A feature of the state of energy today is that at heating plants the number of shutdowns and downtime of boilers has increased, this is due to changes in the regime of energy consumption and heat supply. Equipment is reserved for an indefinite period. When the boiler is stopped, the pressure of the environment drops to atmospheric pressure, there is a possibility of moisture and air getting into it, as a result the boilers undergo corrosion, which is considered dangerous, since there is a possibility of damage to all heating equipment, including pipelines. Therefore, at the moment, the issue of conservation is especially relevant, and the development of technologies in this regard is progressing.

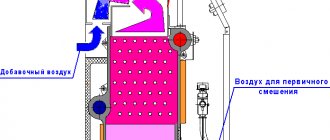

Scheme of a solid fuel boiler.

Thanks to protection against corrosion formed during downtime, the operating condition of the equipment is maintained, the costs of its repair and restoration are reduced, the technical and economic indicators of the operation of thermal power plants are maintained, and production costs are also reduced.

There are several ways to preserve boilers:

- gas preservation method;

- wet preservation method;

- method of applying excess pressure;

- dry preservation method.

A daily downtime of an unpreserved boiler will lead to rust of equipment in the circuit of up to 50 kg of iron oxide. When stopping water heating boilers for a period of 15 hours or drum boilers for up to 1 day, it is recommended to carry out preservation using the overpressure method, for a short period (5-6 days) - the dry preservation method. The choice of a suitable method for eliminating oxygen corrosion is made taking into account the parameters and power of the boilers, and their specific operation.

To prevent standing corrosion of the metal of boiler heating surfaces during major and current repairs, only conservation methods are applicable that make it possible to create a protective film on the metal surface that retains its properties for 1-2 months after draining the preservative solution, since emptying and depressurization of the circuit in this case inevitable.

Wet preservation technology

Gas boiler diagram.

This method is intended for preserving boilers during downtime by reducing the pressure to atmospheric pressure. It is used for the preservation of steam and hot water boilers. During the proposed conservation, the boiler is emptied of water and filled with gas (for example, nitrogen), after which excess pressure is maintained inside the boiler, at the same time, before gas is supplied, it is filled with deaerated water.

The method of preserving a steam boiler involves filling the boiler with gas at an excess pressure in the heating surface of 2-5 kg/cm² while simultaneously displacing water in the drum. In this case, air cannot get inside. According to this scheme, gas (nitrogen) is supplied to the outlet manifolds of the superheater and into the drum. The low excess pressure in the boiler is due to nitrogen consumption.

This method cannot be used when preserving boilers in which the pressure has dropped to atmospheric pressure after shutdown and the water has been drained. There are cases of emergency shutdown of the boiler. During repairs, it is completely emptied, so air gets inside. The specific gravity of nitrogen and air does not differ significantly, therefore, if the boiler is filled with air, it is impossible to replace it with nitrogen. In all areas where air is present and where humidity exceeds 40%, the metal of the equipment will be susceptible to oxygen corrosion.

The small difference in specific gravity is not the only reason. Displacement of air from the boiler and uniform distribution of nitrogen throughout it is also impossible due to the lack of hydraulic conditions, which are caused by the nitrogen supply system (via the outlet manifolds of the superheater and drum). Also in the boiler there are so-called undrained areas that are impossible to fill.

Steam boiler diagram.

- Drum.

- Air balloons.

- Superheater.

- Air balloons.

- Capacitor.

- Air balloons.

- Superheater outlet manifold.

- Remote cyclone.

- Air balloons.

- Screens of boiler circulation panels.

- Economizer.

- Drainage of the lower points of the boiler.

- Superheater outlet chamber vents.

- Nitrogen supply line with valve.

- Air exhaust line from vents with valve.

- Water drainage and supply line with valve.

List of necessary tools, devices, devices:

- Pressure gauges are U-shaped.

- Gas analyzer.

- Set of wrenches.

- Combination pliers.

- Screwdrivers.

- Files.

- Ladder.

- Bucket.

- Solid oil.

- Paronite gaskets.

- Plugs, bolts, nuts, washers.

- First aid supplies and medications.

- Fire extinguisher.

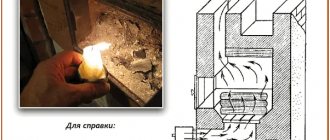

Diagrams of separation devices in the boiler drum.

The boiler is emptied of water after it is stopped by opening all its lower points. After emptying, in some places a steam-air mixture remains, containing oxygen, which causes corrosion of the metal of the boiler equipment. In order to displace the steam-air mixture, all boiler elements (1, 3, 5, 7, 8, 10, 11) are filled with deaerated water.

When supplying nitrogen to the boiler, it is necessary to open the drains of the lower points of all its components. Next, the water is displaced and the boiler is filled with nitrogen. The nitrogen pressure in the boiler is adjusted at the supply line 14 and (if necessary) at the outlet line 16. After the water is completely displaced and the boiler is filled with nitrogen, the excess pressure necessary for preservation is established (25-100 mm water column).

Consequently, the proposed method significantly increases the reliability of preservation due to the absolute removal of air from the boiler, filling it with deaerated water and nitrogen with parallel displacement of water.

Air duct operation diagram.

The boiler is filled with preservative solutions, which create a layer on the metal that retains its properties throughout the entire time the steam generator is inactive. An alkali solution is added to the water with which the steam generator is filled, observing the proportions: 2-3 kg of sodium hydroxide and 5-10 kg of sodium phosphate per 1 l³ of water with the addition of 1 kg of ammonia hydrate or a 10% solution of hydrazine hydrate.

This solution provides a concentration of 200 mg/kg NzH in water and is added using a plunger pump. Reactivation of the boiler and its lighting after this method of preservation takes place quite quickly. To prevent the occurrence of corrosion, use a special protective solution that contains caustic soda. The use of soda ash is also practiced, but this is undesirable, as there is a risk of local corrosion.

Using the wet preservation method, the boiler is filled with a protective solution, which ensures absolute resistance to rust, even if the liquid is saturated with oxygen. When using the proposed conservation method, it is possible to determine the permissible duration without loss of mine workings; determine the timing of drainage, repair of support, ventilation, lifting complex and other equipment with the implementation of other reparative measures.

When carrying out wet conservation of the boiler, you need to ensure that its surface and masonry are dry, and close all hatches tightly. Monitor the concentration of the solution (sodium sulfate content should be at least 50 mg/l). The use of the wet preservation method when carrying out repair work or in the presence of leaks in the boiler is unacceptable, since maintaining tightness is the main condition. If steam leakage is unacceptable with the dry and gas preservation method, then with the wet method it is not so dangerous.

Diagram of a double-turn superheater.

If it is necessary to stop the boiler for a short period, use a simple wet preservation method, filling the boiler and steam heater with deaerated water while maintaining excess pressure. If the pressure in the boiler drops to 0 after stopping it, filling with deaerated water is no longer effective.

https://www.youtube.com/watch?v=0-lb6yc53vo

Then you need to boil the boiler water with the vents open, this is done to remove oxygen. After boiling, if the residual boiler pressure is not lower than 0.5 MPa, preservation can be carried out. This method is used only when the oxygen content in deaerated water is low. If the oxygen content exceeds the permissible value, corrosion of the superheater metal may occur.

Ammonia in gaseous form can be added to the feed water. A protective film is formed on the surface of the metal, protecting it from corrosion.

In order to prevent the occurrence of corrosion in boilers that have been in reserve for a long time, the wet preservation method is used, maintaining an excess pressure of a nitrogen blanket above the liquid in the boiler, eliminating the possibility of air entering the boiler. In contrast to dry conservation, in which drainage agents operate, drainage from the mine is ensured, and boiler equipment is maintained in a condition suitable for use when necessary. At the time of conservation, write-off of mineral reserves is not permitted.

5.1.1. The method is based on the highly effective inhibitory abilities of calcium hydroxide solution Ca(OH)2.

The protective concentration of calcium hydroxide is 0.7 g/kg and above.

When a calcium hydroxide solution comes into contact with metal, a stable protective film is formed within 3-4 weeks.

When emptying the boiler of solution after contact for 3-4 weeks. or more protective effect of films lasts for 2-3 months.

This method is regulated by “Guidelines for the use of calcium hydroxide for the conservation of thermal power and other industrial equipment at Ministry of Energy facilities: RD 34.20.593-89” (M.: SPO Soyuztekhenergo, 1989).

5.1.2. When implementing this method, the water heating boiler is completely filled with solution. If repair work is required, the solution should be kept in the boiler for 3-4 weeks. may be drained.

5.1.3. Calcium hydroxide is used for the preservation of hot water boilers of any type at power plants that have water treatment plants with lime facilities.

5.1.4. Preservation with calcium hydroxide is carried out when the boiler is put into reserve for up to 6 months. or removal for repairs for up to 3 months.

5.1.5. The calcium hydroxide solution is prepared in wet lime storage cells with a floating suction device (Fig. 4). After pouring lime (fluff, building lime, calcium carbide slaking waste) into the cells and stirring, the milk of lime is allowed to stand for 10-12 hours until the solution is completely clarified. Due to the low solubility of calcium hydroxide at a temperature of 10-25°C, its concentration in the solution will not exceed 1.4 g/kg.

READ MORE: How to fix popular dishwasher tank failures yourself

When pumping solution out of the cell, it is necessary to monitor the position of the floating suction device to avoid trapping sediments at the bottom of the cell.

5.1.6. To fill boilers with a solution, it is advisable to use the acid washing scheme for hot water boilers shown in Fig. 4. A tank with a pump can also be used to preserve energy boilers (see Fig. 2).

1 — tank for preparing chemical reagents; 2 - pump for filling the boiler with a solution of chemical reagents; 3 - make-up water; 4 - chemical reagents; 5 — lime milk into pre-cleaning mixers; 6 — cells of lime milk; 7 - hot water boilers;

8 - to other hot water boilers; 9 - from other hot water boilers;

Installation of a safety group in the heating system

If you are modernizing yourself, the total costs will not exceed 3-5 thousand rubles, and the work can be done in the summer, when the heating system is not in use. The lifespan of my heating system is about six years. During this time, the following problems emerged:

1. The safety valve leaked, almost within the first week of operation, it was replaced in the store with a new valve (factory defect). 2. About a year after commissioning, the automatic air vent clogged. Replaced it in the summer with a Mayevsky manual tap. The reason, most likely, is the wrong choice of containers for collecting and preparing rainwater. 3. Due to large voltage surges in the electrical network, the gas control system in the boiler room burned out. The case, of course, is not covered by warranty. I had to buy and install a voltage stabilizer on two sockets and re-purchase a gas control system.

There were no other problems associated with the operation of the heating system. For the first year the boiler was operated on solid fuel, currently it operates on natural gas.

Rules for using hot water boilers in a water heating system

The basic rules for installation, installation and operation of the boiler are usually specified in the instructions. Currently, the choice of boiler equipment is quite large and varied, and it is almost impossible to take into account all the nuances in one article. Based on my personal experience, as well as the experience of my relatives and friends, I consider it necessary to note a number of general points that can help the correct operation of the equipment and heating system.

1. The first and simplest thing to do, no matter how funny it may seem to you, is to write instructions for the proper use of the boiler and heating system and place them in the room where this equipment is installed. It is far from a fact that only you personally will operate the system, just as it is not a fact that all your close relatives are well versed in the nuances of the design and operation of the heating system. This is especially true if gas boiler equipment is used, since erroneous actions can lead to the most unpredictable consequences. 2. Secondly, it is necessary to regularly monitor and monitor the operation of the heating system for the simple reason that certain deviations in the operation of the system can promptly signal to the owner that something is wrong. Unfortunately, I have come across cases where the owner not only does not know (does not monitor) the operating parameters of his equipment, but does not even have basic concepts about it.

GENERAL PROVISIONS

1.1. Preservation of boilers and turbine units is carried out to prevent corrosion of the metal of internal surfaces both during shutdowns (putting into reserve for a definite and indefinite period, putting into current, medium and major repairs, emergency shutdown), and during shutdowns for a long reserve or repair (reconstruction). for a period of more than 6 months.

1.2. Based on the Guidelines, a technical solution for organizing the conservation of specific equipment must be developed and approved at each power plant, defining methods of conservation for various types of shutdowns and duration of downtime, a technological scheme and auxiliary equipment for conservation. When developing a technical solution, it is advisable to involve a specialized organization.

1.3. Conservation methods not provided for in the Methodological Instructions are permitted for use with the permission of the Department of Science and Technology of RAO UES of Russia.

1.4. When developing a technological scheme for conservation, it is advisable to make maximum use of standard installations for corrective treatment of feed and boiler water, installations for chemical cleaning of equipment, and the power plant’s tank facilities.

The technological conservation scheme should be as stationary as possible and reliably disconnected from the operating sections of the thermal circuit.

It is necessary to provide for the neutralization or neutralization of waste water, as well as the possibility of reusing preservative solutions.

1.5. In accordance with the adopted technical solution, instructions for the preservation of equipment are drawn up and approved with instructions for preparatory operations, preservation and re-preservation technologies, as well as safety measures during conservation.

1.6. When preparing and carrying out conservation and re-preservation work, it is necessary to comply with the requirements of the Safety Rules for the operation of thermal mechanical equipment of power plants and heating networks. Also, if necessary, additional safety measures related to the properties of the chemical reagents used should be taken.

1.7. Neutralization of spent preservative solutions of chemical reagents must be carried out in accordance with the instructions of the “Standard operating instructions for installations for the treatment of industrial wastewater from thermal power plants: TI 34-70-043-85 (M.: SPO Soyuztekhenergo, 1985).

Performing re-preservation

During storage, responsible services periodically conduct inspections of equipment, assessing its condition. If traces of corrosion are detected or other defects are identified on the surfaces of the equipment, re-preservation is carried out. This event also involves performing primary surface treatment in order to remove traces of damage to metal or other materials. In some cases, repeated preservation also takes place - this is the same set of preventive measures, but in this case it is carried out in a planned manner. For example, if a protective composition is applied with a certain service life, then after this period the technical service must update the product as part of the same re-preservation.

METHODS OF PRESERVATION OF DRUM BOILERS

2.1.1. Draining the boiler at a pressure above atmospheric pressure allows, after emptying, due to the heat accumulated by the metal, lining and insulation, to maintain the temperature of the metal in the boiler above the saturation temperature at atmospheric pressure. In this case, the internal surfaces of the drum, collectors and pipes are dried.

2.1.2. Dry shutdown (SD) is used for boilers at any pressure in the absence of rolling connections between pipes and drums.

2.1.3. Dry shutdown of the boiler is carried out during a planned shutdown for reserve or repair for up to 30 days, as well as during an emergency shutdown.

2.1.4. To prevent moisture from entering the boiler during idle periods, it is necessary to ensure its reliable disconnection from the water and steam pipelines under pressure by tightly closing the shut-off valves, installing plugs, and inspection valves.

2.1.5. After stopping the boiler during its natural cooling or cooling, drainage begins at a pressure of 0.8-1.0 MPa.

The intermediate superheater is steamed to a condenser. After draining and drying, close all valves and valves of the boiler steam-water circuit, manholes and gates of the furnace and flue, open inspection valves, and install plugs if necessary.

2.1.6. During the conservation period, after complete cooling, periodic monitoring of the ingress of water or steam into the boiler is carried out by probing areas of possible ingress in the area of shut-off valves, briefly opening drains at the lower points of collectors and pipelines, and valves at sampling points.

If water gets into the boiler, measures should be taken to eliminate this ingress. After this, the boiler is melted, the pressure in it is raised to 1.5-2.0 MPa, this pressure is maintained for several hours, and then CO is produced again.

If it is impossible to eliminate the causes of moisture ingress or to light the boiler, conservation is carried out by maintaining excess pressure in the boiler (see clause 2.2).

2.1.7. If, during the boiler downtime, repair work was carried out on the heating surfaces and the need for pressure testing arose, then after pressure testing they continue preservation by maintaining excess pressure in the boiler (see paragraph 2.2).

2.1.8. When removing the boiler from the CO, remove the installed plugs and begin firing operations in accordance with the instructions for starting the boiler.

2.2.1. Maintaining pressure in the boiler above atmospheric pressure prevents air oxygen from entering it.

2.2.2. Excess pressure (EP) is maintained when deaerated water flows through the boiler.

2.2.3. Preservation while maintaining ID is used for boilers of any type and at any pressure.

2.2.4. The ID method is carried out when the boiler is put into reserve or repaired, not related to work on heating surfaces, for a period of up to 10 days.

On boilers with rolling connections of pipes to a drum, the use of the ID method is allowed for a period of up to 30 days.

2.2.5. To maintain ID in the boiler, feed or make-up water can be used.

The use of make-up water is possible provided that the pH value of this water is not lower than 9.0, and the oxygen content in it is not more than the oxygen content in the feed water of the boiler being preserved.

2.2.6. At block power plants, to supply feed or makeup water to the boiler for the period of conservation, it is necessary to install a collector and pipelines to it from each deaerator at a pressure of 0.6 MPa or a collector from the pressure side of the makeup water pumps, as well as pipelines from the collector to the pressure pipeline of the feed pumps each block.

2.2.7. At power plants with cross connections, feed water can be supplied to the boiler via an existing or specially installed bypass feed unit with a diameter of 20-50 mm (with a throttle washer).

To use make-up water from transfer pumps, jumpers are installed from the boiler filling pipeline to the supply pipelines in front of the economizer (E).

At power plants where there is a special conservation pump (Fig. 1), this pump can be used to supply feedwater to the boiler. When implementing this scheme, water is supplied to the inlet of the water economizer and to the outlet collectors of the superheater.

2.2.8. The discharge of conservation water from the boiler is carried out through the drains of the outlet sections of the superheater into drainage tanks or by implementing the scheme shown in Fig. 1, through the lower points of the boiler into the deaerator or lower tanks.

1 - tank for preparing chemical reagents with a capacity of 2-10 m3; 2 - conservation pump with a flow of 30-100 m3/h and a pressure of 0.5-0.8 MPa; 3 - reagents; 4 - make-up water;

5 - into the deaerator (drainage tank, make-up water tank); 6 - from other boilers;

7 - into the bubbler; 8 - feed water to the boiler; 9 — screens; 10 — feedwater deaerator; 11 - on the suction side of the PEN; 12 - to other boilers;

The water discharged from the boiler must be used in the steam-water cycle of the power plant, for which purpose at block power plants it is necessary to provide for the pumping of this water to neighboring blocks.

READ MORE: Print and draw stencils for walls for painting

2.2.9. On the pipelines for supplying and discharging conservation water, in order to disconnect them from the boiler during its operation, it is necessary to provide for the installation of shut-off valves, inspection valves or plugs.

2.2.10. After stopping the boiler and reducing the pressure to atmospheric, water is drained from it, after which they begin to fill the boiler with preservative water and organize its flow through the boiler.

The filling of the boiler is controlled by air vents, and the pressure and water flow are regulated using valves on the inlet and outlet pipelines. At block power plants, if possible, they include LDPE in the flow diagram.

2.2.11. During the conservation period, the boiler is maintained at a pressure of 0.5-1.5 MPa and water flow at a speed of 10-30 m3/h. Water samples are taken every shift from the clean and salt compartments of the superheater to determine the oxygen content.

When the pressure value goes beyond the specified limits, it is regulated by inlet and outlet valves.

If the oxygen content in water samples exceeds 30 μg/kg, increase the water flow through the boiler while intensively purging all air vents.

When preserving according to the scheme shown in Fig. 1 conservation pump can be used to maintain ID on several boilers at the same time.

2.2.12. Upon completion of conservation, the boiler is drained to the firing level and lighting is started in accordance with the instructions for starting the boiler.

2.3.1. When exposed to an aqueous solution containing hydrazine at high temperatures, a protective oxide film is created on the metal surface. A relatively small part of the iron oxides located on the metal surface participates in the formation of the film. Part of the existing iron and copper oxides, due to reduction to oxide and metallic forms, as well as the formation of complex compounds, loses its strong bond with the metal and is removed from the heating surfaces.

During the GO process of the economizer and screens, the heating surfaces of the superheater are filled with steam containing ammonia, which ensures passivation of these surfaces and protects the superheater during steam condensation after the boiler has cooled.

The concentration of hydrazine during treatment significantly exceeds the operational norm and depends on the temperature of the environment and the duration of treatment. The greatest efficiency is achieved at the highest possible ambient temperatures.

2.3.2. When treating a boiler with hydrazine at operating parameters (hydraulic fracturing), depending on the expected duration of downtime, the hydrazine content in the feed water is 0.3-3.0 mg/kg, and the duration of treatment is from 1-2 to 24 hours.

During the treatment period, the boiler operates in normal mode and carries the required load.

2.3.3. The hydraulic fracturing method is used on those boilers where corrective treatment of feed water with hydrazine is carried out.

2.3.4. Hydrazine treatment at operating parameters is carried out before the planned shutdown of the boiler for reserve or repair for up to 30 days.

This treatment followed by a dry shutdown (GRP CO) can be carried out before a planned shutdown of the boiler in reserve for up to 60 days, as well as before a shutdown for medium or major repairs.

2.3.5. At block power plants, it is advisable to dose hydrazine using a standard hydrazine installation on the suction side of feed pumps.

2.3.6. In cross-linked power plants, hydrazine is dosed into the feedwater before E.

To dose hydrazine in an individual-group phosphating scheme, standard phosphate dosing pumps should be used. Schematic diagram of hydrazine dosing (Fig. 2): hydrazine measuring tank with a capacity of 1-2 m3 - hydrazine solution collector on the suction side of phosphate pumps - phosphate dosing pump - phosphate line - jumper from the phosphate line to the boiler feed unit.

With an individual phosphating scheme and the location of phosphate units at a considerable distance from each other, it is advisable to install a separate unit for all or a group of boilers, including a hydrazine measuring tank and two dosing pumps (phosphate type) for supplying hydrazine to the feed unit of each boiler.

The hydrazine line may interfere with any of the feeder bypass or drain lines.

2.3.7. The measuring tank must be provided with a supply of a strong hydrazine solution from the hydrazine facility and make-up water.

In this tank, immediately before treatment, a solution of the required concentration is prepared, taking into account the performance of the metering pump, the required hydrazine content in the feed water and the expected boiler load.

1 — tank for preparing chemical reagents with a capacity equal to the water volume of the boiler with a superheater; 2 - pump for filling the boiler with a solution of chemical reagents at a flow rate of 50-100 m3/h, pressure 0.5-0.8 MPa; 3 - hydrazine measuring tank with a capacity of 1-2 m3;

4 — standard phosphate dosing pumps; 5 — phosphate working solution tank;

6 - hydrazine; 7 - ammonia; 8 — make-up water; 9 - to boiler No. 2; 10 - to phosphate pumps of other boilers; 11 — to the neutralization unit; 12 - to the drainage collectors of other boilers; 13 — make-up water; 14 — chemical reagents; 15 - feed water to the boiler;

HPF conservation project. Composition and list of documentation

If the technical re-equipment of a hazardous production facility is carried out simultaneously with its reconstruction, documentation for the technical re-equipment of such a facility is included in the relevant project documentation. Documentation for the technical re-equipment of a hazardous production facility is subject to industrial safety examination if the specified documentation is not part of the design documentation of such a facility, subject to examination in accordance with the legislation of the Russian Federation on urban planning activities. Regulations on the composition of sections of design documentation and requirements for their content, approved by Decree of the Government of the Russian Federation dated February 16, 2008 No. 87, establishes the composition of the sections of design documentation and the requirements for the content of these sections when preparing design documentation for various types of capital objects

METHODS OF PRESERVATION OF DIRECT FLOW BOILERS

3.1.1. Dry shutdown is used on all once-through boilers, regardless of the adopted water chemistry regime.

3.1.2. Dry shutdown of the boiler is carried out during any planned and emergency shutdowns of the boiler for up to 30 days.

3.1.3. After extinguishing the firebox and disconnecting the boiler from the turbine, close the shut-off valves on the supply pipelines.

Steam from the boiler through the BROU (PSBU) is partially released into the condenser so that within 20-30 minutes the pressure in the boiler drops to 3-4 MPa, while the air intakes remain open.

The drains of the input collectors NRCh and E are opened to displace water from the boiler with its own steam, while the PSBU (BROU) is closed.

After reducing the pressure in the boiler to zero, vacuum drying of the heating surfaces is carried out for 30 minutes, for which purpose the PSBU (BROU) is opened again. Then close the shut-off valves on the steam lines and on all lines connecting the boiler to the condenser.

The intermediate superheater is de-steamed to the condenser by opening the shut-off valves on the discharge lines from the hot steam lines. The vacuum in the system is maintained for at least 15 minutes.

When put into reserve, the ventilation of the gas-air path is carried out in accordance with the PTE, and when stopped for repairs - until the heating surfaces cool down.

3.2.1. Under the influence of an environment containing hydrazine at high temperatures, a protective oxide film is created on the metal surface, which reliably protects the metal from corrosion for a long time.

The concentration of hydrazine during treatment significantly exceeds the operational norm and depends on the duration of treatment.

3.2.2. When treated with hydrazine at operating parameters, depending on the duration of inactivity, the hydrazine content in the feed water is 0.3-3 mg/kg, and the duration of treatment is from 1-2 to 24 hours.

3.2.3. Hydrazine treatment is used on boilers when operating in hydrazine-ammonia or hydrazine mode.

3.2.4. The treatment is carried out in combination with CO when the boiler is put into reserve for up to 3 months. or withdrawal for medium or major repairs.

3.2.5. Hydrazine dosing is carried out using a standard hydrazine installation on the suction side of feed pumps or into the main condensate behind the treatment unit.

Immediately before treatment, a solution of the required concentration is prepared in the installation’s measuring tank, taking into account the performance of the metering pump and the expected load of the boiler.

| Duration of downtime, days | Duration of treatment, h | Hydrazine content, mg/kg |

| Up to 5 | 1-2 | 2-3 |

| 5-10 | 3-6 | 1-1,5 |

| 10-15 | 6-12 | 0,5-1 |

| St. | 12-24 | 0,3-0,5 |

During treatment, hydrazine levels are monitored by taking water samples from a sampling point in the feedwater line upstream of the boiler.

At the end of the GO, the CO is performed.

3.2.7. During the subsequent startup of the boiler, it is also necessary to maintain the hydrazine content in the feed water at 1-3 mg/kg for 24 hours until the quality of the feed water stabilizes at the normal level.

3.3.1. The treatment is carried out to restore damaged protective films due to increased oxygen dosages compared to operational ones. The oxygen content in the feed water increases to 1-2 mg/kg several hours before the boiler shuts down.

READ MORE: Izospan D technical characteristics - scope of application of the laying scheme and price of isospan D

3.3.2. Oxygen treatment is used on boilers when maintaining various modifications of the oxygen water regime.

3.3.3. The treatment is carried out in combination with CO when the boiler is put into reserve for up to 3 months. or withdrawal for medium or major repairs.

3.3.4. Treatment is carried out using standard oxygen or air dosing units.

3.3.5. During the treatment period before the planned shutdown of the boiler, the oxygen content in the feed water increases to 1-2 mg/kg 8-10 hours before shutdown.

During the treatment process, the oxygen content in the feed water in front of the boiler is monitored.

At the end of the specified time, CO is performed.

3.3.6. When starting up the boiler, it is also necessary to maintain an oxygen content of 1 mg/kg in the feed water for 30-40 hours until the quality of the feed water stabilizes at the normalized value.

3.4.1. The boiler is filled with nitrogen at excess pressure in the heating surfaces. During the conservation process, the nitrogen flow should provide a slight excess pressure in the boiler.

3.4.2. Nitrogen preservation is used on boilers of any pressure at power plants that have nitrogen from their own oxygen plants. In this case, the use of nitrogen is allowed at a concentration of at least 99%.

3.4.3. Filling with nitrogen is carried out when the boiler is put into reserve for a period of up to one year.

3.4.4. It is advisable to provide nitrogen supply to the steam exhaust pipeline from the expander at a pressure of 2.0 MPa and to the cold intermediate superheat lines.

The nitrogen supply diagram to the boiler must be made in accordance with clause 2.8.5.

3.4.5. After stopping the boiler and reducing the pressure in it to 0.2-0.5 MPa, open the valves on the nitrogen supply lines to the expander.

Before filling with nitrogen, the intermediate superheater is vacuum dried.

After cooling the boiler, the pressure in it is maintained at 5-10 kPa.

If the intermediate superheater is not switched off, it is continuously purged with nitrogen at an hourly flow rate equal to 10% of the volume of the purged circuit.

3.4.6. During the conservation period, measures are taken to identify possible gas leaks and eliminate them.

3.4.7. If minor repair work is necessary, the gas supply to the boiler may be interrupted for a short time.

3.5.1. Contact inhibitor M-1 creates a protective film on the metal that remains after the preservative solution is drained (see paragraph 2.9.1).

3.5.2. To preserve heating surfaces, the boiler is filled with an aqueous solution of an inhibitor with a concentration of 0.5-1.5%, depending on the duration of inactivity, the composition and amount of deposits on the heating surfaces. The specific concentration of the inhibitor solution is established after a chemical analysis of the composition of the deposits.

3.5.3. Preservation of CI is used for all types of boilers, regardless of the water chemistry regime used.

3.5.4. Preservation with M-1 inhibitor is carried out when the boiler is put into reserve or repaired for a period of 1 month. up to 2 years.

3.5.5. The preparation of the preservative solution is carried out in accordance with paragraphs. 2.9.5 and 2.9.6.

The inhibitor solution from the preparation tank is supplied to the deaerator.

It is also necessary to provide for draining the solution from the feed lines and the boiler after conservation into the storage tank using drainage tanks for this purpose.

3.5.6. Before conservation, drainage of the deaerator, supply pipelines, HPH on the water side and the boiler itself is carried out.

Filling of the boiler, supply lines and HPH is carried out using a booster pump, controlling the filling using air vents. When a continuous stream appears from the vents along the medium, they are closed.

When idle in reserve, the boiler is left filled with a preservative solution, tightly closing all shut-off valves on the boiler.

When taking it out for repairs, to form a protective film on the metal, the preservative solution must be kept in the boiler for at least 24 hours, after which the solution is poured into the storage tank.

3.5.7. To re-preserve the boiler, the preservative solution, after being idle in reserve, is drained from the supply lines, the PVD and the boiler into a storage tank for subsequent use.

There are no special water washes to remove the preservative solution during kindling.

What is re-preservation?

When the time allotted for conservation has expired, the equipment undergoes a reverse process, which involves preparation for operation. This means that preserved parts must be freed from temporary protective compounds and, if necessary, treated with other means designed for use on work equipment. It is worth noting the need to take precautions. Like technical preservation, re-preservation must be carried out under conditions that meet the requirements for the use of degreasing, anti-corrosion and other compounds that are sensitive to temperature and humidity. Also, when performing such procedures, special ventilation standards are usually observed, but this depends on the specifics of the specific equipment.

Method of preservation by creating excess pressure

Boiler valve connection diagram.

The instructions for boiler preservation technology by creating excess pressure are applicable regardless of the heating surface of the boiler. Other methods using water and special solutions are not able to protect intermediate superheaters of boilers from corrosion, since certain difficulties arise during filling and cleaning.

The proposed preservation technology is suitable for both steam and hot water boilers. The principle of this method is to maintain a pressure above atmospheric pressure in the boiler, which will prevent oxygen from entering it, and is used for boilers of any type of pressure. To maintain excess pressure in the boiler, it is filled with deaerated water.

The implementation of the method of maintaining excess pressure in stopped hot water or steam boilers is possible in several ways:

- When boilers are idle for more than 10 days, preservation by dry or wet methods is applicable (determined by the presence of certain reagents, cushioning materials, etc.).

- During long periods of inactivity in winter and in the absence of heating, boilers are preserved using the dry method; The use of the wet preservation method in these conditions is unacceptable.

The choice of one method or another depends on the operating mode of the boiler room, the total number of backup and operating boilers, etc.

Legal registration of the procedure

Preparation for the conservation process begins with the completion of formal procedures. In particular, the preparation of documentation is necessary so that in the future it remains possible to recognize all costs for the implementation of the event. The initiator of conservation may be a representative of the service personnel, who submits a corresponding application addressed to the manager. Next, an order is drawn up to allocate funds for the procedure and instructions are given to develop a project in which the requirements for conservation by technical services will be noted. As for the legal requirements, representatives of the administration, the management of the department responsible for the facilities, economic services, etc. must control the process of transferring the equipment into storage, etc. Thus, the composition of the commission is formed, which carries out the inspection of the preserved objects, draws up documentation, and evaluates the economic the feasibility of the project and draw up an estimate for the maintenance of the facilities.

5.1. Option 1

5.1.1. The most favorable conditions for turbine preservation are the combination of the normal regime of wet steam washing of the turbine flow part (where provided) with simultaneous dosing of a preservative into the steam or by dosing an aqueous emulsion of a preservative into the slightly superheated steam in front of the turbine with condensate discharge (in an open circuit).

5.1.2. Volumetric steam leaks are selected based on the conditions of maintaining low turbine rotor speeds (taking into account critical frequencies).

5.1.3. The steam temperature in the turbine exhaust pipe must be maintained at least 60 - 70 °C.

Specifications

It is worth noting that the characteristics of boilers differ not only due to different performance, but also depending on the fuel consumed.

The range of equipment produced is quite large; models differ in power, design, purpose and type of fuel. For comparison, we present several tables with the parameters of boilers using different fuels at a pressure of 13 Bar without a superheater.

Characteristics of boilers using gas and oil fuel:

Characteristics of boilers operating on solid fuel (coal):

Characteristics of boilers using wood fuel (waste, husks, wood peat):

Causes of equipment freezing

Operational problems can arise with both atmospheric and turbocharged boilers.

Closed-type devices are additionally connected to electricity. The automation and fan are powered from the mains. The latter is installed above the combustion chamber and forcibly removes smoke through a coaxial chimney to the street. The coaxial design consists of two pipes. Combustion air is supplied through one, and smoke is removed through the other.

The steam contained in the combustion products falls into condensate as the temperature decreases. The liquid on the pipe and terminal freezes, which leads to blockage of the draft and discharge paths. In this case, the protection is triggered and the operation of the device stops. Is it possible to turn off the device? It is recommended to open the plug on the top of the housing. Then the equipment will take in air naturally.

You cannot use the equipment in this form for a long time. As soon as the ice disappears and melts, you need to close the cap. Otherwise, contaminants enter the system, which leads to wear and tear of the product.

If freezing occurs frequently, then this method will not work. The solution will be to install an “Anti-Ice” design - this is a type of coaxial chimney.

What temperature should I set for normal operation? The optimal operating temperature at this time is indicated in the instructions for each model. It is best to adjust the thermostat to a lower power (first or second mode), then you will avoid frequent switching on and off, which leads to the formation of condensation.

Open type devices are also susceptible to freezing. The most common problem is the chimney. Ice and snow can be removed mechanically. At the same time, you will not avoid further freezing, so it is recommended to insulate the chimney.

Gas boiler houses

A gas boiler should be chosen if there is a gas main passing nearby. Gas is often the most popular and cheapest type of fuel in our country. It is worth noting that about half of all heating boilers installed in the Russian Federation use this particular fuel. For this type of boiler, you can use liquefied gas in cylinders, but this will increase the cost of its operation due to frequent refills. This heating option can be taken into account when designing, as a backup. The high level of efficiency makes it possible to heat houses with large square footage. Gas boiler houses are easy to use and consume economical fuel, which is its undeniable advantage.

One of the rules for operating boiler houses is: To install a gas boiler, you need to obtain permission from Gazgortekhnadzor, which is not so easy to do. You will need to obtain not only permission to install, but also obtain approval and pay a fee. When arranging such a boiler room, it is necessary to use the services of specialists in the design and installation of a chimney, since the safety of the structure itself depends on it. The room in which the boiler will be located must be equipped with access to the street and have good ventilation. Otherwise, the gas boiler may smoke.

Basic rules for operating boiler rooms with a gas boiler:

- Availability of a separate room (boiler room);

- the boiler room must have an area of at least 4.5 m2, the ceiling height is 2.5 m and above;

- the chimney must be made of acid-resistant and heat-resistant material;

- the upper edge of the chimney (head) must be raised above the level of the roof ridge by at least half a meter;

- horizontal sections of the chimney pipe should not exceed 1 m in length;

- the width of the entrance doors is made at least 80 cm;

- it is imperative to equip the room with a ventilation hole of sufficient area;

- it is necessary to have natural lighting at the rate of at least 0.3 m2 per 10 m2 of boiler room area;

- the presence of a gas analyzer is a must, as it is responsible for analyzing the environment and monitoring air pollution in the room. If the norm is exceeded, it automatically blocks the gas supply to the boiler.

- the boiler must be located at a distance of at least 20 cm from the nearest walls, the surface of which must be protected with fire-resistant material.

Care tips and advice

Proper maintenance of the boiler, performed regularly, will help keep it in working condition for a long time and avoid various accidents and accidents. Otherwise, the unit may break even in the first year of operation. Performing several operations will prevent this from happening:

- even during normal operation of the boiler, you need to contact one of the organizations carrying out work in this area, so that a technician inspects the device for gas and water leaks, the condition of the sensors and chimney, and, if necessary, carries out repair work;

- You should always monitor the water pressure inside or at the outlet of the system. If it drops below 0.8 bar, then water needs to be added;

- The addition of water to the system is usually carried out directly through the boiler, where there is a special tap. In this case, the pressure of the added water must be greater than the pressure of water from the boiler. The supplemented water should only be cold (up to 35°C).

Depending on the model and manufacturer, this process will be slightly different due to differences in design. This can be clarified in the instructions supplied with the device.

What rules must be followed?

When carrying out measures to preserve boilers in production, they are guided by the requirements set out in RD 34.20.591-97 “Guidelines for the preservation of thermal mechanical equipment.”

The same standards should be observed by owners of equipment installed in private homes.

If you are not confident in your knowledge or skills, contact your service organization. Specialists will carry out work to shut down the boiler and preserve the equipment in compliance with all safety requirements

What you need to remember if you decide to mothball your heating or hot water equipment yourself:

The above rules must be followed to protect your own health and preserve the equipment.

After a long period of inactivity, the heating and water heating system will require re-preservation - a process that also requires compliance with certain rules.

Where do we start?

A household gas boiler is a powerful and efficient device designed to heat the coolant and circulate the heated liquid through the heating system of the house. Modern boilers heat not only batteries, but also tap water in large volumes, have electronic controls and various safety mechanisms

When buying a boiler, you should pay attention to the heating area so that it is slightly larger than your living space

Naturally, you have already installed the unit itself and made all the necessary connections and piping of the heating system. We checked the chimney and draft, as well as the device itself for proper operation and absence of leaks. This stage of work, as a rule, takes place in the presence of gas industry employees, who carefully record all the results and “give the go-ahead” for the use of this device.

Before starting the boiler itself, it is necessary to fill the heating system - pipes and radiators - with coolant, that is, water. To do this, unscrew the valve at the bottom of the boiler. For different boiler models, the “appearance” of this supply valve may be different, but it cannot be confused with anything else. As a last resort, check the instructions for your device.

By opening the valve, we will begin to supply water to the pipes and radiators. Be sure to monitor the pressure level, wait for the mark of 2 - 2.5 atm. This indicator can be measured using the pressure gauge built into the boiler.

When the required pressure inside the system is reached, it is necessary to bleed off the air that may remain inside the batteries and pipes. Air locks significantly worsen the heat transfer of your battery, is this the result you are trying to achieve?

To quickly and effectively bleed air, you need to unscrew the Mayevsky taps on each battery. At first, you will hear a whistling or hissing sound - this is normal. If water starts running out of the radiator, it means there is no air lock.

When you have checked all heating devices, look at what the boiler pressure gauge now shows. The pressure will probably drop slightly and you will need to top up the heating system with water.

But in addition to plugs in the pipes, the normal operation of the boiler can be prevented by the air inside the circulation pump. This is easy to fix. Some models are equipped with an automatic air release system, but, as a rule, it is not effective enough, so it is better to get rid of the air manually the first time.

To do this, remove the front cover from the boiler body, then look for the pump itself - a cylindrical part with a plug for a flat-head screwdriver. Sometimes, the pump is located behind the dashboard, which is easily moved away or removed from the closures. To release air from the pump, turn on the boiler and start heating the water. The boiler will start up. The pump will also begin to engage in the working process - this will be confirmed by incomprehensible gurgling sounds inside the unit - do not be alarmed, this is air. Take a flathead screwdriver and slowly unscrew the plug. When water flows, screw the plug back. This procedure should be carried out several times. When you stop hearing the gurgling of water inside the device and your gas boiler starts working, it means that you have managed to completely get rid of the air inside the pump. At this stage, you should again check the pressure gauge readings with the instructions for the device. In principle, you can stop there - now your boiler will heat water inside the radiators, and if it is a double-circuit unit, then in the water supply.

But it would not be amiss to carry out pressure testing and flushing of the heating system. After these procedures, you will be 100% sure that the inside of the radiators is clean and your heating system has no leaks.

What rules must be followed?

When carrying out measures to preserve boilers in production, they are guided by the requirements set out in RD 34.20.591-97 “Guidelines for the preservation of thermal mechanical equipment.”

The same standards should be observed by owners of equipment installed in private homes.

If you are not confident in your knowledge or skills, contact your service organization. Specialists will carry out work to shut down the boiler and preserve the equipment in compliance with all safety requirements

What you need to remember if you decide to mothball your heating or hot water equipment yourself:

The above rules must be followed to protect your own health and preserve the equipment.

After a long period of inactivity, the heating and water heating system will require re-preservation - a process that also requires compliance with certain rules.