Heating in a private house, and indeed heating water in it, is something that must be equipped in order to live in comfortable conditions. And the more economically the water heating process is organized (and in this case you cannot do without equipment such as BKN), the better it will be for the cottage owner, because this will reduce costs. Connecting an indirect heating boiler to a single-circuit boiler is not an easy task, but it can be easily solved independently. The main thing is to understand how this is done.

Connecting an indirect heating boiler to a single-circuit boiler

Indirect heating boiler - what kind of unit?

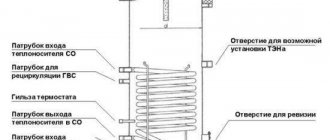

This phrase means a tank filled with water, which is equipped inside with a heat exchanger coil connected to a boiler responsible for heating the house, or to another system within which some coolant circulates. The water in such a unit becomes hot due to the fact that the liquid supplied directly from the boiler to the heat exchange coil gives up its energy to the liquid located in the boiler tank itself. That is, it does not heat up directly, but only absorbs heat from another source. This is where the name for this unit came from – an indirect heating boiler.

Indirect heating boiler

Water heated in the unit can be used for a variety of household needs. Moreover, it remains in a heated state for a long time, since the system itself maintains the desired temperature level. By the way, you can install such a boiler not only in a cottage, but also in an apartment, hotel or other premises.

The boiler itself is a metal or plastic container, parallelepiped or cylindrical. The capacity of the tank can be anything and sometimes amounts to thousands of liters.

Indirect heating boiler device

On a note! The tanks of some units may be coated on the inside with glass-ceramics, enamel or other materials that help maintain water in proper quality and protect the metal of the tank from corrosion.

The water container is usually enclosed in another housing, and thermal insulation material is often laid between these two structural elements. It helps retain heat longer and also protects the outer casing of the tank from extreme heat. The water, which is directly responsible for heating the liquid in the boiler tank, usually circulates through a heat exchanger coil. The tank elements are protected from corrosion by the presence of a magnesium anode. To control the pressure in the unit, a so-called safety valve and thermostat are installed. Water circulation occurs thanks to the presence of a special pump system.

Indirect heating boilers

So BKN is a kind of “thermos” for water in the house. It does not heat the water itself, but is able to keep the liquid heated by the coolant in a warm state.

Advantages, disadvantages, types of equipment

What is so good about this boiler? The most important thing is that the water in it can be heated without unnecessary costs. That is, you will not have to pay additionally for electricity or gas, unlike the same direct heating boilers, which have special heating elements such as burners in their design. The KN boiler uses the ready-made resource of the heating system in the house.

Indirect heating water heater

This aspect also allows us to talk about a reduced load on the electrical network in the house. At the same time, the boiler’s performance is quite high, it is safe and can serve for many years without complaints, because its internal part is even protected from contact with running water. Water from such a boiler is supplied to the consumer as soon as it is needed.

Of course, the equipment has disadvantages. This is, first of all, high cost - it costs more than a direct heating boiler. It is also worth understanding that the water in it takes longer to heat up, but it also stays hot longer. And such a boiler takes up a lot of space; it’s better to place it in a separate room. And one more main drawback - in the summer, in order to heat the water, you will have to start the heating boiler.

When installing a hot water system in a private home, the owner often has to decide which is better - an indirect heating boiler or a double-circuit boiler

On a note! There are several types of indirect heating boilers. Let's see how they differ from each other.

Table. Types of KN boilers.

| View | Description |

| With built-in control | Such heaters are connected to boilers that do not have controls. They are usually equipped with a special sensor that allows you to control the water temperature, and also allow you to accurately control the inclusion and shutdown of the liquid supply to the so-called coil - the coolant circuit. It is easy to connect such a boiler - you just need to connect the supply and return water from heating the house, as well as connect the supply of cooled liquid and the distribution of heated hot liquid. |

| Without built-in control | Such tanks are usually connected to a system equipped with an automated boiler. During installation, it is important to think about installing the temperature sensor and install it in the housing, then connect it to the boiler. |

| Wall | As you might guess, such a boiler is mounted on the wall. It is usually small in size, so it will not heat up a lot of water. It is important to understand that a boiler is not a lightweight structure, and the wall on which it will be mounted must be strong. |

| Floor | This option is placed on the floor and comes in a variety of sizes and capacities. It is rarely used in residential buildings - such a boiler can more often be seen in industrial premises. They put him in a separate room. |

| Vertical | The most common option, as it allows you to intelligently save space in the room. But such a boiler does not have a large capacity. |

| Horizontal | This is usually a fairly large boiler that will hold a lot of water. Often used in enterprises. |

Using an indirect heating boiler and an electric boiler

On a note! It is important to understand that the smaller the boiler, the faster the water will heat up in it. Although modern designs sometimes make it possible to heat a large volume of water in a very short time.

How is the boiler power selected?

Materials and tools

Materials:

- Pipes, shut-off valves, check valves - there are no special requirements for them: use the same materials as for working with hot water supply or heating systems.

- Expansion tank - a separate one is required for the domestic water supply system; it serves to prevent sudden pressure changes when opening/closing taps.

Attention! The tank must be designed for use with hot water; usually such devices are marked with special markings. Circulation pump - as a rule, a separate pump is installed in the heat exchange circuit with the water heater. Circulation pump - as a rule, a separate pump is installed in the heat exchange circuit with the water heater

Circulation pump - as a rule, a separate pump is installed in the heat exchange circuit with the water heater.

In addition, in DHW systems with recirculation, a separate pump is required to circulate water in the DHW circuit.

This will eliminate the need to wait for hot water to arrive through long pipes from the installation site of the water heater: the water will immediately be hot.

- Wires and small electrical wiring - if you plan to connect the water heater thermostat to the boiler automation.

- Fasteners - especially in case of wall installation, also for securing pipes and pumps.

- Standard plumbing set of sealants, seals, gaskets.

Tool:

- gas key;

- wrenches of various diameters;

- Adjustable wrench;

- building level;

- hammer drill, screwdrivers, screwdriver;

- Minimum electrician's kit: knife, wire cutters, electrical tape, phase tester.

Installation process: how to connect

Ideally, the boiler should be located as close as possible to the heating boiler to minimize heat loss.

Cold water is always supplied to the bottom pipe of the boiler, and hot water is drawn from the top.

- Choose a location for the water heater so that it is not in the way and is easy to maintain. Mount brackets, stands, and secure it to them.

- Connect to the cold water network: make a tap, install a shut-off valve and a coarse filter.

- Through a tee, take the cold water line to consumers, connect the second output to the boiler through a safety valve.

- Connect the domestic hot water line to the boiler, not forgetting about the expansion tank on it. In addition, install bypass taps so that you can disconnect it from the circuit during maintenance.

- Now connect the boiler to the gas boiler according to one of the given diagrams. Don't forget to turn off the boiler and shut off the system before connecting!

- Connect electronics, sensors, pumps according to the instructions.

Startup and testing

After installation, the first thing you need to do is connect and fill the boiler with cold water. Make sure that all air pockets are removed from the system and that the boiler is completely filled to avoid overheating.

When the boiler is full, set the desired temperature using automation. Start the boiler, open the coolant supply from the heating system to the boiler.

When the system reaches operating mode, make sure that the safety valve (usually set to 8 bar) is not leaking, i.e. there is no excess pressure in the system. You should also check all connections, seals and taps for leaks.

Selecting a KN boiler

The choice of such a unit as an indirect heating boiler must be approached with all responsibility and, first of all, ask yourself the question: “Will it be convenient to use such a device?” The pros and cons of the unit are described above. In this section, we will note several aspects that you need to know in order to understand whether you need to buy it. They will also help you choose the most suitable KN boiler option.

- To what extent will the purchase of such equipment be justified?? The fact is that it makes sense to buy such a device if the water flow in the house or room is large enough and is at least 1.5 l/min. For comparison, this is exactly the water consumption observed in large families of 4 or more people.

Such boilers have their pros and cons - The presence of such a boiler will definitely increase electricity costsif it is connected to an electric boiler.

- The volume of the boiler is also an important aspect . So, you need to calculate and take into account the hot water needs for your family. It must be selected taking into account the parameters of the room where it will be installed.

- The materials from which the boiler is made also matter. So, those made of stainless steel will allow you to heat the water up to 90 degrees. In enamel, the temperature should be lower. But highly heated water can always be diluted with cold water, which means that the efficiency of even a small tank in a boiler that warms up the water strongly will be higher. It is also important to choose a boiler that will not rust.

Choosing the right indirect heating boiler - The power of the heating boiler itself should also be taken into account . It should be enough to heat not only the unit, but also the heating system.

- The pump for loading equipment should also be optimal. The operating instructions for the equipment will help you choose which one is suitable - it usually contains all the numbers you need to focus on.

Connection diagram for indirect heating storage boiler - The time for heating water will play a decisive role for many, so this point also needs to be taken into account . So, on average, it takes about 2 hours to heat 100 liters of water. But some models of tanks heat water faster - for example, a stainless steel tank will heat the same amount of water in 20-30 minutes.

- The material for thermal insulation inside the unit can be represented by foam rubber, mineral wool or polyurethane foam . Foam rubber is found in cheaper models.

You can organize a constant uninterrupted supply of hot sanitary water in a private home using an indirect heating boiler. It

is also better to take boilers that have some protection elements - safety valves, thermostats, etc. Don’t be lazy and refuse to fill out a warranty card in the store when purchasing. The boiler is expensive, and it would be a shame to purchase it and find out that the quality of the product is inadequate. And it is difficult to change such equipment without a warranty.

Connecting a BKN unit to a boiler with one circuit

Such a unit can be connected to boilers of various types - single-circuit, double-circuit gas, solid fuel boilers, etc. The connection is made according to various schemes and it is important not to disturb them, otherwise you can not only create a dangerous environment for users of hot water, but also completely disable the system out of service. It is best if the boiler is connected by a person who has special skills. But if you carefully read the connection diagram, you can do all the work yourself.

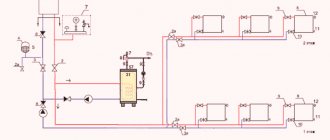

Diagram of a boiler included in the recirculation system

A single-circuit water heater is more common than other types. So we will consider connecting the BKN specifically to a single-circuit boiler. There are several methods.

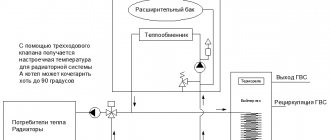

Three-way valve system

If a family needs a large amount of warm water, then it makes sense to think about this type of connection. Here the priority will be heating tap water. The entire system consists of two heating circuits, where one of them heats the water in the BKN tank, and the other is responsible for heating the house directly. Water flows are distributed precisely through the presence of a three-way valve, which is easy to control using a thermostat. It is important to configure the latter correctly - the temperature of the heating liquid in the unit should always be lower than the temperature of the water that heats it directly. Otherwise, thread distribution will not occur.

Connecting the boiler to the boiler using a three-way valve

The valve is installed at the water outlet of the boiler. And he is responsible for switching the direction of flows. That is, if the water in the tank has cooled, the valve will switch to the domestic hot water system, and if it is hot enough, the valve will direct the coolant to the home heating system.

Important! If you set the thermostat incorrectly, that is, set the temperature too high, the valve will always direct water to the hot water supply, and not redistribute it between the water supply and heating.

Boiler thermostat

Two circulation pumps

This option is suitable for those who do not intend to use BKN constantly. In this case, two circulation pumps will be installed at once - one will go to operate the heating system, the second will supply liquid to the boiler tank. Then it turns out that the coolant itself constantly circulates in the heating system of the house. One of the pumps (to the boiler) is connected to a temperature sensor and, as soon as the liquid in the water supply pipes cools down, a signal is sent indicating this. Then pressure is created, which can change the direction of movement of the coolant and send it to the boiler. It turns out that the coolant runs through different pipelines thanks to specially installed pumps.

Installation diagram of a boiler in a system with two circulation pumps

Important! To prevent the coolant from mixing, you need to install a check valve in front of each pump.

The difference between this scheme and the previous one is that the thermostat controls the operation of two pumps at once. That is, if the pump is running to supply water to the user, the heating pump is turned off.

Hydraulic boom

This option is optimal if the house, in addition to the boiler itself and heating, has a water-powered floor heating system or a wall heating system. This means that several water flows will have to be redistributed at once. This circuit is highly complex, so connecting it yourself is out of the question.

Meibes HZW 50/6 135 kW 6 m3/hour, hydraulic arrow

Operating principle

The working circuit of the heating boiler is formed by the following elements:

- its own water heater (heat exchanger), located in the combustion chamber and heated by hot gas combustion products, which enters the furnace through the burner;

- a return pipeline supplying the boiler heat exchanger with cooled coolant (water) from the heating network;

- a direct pipeline of heated water leading from the heat exchanger to the heating system;

- a circulation pump that drives the coolant in a circle.

That's the whole concept diagram of the working cycle of a single-circuit boiler. Make-up (compensation for inevitable water losses) of the heating system of small boiler houses is usually carried out from the city water supply, which has a pressure in its pipelines higher than the pressure in the heating system.

The functional limitations of a single-circuit boiler, expressed in its use only for heating, is a significant disadvantage compared to its double-circuit “brother”.

Features of connecting BKN

KN boilers can be connected in different ways, but there are still general principles for performing such work.

- The unit must only be placed on a flat surface or suspended on a solid brick or concrete wall. Fastening is done using anchors.

Installing an indirect heating boiler - careful handling of heat - It is important to comply with all pressure requirements throughout the entire system - it should not exceed the parameters optimal for the boiler.

- The tank should always be located slightly higher than the heating boiler itself - this will ensure faster heating of the water. So it’s better to put it on a small podium. At the same time, the BKN should not be placed too far from the boiler directly.

- The water inlet and outlet pipes from the boiler must always be oriented towards the boiler itself during installation.

In the photo - indirect heating boiler - To properly connect a boiler, you need to know the basic principles of connecting such devices.

- It is important to take into account that the coolant water must enter the boiler tank from above, and the cooled liquid must exit from below.

Step-by-step installation instructions

To correctly carry out the process of connecting the water heater to the water supply, follow the instructions:

Measure the height of the water heater, mark the lowest point where the bottom of the boiler will be located. Start taking measurements from the bottom mark.

Measure the distance from the bottom of the water heater to the mounting strip.

Measure the resulting distance on the wall and mark it.

Using a level and a marker, draw a horizontal line. Measure the distance between the hooks. Make notes on the wall.

Prepare hooks for fastening. Check its dimensions. Make sure that the hooks you have prepared can support the hanging tank.

Drill holes at the marked points and drive in dowels and screw in the hooks.

This completes the process of installing an electric water heater; now you can approach the procedure for connecting the water supply.

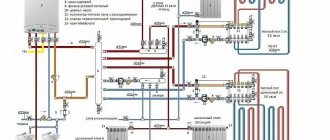

An example of connecting a BKN to a single-circuit boiler

Step 1. The first step is to install the entire heating system and connect it to the distribution manifold system and the heating boiler.

First, the entire heating system is installed

Step 2. Next, you need to install and securely secure the boiler itself in its place in the room. A floor-standing version is used here, which is installed on a small platform near the heating boiler.

The next stage is installing the boiler

Step 3. A thermal relay should be installed on the BKN body, which will help set the desired water temperature.

Thermal relay for setting temperature

Step 4. Behind the boiler itself, you need to connect all communications. These are water supply and outlet pipes. The hot water outlet for consumption must be connected to the topmost outlet through a shut-off valve.

The hot water outlet is connected through a shut-off valve

Step 5. The intake of heated water in this boiler model can be carried out from above the boiler or from behind the topmost outlet. Here you need to install a Mayevsky air release valve in the upper outlet.

Mayevsky air release valve

Step 6. The next option is to connect the hot water recirculation. Here it is important to mount a check valve, the recirculation pump itself and a ball valve. In this way, an equipped system with a ball valve will allow, if suddenly necessary, to turn off the water flow and repair or replace the pump. The equipment turns off when the liquid has warmed up to the temperature desired by the user. When the water cools down, the pump will turn on again. In general, recirculation is required so that hot water is always immediately supplied from the boiler, without draining a small amount of cooled water. It also makes it possible to connect heated towel rails.

Hot water recirculation connection

Step 7. Below the recirculation equipment, you need to connect the water supply directly from the heating pipes to the coil circuit inside the boiler. A pump, check valve and shut-off valve are also installed.

Pump and stopcock

Step 8. At the bottom you need to connect the return pipes, which will lead the water coming from the heating system back out of the boiler chamber.

Return pipes connected

Step 9. Cooled water enters the boiler chamber through the lowest pipe. Here you need to install a tap, then a safety valve, as well as a special expansion tank. The last element you need to buy is one that is suitable for water supply, and not for heating.

How the down pipe is connected

Expansion tank

Step 10. After the connection point of the expansion tank, it is also necessary to install a check valve in this part of the communications.

Another check valve

Step 11. You should also install a shut-off valve at the tank drain and drain the drain into the sewer.

Stop valve for tank drain

Video - How to connect a KN boiler to a single-circuit boiler?

Connection and commissioning of the Buderus Logomax U072 boiler

Connecting the Buderus Logamax U072 boiler

— The Buderus Logomax U072 24k boiler is supplied with a connected mains cable without a plug.

— Install a suitable plug on the mains power cable

— Connect the cable tightly to the distributor.

— If the wire is not long enough, disconnect it.

— If the boiler is connected in a protection zone, then disconnect the wire and use wire type NYM-I 3 x 1.5 mm2.

Connecting an on/off regulator or an Open-Therm regulator

— The boiler can only be operated with a Bosch regulator.

— The regulator must be designed for mains voltage (from the heating boiler) and must not have its own grounding.

— Contacts for connecting the regulator to the control unit are located under the cover.

— Remove the jumper on the TH terminals.

— Connect the regulator to the VT terminals.

To connect the power cable, you need to open the control unit.

— Disconnect the ignition wire.

— Disconnect the old power cable.

— Insert the plug of the new wire on the electronic board.

— Insert the wire clamp into the housing.

— Install the housing cover.

— Connect the ignition wire.

Putting the Buderus Logamax U072 boiler into operation

1-Drain hose, 2-Heating return valve (optional), 3-Cold water valve (optional), 4-Gas valve (closed) (optional), 5-Hot water, 6-Heating flow valve ( additional equipment), 7-Button “Return” (exit the service function/submenu without saving), 8-Button “ok” (confirm selection, save value), 9-Display, 10-Automatic air vent, 11-Button “+” , 12-Button “–” (mode), 13-Button “Stand-by”, 14-Pressure gauge, 15-Filling device

Before putting the Buderus Logomax U072 boiler into operation:

— Set the pre-pressure in the expansion tank in accordance with the static height of the heating system.

— Open the automatic air valve (leave it open).

— Open the radiator shut-off valves.

— Open the cold water tap (Fig. 4).

— Open the hot water tap and keep it open until water flows from it.

— Open the taps of the heating supply and return lines.

— Fill the heating system to a pressure of 1 - 2 bar and close the filling tap.

— Remove air from the radiators.

— Fill the heating system again to a pressure of 1-2 bar.

— Check whether the type of gas indicated on the nameplate corresponds to that available in the gas supply system.

— Adjustment of the rated thermal load according to TRGI is not required.

— Open the gas tap.

— Insert the power plug into the socket: the boiler goes into stand-by mode.

Rice. 5. Display readings

1-Burner operation, 2-Fault display/stand-by display, 3-Heating mode active, 4-Hot water heating active, 5-Summer mode active, 6-Service mode, 7-Temperature display (in ° C)

Setting up gas supply (natural and liquefied gas)

— Fold the control unit down.

— Hang the control unit below on the boiler so that you can simultaneously adjust the gas fittings and work with the control unit.

— To ensure heat transfer, open the radiator valves or the hot water tap.

Rice. 6. Gas fittings for the boiler Buderus Logamax U072 24/18

1-Measuring fitting (pressure at the nozzles), 2-Adjusting screw for maximum gas flow, 3-Cover, 4-Adjusting screw for minimum gas flow, 5-Fitting for measuring the supplied gas pressure

Gas pressure at the injectors at maximum thermal power

— Call service function 1.2.F and set operating mode 04 (maximum heating output).

— Unscrew the sealing screw of the pressure measuring fitting on the injectors and connect a U-shaped pressure gauge.

— Set the pressure on the injectors using the maximum gas flow adjusting screw.

— Turn right - more gas, turn left - less gas.

Checking the network gas pressure

— Turn off the Buderus Logomax U072 24k boiler and close the gas valve, disconnect the U-shaped pressure gauge and tighten the sealing screw.

— Unscrew the sealing screw on the fitting for measuring the gas supply pressure and connect the pressure gauge.

— Open the gas tap and turn on the unit.

— Call service function 1.2.F and set operating mode 04 (maximum heating output).

Checking and maintaining the Buderus Logamax U072 boiler

Cleaning the burner tray, nozzles and sit burner

— Unscrew the five screws and remove the combustion chamber cover forward and upward.

— Remove the injector rod.

— Clean the burner with a soft brush to make sure there is no contamination on the lamellas and nozzles. Never clean the injectors with a wire brush.