Home / Heating

Back

Published: 12/18/2020

Reading time: 3 min

0

1549

The question of what is the difference between a hydraulic accumulator and an expansion tank remains unclear to some consumers, although such equipment has been used in boiler houses for quite a long time.

Water supply and heating systems cannot be imagined without such successful additions; most people are accustomed to distinguishing these devices by their shade.

One of the units is available in blue, and the other in red, but their structure has its own nuances. I want to analyze in detail the differences between the devices and describe the purpose of installing each type of device.

- 1 Design and purpose of the expansion tank

- 2 Design and purpose of the hydraulic accumulator

- 3 What are the differences 3.1 How does the expansion tank work

- 3.2 How a hydraulic accumulator works

What is a hydraulic accumulator

Hydraulic accumulator, it is also called hydraulic tank, hydraulic tank, membrane expansion tank. In a water supply system from a well, it is used as an autonomous storage tank for a summer house or private house, supplying water to the sink, shower and other points, and then draining it into the sewer system in the same way as in city apartments. Hydraulic tanks work in conjunction with the pump.

Design features

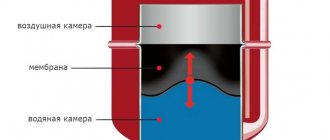

In terms of appearance, both tanks differ from each other only in color. They are available on the market in horizontal and vertical versions. As for the internal filling, the devices consist of a steel tank with a membrane inserted inside.

Since the expansion tank is used in a hot water system, the membrane in it is made of polymers that do not change their technical characteristics when in contact with hot liquids. Manufacturers use EPDM, SBR, butyl rubber and nitrile rubber for this.

Membranes are also used in hydraulic accumulators. But they differ in the form of their execution. In these containers, the demarcation material is presented in the form of a pear. In expansion tanks, this is simply a partition dividing the container into two parts.

The water in the hydraulic accumulators enters the bulb without coming into contact with the walls of the steel tank. Here, the starting material for the membrane is food grade rubber.

How it works and how it works

Air is pumped between the housing and the inner membrane; on one side there is a nipple for pumping or bleeding air into the space between the membrane and the housing. Also, it is better to choose equipment with an integrated pressure gauge and an additional nipple.

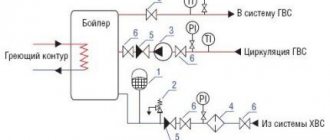

The hydraulic accumulator works as follows:

- After pumping in air, check the pressure;

- Turn on the pump, pump water into the membrane;

- We turn off the pump, then open the tap, the air presses on the membrane and under its influence pressure is created, the liquid enters the tap.

Hydraulic tanks operate without electricity; if there is a power outage, the water will not go anywhere.

Other Features

Hydraulic accumulator design

The differences between the two devices must also be approached from the perspective of the possibility of replacing them with each other. Here we must take into account the fact that the accumulator is used in a drinking water system. Therefore, its pear-shaped membrane is made of food-grade rubber, which does not spoil the characteristics of the water itself, does not change its color or smell. It is not worth installing an expansion tank in the water supply, because its membrane will first of all transmit the pungent odor of rubber to the water.

The main function of the accumulator is to create pressure inside the water supply. This cannot be done using an expansion tank.

Using a hydraulic accumulator as an expansion tank is possible. But there is one point that concerns the pressure of the pumped air. In a heating system, the coolant moves at a low speed created by a circulation pump. This pressure is not enough to overcome the pressure of the pumped air. This is where a problem may arise. It’s not difficult to solve: the air needs to be vented (bleeded). At the top of the tank there is a nipple through which air can be pumped into the chamber with a conventional air pump. Air can be vented through it.

The volume of the expansion tank is selected based on the volume of coolant in the heating system of a private home. The ratio is 10% of the water inside the heating.

As for the hydraulic accumulator, there are no such strict parameters when choosing it. More often, its functionality is taken into account, because, in essence, it is a container for storing water. Therefore, the larger the device, the better.

Prevention

We recommend conducting diagnostics for the presence of bleed air and the integrity of the hydraulic tank membrane annually. In the second case, the hydraulic accumulator ceases to act as protection against water hammer. The membranes are sold separately and can be replaced in a couple of minutes.

Let's summarize. The hydraulic tank easily provides water to a cottage or country house, while protecting the water supply system from water hammer, leading to breakdowns, and premature wear of equipment. This will make it possible to use water without thinking that it may run out or something will happen to the equipment.

Installation rules

This is the only position that does not differ between the two tanks. Typically, both containers are connected to the pipework using American connectors, making the connections detachable. This makes it easy to disconnect the device if it needs to be repaired or replaced with a new one.

As for the installation location, there is no difference here either, if the heating system has a circulation pump in its circuit. If the heating network is gravity-flow, the coolant in it moves under the influence of physical laws (heated up, cold down), therefore the installation location of the expansion tank is the highest point of the heating circuit.

The first thing you need to pay attention to when choosing a hydraulic accumulator and expansion tank is the color of the tank. This is the factor that will prevent you from making a mistake. The remaining characteristics are selected for each network separately, taking into account their complexity and performance.

Tank volume is the main selection criterion

The most important question is how to choose the volume of a hydraulic accumulator for water supply systems. To answer it, you need to bring together a lot of data. This includes the performance of the pump, the equipment of the house with water-consuming equipment, the number of people permanently living in the house, and much more.

But first of all, you need to decide whether you need this reservoir only to stabilize the operation of the system as a whole, or whether there is a need for a supply of water in case of a power outage.

Internal cylinders of different volumes

If the house is small and equipped only with a washbasin, toilet, shower and watering tap, and you do not live in it all the time, you don’t have to make complex calculations. It is enough to buy a tank with a volume of 24-50 liters, it will be enough for the system to work normally and be protected from water hammer.

In the case of a country house for permanent family residence, equipped with everything necessary for a comfortable life, it is advisable to approach the issue more responsibly. Here are a few ways you can decide on the size of your accumulator.

According to pump characteristics

The parameters that influence the choice of tank volume are the performance and power of the pump, as well as the recommended number of on/off cycles.

- The higher the power of the unit, the larger the volume of the hydraulic tank should be.

- The powerful pump pumps water quickly and turns off quickly if the tank volume is small.

- A sufficient volume will reduce the number of intermittent starts, thereby extending the service life of the electric motor.

To calculate, you will need to determine the approximate water consumption per hour. To do this, a table is compiled that lists all devices that consume water, their quantity and consumption rates. For example:

Table for determining the maximum water flow

Since it is almost impossible to use all devices at the same time, a correction factor of 0.5 is used to determine the actual flow rate. As a result, we get that you spend an average of 75 liters of water per minute.

How to calculate the volume of a hydraulic accumulator for water supply, knowing this figure, the performance of the pump and taking into account that it should turn on no more than 30 times per hour?

- Let's say the productivity is 80 l/min or 4800 l/h.

- And during peak hours you need 4500 l/h.

- When the pump operates non-stop, its power is quite sufficient, but it is unlikely to work for a long time in such extreme conditions. And if it turns on more than 20-30 times per hour, then its resource will run out even faster.

- That’s why we need a hydraulic tank, the volume of which will allow us to turn off the equipment and give it a break. At the indicated cycle frequency, the water supply should be at least 70-80 liters. This will allow the pump to remain idle for one minute out of every two, pre-filling the reservoir.

According to the formula of the minimum recommended volume

To use this formula, you need to know the settings of the pressure switch, which turns the pump on and off. The following picture will help you understand:

Changes in pressure in the accumulator when turning the pump on and off

- 1 – initial pressure Pair (with the pump turned off);

- 2 – water flow into the tank when the pump is turned on;

- 3 – reaching the maximum pressure Pmax and turning off the pump;

- 4 – water flow with the pump turned off. When the pressure reaches the minimum Pmin, the pump turns on.

The formula looks like this:

- V = K x A x ((Pmax+1) x (Pmin +1)) / (Pmax - Pmin) x (Pair + 1), where

- A is the estimated water flow (l/min);

- K – correction factor from the table, determined depending on the pump power.

Table for determining the correction factor

You must set the values of the minimum (starting) and maximum (switching off) pressure on the relay yourself, depending on what pressure you need in the system. It is determined by the farthest and highest water collection point from the accumulator.

Approximate ratios of pressure switch settings

To adjust the pressure switch, you need to know how to inflate a hydraulic accumulator for water supply systems with air, or bleed off excess air. To do this, you will need a car pump, which is connected to the tank through a spool.

Now you can calculate the volume. For example, let's take:

- A = 75 l/min;

- Pump power 1.5 kW, respectively K = 0.25;

- Pmax = 4.0 bar;

- Pmin = 2.5 bar;

- Pair. = 2.3 bar.

We get V = 66.3 liters. The nearest standard hydraulic accumulators in terms of volume have a volume of 60 and 80 liters. We choose the one that is larger.