When building a water supply and heating system in a house, equipment such as a double-circuit boiler and a water heater - an indirect heating boiler is widely used. I would like to clarify that these are two completely different systems and therefore such equipment is not intended for them to work together to heat cold water for the heating system.

However, an indirect heating boiler is used in a hot water supply system to quickly additionally heat water in taps to the desired temperature, which can be taken from a double-circuit boiler, so they must be connected in the correct way, without making common mistakes.

Connecting a boiler to a water supply system made of different materials

The boiler is connected to a heat supply system using both traditional steel pipes and more modern polypropylene and metal-plastic pipes.

A cheaper option is polypropylene. The choice will depend on the price of the project and the operating temperature of the heating fluid at the outlet of the boiler. For example, in a solid fuel boiler, the coolant temperature is difficult to regulate; there may be cases where it will spontaneously rise to 100 C, so in this case it is better to install steel pipes.

Although they are less durable, they are designed for the high temperature operating conditions of solid fuel devices.

Polypropylene pipelines

Polypropylene pipes are easily installed using a specialized soldering iron and scissors for cutting pipelines. After selecting the connection point, a section in the pipeline is cut out in width equal to the tee, with a deduction of 20 mm: 10 mm for each.

Using a soldering iron, heat the pipe and fitting to the required technical condition and connect them. At the same time, it is forbidden to scroll them, since this can disrupt the tightness of the connection.

Next, connecting parts of pipes of various lengths and angles, a connection is made to the BKN nozzles. A threaded coupling is soldered to the end of the pipe section and then the entire line is firmly connected.

Insertion into a metal pipeline

Today, it is possible to connect the BKN to water supply utilities without the use of welding; for this, there is a modern “vampire” adapter device, which has a technological hole and a clamp in the body. Installation of this design is very simple. Select a cutting point and clean the area.

A clamp with a heat-resistant gasket is installed on top of the prepared area and tightened with bolts to secure it. Next, turn off the water supply and drain it from the desired section of the pipeline by opening the hot water tap on the mixer.

Next, the pipe section is drilled through the hole in the clamp with an electric drill and then the valve is screwed on and the BKN piping is continued according to the diagram.

Metal-plastic

This is the most reliable and simplest option for connecting a BKN boiler to a double-circuit boiler. The metal-plastic material is simply bent to the desired outlet angle, and the connections of the nodes are made with various crimp fittings.

Before tying the BKN, the pipe is cut to the required length and size. Next, select the insertion point, taking into account the size of the tee and the part of the pipe that will be occupied by the connection.

To prepare a hole in a small area, special scissors are used. The nuts are removed from the tee and, together with the fixation rings, they are put on different ends of the pipe. Flare the ends of the metal-plastic using a special calibrator or screwdriver.

The tee is inserted all the way, then the rings are moved and the nuts are tightened with a wrench. You can also use fittings for metal-plastic pipes, which will require crimping and additional specialized tools and devices.

Expert recommendations

If greater productivity is needed, you should pay attention to remote hot water tanks. Such boilers, whose capacity can reach 500 liters, can be connected to heat generators that have this ability. This indicates that the equipment must have inlet pipes, and inside there must be a circulation pump necessary to service the hot water circuit. The power of the boiler must correspond to the capacity of the boiler, otherwise the water temperature will never reach normal levels.

Installation principle

If you need to mount a tank with a capacity of up to 200 liters, this can be a wall-mounted product. For its fastening, special kind of brackets are provided, which must be located on flat and strong vertical surfaces. Conventional plasterboard partitions are of little use for mounting even such a “light” storage device. You need to choose between saving on the arrangement of interior space and saving on the boiler. Floor-standing units are preferred to meet the needs of large households; sometimes they even install products with a capacity of over a thousand liters and allocate a special boiler room for them.

In private homes, you can limit yourself to indirect heating boilers that accumulate from 250 to 300 liters of water. The exact choice of capacity must be made taking into account real and projected needs. When connected to a double-circuit boiler equipped with a built-in pump, the boiler automation itself takes over the coordination of the valve operation based on signals from the thermostat

This is very important because a double-circuit heating device, unlike a single-circuit heating device, must supply hot liquid both to the heating system and to the hot water supply circuit

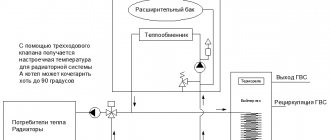

If you install a three-way valve, the water heater will have an advantage in the system compared to the heating circuit. This approach is acceptable when a large capacity tank is installed. Please note: this connection method is also practiced when forced to use hard water, which complicates the normal use of the hot water system. Although, of course, it would be much more correct to take care of softening the incoming coolant. But sometimes you have to adapt to it against your will.

Problems may arise due to the fact that significant consumption of hot water can complicate the functioning of this circuit. In this case, the method of obtaining heat, including using a pellet or other solid fuel boiler, is not significant. And this is where the boiler comes to the rescue, smoothing out fluctuations in two circuits. Thanks to it, even intensive coolant consumption has little impact on people’s daily lives. Installers must consider which function will have the highest priority.

Connecting indirect heating boilers to a single-circuit boiler can be done using a pair of pumps. Then, with their help, water flows are distributed through two pipelines. It is usually assumed that the hot water supply circuit will come first. The operation algorithm of the boiler in conjunction with a single-circuit device is also adjusted accordingly. To prevent liquid flows of different heating levels from changing each other’s basic parameters, both pumps must be preceded by a return valve. Hot water is supplied exclusively from the boiler.

Additional water system improvements

To create an additional level of comfort and improve the performance of the water supply system, additional improvements can be made, such as:

- additionally take care of disconnecting the water heater from the system by installing ball valves in case of need for its maintenance, breakdown or simply shutdown to reduce energy costs;

- installation of additional heated towel rails that will be warm all year round;

- carrying out additional thermal insulation of pipes from the water heater to the water supply systems to reduce heat loss;

- installing the water heater as close to the water supply points as possible, otherwise you will have to drain cold water from the taps in order to wait for hot water. In this case, it is necessary to install a recirculation pump for more efficient and economical use of cold water drained from the tap into the hot water supply system to the water heater - to reduce its consumption and economical use, so as not to drain it into the sewer. Calculations indicate water savings per year for a family of 4 people at the level of 15,000 - 000 liters.

The results of these improvements:

- savings (on water, on gas - since the boiler will rarely turn on, on electricity);

- always warm water on taps;

- the service life of the main boiler increases, since the boiler will turn on less often and operate less often, so all components will last much longer.

What is an indirect heating boiler and what are they?

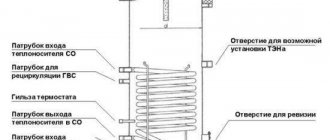

A water heater or indirect exchange boiler is a tank of water in which a heat exchanger is located (a coil or, like a water jacket, a cylinder within a cylinder). The heat exchanger is connected to a heating boiler or to any other system in which hot water or other coolant circulates.

Heating occurs simply: hot water from the boiler passes through the heat exchanger, it heats the walls of the heat exchanger, and they, in turn, transfer heat to the water in the container. Since heating does not occur directly, such a water heater is called “indirect heating”. The heated water is used for household needs as needed.

Indirect heating boiler device

One of the important parts in this design is the magnesium anode. It reduces the intensity of corrosion processes - the tank lasts longer.

Kinds

There are two types of indirect heating boilers: with and without built-in controls. Indirect heating boilers with built-in control are connected to a heating system powered by boilers without control. They have a built-in temperature sensor, their own control that turns on/off the supply of hot water to the coil. When connecting this type of equipment, all you need to do is connect the heating supply and return to the appropriate inputs, connect the cold water supply and connect the hot water distribution comb to the upper outlet. That's all, you can fill the tank and start heating it.

Conventional indirect heating boilers work mainly with automated boilers. During installation, it is necessary to install a temperature sensor in a certain place (there is a hole in the housing) and connect it to a certain boiler input. Next, they wire the indirect heating boiler in accordance with one of the diagrams. You can connect them to non-volatile boilers, but this requires special circuits (see below).

What you need to remember is that the water in an indirect heating boiler can be heated slightly below the temperature of the coolant circulating in the coil. So if your boiler operates in low-temperature mode and produces, say, +40°C, then the maximum temperature of the water in the tank will be exactly this. You won't be able to heat it up anymore. To get around this limitation, there are combination water heaters. They have a coil and a built-in heating element. The main heating in this case is due to the coil (indirect heating), and the heating element only brings the temperature to the set one. Also, such systems are good when paired with solid fuel boilers - the water will be warm even when the fuel has burned out.

What else can be said about the design features? In large-volume indirect units, several heat exchangers are installed - this reduces the water heating time. To reduce the heating time of water and to cool the tank more slowly, it is better to choose models with thermal insulation.

Which boilers can it be connected to?

Indirect heating boilers can work with any source of hot water. Any hot water boiler is suitable - solid fuel - using wood, coal, briquettes, pellets. You can connect to any type of gas boiler, electric or liquid fuel.

Connection diagram to a gas boiler with a special outlet for an indirect heating boiler

It’s just that, as mentioned above, there are models with their own controls, and then installing and tying them is a simpler task. If the model is simple, you have to think through a system for regulating the temperature and switching the boiler from heating radiators to heating hot water.

Tank shapes and installation methods

An indirect heating boiler can be installed on the floor or hung on a wall. Wall-mounted options have a capacity of no more than 200 liters, while floor-mounted ones can hold up to 1500 liters. In both cases there are horizontal and vertical models. When installing the wall version, the mounting is standard - brackets that are mounted on dowels of a suitable type.

If we talk about shape, then most often these devices are made in the shape of a cylinder. In almost all models, all working terminals (connection pipes) are located at the rear. It's easier to connect and looks better. On the front part of the panel there are places for installing a temperature sensor or thermostat; in some models it is possible to install a heating element - for additional heating of water when there is a lack of heating power.

According to the type of installation, they are wall-mounted and floor-mounted, the capacity is from 50 liters to 1500 liters

When installing the system, it is worth remembering that the system will only work effectively if the boiler power is sufficient.

The nuances of strapping

Despite the fact that the harness is selected individually, there are several general provisions that must be adhered to:

- The boiler for schemes with natural heating circulation is installed below the level of the radiators.

- The base for installing floor-standing units must be made of non-combustible materials.

- Boiler rooms are equipped with ventilation and lighting.

- The boiler unit is connected with the inclusion of a coaxial chimney.

- After assembling and installing the unit and smoke ventilation systems, a safety group is installed: a control pressure gauge, a pressure relief valve and then an air vent.

- The expansion tank is installed between the hydraulic switch and the boiler unit.

Connecting a wall-mounted boiler

This type of boiler allows installation on the wall in the kitchen. Structurally, it is made in such a way that the necessary piping has already been carried out by the manufacturer, and its elements are supplied as a kit. Depending on the type of unit, they can be single or double circuit, so the number of pipes for piping may differ.

Wiring a wall-mounted gas boiler

Algorithm for piping a double-circuit gas boiler:

- Remove the plugs from the pipes.

- Install a strainer on the return line to remove dirt and suspended solids.

- A filter is installed to purify water from hardness salts; it can be installed on the common tap water inlet.

- When piping a wall-mounted gas boiler, shut-off and control valves with detachable connections, for example, “American” ones, are installed.

- The cold water pipes are located on the left side relative to the center of the boiler, and the hot water pipes are located on the right.

- The boiler is connected to the gas mains with the involvement of a certified specialist; the final approval of the boiler will be issued by a representative of Gorgaz after a test run of the boiler equipment.

- When piping a double-circuit gas boiler, the threaded gas connections are sealed only with tow.

- Install a special filter on the gas shut-off valve.

- The boiler is connected to the gas main with a corrugated hose and a union nut with a paranitic gasket.

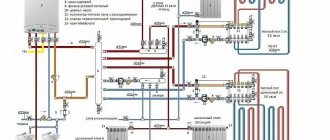

Connecting a floor-standing gas boiler

This scheme requires a separate room to house the boiler, since floor-standing models are large and often have an open firebox design that works with natural circulation through the gas-air path. The scheme also includes a pump for coolant circulation, especially for piping a double-circuit gas boiler and for a multifaceted heating level: number of floors, different types of heating - radiator and “warm floor”.

The circuit for dual-circuit heating (heating and domestic hot water) consists of 5 pipes: 1 - gas, 4 - water coolant. The first is connected to the burner device with a ball valve.

Connection diagram for water coolant when piping a floor-standing gas boiler:

- Heating boiler inlet;

- heating boiler output;

- DHW heat exchanger inlet;

- DHW heat exchanger output.

The distribution of water flows is automatic, performed by a three-way valve, hydraulic arrow or balancing valves.

For piping a floor-standing gas boiler with extensive heating networks and a long distance, it is recommended to connect 2 collectors with an autonomous pump, for example, one for low-temperature coolant up to 50 C for a “warm floor” system, and the other up to 90 C for conventional radiators.

To reduce the temperature, the manifold can be equipped with a mixer or a three-way valve with a servo drive installed between the supply and return on the comb. Sensors allow you to set different temperatures in the circuits.

Thus, in order to properly tie the boiler, you will need not only experience in installation work, but also strict compliance with state operating rules and the requirements of the manufacturer.

Types of indirect heating boilers

Modern indirect type boilers have a variety of designs and shapes. In addition to the round thin-walled tank, there are boilers that have a more complex structure, allowing the equipment to be more economical and efficient. Equipment is classified according to several criteria.

Heat exchanger types

Indirect water heaters can have a heat exchanger of various designs:

- single-circuit coil - a spiral-shaped metal thin-walled pipe located inside a capacitive tank. Due to the circulation of coolant through the pipe, the coil heats up and transfers thermal energy to the cold water located in the tank. This is the simplest and most affordable design on the market;

- double-circuit coil - a design similar to the option described above with the only difference being that the water heater provides simultaneous supply of heated water and coolant for central heating. Such equipment is somewhat more expensive than its simpler counterpart, but is much more effective when it is necessary to heat a large amount of water;

- “tank-in-tank” design – the equipment has a tank consisting of larger and smaller containers. Inside the large tank there is water that needs to be heated, and inside the smaller tank there is a coolant. Such boilers not only have a high rate of heating water up to 75–90 °C, but are also manufactured in larger housings;

- combined boiler - a water heater design with two heat exchangers. The first is a regular coil made of aluminum or copper pipe. The second is made in the form of a tubular electric heater. Combined models are quite expensive, but they also combine the functions of different devices.

Heat exchanger material

For the manufacture of a heat exchanger in the form of a coil and an internal tank, materials such as:

- brass - low thermal conductivity, 100–110 W/(m∙°C);

- aluminum - average thermal conductivity, 200–240 W/(m∙°C);

- copper - high thermal conductivity, 360–390 W/(m∙°C).

The higher the thermal conductivity of the heat exchanger material, the more expensive the boiler.

Installation method

Depending on the installation method, devices are divided into two types:

- Wall-mounted - the equipment is mounted on a hanging bracket fixed to the wall surface. The capacity of household wall-mounted boilers usually does not exceed 200 liters, but in the range of some manufacturers you can find designs with a capacity of up to 650 liters.

- Floor-standing - the tank is installed on the floor surface in close proximity to the heating boiler. The average capacity of household floor-standing models varies from 200 to 500 liters. Industrial options have only a floor-mounted installation method.

Layout method

According to the method of arrangement of structural elements, water heaters are divided into two types:

- Vertical is the most common layout method, allowing you to save internal space in a room. Vertical devices have limited volume and dimensions, so this design is quite suitable for use in the private sector.

- Horizontal - has no clear restrictions on volume and dimensions. As a rule, such devices, due to their larger size, have many additional functions. For example, a thicker thermal insulation layer, recycling and storage.

Choosing a boiler for self-production

The general design of an indirect heating boiler is quite simple - if you know how to work with power tools and welding, you can make a water heater yourself.

It is not advisable to make your own boiler with a “tank-in-tank” heat exchanger. Firstly, you will need to find or make the tank itself, which will require quite a lot of effort and time. Secondly, when producing large-volume water heaters, the design dimensions increase several times.

In addition, factory models manufactured using this technology have a special coating (enamel, ceramic, silver plating) on the heat exchanger. It will not be possible to repeat the application of such a coating in “garage conditions”.

Common installation mistakes

The indirect heating boiler is a new type of capacitive heater and, despite its simple appearance, it is a complex thermal device that requires careful selection, precise installation and adjustment of functionality. When installing BKN, mistakes are often made, the most common of which are:

- Incorrect location for equipment installation. For example, a plastic or stainless steel housing must be placed extremely close to the boiler unit.

- Improper piping of the tap water source.

- Incorrect piping of the circulation pump.

- Violation of DHW insulation with a layer less than 20 mm and the thermal conductivity of the insulating layer is 0.030 W/m2. This insulates the hot heating surfaces of not only the pipes, but also all operating components.

- Incorrect plumbing connections or lack of insulation are the main causes of condensation on these lines.

- A common mistake in the BKN system is the absence of an expansion vessel that compensates for the pressure caused by the thermal expansion of water in the container.

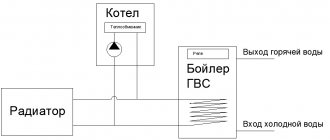

Connecting the indirect heating boiler and boiler

According to the mind, there is no need to use the capabilities of the second circuit of a double-circuit boiler when heating an indirect heating boiler. It is necessary to tie the operation of the primary circuit to simultaneous operation with heating and hot water heating. To do this, it is necessary to connect the boiler and boiler through the distribution manifold. The collector will act as an intermediary and will distribute the hot coolant throughout the heating system and indirect heating boiler. All this will be heated by a double-circuit boiler.

In order to avoid overspending on heating hot water, you must connect your own pump to the boiler circuit. It is necessary to purchase an external thermostat for the boiler. The remote thermostat must be connected to the pump so that it turns the pump on and off.

When the boiler cools down, the thermostat will signal the pump to turn on. The boiler will begin to heat up. Having reached the desired temperature, the thermostat will signal to turn off.

This scheme for connecting a double-circuit boiler and an indirect heating boiler cannot be called ideal, but it allows you to heat normally hot water. The best and most economical solution would be to purchase a single-circuit boiler with a boiler connection function. Such a scheme would not have to be fenced off.

Advantages and disadvantages

The strengths of indirect water heaters can be safely considered:

- Significant volumes of hot water and uninterrupted supply of hot water, not warm water.

- Simultaneously providing several sources of hot water consumption at the required temperature.

- During the heated period of the year, the cost of heated water is the lowest in terms of costs. Since heating occurs due to the heat already received from another medium (heating system).

- Unlike flow-through heaters, water heating occurs without an inertial delay. I opened the tap and hot water came out.

- Depending on the availability of heat sources, several energy options can be used, including solar energy.

Weaknesses include:

- Additional financial investments are required. The water boiler works in conjunction with other equipment.

- It will take considerable time for the boiler to initially heat up. During this heating period, the heating temperature of the house may decrease.

- The boiler must be installed in the same room as the heating system. The volume of the room must provide a complete installation of both the heating system and the boiler.

Types of double-circuit gas boilers with a built-in boiler: are they needed?

Boilers are used in conjunction with single- and double-circuit gas boilers. In the second case, the unit itself works only for heating. There are free-standing and built-in boilers.

The former are often purchased separately, have a large capacity, and are suitable for single- and double-circuit devices of open and closed type. Requires complex connections.

Built-in tanks are part of ready-made solutions based on double-circuit boilers. They are compact due to their small volume, are equipped with advanced automation from the factory, and can be easily connected.

Important! The volume of a free-standing boiler is selected in proportion to the boiler power. If the tank is too large, then the water in it will not warm up to the required 60 °C according to sanitary standards. This is fraught with the appearance of Legionella colonies that are hazardous to health.

This is fraught with the appearance of legionella colonies that are hazardous to health.

Modern devices with built-in storage devices have an anti-legionella function: the boiler automatically warms up to 65 °C for 30 minutes from time to time, thereby killing harmful bacteria.

Double-circuit gas boilers with boilers differ in location, type of storage tank and its capacity.

By location: floor-mounted non-volatile and wall-mounted

Floor-standing, non-volatile boilers are large in size and have high power. The mass of the heating device without liquid reaches 100 kg. They are equipped with built-in boilers with a volume of up to 120 l, external mounted or floor-mounted - 50–500 l.

Photo 1. Floor-standing double-circuit gas boiler with an indirect heating boiler, installed in a special room.

They often require placement in a specially equipped boiler room. They heat and supply water quickly, but are sensitive to power surges. They create problems when connecting the recirculation system.

Wall-mounted equipment is smaller and weaker than floor-mounted equipment. Does not require the arrangement of a separate room; it can be installed in bathrooms and kitchens. They are usually equipped with built-in indirect heating tanks with a capacity of 10–60 liters with constant heating of the liquid by a secondary DHW circuit.

They are less often connected to free-standing boilers of similar volume. Their heat exchangers have a small internal cross-section, which is why the devices are afraid of scale and are very sensitive to water quality.

Boiler type with electric heater

The direct heating boiler is equipped with its own heating element, which independently increases and maintains the water temperature. Often this is a tubular electric heater (TEH), powered by mains or gas. Installation of the second option also requires permission from regulatory authorities.

The DHW system can be based solely on a directly heated storage tank, bypassing the connection to the boiler.

Indirect heating boilers do not have their own active heating element. A coil is placed in the water tank, which passes coolant through it, previously heated in another heating device. They are installed with gas equipment with a power of 25 kW or more; for the automation to work, a connection to the network is required.

Photo 2. A double-circuit gas boiler with a combined boiler heats the water in the tank due to the operation of the coil.

Combined boilers have a coil that operates on an indirect principle and a heating element that directly heats the water in the tank. The working element maintains the temperature at the required level, but most of the heating is provided by the coil.

Reference! Combined drives are suitable for single- and dual-circuit low-power equipment. They reduce electricity consumption during the heating season, providing the necessary water heating throughout the entire service life.

Types of layouts

The advantages and disadvantages of double-circuit gas boilers are well known; they are good enough to serve 2-3 small consumers. But what if there are more consumers and the use of electric water heaters is excluded? There are several modern solutions for this:

- Wall-mounted gas boilers with built-in boiler.

- Heating installations with a remote storage tank for hot water.

- Indirect heating boilers.

Practice shows that for a family of 3 people, for household and sanitary needs, it is enough to have a capacitive electric heater with a capacity of 50 liters in the house. Of course, this means using hot water within reasonable limits. In order not to purchase such a heater and not to deal with laying extra cables and pipelines, you just need to choose a wall-mounted heating unit, inside of which there is a tank with a capacity of 46-50 liters. Its design is two in one: a gas boiler with an indirect heating boiler inside. The principle of operation is also preserved: one part of the coolant goes into the heating system of the house, and the other into the coil of the internal boiler. Having reached a certain temperature of the water in the tank, which is determined by the sensor, the entire volume of the coolant is switched to heating the house.

1 – fan – smoke exhauster; 2 – heat exchanger with increased productivity; 3 – combustion chamber; 4 – storage tank made of stainless steel; 5 – control unit with display.

The heater design includes 2 circulation pumps, one pumps coolant through the heating system, and the second through the boiler coil, while the burner operates at maximum to quickly heat the water in the tank. Later, the circuit switches to maintaining water temperature, which reduces fuel consumption.

More powerful wall-mounted gas boilers are equipped with containers of greater capacity, but usually it does not exceed 100 liters.

Features of a double-circuit boiler

A double-circuit boiler is intended not only for the implementation of a heating system in the house (circuit 1), including heated floors, ceilings, etc., which is its priority, but also for the water supply system in the house (circuit 2), (washbasin, shower, kitchen sink). As soon as the boiler receives a request for water supply, it immediately stops heating water in the heating system and opens the valves and automation for heating water for the water supply system, i.e. switches to circuit 2.

The usual capacity of a double-circuit boiler for a water supply system is 12-13 liters of water per minute.

In some cases, the given power of a double-circuit boiler may not be enough for such consumer requests - at increased loads, when both taps and showers are used at the same time. In addition, the temperature of the hot water in the taps will be slightly different from the temperature of the water in the heating system.

In these cases, it makes sense to use in the water supply system an indirect heating boiler with a single-circuit boiler instead of a double-circuit one, or a water heater that has its own pump with additional capacity.

Functions of a water heater in a water supply system

An indirect water supply boiler is a buffer tank that does not force the boiler to switch to the water supply mode from the heating mode at a low water consumption of 1..3 liters and smoothes out all its temperature differences at the beginning and end of its consumption.

For this purpose, it makes sense to install a membrane expansion tank with a volume of up to 10 liters , so that water flows into the taps and showers from the water heater first due to the pressure of the expansion tank and does not turn on the main heater for these purposes, increasing energy savings. It will only start when there is a large consumption of hot water into the system.

If there is no water heater in the system, when you turn on hot water, you may not get it, since sometimes you have to wait a long time until the process of restarting the main boiler is completed and the process of heating it in the circuit takes place.

In addition, the water heater can also serve as a backup source of hot water during the period of preventive maintenance of the main boiler for its maintenance - often in the summer.

The mechanism of operation of an indirect heating boiler, which is mounted on a wall or on the floor, can be described as follows: there are two tubes for inlet and outlet, often installed at the bottom. Cold water enters the boiler from below. The heated water for heating is taken from above. The tank is heated through a coil, which acts as a heat exchanger. Hot coolant from the boiler flows through the coil.

What is a single-circuit boiler

Of the two existing types of boilers, differentiated by the number of built-in heating circuits, the single-circuit one differs in that it is endowed with only one useful function - heat supply to the batteries to increase the room temperature. Its design itself is not capable of supplying hot water to the tap, so the role of the mixer in this case is reduced to zero. Boilers are electric (heating heating elements, induction, electrode) and gas, which is due to different methods of heating, power, and consumption.

The electric boiler has the following nomenclature: a central tank that performs the function of a heat exchanger, tubular heating elements (heating elements), inlet and outlet pipes in the lower part of the body, a circulation pump for circulating water in the system, a thermostat, and indicators. In the induction boiler, instead of heating elements, there are coils that are driven by electromagnetic induction; the outlet pipe with hot water is installed on the top cover of the structure. Electrode boilers operate, respectively, through poles of a closed electrical circuit (anode and cathode) installed in parallel, generating electrical voltage and heat generation.

A gas single-circuit boiler is equipped with a heat exchanger, a combustion chamber for incoming fuel from a gas burner, a three-code valve, a circulation pump, an expansion tank, and a valve for connecting to the gas supply line.

All modern models of single-circuit boilers include, in addition to the water inlet and outlet pipes, pipes for connection to external water heating units. Thus, the possibility of synthesizing a single-circuit boiler with an indirect heating boiler to create a multifunctional heating and hot water supply system for a home is realized.

Types

Manufacturers of water heating devices do not skimp on developing cutting-edge models, having correctly taken into account the public interest in autonomous heating and hot water supply devices for private homes that emerged several years ago.

Currently, there are two types of single-circuit heating devices:

- floor;

- wall-mounted

Floor-standing options are more powerful, but their placement requires separate rooms in the form of an extension. Wall-mounted water heater – compact, small-sized, installed on the wall. That is why the first of these models became widespread among owners of country and city private houses, dachas and cottages, and wall-mounted boilers found their admirers in urban areas.

Both boilers have a simple and understandable design, attractive appearance, and a high degree of safety. You only need to form your own opinion about which ones are better depending on the tasks they face. Sometimes it is more profitable to purchase a single-circuit wall-mounted unit with less power, but which is enough for a full-fledged heating system at home, and make a simple connection to connect the wall structure to a column used to heat cold water for your own needs (the column can be electric or gas). The hose tying kit can be purchased separately.

Boiler installation tips

It is important to install the boiler in accordance with current standards and rules, then the system will work for a long time and without failures. During the installation process, you must follow the following recommendations:

- Ground the boiler.

- To eliminate possible water hammer, a hydraulic accumulator should be provided on the output line.

- Provide for the possibility of connecting the boiler to an outlet if the gas boiler suddenly fails.

- Install shut-off valves on the supply and return lines of the container so that, if necessary, you can disconnect it.

- To heat the water faster, it is recommended to install the boiler as high as possible than the radiators.

- It is better to install it near a gas heating boiler.

The connection diagram of the boiler to the gas boiler is selected depending on the existing conditions and operating features of the system. In this regard, they think through all the nuances in advance and make the right choice. The best option is a system that consumes little gas and is maximally efficient.

What does tank size matter?

The shape of water heaters can be cylindrical or cubic and, depending on the volume, they have different sizes. The tank capacity can range from 80 to 1500L, the user must select the tank according to the need. The dimensions of the container are also significant for installation conditions, since wall placement is allowed only for models up to 200 liters; the rest are placed on the floor. Wall-mounted tanks are equipped with mounting devices, while floor-mounted tanks are equipped with support elements. It is worth considering that cubic boilers are more compact and take up less space.

How to choose an indirect heating boiler

Making the right choice of the appropriate indirect heating boiler model is a difficult task for a beginner. However, there is nothing overwhelming here, you just need to take into account a few important nuances:

When choosing an indirectly heated water heater for an apartment or private house, the first step is to determine the optimal volume of the storage tank. To ensure that there is enough hot water for all family members, it is calculated taking into account the approximate consumption of 100 liters per day by one person. An indirect water heating boiler is economically beneficial for a family of four or more people

With this number of people, the approximate DHW consumption is 1.5 l/min. Paying attention to the volume of the tank, take into account the heating time. A larger container will take longer to heat up. It may be worth giving preference to a model with two heat exchangers or a tank-in-tank system. The composition of the thermal insulation determines how long the water will remain hot after the boiler is turned off.

Cheap water heaters come with foam rubber. The porous material retains heat poorly and quickly decomposes. The optimal thermal insulation is mineral wool or polyethylene foam. To make the right choice, you need to compare the power of the indirect water heater and the heating boiler. If the latter is characterized by weak parameters, the boiler will become an unbearable load. When buying any model, be sure to pay attention to the presence of a thermostat, valve and other safety elements.

It may be worth giving preference to a model with two heat exchangers or a tank-in-tank system. The composition of the thermal insulation determines how long the water will remain hot after the boiler is turned off. Cheap water heaters come with foam rubber. The porous material retains heat poorly and quickly decomposes. The optimal thermal insulation is mineral wool or polyethylene foam. To make the right choice, you need to compare the power of the indirect water heater and the heating boiler

If the latter is characterized by weak parameters, the boiler will become an unbearable load. When buying any model, be sure to pay attention to the presence of a thermostat, valve and other safety elements.

When all the important nuances have been resolved, you can pay attention to the form, design, manufacturer and other details

Calculation of storage tank volume

To make an approximate calculation of the volume of the storage tank, you can use a simple reading of the water meter. When the same number of people constantly arrive in a house, the daily consumption will have the same data.

A more accurate calculation of volume is based on counting water points, taking into account their purpose and the number of living family members. In order not to go into complex formulas, hot water consumption is taken from the table.

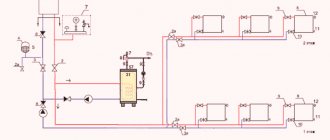

Connection diagrams to the heating system

When choosing a connection diagram for an indirect boiler for heating water, take into account the location of the device in the house, as well as the wiring features of the heating system.

A simple and frequently used circuit is based on connecting an indirect device through a three-way valve. As a result, two heating circuits are formed: heating and hot water. After the boiler, a circulation pump is installed in front of the valve.

If the need for hot water is small, a system with two pumps is suitable. The indirect water heating device and the heating boiler form two parallel heating circuits. Each line has its own pump. The scheme is suitable for country houses where hot water is rarely used.

The connection diagram becomes more complicated if a “warm floor” system is installed in the house along with radiators. To distribute pressure along all lines, and together with the indirect boiler there will be three of them, a hydraulic distributor is installed. The unit normalizes water circulation through the “warm floor”, water heater and radiators. Without a distributor, the pumping equipment will fail.

Indirect water heating devices with recirculation have three pipes coming out of the body. Traditionally, two outputs are used to connect to the heating system. A looped circuit leads from the third branch pipe.

If the indirect water heating device does not have a third pipe, and recirculation needs to be done, then the return line circuit is connected to the cold water pipe and an additional recirculation pump is installed.

Recirculation allows you to get hot water at the outlet of the tap even before the liquid in the boiler storage tank is completely heated.

Double-circuit storage device for heating

A boiler is a tank for heating and storing water at the required temperature, which it will dispense as needed by the owner. The simplest model: a tank equipped with four holes with reinforced and insulated walls, inside of which there is a coil.

The work is carried out according to the following algorithm:

- Supplying hot water from the heating system to the coil.

- Return.

- Cold water flows directly into the tank.

- Discharge of heated liquid from the tank to the tap.

Additionally, the device includes:

- Circulation pump.

- Temperature sensor.

- Safety valve.

- Locking mechanism.

- Check valve.

- Anti-corrosion protection.

Reference! Some models provide for the circulation of heated water from the boiler between the walls of the outer and inner tank. So, you have to wait much less for it to heat up, but such a device also costs more.

The water heater is connected to the heating system directly at the boiler in parallel with the main wiring to the appliances. Its own circuit allows you to maintain heating priority in relation to the heating system. Reduces the temperature spread on heating storage devices when the heater is turned on.

The temperature sensor detects a decrease in heat in the tank, followed by a command to the circulation pump in the circuit.

Water from the heating system is supplied to the coil, passes through it, giving part of the energy to the still cold water already in the tank.

After it heats up to the desired level, the automation turns off the pump. When the faucet tap is opened, the incoming cold water gradually displaces and dilutes the hot water. Then the cycle repeats.

The cold water inlet is equipped with a check valve, which prevents it from draining when the pump is turned off. The pressure in the tank increases because the faucets are not used constantly, and the water cannot flow back out. The safety valve prevents the pressure from reaching a critical level, releasing a certain volume of liquid into the drain.

Important! The water heater is mounted on a flat surface next to the boiler. For hanging models, a log or brick wall at the same level as the boiler or slightly higher is suitable

Under the floor, a part of the space on the floor is leveled or a special ramp is first placed on it, on which the boiler is placed.

Advantages and disadvantages

The undoubted advantages of boilers with indirect heating heaters include savings on electricity.

No gas burner or power source is needed, as with direct heating devices. The heating system will do everything itself, which significantly reduces financial costs.

Other advantages:

- Performance: a tank with a capacity of one hundred liters produces approximately 400 liters of hot water per hour.

- Almost instantaneous supply of hot water.

- Possibility of using multiple energy sources, for example, a geothermal system.

- Reasonable price.

- Simplicity in the device.

Minuses:

- The warm-up speed, even in the newest models, will not be instantaneous.

- Bulky.

Attention! If the family is quite large, then one room will have to be given over to the boiler room, displacing itself. Small models will not solve the problem of washing

Recommendations

When choosing a model, you need to pay special attention to the following characteristics:

- Capacity: for two people - 80-100 l, for three - 100-120 l, four need at least 120-150 l, five - 150-200 l.

- Power: - directly depends on the number of users, but it should not overload the potential of the heating system. According to experts, for normal coordinated operation of the boiler and water heater, a power of at least 24 kW is needed.

- Tank material: it is better to choose tanks made of medical or stainless steel.

- Warm-up time.

It is recommended to purchase an automated version with a temperature sensor - this will make using it easier and safer even for younger family members.

Features of operation

- Pump filters need to be systematically checked and cleaned.

- Any model requires the correct setting of the thermostat, otherwise the boiler may overheat.

Photo 3. The technician adjusts the thermostat of a gas boiler with a boiler to avoid overheating.

- It is necessary to ensure that the temperature in the tank does not rise above the antifreeze level.

- Check anodes for corrosion. If one is found, the part is replaced. This should be done once every six months, and when the water is not hard, then once a year.

What is a single-circuit boiler

Single-circuit gas boilers are used to heat the coolant that fills the heating system. A single-circuit boiler does not prepare water for hot water supply. In rooms where the heated area sometimes exceeds three hundred square meters, floor-standing boilers are used. These heating devices are much more powerful than wall-mounted ones.

Wall-mounted single-circuit heating devices are most often used in high-rise apartments and can heat an area of up to three hundred square meters. These boilers are much more compact than floor-standing ones, and weigh just over 40 kilograms. The wall-mounted single-circuit boiler fits organically into the interior. Also, these wall-mounted devices are more functional than their floor-standing counterparts. The power of the most advanced models of wall-mounted single-circuit boilers is no more than 35 kilowatts.

A single-circuit gas boiler does not have any complex elements or mechanisms in its design. This boiler consists of:

- burners;

- heat exchanger;

- control unit;

- water pump;

- turbine electric motor (if the boiler has a closed combustion chamber);

- pressure gauge;

- sensors;

- shut-off valves.

Operating principle of single-circuit boilers

Gas single-circuit boilers with an indirect boiler operate according to two main connection schemes. The principle of operation of the first is as follows:

- The three-way valve dominates here. A pump is installed directly into the outlet of the gas boiler, which provides circulation and creates pressure. The next step is to install a three-way valve, which is connected to the boiler thermostat. When heating tap water or other coolant, its flow is directed to the heating system, with priority for the hot fluid entering the boiler coil. This happens with the help of an additional, second pump. And it turns out that in this case the hot water supply and the heating system are connected in parallel, and they can form two circuits, precisely in this closed chain. And after the boiler, an additional pump is installed, which helps regulate the operation of the thermostat. The principle of starting and stopping the process is also regulated by a thermostat, namely, when the heating is strong, the fuel supply is forced to shut off, when the coolant cools down, the fuel is passed through again, and the burner is automatically ignited.

- If there is no double circuit and priority is not given to heating hot water, the boiler is mounted in a common system, installed in a convenient location, and water is heated along with all radiators.

Principle of operation

The main element of the boiler is a heat exchanger made of steel or brass. It has a large surface area and is located inside a tank coated with paint. To prevent rapid decrease in water temperature, thermal insulation or casing is provided.

One of the main parts of this device is the magnesium anode. It is needed to slow down the corrosion process, which extends the life of the boiler.

The device is equipped with a safety valve and a thermostat that protect it from sudden increases in pressure. If protection is not structurally provided, then it is installed during piping of the water heater. The process of heating water is quite simple: the hot coolant in the coil heats its walls, after which the heat from the metal is transferred to the cold water in the container.

Indirect device

Piping of the boiler and indirect heating water heater

In order to connect the two considered heat supply system devices (single-circuit boiler and indirect heating boiler), it is important to keep in mind that there are special recommendations before direct connection

- It is necessary to choose the location of the boiler based on the installation location of the boiler itself. It is best to place them as close to each other as possible. This will reduce the time it takes for hot water to enter the tap;

- Purchase and install a membrane accumulator at the outlet of the hot liquid from the boiler, which helps prevent damage due to the effect of thermal expansion;

- Additionally, install a ball valve on each circuit;

- Attach check valves to regulate the direction of water flow;

- Place filters for cleaning;

- The pump shaft must lie horizontally.

Tying can be done in several variations:

Option 1. Connection using a three-way valve.

We have already mentioned the three-way valve. It is he who is put at the forefront in this scheme, branching the duct from the boiler, entering the boiler and exiting to the heating sector. This unit is designed as a parallel connection between the system and the boiler, which ensures maximum speed and productivity of the work performed. Its advantage is the ability to switch heat priority from radiators to quick heating of an indirect heating boiler. Needed by those consumers who often use the boiler.

Watch a version of this strapping scheme in our video

Option 2. Two circulation pumps

There is no three-way valve in this circuit. The transfer of water to different parts of the system is carried out by standard tees. The first pump is installed on the BKN supply pipe, the other on the heating circuit. The purpose of this solution is to provide the household with warm water at any time.

Option 3: Using a hydraulic boom

An extremely labor-intensive installation process, involving operations to install equipment on several independent circuits. It is distinguished by multi-level, for example, in a two- and multi-story building. Suitable for that category of customers who use a large number of warm surfaces and simultaneously open several taps with hot water.

Option 4. Coolant recirculation

The zigzag towel dryer is the same battery for heating a bathroom. To maintain a constant temperature level, constant circulation of water masses inside the circuit is used. Disadvantage: high energy consumption.

Materials and tools

Materials:

- Pipes, shut-off valves, check valves - there are no special requirements for them: use the same materials as for working with hot water supply or heating systems.

- Expansion tank - a separate one is required for the domestic water supply system; it serves to prevent sudden pressure changes when opening/closing taps.

Attention! The tank must be designed for use with hot water; usually such devices are marked with special markings. Circulation pump - as a rule, a separate pump is installed in the heat exchange circuit with the water heater

Circulation pump - as a rule, a separate pump is installed in the heat exchange circuit with the water heater.

In addition, in DHW systems with recirculation, a separate pump is required to circulate water in the DHW circuit.

This will eliminate the need to wait for hot water to arrive through long pipes from the installation site of the water heater: the water will immediately be hot.

- Wires and small electrical wiring - if you plan to connect the water heater thermostat to the boiler automation.

- Fasteners - especially in case of wall installation, also for securing pipes and pumps.

- Standard plumbing set of sealants, seals, gaskets.

Tool:

- gas key;

- wrenches of various diameters;

- Adjustable wrench;

- building level;

- hammer drill, screwdrivers, screwdriver;

- Minimum electrician's kit: knife, wire cutters, electrical tape, phase tester.

Installation process: how to connect

Ideally, the boiler should be located as close as possible to the heating boiler to minimize heat loss.

Cold water is always supplied to the bottom pipe of the boiler, and hot water is drawn from the top.

- Choose a location for the water heater so that it is not in the way and is easy to maintain. Mount brackets, stands, and secure it to them.

- Connect to the cold water network: make a tap, install a shut-off valve and a coarse filter.

- Through a tee, take the cold water line to consumers, connect the second output to the boiler through a safety valve.

- Connect the domestic hot water line to the boiler, not forgetting about the expansion tank on it. In addition, install bypass taps so that you can disconnect it from the circuit during maintenance.

- Now connect the boiler to the gas boiler according to one of the given diagrams. Don't forget to turn off the boiler and shut off the system before connecting!

- Connect electronics, sensors, pumps according to the instructions.

Startup and testing

After installation, the first thing you need to do is connect and fill the boiler with cold water. Make sure that all air pockets are removed from the system and that the boiler is completely filled to avoid overheating.

When the boiler is full, set the desired temperature using automation. Start the boiler, open the coolant supply from the heating system to the boiler.

When the system reaches operating mode, make sure that the safety valve (usually set to 8 bar) is not leaking, i.e. there is no excess pressure in the system. You should also check all connections, seals and taps for leaks.

Optimal operating mode of an electric boiler

Setting the temperature to the minimum permissible is highly not recommended for the following reasons:

- Reduced efficiency of water heating equipment;

- Liquid temperature 30-40⁰ C is an ideal environment for the formation and proliferation of bacteria and mold, which inevitably end up in the water;

- The rate of scale formation increases.

These devices are often equipped with an economy mode option, designated by the letter E. This operating mode means heating the liquid inside the capacitive tank to a temperature of +55⁰ C, which allows you to extend the period of use before maintenance. That is, at a given temperature regime, scale forms the slowest, and accordingly it is necessary to clean the heating element less often. This does not apply to energy savings.

Positive consumer reviews about the operational features of the Vitopend 100 boiler

The above-described gas boiler with a boiler, reviews of which are quite often the most positive, is, as mentioned, effective in operation. This is expressed in the fact that the modulating burner maintains the water temperature in the circuit, which allows for the most precise regulation.

Buyers also talk about simple control, because the case has a panel with a display that allows you to adjust the temperature and control the operation of the device. Among other things, buyers note that due to its compact size, this equipment can be installed even in small rooms, niches or openings.

The best known manufacturers and models: characteristics and prices

All the models listed below are the most well-known and widespread, one of the most trouble-free and proven, optimal price-quality ratio double-circuit wall-mounted boilers. It is quite difficult to sort them into a rating based on reliability or quality, since most of them are the most successful models on the competitive market, almost identical when assessed based on a set of parameters, but clearly having their own characteristics.

BAXI ECO-4s 24F

The most common and “favorite” in Russia is the Italian double-circuit boiler with a closed combustion chamber (prefix F in the name). It is highly efficient and economical, its efficiency is one of the highest in the price segment - 92.9%, maximum gas consumption - 2.73 m3/hour. At the same time, the boiler is perfectly adapted to domestic conditions: unstable gas and water pressure, as a rule, is not the cleanest coolant, the automation and pump tolerate minor voltage drops.

The primary heat exchanger is copper, there are almost all protection systems available today: from overheating and freezing, blocking the circulation pump, auto-diagnostics. A water filter is also pre-installed. The quality of assembly and layout is excellent; after operating for more than 6 years, the boiler is known for its trouble-free operation. Owners also note almost silent operation. Among the shortcomings, only slight instability of the temperature of the heated water can be noted.

Vaillant turboFIT VUW 242/5-2

Despite its less popularity, in our opinion this is one of the best wall-mounted double-circuit gas boilers for heating a private home. TurboFIT VUW 242/5-2 is one of the German reference models with a closed combustion chamber. It is distinguished by excellent efficiency, efficiency – 93.5%, and maximum gas consumption – 2.66 m3/hour. The heat exchangers in it are separate, the primary one is copper. The performance between the circuits is carried out using a three-way valve, which allows you to maintain the temperature of the coolant when hot water consumption points are open. DHW performance is at the level of analogues.

The model has been on the market for only a few years (since 2022) and so far there are no known cases of service failures. However, the manufacturer has long been known for its high reliability and durability. Judging by the layout, this model is no exception: all pipes are copper, not rubber, connections are threaded, excellent build quality. All necessary protection systems are present. The turbine, servo drive and ignition operate almost silently.

Its only drawback is its higher price; in fact, it is a budget model from a well-known premium manufacturer. It is also worth considering that it is advisable to connect the boiler through a voltage stabilizer to prevent failure of the electronic control board.

Viessmann Vitopend 100-W A1JB010 24

Another reference German boiler with a closed combustion chamber, slightly inferior in performance to the Vaillant turboFIT. Efficiency – 91% at maximum gas flow – 2.77 m3/hour. The heat exchangers are separate, the primary one is made of steel, although with thick walls, designed for an operating pressure of up to 3 bar; during operation in Russia, no problems with burnout or leakage are known. The distribution of performance between the circuits is also through a three-way valve, and there are all protection systems.

A special difference is the presence of a programmer that allows you to set boiler operation settings for a day or a week, which, with proper operation, can significantly reduce consumption. A built-in programmer is a rarity in boilers in this price category.

The disadvantages are standard for most Viessmann models: vulnerability to voltage surges (the protective mechanism is designed for 170-253 V, which is not always enough); again, we recommend connecting the boiler through a voltage stabilizer. Also, in rare cases, the flame sensor and the burner module as a whole may become clogged, causing the automation to display error F4. It is imperative to regularly clean the boiler (at least once every 3-4 years) and monitor the condition of the gas filter.

Bosch Gaz 6000 W WBN 6000-24 C

A budget model from a well-known manufacturer, not the most outstanding in terms of characteristics, but proven in operation. Maximum gas consumption – 2.8 cubic meters. m/hour, separate heat exchangers, the primary one is copper, the distribution of productivity between them is carried out by means of a three-way valve. It operates almost silently, at the level of the reference Vaillant, in particular thanks to the smooth ignition technology, without the characteristic pop.

The device and materials used are not very different from previous analogues, but some connections are not threaded, but use rubber. In general, there are no serious complaints about technical reliability, but the boiler is very demanding on the presence of grounding, preferably dedicated specifically to the boiler, otherwise it will constantly generate an EA error.

Step-by-step instructions for grounding a gas boiler in a private house

Also, owners often note less convenient controls; to change the temperature of the DHW circuit and some other settings, you need to perform several actions, unlike separate buttons or “knobs” in previous models.

Buderus Logamax U072-24K

A German model with a closed combustion chamber, but with Russian localization (assembly is carried out at a Russian plant), which significantly influenced the cost of the boiler and made it possible to distinguish it from others. Efficiency – 92%, maximum gas flow – 2.8 m3/hour, primary heat exchanger – copper. The layout of the boiler is not much different from previous German analogues; the connections are threaded, but the quality of Russian assembly is sometimes inferior to European ones.

In general, this is an extremely budget-friendly, efficient, reliable and stylish model, but at the same time it has a slightly larger number of shortcomings. Firstly, in addition to the lower quality of assembly, it is a plastic water supply valve, which is easy to break over time. Secondly, the electronic board is vulnerable to voltage surges. However, the price of the boiler makes it competitive and worthy of attention.

Ariston ALTEAS X 24 FF NG

An extremely stylish, efficient and high-tech boiler with a closed combustion chamber. Efficiency – 93.7%, maximum gas flow – 2.73 m3/hour, separate heat exchangers, distribution via a three-way valve. In addition to the design and build quality, the main difference from previous analogues is the presence of a programmer and the ability to control from an application on a smartphone via Wi-Fi. Owners also note a large number of fine settings (limiting the coolant temperature, influencing the on/off frequency, etc.).

The only drawbacks are the interface, which is somewhat difficult to master, the impractical glass cover, which shows fingerprints, and the rather high price, which, however, can hardly be considered overpriced.

Undoubtedly, there are other excellent models from the same or other manufacturers, in some respects inferior to those listed, and in others superior; it is impossible to list them all within the scope of the article.

If you wish, you can also pay attention to models from such companies as Protherm, Lamborghini, MORA-TOP, De Dietrich, Wolf. Due to the increased problems and quality, we do not recommend choosing Korean models, Russian-made boilers and similar ones that are attractive for their cost: Navien, Kiturami, Lemax, Ferroli (assembled in China).