone! Become our satisfied client right now!

Malfunctions

During operation, characteristic malfunctions of the CFM may be observed.

| Type of malfunction | Causes | Remedy |

| Leak formation at nipple connections | The boiler is depressurized, the bolt nuts are loose due to violation of operating rules | Strengthen the fastening of the nuts to the bolts; if this fails, then contact a specialist |

| The appearance of moisture on the walls of sections | Sections are depressurized. Manufacturing defect or improper operation | In places where moisture appears, wipe with a solution of ammonia. |

| Leak along the walls of sections | Rivet the leak with a core and a hammer. If you cannot eliminate the leak, contact a specialist |

In addition to common breakdowns, you should know the list of wearing parts: scorching door shield, scorching and loading door reflectors, thermocouple, temperature regulator, igniter.

Connection conditions

There are certain requirements for installing and connecting the boiler. Compliance with them will extend its service life and make operation comfortable and safe. The unit must be positioned in the room so that the distance from its back to the wall reaches 25 cm, and from the side walls - 10 centimeters. Periodically during repairs you will need to approach the rear surface, so leave 400 mm between one side and the wall. You need to leave a space of 1 m² in front of the boiler, which will allow you to easily add new fuel and clean the ash pan.

The boiler must be installed on a floor finished with heat-resistant materials or on a special pedestal. All flammable substances and fuel are located at a distance of no closer than 40 cm from the structure. Clean water without any impurities is poured into the heating system, since hard liquid leaves scale and shortens the service life of the boiler and the system itself. KChM is suitable for heating with natural and forced circulation.

Installation of the boiler must begin by installing it on a plinth or stand. It is then connected to the heating system and chimney. After this, you can add water and check all pipes for leaks. When heating for the first time, it is necessary to monitor the operation of the boiler.