Heat supply can be local or centralized. A district heating system serves residential or industrial areas, and a local heating system serves one or more buildings. In Russia, centralized heat supply has acquired the greatest importance.

Depending on the method of connecting the hot water supply system to the heating system, the latter is divided into open and closed.

Open heating systems

In an open system, water is constantly supplied from the heating plant and this compensates for its consumption even if it is completely dismantled. In Soviet times, approximately 50% of heating networks operated according to this principle, which was explained by efficiency and minimization of heating and hot water costs.

But an open heat supply system has a number of disadvantages. The purity of water in the pipelines does not meet the requirements of sanitary and hygienic standards. As the liquid moves through long pipes, it becomes a different color and acquires unpleasant odors. Often, when sanitary and epidemiological station workers take water samples from such pipelines, harmful bacteria are found in it.

The desire to purify the liquid entering through an open system leads to a decrease in the efficiency of heat supply. Even the most modern methods of eliminating water pollution are not able to overcome this significant drawback. Since the length of the networks is considerable, costs increase, but the cleaning efficiency remains the same.

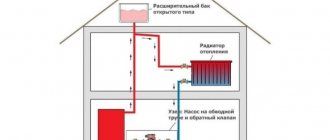

An open heat supply circuit operates on the basis of the laws of thermodynamics: hot water rises, due to which high pressure is created at the outlet of the boiler, and a slight vacuum is created at the entrance to the heat generator. Next, the liquid is directed from a zone of high pressure to a zone of lower pressure, resulting in natural circulation of the coolant.

Being in a heated state, water tends to increase in volume, so this type of heating system requires an open expansion tank, such as in the photo - this device is completely leaky and is directly connected to the atmosphere. Therefore, this heat supply received the appropriate name - an open water heat supply system.

In the open type, water is heated to 65 degrees and then supplied to water taps, from where it is supplied to consumers. This heat supply option allows you to use cheap mixers instead of expensive heat exchange equipment. Since the distribution of heated water is uneven, for this reason the supply lines to the end consumer are calculated taking into account maximum consumption.

What types of heating systems exist

The classification of heating systems divides them into autonomous and central. Based on the coolant, they are divided into steam, water and air. By energy source - gas, electric, liquid fuel or solid fuel.

Based on the movement of the coolant, they are grouped into systems with natural and forced circulation. Types of heating systems for an apartment building according to the heating system wiring diagram are grouped into the Leningradka system, two-pipe heating systems, single-pipe heating systems and radiant systems.

Types of coolants:

- water;

- steam;

- air.

Vodyanoye

In these systems, thermal energy is transferred by hot water coolant. It is heated in the heating source and enters through a pipe system into heating devices that have a developed heating surface.

The supply coolant transfers heat through the surface of the radiator walls into the surrounding space, cools down and returns through the return pipeline to the heating boiler.

Classification of water heating systems is carried out according to the calculated temperature of the supply coolant:

- low temperature coolant up to 70 C;

- average from 75 to 100 C;

- high over 100 C.

Types of wiring:

- top, when the supply is above the radiator and the return is below;

- lower, if both pipes are below the battery;

- with inverted circulation, if the supply is below the battery and the return is above.

In the simplest version, heating of industrial premises can take place without radiators through large-diameter pipes assembled in sections. However, such a system is considered less efficient, more metal-intensive and labor-intensive, and therefore is not used in residential construction.

Gas

This option for heating a house involves using energy from the combustion of gas fuel. At this point in time, this is the cheapest and most automated type of heating. It is used in gasified areas.

The heating source is a wall-mounted or floor-mounted gas boiler. Single-circuit for heating only. Heating of water in such boilers can be organized through an external indirect heating boiler.

For joint heating and hot water preparation, gas double-circuit boilers are installed. Gas boilers have the ability to operate in 100% automation mode, including remote control via modern information transmission networks: Wi-Fi, SMS and the Internet.

Weather-compensated automation adjusts the indoor temperature in accordance with the outdoor temperature.

This type of heating also includes convector gas heating. The devices externally resemble water or electric convectors. The only difference is that heating radiators are powered from a gas or solid fuel boiler, and gas convectors have a direct gas connection; there is no piping system.

Heat is transferred by convection from the burned gas through the walls of the device. From an efficiency point of view, this is the most efficient heating device; there are no losses along the length of pipelines and installation costs are reduced. The only drawback is the need to install a smoke exhaust system for each convector.

Air

The most ancient traditional type of heating. It comes from a traditional Russian stove. For a developed air heating system, it is necessary to install a large number of air ducts and heated walls that will transfer heat from the flue gases to the surrounding air.

The advantage is the high accumulative capacity of such a system; walls heated to a temperature of 60-100 C cool down very slowly, practically such a heating source is heated once a day.

Classification of air heating systems:

- central heating using an air duct system;

- local, operating in the installation area.

Since air is considered an excellent controlled medium, air systems have taken on a new life today.

Such an engineering solution can be presented, for example, as a split-system air conditioner with indoor and outdoor units operating in heating mode.

Electrical

With the enormous efficiency of this type of heating, the efficiency of which tends to the maximum 98-99%, this type of heating of houses remains the most expensive due to the cost of electrical energy. Modern sources of electric heating are very diverse, from stationary installations in the form of heating boilers to mobile air heaters.

The most popular is a water heating scheme with an electric boiler and a circulation pump. Due to the characteristics of electric heating, such a system can only be of a closed type and must be equipped with a membrane-type expansion tank.

Electric heating has 100% automation of thermal processes, including with a remote control mode, and is equipped with a weather-dependent automatic system.

Infrared floor

Infrared flooring refers to electric heating; it can be turned on from an outlet or a control unit that adjusts the zone-by-zone temperature regime in the house.

The system is manufactured in the form of laminated panels, with an internal arrangement of heating elements in the form of a strip. Carbon plates are soldered into them, emitting an infrared spectrum when electricity passes through.

Unlike water heated floors, this type of heating is less labor-intensive during installation and does not raise the level, while it provides the fastest and highest quality heating. In addition, if necessary, such a heating system can be easily dismantled and moved to the desired room.

Heat pumps and geothermal installations

The competent use of the temperature of the earth's surface to heat houses is unfairly underestimated in Russia, although Western European users successfully use this practice.

Geothermal heat supply is a limitless and almost free resource that allows you to provide your home with all types of heat supply: heating, ventilation and hot water supply. It does not matter the volume of services, time of year, outside temperature or place of residence.

Modern innovative technologies are capable of accumulating the inexhaustible heat of the earth. Given the high costs of installing such equipment and the low cost per unit of generated thermal energy, the payback period for geothermal heating is 5-6 years, which is quite consistent with global energy indicators.

Solar collectors

Another modern type of heating, which is gaining volumes in the installation of autonomous heat supply systems. And if this option for preparing hot water has been used since time immemorial, for example, when installing a summer shower.

Solar energy has been used relatively recently for heating systems. This was facilitated by the industrial production of inexpensive solar panels installed on the roofs of houses. When exposed to sunlight, they produce electricity that feeds the heating system.

The devices are installed at an angle of maximum absorption of sunlight. The system contains batteries that accumulate electrical charge and transfer it to the heating system at night.

The payback period for such systems is approximately equal to systems with heat pumps, but the costs are still higher, and the turnaround period when a complete battery replacement is required remains short - only 2 years. These circumstances hinder the widespread use of solar systems in domestic heat and power.

Combined heating

Combined heating includes systems that simultaneously include two or more different sources: gas-electric, gas-solid fuel, gas-heat pumps, heat pumps-solar collectors and so on.

Such a combination of various sources of thermal energy makes it possible to carry out autonomous heating of an individual cottage with a high level of protection that does not depend on one energy source.

The combined scheme is able to select a thermal mode that will provide the lowest cost per unit of heat, and will also allow the use of waste heat for additional heating of water in the DHW system.

Industrial heating systems

Carrying out production processes involves maintaining the required temperature conditions indoors, especially in the autumn-winter period. Most often, steam heating is installed in production.

Steam heating systems are classified according to steam pressure:

- low pressure 0.7 atm;

- high pressure above 0.7 atm.

Design developments during the construction of engineering systems of industrial buildings depend on the specifics of such production, and therefore a significant role in this process is played by the analysis of thermal emissions during the production process, for its subsequent use in the heating system as secondary energy sources.

The costs of heating industrial premises are included in the cost of production. The market demands low prices, and therefore the problem of energy saving is acute in industrial space heating.

Closed heating systems

It is a closed heat supply system design in which the coolant circulating in the pipeline is used only for heating and water from the heating network is not taken for hot water supply.

In this case, all elements of the heating network are closed from the environment. A closed heat supply circuit also has a slight leakage of coolant, but its losses are replenished using an automatic make-up regulator (more details: “Automatic make-up of a heating system - diagram of the unit and make-up valve”).

In a closed version of providing space heating, the heat supply is regulated centrally, and the amount of liquid in the system remains unchanged. Thermal energy consumption depends on the temperature of the coolant circulating through the pipes and radiators.

Closed heat supply systems, as a rule, use heating points into which hot water is supplied from a heat energy supplier, for example a thermal power plant. Next, the temperature of the coolant is brought to the required parameters for heat supply and hot water supply and sent to consumers.

When a closed heat supply system operates, the heat supply scheme ensures high quality hot water supply and an energy-saving effect. Its main disadvantage is the complexity of water treatment due to the remoteness of one heating point from another.

Functional diagram of the dependent vehicle system. Wiring throughout the premises - classic, two-pipe

- The dependent heat supply system is still the most common in the country. Its main feature is the use of an elevator unit (EU) to organize the mixing of the supplied network coolant with the circulating intra-house coolant. The elevator nozzle is installed at the entrance of the pipelines to the house, it ensures not only the mixing of superheated water with low-temperature water, but also has the effect of sucking in the coolant coming from the return pipe of the internal house network. The heat metering unit is installed in front of the elevator unit. The network coolant enters the internal home network directly, which causes a direct dependence of the quality of heating in each room on the operation of the boiler room and the functioning of the heating system of neighboring houses.

The circulation of the coolant in the external and internal networks is ensured by the pumping equipment of the local boiler house. Regulation of energy supply to neighboring buildings is ensured by washering of pipelines. In the buildings closest to the boiler room, the diameter of the inlet pipeline is reduced by means of a washer of design diameter mounted in it. In pipelines of remote buildings, washing is carried out to a minimum extent or is absent altogether.

Apart from the extremely low cost of installation, the dependent vehicle system has no advantages. The disadvantages of the system include, first of all, dependence. In the event of an accident in any of the houses connected to the local boiler house, the heat supply may be interrupted in the entire block for a long period of time, until the accident is localized. In addition, such systems do not allow either adjusting the temperature schedule or switching to a different vehicle mode. Setting up and repairing an elevator unit is a capital work and is carried out in the off-season through the complete dismantling of a certain section of pipelines. Damage to the network and their natural wear and tear can lead to an imbalance in the heating modes of the buildings in the block, which forces a change in the washer parameters (washer diameters) in the entire block, powered by one boiler house. It is not always possible to ensure user comfort and even indoor air temperature standards. In modern urban planning, the dependent TS system is not used. Owners, when carrying out major repairs in their house, should switch to an independent vehicle scheme.

- An independent heating system is rightfully considered a modern method of heating buildings. In an independent heating system, the coolant from the boiler room reaches through the network pipeline only to the individual heating point (IHP) of the building. The basis of ITP are heat exchangers, the function of which is to transfer energy to consumers, without direct flow of network coolant into the internal heating system of the house. Heat exchangers provide effective thermal contact between the external and internal networks of the vehicle and their complete independence from each other. We will tell you more about the ITP device below.

The heating mode of the building is supported by the automation device serving the ITP. The automation unit receives data from electronic thermometers, one of which is installed on the internal return pipeline (T4), and the other measures the ambient air temperature. Comparing the information received with the specified values of the temperature graph, the automation varies the heat supply through a specially installed control valve K1.

Dependent and independent heat supply systems

Both open and closed heat supply systems can be connected in two ways - dependent and independent.

The dependent connection method of an open system means connection through elevators and pumps. In the independent type, hot water flows through a heat exchanger.

Unlike the dependent connection option, the independent connection is considered more expensive, but the quality of the water in the pipeline is higher (more details: “Dependent and independent heating systems - differences in schemes, pros and cons”).

Heat generation scheme

The functional schemes of the operation of thermal power plants and state district power plants are very similar, the difference lies in the power and construction of the equipment.

Electrical and thermal energy is generated at thermal power plants and state district power plants by burning fuel. To operate, you need coal, fuel oil or natural gas.

CHP device

The main components of the thermal power plant are:

- fuel facilities - a set of places for storing and preparing fuel;

- boiler room consisting of a boiler and auxiliary equipment;

- turbine and electrical equipment;

- condensate installation;

- heat exchangers that remove heat for central heating;

- technical water supply system.

Additional systems include smoke removal and smoke purification systems, ash and slag removal systems, and pipelines.

Boiler houses are much simpler - they do not contain turbines, condensate units, or other auxiliary equipment.

Algorithm for operation of heat sources

The principle of operation of thermal power plants,

thermal power plants and state district power plants are extremely complex structures, but the principle of operation of heating the coolant is not difficult to understand:

- The prepared fuel is supplied to the boiler room. The coal must be ground, preferably to a dust state. For combustion, air is supplied to the combustion chamber by pumps.

- In the boiler room, process water in boilers is brought to the state of steam, which is under high pressure.

- Through pipelines, steam is supplied to the turbine blades, which, as they rotate, generate electrical energy.

- After the turbine, the cooled steam enters the heat exchanger, where it transfers thermal energy to water for a centralized heating system.

- The cooled steam passes into the liquid phase, which the condensate unit cleans of vapors and impurities.

- Purified water is supplied to the boiler room, where a new heating cycle begins.

In summer use, when much less hot water is required, CHP plants are switched to electricity generation mode. In this case, the steam is cooled in cooling towers to the state of water, pumped to a height of up to 12 meters and sprayed with special installations. Excess steam is released into the atmosphere.

The water enters the pool, where it is cooled. Then it is supplied to the boiler room by condensing units. The process is repeated. To compensate for losses, water is added from external sources - rivers or lakes.

Coal-fired thermal power plants and state district power plants must be equipped with smoke removal systems.

Saving resources

The dependent type of closed system provides that water flows to the consumer without passing through heating points. In this case, there is no need to install circulation pumps, devices for regulating heat exchange and automatic control. But there is also a minus - the inability to regulate the temperature in the system.

Independent closed heating systems save energy resources in the amount of 10-40% per year. They allow you to regulate the amount of heat supplied, the temperature of the coolant and improve its quality characteristics, which leads to reliable operation of heating equipment.

An example of an open heating system in the video:

In-house heating equipment

Pipe distribution diagrams for central heating

Heat distribution throughout the premises of an apartment building is carried out according to one of the following schemes:

- single-pipe with top filling;

- single-pipe with bottom filling;

- two-pipe with bottom filling;

- two-pipe with top filling.

In the first case, the coolant under pressure rises along the central riser to the upper floor. Then, by gravity, the water, having given up some of the heat to the batteries, returns to the heating unit and is then transported towards the thermal power plant (boiler house).

The risers run inside the apartments and disconnecting your home from the general system is technically difficult and sometimes impossible. The temperature of the radiators can be regulated by special thermostats, the installation of which requires welding. In high-rise buildings, additional pumps are installed in heat supply units to supply coolant to the top floor, which increases costs and the cost of services provided.

Interfering with the operation of the second scheme is also technically impossible - the pipes here also run inside the apartments.

It is possible to replace central heating radiators from cast iron to bimetallic

Recently, in new houses and during the reconstruction of old buildings, two-pipe schemes have been used with the location of common communications in the entrances or technological shafts. In such cases, it becomes possible to disconnect an individual apartment from the heat supply.

Russian legislation categorically prohibits turning off the heating without authorization for any reason.

There are restrictions on the installation of radiators in apartment buildings. The pressure in a 5-story building is from 2 to 4 Atm, and in a 9-story building up to 7 Atm.

In the summer, after repair work on communications, pressure testing is carried out - the pressure is raised to 10-12 atm to detect leaks. When the system is filled with coolant, water hammer may occur.

Based on possible loads, when replacing radiators, they abandon all-aluminum products, choosing bimetallic radiators. Pay attention to the guaranteed pressure indicators that the battery can withstand.

How do they heat houses in other countries?

One of the ways to save is energy-efficient houses.

Our country inherited central heating as a legacy of the socialist economy. In a planned economy and with large energy resources, centralized heating was built and, for the most part, paid for by the state.

Pipes with coolant cooled in houses on the way to the thermal power plant were a source of heat for greenhouses, industrial enterprises, and cattle breeding complexes.

Mass production of equipment for individual heating began systematically in the mid-90s; before that there was a shortage even for private households.

There are very few countries on the planet with similar climatic conditions and comparable population density. To save resources, heating in most parts of the world is decentralized.

Heat in the ground can be used for heating, but installations are expensive

In Germany, France, Canada, systems similar to ours were built until the 50s of the last century. The ensuing global energy crisis prompted the development of heating systems that serve one or more multi-storey buildings. A separate boiler room is being built for this purpose. There are no long communications for transporting hot water - losses are minimized.

The installations are easy to put into operation during a sudden cold snap, and on warm days it is possible to reduce energy consumption by reducing the temperature of the circulating water.

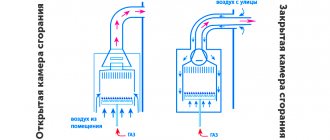

There is no centralized heating in France and the UK - there, each apartment has a separate boiler with a closed combustion chamber, the operation of which is controlled by the owner of the apartment.

The availability and accessibility of energy resources in the region plays an important role.

In Poland and China, many homes are heated with coal, in Iceland - with water from thermal springs. Norway actively uses cheap electricity.

Advantages and disadvantages of centralized heating

Heat loss is always present, since the length of the main line can be several tens of kilometers.

Any equipment, technical systems and communications have advantages and disadvantages. The pros and cons are considered in conjunction with the economic component and ease of use.

The positive qualities of centralized heating include:

- Operating costs with a central system are comparable or lower than fees for energy purchased individually.

- Most thermal power plants, state district power plants, and district boiler houses operate on any type of fuel, which makes it possible to create emergency reserves for work.

- The only heating equipment in residential premises is radiators. Boiler installations are located away from residential areas, and sanitary zones are installed around them, which improves the environment.

- The owner does not purchase expensive equipment (boilers).

- Heating of the apartment does not depend on the supply of energy and electricity to the house.

- The likelihood of accidents and disasters associated with gas leaks is reduced.

- There is no need to enter into contracts and pay for servicing gas equipment.

- Accidents are eliminated by the supplying organization as soon as possible at its own expense.

Heat tariffs are set by regional commissions

. Disadvantages include:

- losses in networks delivering heat to the house - the length of the pipeline can be 10 km;

- the supplying organization includes possible costs in the tariffs, so the payment is significantly higher than it could be;

- limited temperature control in the apartment caused by the schemes for constructing intra-house networks;

- the impossibility of disconnecting an individual apartment from the general building network without a court decision;

- dependence on tariffs (set by regional commissions), which the homeowner is not able to influence.

The most important drawback in ease of use is considered to be the inability to heat the house during the non-furnace period. In spring and autumn, sudden temperature changes are common, to which the thermal power plant cannot quickly respond. Changing operating modes entails large financial losses.

Ways to reduce costs

Insulating the heating main is one of the ways to save energy.

There are few opportunities to reduce operating costs for the supplier and heating costs for apartment owners:

- high-quality thermal insulation of main pipelines, especially those located on the surface;

- installation of general house meters for energy consumption, which compare the temperature of the coolant at the inlet and outlet - knowing the volume of flowing liquid, the equipment automatically calculates the calories consumed;

- installation of individual metering devices in each apartment, which is applicable only for schemes 3 and 4 discussed above.

There are no other options to influence payment.