What does the order say?

Preparation of thermal facilities for operation during the autumn-winter period (AWP) should begin with the execution of the appropriate order.

First of all, it defines the person responsible for the operation of thermal power plants and his deputy. For organizations involved in generating heat and supplying it to consumers, the responsible person must have a higher heat and power education. Responsible persons are also required to undergo an annual knowledge test with an exam at Rostechnadzor.

The order for preparing thermal equipment for work in the open-air zone should reflect the following main points:

- Creation of a commission to prepare the heating sector for work in the open industrial zone, accepting the readiness of the heating sector, fixed on the balance sheet of the organization.

- Determination of responsible persons and end dates for each item of the order.

- Development and approval of an autumn-winter action plan (AAP) to prepare the enterprise’s heating equipment for operation in the autumn-winter period.

- Procedure for monitoring and reporting on preparations for the heating season.

- The procedure for commissioning and testing of the heating system.

- The procedure for obtaining a certificate and passport confirming readiness for the occupational health program.

The development of a health maintenance plan should be carried out taking into account the identified failures in the thermal-hydraulic operating modes of heating equipment in the last winter period.

The corresponding orders and instructions of the heads of district administrations, as well as the heads of private management organizations, including HOAs and housing cooperatives, independently managing residential buildings must be published annually before April 30.

Thus, meetings to prepare for the 2020 heating season were held in May 2022, at which plans were approved to prepare heat and power equipment for work in the winter zone.

Formation of an act based on the autumn inspection

Following the implementation of repair and restoration work and maintenance of heating networks, the established preparation commission is obliged to conduct an autumn inspection of the measures taken, the reliability and readiness of the facilities for the heating period, before the fifteenth of September. After completing this procedure, those responsible for the implementation of the measures must adjust the repair plans, taking into account all detected problems at heat supply facilities. Such deficiencies must be eliminated without fail by September fifteenth. Then you can begin the procedure for drawing up the necessary acts and obtaining a confirming passport.

Connection to existing heating networks occurs before the first of September, and after the fifteenth of September, before the start of the heating season, tests are carried out, which consist of launching heating supply units. According to information from the relevant Ministry of the Russian Federation, after an inspection of about 950 electric power industry entities in 2022, 83 percent received passports confirming their readiness for the heating period. Activities continue at other sites.

Beginning and end of the heating season

The beginning and end of the open work period are established by regulations and decisions of local authorities. At the same time, the start of the heating season occurs when the average daily temperature outside drops to +8 C, which will last for at least 5 days.

The end of the heating season occurs when the average daily outside temperature rises above 8C, which will occur continuously for more than 5 days.

As for the housing stock, the provision for the inclusion of houses is determined by Government Decree No. 307 of 2006.

The second section, which provides that in the case when the owners of apartments in an apartment building or the owners of individual housing constructions have not determined the procedure for establishing the start/end date of the heating season, and heat energy is supplied through central heating networks, then the service provider begins and ends the heating season in the period determined by authorized bodies.

Additional recommendations

To ensure the flow of additional heat from radiators, you can resort to the following tricks:

- do not place furniture in front of them;

- raise or move curtains;

- place a special reflective screen behind the battery, which can be purchased in a store or made with your own hands from foil;

- paint radiators in light colors.

When purchasing heaters, experts advise giving preference to oil heaters, as they are the most efficient and safe.

If you prepare your apartment for the cold in a timely manner, you can be absolutely sure that it will be warm and dry in any weather conditions.

Why you need to prepare for the heating season

Reliable performance of housing and communal services facilities, timely and complete preparation for the new heating season is carried out to ensure a stable energy supply to consumers at subzero outside temperatures. Providing the required technological modes for heating buildings is a priority issue for public utilities in the regions of the Russian Federation.

If everything is ready, no problem

Preparing housing and communal services facilities for winter protection is carried out to reduce the impact of temperature and other atmospheric factors on the structural stability of utility facilities, prevent emergency wear and tear and prevent malfunctions of equipment in life support systems.

The preparation of housing and communal services facilities for the heating season must guarantee:

- regulatory technological operation of housing and communal services facilities;

- implementation of the generally established sanitary and hygienic regime for permissible temperatures and humidity in the premises;

- extreme reliability and high efficiency of operation of thermal facilities;

- rational consumption of materials and fuel.

Preparing actions based on inspection results

After the spring inspection, it is necessary to draw up organizational measures, which will take into account the starting and ending numbers, when all the deficiencies found will be specifically eliminated:

it is mandatory to ensure high-quality drainage of natural waters on the territory of the house, blind areas, and basement; all structural elements necessary for work in the basement premises must be checked for serviceability; all joints and interfaces must be completely isolated from water, they must be free of any cracks, moisture stains, peeling of the protective layer of concrete structures and other problems; during an external inspection, it is necessary to ensure the proper condition of the walls, which should not have any cracks, collapsed plaster or insulation; when inspecting windows or doors, you need to take into account the serviceability of the frames, external glazing and the full volume of glazing; roofs must be provided with the required temperature and moisture conditions; ventilation systems must be checked to ensure they are fully capable of removing waste from gas stoves and water heaters; monitoring and complete control of the state of thermal insulation of heating systems inside houses.

Requirements for preparing residential buildings for the heating season

There are a number of strict requirements for preparing a house for the heating season and in-house engineering systems, without which the operating organization will not receive permits to launch thermal energy at a heat supply facility.

The main directions of the health care plan:

- Technical spring/autumn inspection of structural elements of apartment buildings, ITP and structures.

- A set of repairs and restoration of subordinate heat and power equipment in accordance with the current schedules of scheduled maintenance and the results of the spring inspection.

- Water flushing of network pipes.

- Hydraulic testing of heating networks.

- Providing heating supply systems with missing equipment and instrumentation.

- Providing boiler houses with backup energy sources.

- Drawing up an act of emergency and technological protection of heat supply.

- Carrying out measures to insulate building structures.

- Obtaining a certificate and certificate of readiness of the boiler room for winter protection.

Checking the thermal insulation of a house

Heat can leave a home in a variety of ways:

- 18–20% of heat evaporates through windows and doors;

- using a ventilation system (including chimney) – 15%;

- poorly insulated floor – 10%;

- not insulated or wet walls – 30 – 35%;

- attic floor – 20%.

Therefore, all these sources of heat loss must be carefully checked and, if necessary, insulated. It is easy to insulate windows and doors using either a modern sealant or the old “old-fashioned” methods using cotton wool, newspapers, adhesive tape, and foam rubber.

If you still have old wooden frames with dangling glass, then in the summer you need to replace the glazing beads with new ones, placing them on window putty. This will significantly reduce heat loss through window frames.

How are preparations going for the heating season?

Responsibility for the complete implementation of the MCH plan rests with the heads of housing and communal services institutions and companies. They are required to organize the work in three stages:

- Preparatory, the results of the last heating season are reviewed, an analysis of failures, breakdowns and emergency situations is performed. During this period, comprehensive health care plans are drawn up, until April 30.

- Completion of restoration and repair work until September 1.

- Checking the readiness of the equipment for the open fire, testing the systems for operability, eliminating identified violations, the period is until September 15, after which the period ends.

Then the cycle repeats. For example, on April 30, 2022, preparations for the 2020-2021 heating season will begin.

The headquarters at local administrations, according to the approved schedule, holds its meetings in the course of implementing plans for preparing for the heating season, during which they review the reports of responsible persons.

After the commissions have discussed the preparation, decisions are made on the results of the implementation of the preparation plan for the region, which are brought to the attention of the population immediately.

Spring inspection of common property

During the spring inspection, the technical condition of housing and communal services equipment, the availability of fuel, the technological reliability of supplying consumers with utilities, and the implementation of technological operating modes of heating networks in the past winter protection period are examined.

The main directions for carrying out a spring inspection:

- Inspection of engineering structures of residential buildings: roofs, windows, doors, walls, condition of insulation systems and in-house utility networks.

- Drawing up an inspection report of objects indicating the necessary types of repairs, material and financial support, persons and dates of completion.

- Based on the inspection report, a health care plan is developed.

- The plan is coordinated with local authorities and approved by the head of the company.

Preparation of activities based on the results of the spring inspection

Based on the results of the spring inspection, organizational measures are drawn up, indicating deadlines for eliminating the detected defects:

- the area where the house is located, the blind area and the basement must ensure high-quality drainage of natural waters;

- structural elements in basements and semi-basements must be in good working order;

- waterproofing of joints and interfaces should not have visible cracks, wet spots, corrosion of reinforcement and peeling of the protective layer of concrete structures;

- the technical condition of the walls is checked by external inspection; there should be no cracks, collapse of plaster or insulation;

- when inspecting windows and doors, check the serviceability of frames, external flashings and completeness of glazing;

- check the roofs to ensure the required temperature and humidity conditions in the attic structure;

- check ventilation systems to ensure complete removal of emissions from gas furnaces and water heaters;

- monitor the state of thermal insulation of intra-house heating and hot water systems.

Drawing up a certificate of readiness of the building for the winter heating period

The passport is made according to a standard sample, and it is issued by the special body that created the commission within 15 days after the document is issued.

The document is issued only when the object is ready for the open plan, or in the case when the deficiencies discovered by the commission were corrected within the prescribed period. The authorized bodies at housing and communal services facilities include territorial authorities.

The time frame for issuing house passports for the heating season is established by the authorized body based on the distinctive features of weather conditions, but no later than September 15 for consumers, and no later than November 1 for heat and power supply companies.

Autumn inspection and drawing up a report

After the restoration work and maintenance of heating networks, a special commission for the preparation of the operational safety documentation, until September 15, carries out an autumn inspection of the work done and the readiness of the buildings for the heating season.

After completing the inspection, the responsible persons adjust the repair plans in accordance with the identified defects at heat supply facilities, which must be eliminated by September 15, after which they proceed to the procedure for issuing reports and obtaining passports.

Connection to existing heating networks is carried out before September 1, and in the period from September 15 to the official start of the heating season, test runs of heat supply installations are carried out. So, as of November 15, 2019, according to the Ministry of Energy of Russia, after an inspection of 941 electric power industry entities on their readiness for the winter season in 2022, 83% received passports; work continues on the remaining facilities.

Checking the water supply system

If there are pipes in the house that are not used in winter, it is necessary to shut them off and drain the liquid from them using a hose. If there are pipes passing through cold rooms, then they must be insulated with an additional layer of thermal insulation (mineral wool or polyurethane foam shells can be used).

Next you need to carry out the following activities:

- Before the onset of winter, you need to check the serviceability of all taps and valves on the water supply. Pipes need to be checked for leaks and repaired immediately. If possible, it is better to replace sections of pipes with defects with serviceable ones.

- If you have your own source of water supply - a well or a well, the water from which is supplied to the house using a pumping station, then it is better to install the station in a heated room, since it cannot work in the cold.

- If water is pumped into the storage tank using a submersible pump, then it can be left in water during the winter period. This is possible because usually the level of a well or borehole is below the freezing depth of the soil, so the water in them does not freeze.

- If the storage tank is located in a cold attic, it must be insulated from the outside.

- If the system has pipes through which liquid does not move constantly, especially if they are of small diameters, then there is a high probability of them freezing. To avoid this, you can use an electric heating cable to heat them.

- Water supply pipes lying in the ground must be insulated if they are located above the freezing depth of the soil. If they are located deep enough, then only that section of the pipe that is located at the entrance to the house will have to be insulated.

What work is being carried out in preparation for the heating season?

Repair measures in consumer heating networks are linked to the repair plan for thermal power systems of heat sources. Reports and information on the scope of repairs performed and the results of pre-start inspections are prepared by the responsible persons.

Checking boiler equipment

When preparing the boiler room for the heating season, the following basic activities must be completed:

- repair of boiler heating surfaces according to PPR, replacement of defective sections of pipes, economizers, air heaters, boiler fittings, fittings, smoke ventilation systems and boiler lining;

- restoration repairs of pumps, smoke exhausters and fans;

- restoration of fittings and primary instrumentation sensors;

- repair and adjustment work of instrumentation and automation;

- repair and adjustment work of electrical power equipment;

- repair and adjustment work of water chemical treatment facilities;

- repair and adjustment work of the fuel supply system;

- preparing stoves for the heating season;

- State verification of heat meters.

After completion of the repair and restoration work, the thermal diagrams of the boiler units are collected and hydrotests of the boiler units are performed with a pressure equal to 1.25 of the working pressure of the saturated steam in the boiler.

Repair work

Repair work is necessary.

Photo source: ao-ustek.ru In heating networks, based on the results of the spring inspection and maintenance work, the following main types of repairs are required:

- replacement of defective pipe sections;

- restoration of thermal insulation and anti-corrosion coating;

- repair and inspection of shut-off valves, drain valves, air vents, check and safety valves;

- inspection and repair of network and make-up pumps;

- replacement and repair of electromagnetic and hydraulic actuators of control valves and starting devices;

- replacement and repair of control and measuring instruments;

- cleaning mud traps and battery tanks;

- repair and adjustment of security automation, control device recorders.

Upon completion of all planned work, a thermal diagram is assembled and hydraulic tests of heating networks are performed with a pressure of 1.25 working, but not less than 1.6 MPa and a network water temperature not exceeding 40 C.

Instrument verification

According to the Rules for Heat Energy Accounting, each heat source and receiver must be equipped with commercial metering devices, in addition, boiler rooms and consumer ITPs are equipped with safety system devices.

To ensure reliable operation of the above devices in the OZP, the following devices are repaired and calibrated:

- heat consumption adjustment;

- temperature control in the DHW system;

- maintaining static pressure in thermal systems;

- by pressure in the supply/return network pipeline;

- to protect heat supply systems from over/under pressure;

- to protect heat supply systems from excess temperature in the supply network;

- to automatically turn on the backup pump;

- for automatic protection of the storage tank from overflow;

- automatic switching on/off of drainage pumps.

Commissioning and preparation of operating charts

After flushing and hydraulic testing of heating networks, commissioning work is carried out at thermal power plants, both at heat supply organizations and at consumers. Based on the results of commissioning, operating schedules for thermal power equipment are established.

Basic data of regime cards:

- Calculated volumes of coolant for operational sections of the heating network.

- Operating parameters for pressure in network pipelines: forward and return lines.

- Operating temperature graph of forward and return network water, depending on the ambient temperature.

- Coolant costs for consumers.

- Calculation of thermal expansion of the heating network.

- Analysis of hydraulic and thermal operating modes of the heating network.

- Calculation of the diameters of restrictive washers and nozzles of elevator units at the consumer.

Communications audit

In the summer, it is necessary to check all the engineering systems of the house:

- heating system;

- ventilation system and chimneys;

- stove or heating boiler;

- water supply system;

- drainage systems;

- power supply system.

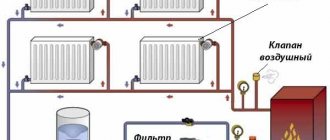

Checking the heating system involves a thorough inspection of pipelines and heating devices for leaks and leaks. To do this, it is necessary to carry out a test run of the heating system in advance:

- Fill it with water or other coolant through the drain valve located at the lowest point of the system. Rising upward, the coolant will gradually displace all the air accumulated in the pipelines and squeeze it out through the air vent valves.

- Keep the pipelines filled for at least half an hour, during this time checking the tightness of all connections and heating devices for leaks.

- Using a pressure gauge at the system inlet, you need to make sure that the pressure in the system is stable. If it falls, it is necessary to find places of leakage.

- If there are leaks, the coolant must be drained and all defects in the heating pipeline must be eliminated.

- Then the test is repeated.

- Next, you need to raise the temperature in the system and check how quickly and evenly the devices warm up. If there are problems, they are fixed.

- Then the temperature in the system is gradually reduced.

Certificate of readiness for the heating season

After completing all repair work according to the OZM plan, the head of the organization sets a time to check the completeness of the implementation of the action plan. You can download it here.

To assess the preparedness of consumers for the heating season, the commission checks:

- completeness of implementation of the health care plan;

- Carrying out washing and pressure testing of thermal devices;

- availability of commissioning tests and operating charts of equipment;

- level of insulation of buildings;

- technical condition of pipes and shut-off and control valves;

- serviceability of heat and electricity metering devices and their verification;

- serviceability of automatic protection;

- availability of thermal equipment passports, diagrams and production instructions;

- the presence of seals on limit washers and elevator units.

When the consumers' heating facilities are fully prepared for the autumn-winter period, an act of the established form is prepared, which is signed by all members of the commission. Comments may be attached to the act, and deadlines for their corrections may be established. After notifying the commission that the deficiencies have been eliminated, the consumer can receive certificates of the facility’s readiness for the winter period.

document

Download as .doc/.pdf Save this document in a convenient format. It's free.

ACT OF READINESS OF THE HEATING STATION FOR OPERATION DURING THE HEATING PERIOD OF 200__/200__. D. __________________ “____” ____________200__ D. Consumer (subscriber) N _________________________________________ Address: _______________________________________________________ We, the undersigned, a representative of the heat supply organization ______________________________________________________ (position, surname, first name, patronymic) and a representative of the subscriber _________________________________________ (position, surname, first name, patronymic) made acceptance heating station prepared for winter. The test and inspection results are as follows: 1. Hot water heater: _____________________ During the hydraulic test, the pressure was raised to the required according to the instructions ________________ kgf/sq. cm, while after 15 minutes. after turning off the press, the pressure gauge needle dropped to ______ kgf/sq. see 2. Heating heater: __________________________________ During the hydraulic test, the pressure was raised to the required according to the instructions _______ kgf/sq. cm, while after 15 minutes. After turning off the press, the pressure gauge needle dropped to ___________ kgf/sq. see 3. Pumping equipment _____________________________________ 4. Shut-off valves and pipelines _________________________________ 5. Hydraulic automation _________________________________ 6. Electrical automation _______________________________________________ 7. Instrumentation equipment ________________________________________________ 8. Metering unit ________________________________________________ 9. Insulation condition _________________________________ 10. Condition of the premises, lighting, ventilation, doors and shut-off valves door devices, drains, pits, etc. ___________ ___________________________________________________________________ 11. Implementation of safety measures ___________ ___________________________________________________________________ 12. Completion of technical documentation ________________ ___________________________________________________________________ 13. Communication with the dispatch service of the organization operating the housing stock _________________________________________________ Conclusions: The heating unit was accepted for operation in winter conditions _______ _________________________________ and is ready for connection to the heating network by the heat supply organization. Representative of the heat supply organization _______________ _________________ (signature) (full name) Subscriber representative _______________ _________________ (signature) (full name)

Download as .doc/.pdfSave this document now. It will come in handy.

You found what you were looking for?

* By clicking on one of these buttons, you help form a rating of the usefulness of documents. Thank you!

Related documents

- Act: samples (Full list of documents)

- Search for the phrase “Act” throughout the site

- “Act of readiness of a heating point for operation during the heating period in the city of Lyubertsy, Lyubertsy municipal district, Moscow region.”doc

Documents that may also interest you:

- Certificate of readiness of trade, public catering, and consumer services enterprises to serve the population in the city of Protvino, Moscow Region

- Certificate of readiness for the production of a prototype/pilot batch, obtained during the implementation of a state contract within the framework of the Federal Target Program “Scientific and scientific-pedagogical personnel of innovative Russia” for 2009 - 2013

- Certificate of readiness of engineering systems of the housing stock of the city of Zheleznodorozhny, Moscow region

- Certificate of readiness of the subscriber's heating systems and heating networks for operation during the heating season in the city of Lyubertsy, Lyubertsy municipal district, Moscow region

- Certificate of readiness of special self-propelled rolling stock (SSPS) for transportation as part of a train

- Certificate of readiness of an aircraft (helicopter) to perform a controlled flight

- The act of dismantling and transferring to the warehouse components and parts containing precious metals removed from products

- Act of dismantling and transferring to the warehouse components and parts containing precious metals removed from products (sample)

- The act of dismantling and transferring batteries to a warehouse, as well as components and parts containing precious metals removed from products to the Federal Service for Technical and Export Control

- Certificate of defect detection of ship mechanisms

CRITERIA FOR RELIABILITY OF HEAT SUPPLY TO THERMAL ENERGY CONSUMERS TAKEN INTO ACCOUNT OF CLIMATIC CONDITIONS

1. Based on the reliability of heat supply, heat energy consumers are divided into three categories:

the first category is consumers for whom interruptions in the supply of thermal energy and reduction of air temperature in the premises below the values provided by technical regulations and other mandatory requirements are not allowed;

the second category is consumers for whom it is allowed to reduce the temperature in heated premises for the period of liquidation of the accident, but not more than 54 hours:

residential and public buildings up to 12 °C;

industrial buildings up to 8 °C;

the third category is other consumers.

2. In case of emergency situations at a source of thermal energy or in heating networks, during the entire repair and restoration period the following must be provided (unless other modes are provided for in the heat supply agreement):

supply of thermal energy (coolant) in full to consumers of the first category;

supply of thermal energy (coolant) for heating and ventilation to housing, communal and industrial consumers of the second and third categories in the amounts indicated in Table No. 1;

emergency mode of steam and process hot water consumption agreed upon by the parties to the heat supply contract;

emergency thermal operating conditions of non-switchable ventilation systems agreed upon by the parties to the heat supply contract;

average daily heat consumption during the heating period for hot water supply (if it is impossible to turn it off).

Table No. 1

| Indicator name | Calculated outside air temperature for heating design t °C (corresponds to the outside air temperature of the coldest five-day period with a probability of 0.92) | ||||

| minus 10 | minus 20 | minus 30 | minus 40 | minus 50 | |

| Permissible reduction in thermal energy supply, %, up to | 78 | 84 | 87 | 89 | 91 |