Advice from professionals

To ensure quality work when plastering a stove, professionals recommend:

- Proper mixing of the solution. To do this, you can take a small amount of the mixture and roll it into a ball in your palm. If cracks form on it, you need to add a little water.

- The mixture should be viscous so that it can be easily applied.

- Before starting work, all cracks must be repaired.

- To strengthen the plaster, use reinforcing mesh.

- After plastering, you cannot immediately heat the stove, otherwise the coating may crack. You need to wait until it dries completely.

For high-quality plastering of the stove, the main thing is to mix the solution correctly - it should not be too liquid or thick. Following the instructions will allow you to avoid common mistakes and get a durable and aesthetic lining for your home stove.

Surface preparation process

It is important to start work by treating the surface of the oven. If there is old plaster on it, it must be removed

Exposed brickwork must be perfectly clean. You can use a spatula to clean it. The surface must be cleaned carefully, avoiding sudden movements that could damage the masonry.

If cracks are found on the surface, they should be treated with special oven glue.

To treat cracks, the glue is brought to a thick sour cream state, after which the surface must be cleaned of dust using a brush

Then, it is important to moisten the same brush with water and treat the holes. Next, this defect must be treated with glue using a spatula

After all defects have been eliminated, it is necessary to apply a primer mixture to the working surface. An acrylate mixture is suitable, which is capable of penetrating deeply into the material, filling all the pores, and forming a film on the surface.

This will ensure a stronger connection between the primer and putty. The mixture should be applied with a brush and rubbed in. After this, you need to dry the oven, leaving it on for a day.

General rules for carrying out work

Before directly plastering the stove onto the work surface, the following work must be completed.

- The plaster must be stirred to achieve a homogeneous mass and the consistency of thick sour cream.

It is important to remove all contaminants from the working surface of the stove (dust, remnants of the previous plaster that were used when laying the stove). To improve the “grip of the mortar”, you need to clear the masonry seams to a depth of about fifty millimeters

Before application, it is important to heat the oven a little in order to achieve 20–25 degrees of heat; On warm walls, the plaster will lie more evenly, and an excellent level of quality will be achieved.

After all the preparatory procedures, you need to proceed to the main part:

- Additional surface cleaning.

- Treatment of cracks.

- Surface primer.

- Installation of reinforcing mesh.

- Plastering the stove

Plastering stoves with your own hands

When building a stove or creating a fireplace, you will need to decide not only on their design, but also on the facing material, mortar for fireplaces and stoves, chimney, and backing brick. A direct component of the process of creating a fireplace or stove is the solution for lining the stove or fireplace. The appearance of unlined stoves, as a rule, is not aesthetically pleasing; in addition, dust accumulates in the masonry seams, which, when the stove is heated, becomes a source of unpleasant odors. You can avoid such unpleasant consequences by plastering the stoves yourself or by covering them with decorative ceramics, tiles, glazed tiles, etc.

Composition of solutions for plastering ovens

The composition of mixtures for stoves and fireplaces may be different. To plaster the stove, you can use simple clay or complex mortars: lime-clay-sand, lime-gypsum, cement-clay-sand. The mortar for plastering the stove can be prepared either independently or purchased ready-made. Which dry mixes for the oven should you prefer in your case?

Plastering stoves with clay is the most common application. Plastering of the front surfaces of the structure begins after the brickwork has completely hardened, when the possibility of its further shrinkage is excluded. As a rule, this requires at least a month. Properly prepared composition of the mortar for plastering the stove is a guarantee of a long service life.

To prepare a clay solution, the clay must be soaked the day before work begins so that it absorbs water. The sand is pre-sifted. A mixture consisting of soaked clay, sand and water is stirred with a hammer drill with a mixing attachment until a homogeneous mass is obtained.

The amount of sand required for mixing into the clay is determined by its fat content. At a high value of this indicator, the proportion of the constituent components of the mixture is either 1/3 or 1/4. The strength of the plaster is increased by adding crushed glass fiber or asbestos fiber (0.1/0.2 share) to the clay solution.

PLEASE ATTENTION: a high-quality solution for plastering a stove should lie relatively easily on its surface and at the same time be smoothed out well

How to properly lay plaster on the surface of the stove?

The start of work is preceded by cleaning the front surface of the structure from dirt, dust and remnants of masonry mortar. To improve the adhesion of the mortar to the brickwork surface, first clear the seams to a depth of about 0.5 cm. Before lining, the oven is heated so that the mortar is applied to the warm walls.

How to prepare plaster for a stove? Below are the proportions of the most common types of plaster mixtures for plastering stoves:

Necessary tool

When carrying out work on plastering the stove on your own, you should prepare in advance the appropriate tools and containers for the solution:

- trowel or plaster spatula;

- falcon;

- grater and grater;

- rule;

- metal brush;

- brush or brush for wetting the surface;

- construction mixer;

- corner rail.

When preparing the solution, you will need a shovel, scoop, measuring containers, sieve, scales, and a container for mixing ingredients. It is better to control the leveling of the surface using a building level. A chisel and hammer may be useful for removing old plaster. A vacuum cleaner will help get rid of dust.

What results can be expected after finishing its cladding?

The results that indicate the successful completion of the stove plastering work are:

- The deviation from the vertical plane along the entire height of the structure should not exceed 1 cm.

- The horizontal deviation of a similar indicator should not be more than 2 cm.

- The deviation of the thrust between the corners from the straight line should not exceed 0.3 cm.

- The depth of differences from a flat plane formed when applying the two-meter rule should not exceed 0.2 cm.

Choosing the composition of the plaster

The question of how to plaster brick stove walls is the most important one when planning such an event. It should be said right away that the usual cement-sand mortar used for plastering the walls of a building is not suitable for stoves. It will simply crack in a very short time. For plaster, you can use a ready-made mixture intended specifically for this purpose, or prepare it yourself, but according to a special recipe.

To solve the question of what to plaster with, simple 2-3-component mixtures and complex compositions with the addition of various ingredients (fiberglass, asbestos, salts, plasticizers, etc.) can be used. The composition of the mortar also depends on the type of brick used for the construction of the stoves (fireclay, red brick, silicate varieties, etc.). Certain components added to the plaster increase its adhesion to the material.

If you decide to use ready-made materials, then you need to purchase a stove or fireplace plaster mixture. All the necessary ingredients have already been added to it, and preparation for application consists of diluting it with water in the proportion specified in the instructions. When using them, one caveat should be taken into account: their long-term storage is undesirable, since atmospheric moisture can lead to premature hardening of the mixture in the form of poorly soluble lumps.

Most often, homemade solutions for plastering stoves are prepared of the following types:

- clay;

- lime-clay;

- calcareous-sandy-clayey,

- lime-gypsum;

- cement-sand-clay.

The practice of furnace construction shows that it is precisely such compositions that are least susceptible to cracking when heated. Other additives are also introduced to improve properties.

When preparing the solution, it is important to choose the correct proportions of ingredients. Precisely selected composition allows you to easily and evenly apply a thin layer to the stove wall

In particular, a certain consistency of the composition is used as grout. The viscosity of the solution is regulated by the proportions of water, the plasticity largely depends on the amount of sand, and the more sand there is, the less elasticity of the mass.

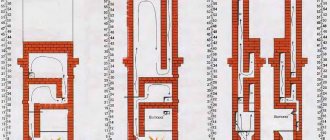

Stove plastering technology

When the decision on how to plaster the stove has been made, you can begin work, the first stage of which is to prepare the following list of tools:

- Suitable container for mixing the solution;

- Drill with appropriate attachment;

- Trowel;

- Sandpaper;

- Grater;

- Brush;

- Bucket for water;

- Building level;

- Burlap or fiberglass mesh with small cells;

- Nails;

- Primer.

The stove is plastered using the following technology:

- The stove masonry is moistened with water, after which a liquid solution is applied to it from top to bottom. A thicker composition can be applied on top of the liquid layer. The thickness of the layers of plaster should not exceed 5 mm, and in order for the coating to dry evenly, it must be applied in even layers.

- When the plaster begins to dry, it needs to be rubbed in with a wooden float to get a smooth and even surface. If the coating has already set and does not allow itself to be smoothed, then the plaster is sprayed with water and rubbed with a wooden brush.

- The applied and hardened plaster must be completely covered with lime milk and salt (100 g per bucket of water). At the end of the work, you need to check the plaster for alignment: the deviation from the vertical should not exceed 10 mm, from the horizontal - 2 mm, and the deviation of the thrust from the vertical axis can be no more than 3 mm.

Features of the problem

Why is it recommended to plaster a brick oven? In terms of increasing the reliability of the entire structure, it is necessary to note the fact that the plastered brick is protected from the direct influence of aggressive bath factors (temperature changes, moisture, steam). The brickwork itself increases the strength and tightness of the seams. The bonding material is less susceptible to cracking. 2 important reason - improved appearance. After plastering, the stove has a smooth wall surface, which gives it neatness and makes it possible to create a specific interior.

//www.youtube.com/watch?v=kXcpeiwD3dw

Brick oven plaster has its own specific characteristics. First of all, this is due to the high temperature on the walls during its operation. The plastered layer must withstand the following influences: prolonged heating and open flame, temperature changes, mechanical influences, smoke and steam, oil splashes during cooking. As the oven heats up, the brickwork tends to expand significantly, and therefore the plaster solution for ovens must have increased elasticity in order to withstand such loads without cracking.

One of the functions of the stove is to heat the room. This condition dictates one more requirement for stove plaster - good thermal conductivity. If additional significant energy is required to heat this layer, then the efficiency of the entire structure will significantly decrease. In addition, when heated, the material used for plaster should not release substances harmful to the human body.

How to close the chimney?

Clay plaster

It can be tiled with ceramic tiles using cement plaster as a base. The proportions of cement and sand are 1:4. A fireplace chimney does not heat up as much as a stove chimney, because there is much less draft in it.

Lime-cement mortar is suitable for very hot surfaces. It is much stronger than clay, but it is more difficult to repair.

Chimney lining outside the house

The brick walls of the chimney are subject to large temperature changes, especially in winter. On one side there is hot smoke, on the other there is cold air. Because of this temperature difference, the brick breaks down over time. In addition, stove smoke contains oxides of sulfur and nitrogen. If the top of the chimney is cold, then water vapor on its walls condenses and, mixing with oxides, forms acids. This acidic condensate, as well as the temperature difference, destroys the brick pipe.

To prevent such a situation, part of the chimney outside the house must be insulated. To do this, a frame is installed, insulation is fixed on it, and everything is covered with tin sheets. Simply plastering the brickwork will not be enough.

chimney, insulated and covered with tin

Purchased heat-resistant mixtures

Ready-made stove plaster can also be used for finishing. There are many varieties of such mixtures. But the most popular are “Pechnik” and “Terracotta”. The advantage of such plasters in comparison with those prepared by hand is a high degree of heat resistance. “Pechnik” and “Terracotta” are able to withstand temperatures up to 200 degrees.

Whatever mixture is used for plastering the stove, purchased or homemade, there is no need to prepare a large amount of it at once. The volume of a single serving should not exceed 8-10 liters. In any case, the solution needs to be developed in a maximum of 2-2.5 hours.

Finishing stoves and fireplaces after plastering

How to paint a plastered stove?

In the future, the plastered surface can simply be whitewashed with water-based emulsion, lime, chalk, painted with heat-resistant paint, colored varnish and decorated with stucco. Since oil solutions darken faster when exposed to temperature, it is better to use pentaphthalic paint or nitro enamel.

Please note that all heat-resistant compounds have a very strong odor and release toxic substances when dry, so it is better to work with them in a respirator. Such compositions take longer to dry than conventional ones.

Decorative plaster

As decorative materials, you can use mineral compositions such as Bayramix, Misan, Ortner, etc. The surface of a stove or fireplace, finished with stucco or a rough decorative primer, and then treated with latex water-dispersed dyes, looks very original.

Another interesting option is to add brick flour to the water-based emulsion and then coat it with colorless heat-resistant varnish. For decoration, special plastic stamps for plaster are also used, with the help of which all kinds of embossing are made on the surface. Material costs with this method are minimal, and a stove or fireplace finished in this way looks simply great.

Tiles and tiles

As mentioned above, ceramic tiles can only be glued to those walls of fireplaces and stoves that do not heat up very much, for example, to a fireplace chimney. Even heat-resistant tile adhesive will not last long on hot surfaces.

Tiles have been used for hot stove walls for centuries. This is a special ceramic tile with a rumpa - a frame on the back side, which is filled with clay or sand. In the walls of the pump there are holes for attaching the tile to the stove masonry with wire or pins.

This type of finishing has many advantages:

- The thermal cushion of the pump allows you to retain heat longer without additional heating;

- protection from burns and fire at home;

- reliable mechanical fastening will not allow the tiles to fall off;

- a beautiful front side will turn the stove from a heating device into a home decoration;

- The surface covered with enamel or glaze is easy to clean.

Tiles are not only a functional solution for cladding, but also a way to create a unique interior for your home.

So, finishing stoves and fireplaces with your own hands is not such a difficult process. If the sequence of work is followed and the correct choice of mixture for plastering and final finishing, such a structure can be turned into an original and unusual part of the interior.

Decorative design

The versatility of plaster makes it very flexible when it comes to decorative work. Since ancient times, stoves have been decorated with paintings, which can still be done by covering the walls with whitewash, as well as using water-based paints. Moreover, a damp, unbleached coating is an excellent opportunity to decorate the interior with frescoes.

Many types of decorative plaster can imitate noble stone chips. Special tools or the use of improvised means in the form of brushes, washcloths and even plastic bags will allow you to create a unique surface texture for every taste.

In addition, plaster goes well with decorative tiles, from which you can lay out interesting patterns, and, if desired, mosaics. Also, the presence of corner elements will make the creative process a little easier, and the appearance of the stove much more impressive.

Furnace painting

So, now you know how to plaster a stove so it doesn’t crack. Of course, after the applied solution has dried, its surface must also be whitened. It is best to use a milk-chalk mixture for this purpose. This whitewash tolerates temperature changes well and also does not get dirty. In order to prepare it, you just need to mix 1 kg of crushed chalk with 2 liters of milk. You can also paint the stove with regular lime. This finish will also not deteriorate due to high temperatures. In order for the lime to stick better to a hot surface, you can add a little table salt (35 g per 1 kg).

You cannot paint stoves and fireplaces using oil paint. The drying oil contained in such paints will begin to evaporate at high temperatures, and an unpleasant odor will appear in the room.

Secrets of professional cladding

There may be several reasons why stove plaster may begin to peel off:

- Incorrect seam thickness.

- Incorrect ligation of brick rows.

- Stove overheating.

In order to prevent this problem, the stove is covered with burlap before lining. To do this, it is pre-soaked in liquidly diluted clay, and the surface of the furnace walls is covered with a thin layer of clay solution. A piece of burlap is straightened and placed around the perimeter of the oven in such a way as to avoid air gaps. In this case, the furnace must not be allowed to overheat.

As an alternative to burlap, you can use a thin steel reinforcing mesh, the cell size of which is no more than 1×1 cm. To attach the mesh to the brick, use wire 0.3 cm thick. It is important to remember that it must be installed in advance at the construction stage ovens in each of the rows of masonry. After the mortar for plastering the stove has completely hardened, it is covered with lime milk, to which salt is added (at the rate of 100 grams per bucket). Paint the stove with chalk and lime milk.

NOT ACCEPTABLE: professionals strongly recommend not using oil paints - when heated, they decompose, and the drying oil begins to burn.

Preparation of the solution

If you want to save money, make your own mortar for plastering stoves: the proportions and preparation technology are below.

Simple solution

Prepare a simple mixture like this: sift the sand, mix it with clay, pour it into a container, add water and stir with a mixer until creamy.

The proportions of clay and sand for plastering stoves depend on the fat content of the clay. If it is oily, add 3-4 parts of sand to one part. To determine the fat content of clay, put it in a bucket, pour in water and at the same time stir until creamy. Then scoop up a little with a board. If the clay covers it by 1 mm, it means it is not greasy. If it’s in a thick layer, it’s oily.

Application stages

Preparation of work

Before applying the solution, a reinforcing mesh is fixed to the walls of the structure. Before plastering the stove with clay and sand, you need to carry out preparatory work:

- Make sure the brickwork is completely dry. It is prohibited to finish the structure immediately after completion of the masonry. You need to wait from 2 weeks to a month.

- Plaster will not last long if the masonry is not thoroughly cleaned of dust and soot. This rule is especially relevant for sauna stoves.

- Thoroughly rub the walls and light the stove, since the solution is applied exclusively to a warm surface.

- After cleaning, it is recommended to secure the reinforcement wire. This way the plaster will stick better.

- At uneven angles, metal analogues are installed. and the seams should be primed.

Covering

The last layer of plaster is necessary in order to completely level the surface of the stove. The primer needs to be moistened quite generously before applying it. The solution in this case should be used even less thick than for the first two layers. The mixture should fill absolutely all cracks and irregularities remaining on the surface. The thickness of the covering layer can be from 2 to 5 mm. It is impossible to level the stove in planes with plaster. Ultimately, the total thickness of the finishing layer should be no more than 1-1.5 cm. When laying out brick stoves for your home with your own hands, this should be kept in mind. When performing this work, you should initially try to make the walls as even as possible.