Many residents of city apartments had to learn from their own experience that it is impossible to create a favorable microclimate in an apartment without high-quality ventilation. It’s great when ventilation provides an influx of clean winter air into the apartment from the street, but it’s bad that at the same time we lose the same volume of heated air. In order to receive sufficient fresh oxygen and at the same time prevent heat loss, it is necessary to use a recuperator. There is a huge selection of recuperation systems on the market, but if you wish, you can easily make and install a recuperator with your own hands.

How to find out the efficiency of a recuperation system

Formula for calculating the efficiency of a recuperator

When making a recuperator yourself, it is not always possible to assemble a device with maximum efficiency. Moreover, the efficiency of the recuperator depends on the temperature and humidity of the air outside the room.

To calculate the efficiency of the recuperator, the formula is used: H = (tр - tу) / (tд - tу), where:

- tр – air temperature after recuperation;

- tу – air temperature before recovery;

- td – temperature of exhaust air leaving the room.

The total value should be multiplied by 100%. For example, let's calculate the efficiency of a device for specific conditions. The air temperature outside is 5 oC, after recuperation - 17 oC, indoors - 24 oC. Efficiency = (17 – 5) / (24 – 5) = 0.63 * 100% = 63%.

Advantages and disadvantages

Different models of devices differ in their characteristic features. For example, devices with a rotor are highly efficient, are not subject to icing in winter, and are able to control air humidity (within certain limits). Their disadvantages include a bulky structure with a large number of moving elements, which increases the likelihood of failure and increases the need for maintenance. In addition, they are quite noisy.

Plate models often attract attention due to their low price, compactness, and simple structure without moving elements. But in cold weather, under the influence of condensation, the plates freeze. This forces us to look for ways to combat this phenomenon. The most effective of them is to install a cellulose cassette that absorbs excess liquid. In this case, the water from the condensate is directed into the home and humidifies the air. This device works in all weather conditions.

How to make an air recuperator with your own hands for a private home

The first stage is the development of a drawing and selection of materials. The volume of passing air is taken into account. The air exchange rate is at least 0.35 per 1 hour or 30 m³/hour per resident. In the kitchen this figure is equal to or more than 75 m³/hour. These values depend on the fan performance and the useful cross-section of the air ducts.

Performance is calculated using the formula:

L is the required capacity, n is the calculated air exchange rate, and v is the volume of the room. Air duct diameter – 100, 125 or 150 mm. Depends on the size of the impeller. Artificially reducing the fan pipe can lead to the formation of a pressure difference.

Lamellar

A homemade plate recuperator differs in the directions of circulating flows. In direct-flow ones they have one vector of movement, in counter-flow ones they move towards each other. For self-production, it is better to apply the third principle - cross-cutting. The directions in the design intersect crosswise.

A plate recuperator can be easily made with your own hands

- Aluminum, galvanized metal. They bend easily, which simplifies processing, and they have a relatively low cost. But it must be taken into account that metal has a high thermal conductivity coefficient, which leads to freezing and the appearance of condensation.

- Polymers (plastic). Reliable, low probability of condensation. The disadvantage is the high cost.

- Special pulp. They have the highest efficiency and are easy to process. But they quickly collapse under high humidity in the building and are not suitable for swimming pools, bathhouses and similar premises.

For production you need plates. They are made from aluminum, steel, paper or plastic. Total area – up to 4 m². The gaps are formed from technical cork (roll) 2 mm thick. The elements are fastened with metal corners. The body is made of galvanized iron or plastic. You also need glue and sealant.

Manufacturing procedure

- Formation of sheets measuring 20*30 cm in the amount of 70-75 pieces.

- Glue three strips of sealant (cork) onto one side of the plate. One is located in the center, two are located on opposite edges.

- Glue the two finished platinums through the spacers. The stripes are perpendicular.

- This is how a sectional core is formed, in which the channels alternate in direction by 90°.

There are no cracks in the box and it is sealed. To reduce heat loss, insulation is installed on the inside. To connect to the air duct, inlet and outlet flanges are attached to the ends.

In the same way, you can make a plate recuperator from polycarbonate. Its advantage is that the gaps are already formed in the sheets. The polycarbonate should be cut into plates and glued together, taking into account the 90° offset of the direction of the air ducts relative to each other.

Tubular

The operating principle of this air exchange scheme is similar to the coaxial air duct for gas boilers. The tubular recuperator has two channels - external and internal. In the first, flows from the street pass through the space between the outer casing and the inner pipe. To exit the building, a pipe of smaller diameter is installed. Heat exchange occurs through its walls.

The outer box will be a sewer plastic pipe with a cross-section of 15 cm; a corrugated sleeve of 10 cm is used for the internal pipe. Adapters (adapters) from 150 to 100 mm for the tightness of the corrugation. Tees are used to form an air channel.

Manufacturing procedure

- Cut the plastic blank and trim the edges.

- Install two tees along the edges of the structure.

- Install the corrugation. It should be located in the center of the polymer pipe, without touching its walls.

- Connect the adapters using rubber seals and secure the edges of the corrugation. The joints can be treated with sealant.

For better circulation, a fan is installed in the reversible pipe. Ventilation grilles will provide protection from debris and dust. However, they will artificially reduce productivity due to a decrease in the useful cross-section of the line.

An alternative is to install a set of plastic pipes with a diameter of up to 16 mm and with a minimum wall thickness instead of a corrugated hose. Such drawings and diagrams will ensure maximum heat exchange, as the contact area of two media with different temperatures increases.

How to choose for private housing

The plate heat exchanger is ideal for use in private and country houses

The efficiency of the device directly affects the amount of stored thermal energy, service life and reliability of the recuperator. Rotor designs are the most efficient, but they involve many moving parts and require electricity. Plate and tubular recuperators have lower efficiency, but they are silent and do not require power supply for their operation.

The choice of a recuperator for private housing should first of all be based on the owner’s requirements and take into account what kind of ventilation system is present in the house. For a residential building, a supply and exhaust ventilation device with a rotary heat exchanger is optimal.

This system will have sufficient power, capable of not only carrying out heat exchange between air flows, but also regulating the level of humidity of the supplied air by regulating the speed of the device.

Ventilator with heat recovery for an apartment

If the house area is small, then instead of a rotary heat exchanger, you can install a device with metal plates. This will make the system not only more reliable, but will also help maintain the autonomy of the supply ventilation.

For standard apartments, one of the most important requirements when choosing a recuperator is its dimensions. In most apartments, the ventilation system is represented only by a common house hood, and fresh air is supplied through normal ventilation.

For apartments, the best choice would be to install supply and exhaust valves or air recovery units. These are compact devices that are mounted on the wall. The control unit is equipped with a remote control, which allows you to set the optimal parameters for ventilation and air heating.

Power calculation rules

When making a device with your own hands, you need to correctly calculate its power. Determine the amount of heat passing through the plates. For this, the formula is used: P=0.36xQxdT; Where:

P – recuperator power in watts: Q – energy required to heat or cool the air flow.

It is determined by the formula: Q=0.335xLx(t k.-t n.); Here:

L – air flow. Calculated in m3/hour. For 1 person this value corresponds to 60. t n. – initial temperature value; tk – final temperature, which increased as a result of heat exchange; dT – temperature.

After manufacturing and installing the recuperator, it is necessary to ensure the efficiency and duration of its operation. It is better to integrate special filters into the system, which include aluminum. Change them promptly if they become dirty. In winter, prevent the formation of an ice crust. To do this, sometimes it is necessary to turn off the fan that provides the flow of cold air.

Manufacturing of a tubular recuperator

Creating a tubular recuperator is much more difficult. But this task can be done if you follow the instructions correctly.

For this you will need:

- Pipe, 160 mm thick. For example, a cylindrical piece of sewer will do;

- Adapter splitters (100mm);

- Aluminum corrugation (100 mm).

The process of creating a recuperator consists of several steps:

- It is necessary to prepare the pipe by first polishing it;

- Next, you need to stretch the corrugated paper as much as possible and fill the pipe with it so that it is in the shape of a spiral;

- Now, you should seal the holes with corrugation from the open ends;

- The last stage of the assembly process is installing the adapters and running the air ducts through them.

Corrugated paper in this design acts as a “heat keeper”.

Recuperator diagram for home

What needs to be taken into account in the operation of different equipment models

Each air recovery system for a private home has its own strengths and areas of application.

The ventilation system in a private house with recuperation involves not only maintaining temperature and humidity levels, but also eliminating unfavorable odors. There is a varied selection of models on the market, differing in their functional characteristics and installation methods.

For example, a hood installed in the ventilation allows you to remove soot, odor and grease. At the same time, clean air enters the room, and greasy dust does not settle on the furniture. Such conditions have a beneficial effect on well-being and make cleaning the room easier.

Plate heat exchanger

The design of the heat exchanger is such that, due to separation by metal plates, the air flows do not mix. This simple engineering solution provides more efficient heat transfer. To create such equipment does not require large investments. Due to the absence of moving parts, such a device will last a relatively long time. Currently, the efficiency of such devices reaches 60-65%.

The elements are made of aluminum alloys. They are not subject to corrosive changes and have high heat transfer rates.

Rotor system

In such equipment, a small part of the air flows is mixed, since the air flow insulator is a brush with fine bristles. The rotor system occupies a larger area than the plate system, but also has high efficiency (up to 86% in the best models). The rotating rotor and the belt that turns it reduce the overall reliability of the device and increase energy costs for recovery.

Liquid recuperator in an office building

Scheme of liquid recovery in an office building

These are expensive models, but their efficiency is no higher than that of similar equipment. The main positive difference is the ability to place individual blocks at a great distance from each other. Therefore, liquid recuperators are mainly used in large commercial buildings. In private residential premises, a plate or rotary air recuperator for the home is usually used.

Breezer

An air recovery system for a private home and a breather differ in their purposes. The direct purpose of a breather is to heat the air. There is no heat exchange process in it, so it will take a lot of electricity to increase the air temperature.

Compact recuperator model

This model is local ventilation with a recuperator in a private house. Its use is worth thinking about. Compact models can be installed in the walls of different rooms. They operate separately, so they do not require connection to a centralized installation that configures and controls the operation of all devices.

In such models, due to the built-in fans, two air flows move synchronously. Work productivity can be changed using the remote control. At night, the device can be switched to quiet operation mode.

To prevent freezing, special channels are provided, next to which some of the warm air passes. But the effectiveness of this protection remains only up to -15ºС. Activating the exhaust mode helps remove frost and ice from the surface of the heat exchanger. This mode will also cope with purifying the air in the room from choking smoke and other pollutants.

A built-in filter protects against the penetration of debris from the street. The size of the filter cells is selected in such a way that it does not create any special obstacles to air flow, but protects against the penetration of insects and plant fluff. For maintenance, a removable cover is attached to the inside of the recuperator.

SOLUTIONS

Installation of a recuperator through a balcony or loggia.

A common task is to install a recuperator in a room adjacent to a balcony or loggia. In this case, we offer the following solutions.

1. Installation of the recuperator in a standard version, while the glazing sash of the balcony or loggia must be open. Air supply and exhaust is carried out from the balcony.

2. Installation of the device into the wall with a ventilation duct through the loggia to the street. Air supply and exhaust are carried out from the street.

Installation of the recuperator in a thin wall.

Modern insulated houses, houses made of timber or logs often have a wall thickness of less than 280 mm. Installation of devices in such walls is carried out using a special lining - a hood. The need to use a hood is due to the design of the Marley recuperator: a motor, filter and heat exchanger are located inside the channel.

The total length of the components is 28 cm. The hood creates a “thickening” of the wall; it is made of dense insulation and covered with a layer of elastic plaster for all-weather use. The mounting holes for attaching the external visor are prepared; installation does not require special skills.

Installation of the recuperator in a wall from 500 mm.

The standard configuration of Marley recuperators provides for installation of the device in walls from 28 to 50 cm. Above we looked at installation in thin walls. For walls from 500 mm and up to 1.5 meters, additional channels are used that are connected to the main elements of the recuperator.

When the color doesn't suit you.

The color range of Marley products is neutral - the devices are white, protected from ultraviolet radiation. When the design of premises or facades requires compliance, the parts of the recuperator can easily be painted in any color. The plastic elements of the MenV-180 and MEnV-180-PLUS recuperators are not glossy and the spray paint adheres reliably and lasts for many years.

Another option is to hide the device behind a picture. Marley supplies air to the sides and the painting will not be a hindrance!

When there is no access to an external wall

The recuperator installation technology involves installing the device without access to the external wall - all work is carried out from the room. From the street side you can see a flat ventilation grille, matched to the color of the facade.

Silent operation

The standard version of the Marley heat exchanger allows it to be considered the quietest due to its brushless silent fan, significant volume of heat exchanger, filter density and noise-reducing pads. But even these parameters can be easily improved by using an acoustic wave in the device channel and on the decorative panel.

Non-trivial solutions

The professionalism of our installers allows us to solve the most unexpected and difficult problems!

1. Installation of a recuperator in a domed house.

2. Installation of the recuperator through the loggia and cabinet.

Operating principle and device

The design of the product is quite simple: a monoblock, inside of which there are:

- heat exchanger;

- filters;

- fans;

- heaters (if necessary);

- additional devices (noise absorber, bypass air duct, etc.). These components are optional.

The recuperator works as follows:

- Using a piping system, an incoming and outgoing air flow is introduced into the device. In this case, no mixing occurs; they exchange heat through a thin metal partition;

- the treated incoming air enters the room.

Efficiency example:

A relatively cheap, technically simple plate recuperator is capable of heating incoming air with a temperature of -10 degrees to +6 due to the outgoing flow at a temperature of 24 degrees (comfortable home climate). Therefore, the heating system needs far fewer resources to make the fresh air pleasantly warm again.

Recuperator plates

What is a recuperator for a private home?

So, what is a recuperator? We are talking about a small household product, functionally consisting of several elements:

- intake mechanism - directs air from the street into the channel,

- a set of channels through which air flows circulate,

- drainage device - used to remove dirty masses from living space,

- ventilation with recuperator,

- diffusers are lattice elements that allow you to adjust the volume of oxygen moved and its direction.

The standard ventilation unit is not equipped with a recuperative heat exchanger. The movement and temperature of air masses remain the same. Ventilation systems with heat recovery are designed in such a way that fresh oxygen from the street, when passing through a heat exchanger, is heated by warm air that is removed from the room. The main feature of the installation is that the flows of cold and warm streams do not mix with each other.

This ventilation system not only ventilates the rooms in the apartment, it contributes to the formation of an optimal temperature in the living space without additional costs for heating it.

Why do you need a recuperator in an apartment? Device functions

The most important function performed by the recuperator is to provide room ventilation. The use of equipment gives many other positive effects, performing a number of functions:

Recuperator functionality

- Energy saving;

- Ventilation. Instead of exhausted warm air with low oxygen content, the apartment is filled with fresh air;

- Heating. The device fills the apartment with warm air, even if it is -30 degrees outside;

- Air cleaning. Relieves the room of unpleasant odors and dirt in the air;

- Unlike ordinary ventilation, during the exchange of air masses, dirt from the street, dust, insects does not enter the house, and drafts are also excluded.

During the recovery process, heat transfer occurs naturally, without the use of heaters. The heat exchanger does not affect the chemical composition of the air in any way.

Recuperator: what is it?

Air exchanger device

Supply and exhaust ventilation with a recuperator consists of several parts:

- device for air intake from the street;

- a device for removing air from the room to the street;

- ventilation with recuperator;

- connecting channels;

- adjustable diffusers that control the direction and amount of air moved.

The main difference between this system and conventional ventilation is the heat recuperator. Fresh air from the street passes through a heat exchanger, where it meets warm indoor air. The streams do not mix, but the cold stream warms up and enters the house already warm. This heating method makes it possible to achieve the optimal temperature in the room without increasing heating costs.

The device will eliminate fogging of windows and high humidity in the room

INCORRECT installation:

thanks our highly respected customer Yulia, who laid the foundation for this column! We invite you to share your experience, which will help other buyers of ventilation equipment avoid mistakes when installing recuperators.

Poor choice of installation location.

- installation in close proximity to the external unit of the air conditioner - noise and fumes enter the room.

- installation in the inner corner of the building - increased wind loads on high floors.

— this installation method significantly complicates service maintenance.

Installation in thin walls is not permitted.

The minimum wall thickness for installing a recuperator is 170 mm. Failure to comply with this requirement may result in the formation of cold bridges and, as a result, condensation on the inside of the outdoor mounting plate. This problem is eliminated by installing another hood on the side of the room. When using a hood, we recommend installing the motor as recommended.

WRONG:

RIGHT:

Model rating

Thanks to reviews from satisfied users, we were able to compile a rating of the best recuperators known today. Each model is accompanied by a brief overview describing the characteristics and features of the devices.

Vakio base

The presented model of the recuperator is equipped with 3 operating modes: exhaust, ventilator, recovery. In winter, there is no need to pay for heating the living space. The device works automatically.

The described recuperator extracts exhaust air for 40 seconds, after which the direction of movement of the blades changes, returning heated fresh air to the room. The rotating platform, which provides high pressure of air masses, is responsible for changing modes.

Today, this model is presented in several trim levels. Some have a built-in noise suppressor, while others have this structural element as a separate unit. Also included are filters.

An important advantage of the product is its low cost, no electricity costs and compact size. Installation of the device does not require special knowledge or effort. Among other things, the presented model easily removes dust floating in the air.

Marley

The operating principle of this model is reversible air supply. The direction of air masses changes every 70 seconds. A complete change of air in the apartment occurs in 2 hours.

This model is distinguished by a high level of efficiency, achieved thanks to the operating modes of several recuperators, the connection of which occurs via radio communication. A special cover is installed in the room, which indicates by flashing a red light that the air needs to be replaced.

The design of the presented model contains ceramic elements located inside a heat-insulated tube. It is responsible for heating the air entering the room. On the outside there is an external casing that does not allow insects and large dust particles to pass through. A fan with 3 power levels is hidden under the casing.

An important advantage of this model is its ease of operation. You can carry out a technical inspection yourself; just remove the cover, remove the ceramic element and remove the filter.

Mitsubishi electric lossnay

Thermal exchange of air masses processed by this recuperator model occurs inside the chamber. Not far from the filters there is a special mesh that protects the exhaust fan. Below there is a centrifugal fan that creates high pressure. When installing this model, it is necessary to make 2 holes in the wall at a slight angle through which the air ducts will pass.

At low speed, air processing is significantly reduced, but there are no extraneous sounds.

Thanks to the thin walls of the filter, there is a free exchange of air and humidity, which creates an optimal microclimate in the room. The device body contains the terminals necessary to connect the switch. Of course, you can make a switch with a socket or install the device in hidden wiring.

How to make an air recuperator for your home with your own hands

To make your own air heat exchanger you will need:

- Galvanized iron, 2 sheets.

- Plywood frame for the recuperator body.

- Cork material 20 mm thick for laying between sheets.

- Silicone sealant.

- Pressure meter.

- Plastic flanges.

- Jigsaw and hardware.

- Metal corner.

- Thermal insulator (mineral wool).

Air exchanger diagram

- Galvanized steel is cut into square pieces with edges of 30 and 20 centimeters. To make a recuperator for a private house, you will have to cut 70 plates. The metal is cut with a jigsaw, trying to ensure that the edges are completely smooth.

- A cork covering is glued to one side of each plate, with the exception of the last one. You can use a cork with a ready-made adhesive layer.

- All plates are assembled into a single system, with each of them being laid at right angles to the previous one. The installation is completed by a plate without cork covering.

- The resulting structure is secured using a metal corner.

- To secure the flanges to the walls of the cassettes, you will need to install fasteners. A drainage hole is left at the bottom to remove condensate through the tube.

- Metal corner guides are installed on the surface of the walls. If necessary, the cassette can be removed from the housing and cleaned.

- Mineral wool 4 centimeters thick is attached inside the body. A pressure sensor is attached to the places where warm air passes. It will help you deal with icing in a timely manner.

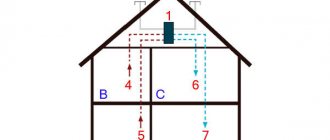

The basic principle of organizing ventilation

All that remains is to install the finished device in the ventilation sleeve. Using the same principle, you can make a recuperator for an apartment.

What is an air recuperator?

The air recuperator is a surface type heat exchanger. It is used to reuse the heat from the exhaust gases. This occurs continuously through the wall, which acts as a separator. Unlike a device such as a regenerator, the flows in a recuperator do not change their location.

An air recuperator is a device that minimizes losses through the ventilation system. As a result, this device can be called an energy-saving device. It involves the reuse of heat in the implementation of one technological process.

How the device works

The design of the air recuperator is quite simple. This affects the operation of this device. Its functioning is as follows:

- The flow of air into the room and its exhaust from the room occur simultaneously - in parallel with each other.

- Warm exhaust air is sucked into the device by a fan, thus entering the heat exchanger.

- Passing through the heat exchanger, the warm exhaust air exits to the outside of the structure itself.

- Cold fresh air is sucked into the room using reverse draft, passing through other parts of the heat exchanger.

- The heat from the air in the room is thus used to heat the cold flow that enters the room through the device.

Constant, non-intersecting air flows of different temperatures can provide recovery efficiency of more than 90%.

Why do you need a recuperator?

The popularity of air recuperators is due to several factors. They are used for the following purposes:

- improving the functioning of supply and exhaust ventilation in premises;

- providing apartments, private houses, businesses and offices with clean air;

- normalization of the temperature of the air flow entering from the outside;

- creating an optimal microclimate for human life in the room.

A recuperator is an effective and reliable device that is much better than standard supply and exhaust ventilation systems. It allows you to remove exhaust air from the premises, using its heat to heat the flows coming from outside the building. In turn, in the summer, the device works in the opposite way. In such situations, the cooler air in the room cools the warm flow that enters the room from outside.

Which one to choose for an apartment or a house?

The consideration of the types of existing recuperators can be continued further by talking about the types of ribbed plate recuperators, etc. But the issue of independent production of such a design and its practical application in one’s own house or apartment is of interest. First of all, you need to think about the required type of heat exchange unit. If all the windows in the apartment are plastic and effective ventilation is required, it is better to give preference to the ready-made industrial compact assembly DRTVV (“warm window”).

The recuperator will provide good ventilation in the room

For private households, where the issue of free space is not so acute, one of the cross-flow or counterflow plate designs is quite suitable. They are the easiest to make yourself. Below we consider the simplest way to independently manufacture a plate-type heat exchanger itself. Circuit solutions for automatic control, a damper device for switching to the bypass channel, etc. can be found on the corresponding Internet resources or in specialized literature.

Recuperator installation

During installation, a ventilation system with heat recovery requires mechanical fastening to the main wall and connection to common exhaust inlets and outlets. The junction points are sealed, and the recuperator is placed in a special housing designed to enhance thermal protection and noise absorption.

More difficulties arise at the stage of designing a ventilation system, when it involves the installation of a duct recuperator. The need immediately arises to lay a pair of air ducts in each living space to take in and supply air. Correct calculations are very important here, on which the noise level depends.

General house ventilation with recuperators organizes air exchange exclusively in residential premises. Kitchens and bathrooms are excluded from the network and the installation of exhaust ducts goes past the heat exchanger, which is sensitive to high levels of dirt and humidity. Or additional air flow filtration units are installed, equipped with grease-stopping and disperse membranes. It is also possible to install multi-channel recuperators with the connection of auxiliary circuits for technical premises.

Option for installing supply ventilationSource climate-technology.ru

How does the heat exchange mechanism work?

Let's take a closer look at how a recuperative heat exchanger works and how economical heat consumption is achieved. To understand all the processes taking place in a small building, you should dwell on the principle of operation of the installation.

- Inside the device there is a heat exchanger that retains the heat of the room air and transfers it to the supply oxygen. An air recuperator is most beneficial for a home or country cottage, where you have to pay for every kilowatt of electricity consumed.

- The flows do not mix with each other, which allows you to maintain the purity of underwater oxygen.

In the context of savings, ventilation with heat recovery for an apartment is already losing its relevance. The system’s ability to eliminate allergens and dangerous impurities that are so rich in the urban environment comes to the fore.

An air recuperator for an apartment is capable of completely renewing the atmosphere within a living space in 2-3 hours, filling it with filtered oxygen at the optimal temperature.

Air exchange is carried out in a small two-chamber device. Each of the flows moves through its own chamber, which eliminates the possibility of mixing. Supply ventilation, supplemented by a recuperator, retains up to 70% of heat. The efficiency of the unit depends on the quality of the ventilation system.

A heat recovery system in the form of an integrated ventilation unit is more expensive than conventional solutions. The average return on costs is 2-3 years. If we add to this the health benefits of residents, who do not get sick with acute respiratory infections so often and use anti-allergy medications less often, then the benefits of the installation become obvious.

How to make an air recuperator for your home with your own hands

To make your own air heat exchanger you will need:

- Galvanized iron, 2 sheets.

- Plywood frame for the recuperator body.

- Cork material 20 mm thick for laying between sheets.

- Silicone sealant.

- Pressure meter.

- Plastic flanges.

- Jigsaw and hardware.

- Metal corner.

- Thermal insulator (mineral wool).

Air exchanger diagram

- Galvanized steel is cut into square pieces with edges of 30 and 20 centimeters. To make a recuperator for a private house, you will have to cut 70 plates. The metal is cut with a jigsaw, trying to ensure that the edges are completely smooth.

- A cork covering is glued to one side of each plate, with the exception of the last one. You can use a cork with a ready-made adhesive layer.

- All plates are assembled into a single system, with each of them being laid at right angles to the previous one. The installation is completed by a plate without cork covering.

- The resulting structure is secured using a metal corner.

- To secure the flanges to the walls of the cassettes, you will need to install fasteners. A drainage hole is left at the bottom to remove condensate through the tube.

- Metal corner guides are installed on the surface of the walls. If necessary, the cassette can be removed from the housing and cleaned.

- Mineral wool 4 centimeters thick is attached inside the body. A pressure sensor is attached to the places where warm air passes. It will help you deal with icing in a timely manner.

The basic principle of organizing ventilation

All that remains is to install the finished device in the ventilation sleeve. Using the same principle, you can make a recuperator for an apartment.

How to find out the efficiency of a recuperation system

Formula for calculating the efficiency of a recuperator

When making a recuperator yourself, it is not always possible to assemble a device with maximum efficiency. Moreover, the efficiency of the recuperator depends on the temperature and humidity of the air outside the room.

To calculate the efficiency of the recuperator, the formula is used: H = (tр - tу) / (tд - tу), where:

- tр – air temperature after recuperation;

- tу – air temperature before recovery;

- td – temperature of exhaust air leaving the room.

The total value should be multiplied by 100%. For example, let's calculate the efficiency of a device for specific conditions. The air temperature outside is 5 oC, after recuperation - 17 oC, indoors - 24 oC. Efficiency = (17 – 5) / (24 – 5) = 0.63 * 100% = 63%.