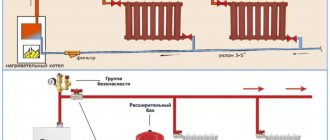

The expansion tank is built into closed heating systems to perform the following tasks:

- Compensation for thermal expansion of the coolant. For every 100 °C increase in temperature, the volume of water in the system increases by 4.33%. The pressure in the system circuit increases and acts on the inner surface of pipes and equipment. To prevent destruction of the heating system, an expansion tank is installed on the boiler return, it is filled with “excess” coolant;

- Due to the operation of the expansion tank, water hammer in the heating system, which occurs due to air locks or sudden shutdown of the fittings, is suppressed. To prevent water hammer from damaging the boiler, the tank is placed on the return line, in front of the heat generator.

There are two types of hydraulic tanks on sale - balloon and membrane (diaphragm) types. The former are more often used for cold water supply and are painted blue, the latter are red and are used in heating systems.

Setting indicators in the new expansion tank before starting the system

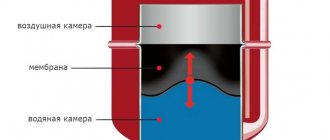

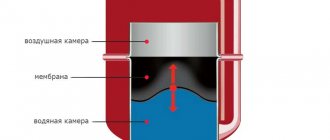

The diaphragm type tank is divided by a membrane.

One of the halves is under pressure, air or nitrogen is pumped into it. You can clarify this parameter by looking at the documents for the tank. Preliminary (factory) pressure will not necessarily be optimal for circuit operation. This setting can be easily reconfigured. Manufacturers have provided for this by leaving a spool in the body of its “air” part, with which you can regulate the air pressure. It is worth considering that all pressure gauges only show excess pressure. That is, if you need to use the concept of absolute pressure in calculations, then you always need to add one atmosphere (bar) to the pressure gauge readings.

The initial pressure in the expansion tank is set 0.2 atm higher than the coolant pressure in the cold system, which is equal to the static pressure of the circuit. This pressure is determined as the height distance between the top point of the circuit and the middle of the expansion tank. For example, if the height of the heating system is 8 m (2 floors), then the statistical pressure will be equal to:

∆P = 0.8 atm (10 m = 1 atm), then the pressure in the membrane tank is calculated as follows:

∆P + 0.2 = 0.8 + 0.2 = 1.0 atm (bar).

Below are the consequences of incorrectly set pressure:

- The tank is pumped. For example, the air cavity is initially set to 3 bar with a static pressure of 1.5 bar. When the pump starts, the coolant pressure will change, but not much - within 1 atm. It turns out that when the pressure gauge at the boiler shows a maximum of 2.5 bar, there is still 3 bar in the air part of the membrane tank. This setting negates the entire compensating ability of the membrane device - the air will tend to push the coolant out of the tank.

- The readings inside the expansion tank are underestimated. In this case, when filling a closed system, water or antifreeze will easily push through the membrane and fill the entire container. With each increase in temperature, and with it the pressure, the safety valve will operate. In this case, the hydraulic expansion tank also becomes useless.

Advice! The initial air pressure was set correctly, but the safety valves of the heating system continue to operate. The expansion tank volume may have been selected too small. To avoid this, it is recommended to install a tank whose volume is at least 10% of the total coolant volume.

If you liked the article, please share it

Previously on the topic:

Share

How to measure and adjust the pressure in the expansion tank

The pressure in the heating system is controlled by pressure gauges, but the tank itself does not have a fitting for installing this device. However, there is a nipple in which a spool is mounted for pumping or releasing air. It is located on the side opposite the coolant supply. The nipple, in fact, is an analogue of a car pump, so to check this parameter or adjust it, you can use an ordinary car pump with a built-in pressure gauge.

Design features and operating principle

All tanks are similar in design. They have a metal body, divided from the inside into two rolled compartments. The tank has a nipple on one side, and on the other there is a neck designed for connection to pipes.

There is a diaphragm inside the body. When the container is empty, it fills most of it, and the remaining space is occupied by air. During the operation of the network, the coolant heats up, its volume increases, and the excess penetrates into the cavity between the diaphragm and the housing.

After the temperature drops, the working medium decreases in volume, and the previously pumped air squeezes it back into the system.

What air pressure should be in the expansion tank of the heating system?

Indicator of the empty capacity of the air chamber at room temperature. It should be equal to the static value in a tank filled with water. In this position, the membrane is in equilibrium, and the gas pressure is compensated by the liquid pressure. For every 10 meters of pressure, about 1 atm is required. Despite this, for normal operation of the entire system it is enough to create the indicator specified in the device passport.

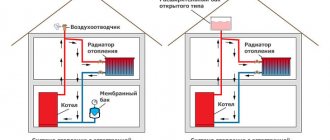

Photo 1. Diagram of the expansion tank for closed-type heating systems. Arrows indicate parts of the product.

, 0.9 atm is enough for favorable operation This is due to the pressure that the membrane creates during operation. Its average is 1.2 atm . Both values fluctuate within a small range with a maximum deviation of 0.1.

If the heating system is not made according to classical schemes, separate calculations are carried out for it: the volume of the coolant, the tank, the efficiency factor and the initial charging pressure are determined. To do this, you should invite a specialist who will take into account other minor factors.

How to check the indicators

The easiest way to take a measurement is to attach a pressure gauge . The problem arises during the preparation phase as most tanks do not have space for mounting. At the same time, the device must have a nipple to which a compressor with a sensor can be easily connected.

Reference. It is easy to convert the dimension of the values: 1 Bar = 1 atm = 0.1 MPa.

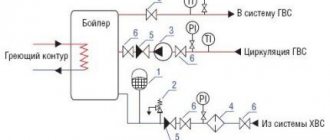

How to adjust the hot water pressure in the system

Water pressure is a fairly easy to adjust parameter. For this you will need:

- Make a calculation. Having completed it, 0.2 atm is subtracted from the obtained value.

- Before starting installation, bleed (or pump) air from the system to the required level.

- Connect the container to the pipeline and fill it with liquid. The process is done slowly so as not to miss the moment of establishing normal pressure.

- Connect the pump and pump in liquid until operating pressure is achieved.

- The first switching on of the device occurs after maximum water heating . In this case, the volume of liquid will increase to a value that takes into account the specific increment.

Hydraulic accumulator repair

As we have already determined, the most common breakdowns are the loss of tightness of the membrane or housing. They are easily removed.

The membrane is permeable

We are looking for the bag (pear) we need. They are actually consumables and are interchangeable even for products from different companies.

You just need to pay attention to the following things:

- so that the volume of the bag matches the volume of the hydraulic accumulator;

- you need to select the diameter of the pipe to connect the water supply;

- The flanges must also match in size and location of the holes for the mounting bolts.

Advice. There are membranes for hydraulic accumulators for heating and hot water supply. They are designed for higher temperatures and are more expensive. If you are just repairing a cold water pipeline, then you should not overpay.

The replacement process itself is easy to do yourself:

- We disconnect the hydraulic accumulator from the water supply system by unscrewing the corresponding coupling or flange.

- Relieve the pressure in the housing by turning out the spool.

- We unscrew the nuts connecting the flange to the terminal for connecting the battery to the water supply, and at the same time securing the bulb (membrane).

- We remove the old membrane. You can look for its defects with your own eyes.

- We clean the flanges and ebbs of the new “pear” with which it will be attached and degrease them.

- For greater reliability, we coat the contact points of the flanges with sealant.

- We assemble the hydraulic accumulator and connect it to the water supply.

- Pump air into it to the required pressure

- We adjust the pump control system to the required pressure. Usually they choose to turn on at 1.5 atmospheres and turn off at 2-3. We talked above about how to set up a hydraulic accumulator in a water supply system.

- We flush the system by draining the water for at least an hour.

Passes through the body

It is not advisable to use glue (cold welding) to repair the case

Having found the leak, you can try to weld it. Glue (including epoxy - “cold welding”) is unlikely to help. If this is not possible, the procedure is the same. as when replacing the membrane.

True, it is better to change the hydraulic accumulator assembly, since the housing is an order of magnitude more expensive than the “pear”, and it is not worth installing the old one because of its cheap price.

Setting indicators in a new membrane-type expansion tank

The device is divided into two parts, separated by a membrane. It exerts pressure on one of the halves , this is taken into account when setting up.

Most devices have factory default values, which are not always suitable for use in certain conditions.

To change the indicators, there is a nipple to which the plumber connects a compressor or hand pump.

Attention! Many pressure gauges show excess. To determine the actual pressure, add 1 atm.

The initial indicator is made equal to that obtained in the cold system by adding 0.2 atm. The sum gives the value of the static head divided by 10 . For example, in a house 8 m high:

P = 8/10 + 0.2 atm.

The values are achieved by filling the container with air through the spool.

Incorrect calculations can lead to one of two problems:

- Tank overflow. Sometimes the air cavity exhibits a value twice the static pressure. Turning on the pump will lead to a change in the number, but not more than 1 atm. If the difference is larger, there will be a disadvantage, due to which the compensator will begin to push the coolant out of the tank. This could lead to a serious accident.

Photo 2. Pressure standards in the expansion tank: when it is empty, filled with water and when the filling of the device reaches the limit.

- Receiving an insufficient indicator . In a filled system, the working fluid will push through the membrane and fill the entire volume. Each time the heater is turned on or the pressure increases, the fuse may trip. The expander will become useless in such a situation.

Important! The initial setup must be done correctly to avoid problems. But even after the work of a good specialist, fuses may begin to trip. This is usually due to insufficient volume of the expansion tank.

To solve this you will need to purchase a new device. It must contain at least 10% of the volume of the entire harness.

Looking for a leak

Loss of the sealed state of the heating system leads to a loss of pressure. By conducting a complete inspection of the heating device and pipe system, leaks can be detected. Leaks to the naked eye are determined by the accumulation of moisture at joints or holes with a characteristic white coating.

When inspecting, you should pay attention to the connecting elements, couplings at soldering points and direct connections to heating devices. A system with metal pipes may leak at longitudinal seams. Once a leak is discovered, it is worth taking care of its elimination. The joints are repacked, gaskets and gland seals are installed, with a thickness slightly greater than the previous one. If the pipeline is damaged, the damaged section must be replaced.

Why does blood pressure drop?

The indicator should be constant, but in some cases there are problems with deviation. The value decreases:

- When a leak occurs. They rarely occur in water-filled systems. Other liquids contribute to the formation and expansion of small cracks that cause the problem.

- In case of malfunctions with the boiler. If there is no leak, but the pressure drops, you should call a specialist. He will help identify the problem and recommend a solution.

Malfunctions of hydraulic accumulators

Due to the simplicity of the design, there are not so many malfunctions of hydraulic accumulators. Let's consider them together with those breakdowns that are not caused by a malfunction of this unit of the autonomous water supply system, but are associated with it.

To make it easier to navigate, we present the symptoms of the malfunction along with methods for accurately identifying the problem and eliminating it.

The pump turns on very often or runs constantly

This is the most common problem, so we will consider it first. The instructions for determining the cause of the malfunction are as follows (there is no need to perform it step by step, we select the actions that are most suitable for your situation).

Make sure the pump is working properly

First of all, you need to make sure that the pump creates normal pressure. At its outlet it should be at least 1.5 - 2 atmospheres (0.15-2 mPa). If this is not the case, then most likely the problem is in the pump (the impeller is worn out or rotates on the shaft, etc.).

What to do if the pump is working but there is no pressure

The reason that the pump does not provide the required pressure may be the well’s loss of flow rate. That is, the groundwater has gone lower (most often this happens in case of drought), and its intake is simply above their level, or the casing filters are clogged.

Maintenance

Regular monitoring of the condition of the equipment will help avoid problems during the heating season. It is recommended to carry out fault detection work twice a year: before and after the end of winter. To do this, you should invite a specialist who will carefully check the system.

A single-circuit or double-circuit gas boiler is equipment that makes our life in a house or apartment more comfortable. Manufacturers now produce a huge range of gas appliances, differing in power, functionality, and installation method. However, even the most expensive and reliable models can fail. Agree, it’s not very pleasant to be left on a winter evening without heat and hot water.