Insulation of foam blocks is a mandatory measure, thanks to which it is possible to significantly improve the performance characteristics of residential buildings and significantly extend the service life of the entire structure. Foam block is a type of cellular concrete that is characterized by its low weight, large size, high sound/heat insulation properties and many other advantages.

Despite the fact that the foam block can be finished with any materials and its heat saving indicators are quite high, insulating the walls with special materials still makes sense. Initially, insulation of walls made of foam blocks was not intended due to the fact that the material already has high thermal insulation characteristics, but different materials are used to protect the block itself and improve its properties in harsh winter conditions.

Another reason for the need to insulate the block is its fragility - foam concrete has sufficient strength, but is afraid of external influences and becomes more prone to deformation under the influence of moisture and frost.

What are the advantages of insulating a house from foam blocks from the outside:

- Saving internal space.

- Maintaining the integrity of blocks.

- Effective protection of walls from moisture and freezing, which significantly extends the life of the building.

- Eliminating the possibility of condensation accumulating inside the material is to remove it outside and remove it with air.

- No cold bridges, more efficient heat conservation.

- Increasing the efficiency of thermal insulation by 20-30%.

- The frame created for installing the insulation can serve as the basis for finishing.

To insulate foam concrete, light options are used - mineral wool, polystyrene foam, etc.

Is it necessary to insulate the façade walls?

Foam blocks were invented specifically for the construction of single-layer walls.

Due to their good thermal insulation properties, such buildings in warm countries do not require additional thermal insulation .

But due to the fact that Russian winters are characterized by their harsh weather, experts advise additional insulation of the house from foam blocks.

If you look from the other side, foam blocks are a fragile material and when exposed to certain weather conditions they freeze and absorb moisture. In order to prevent this, the walls are insulated from the outside.

As a final finish on top of the insulation, it is better to use lightweight structures. Decorative brick is not suitable for these purposes; most builders use plaster or cover the house with siding .

Should I do it?

The reasons for insulating a house are different, for example, climatic conditions, insufficient wall thickness, the desire to reduce heating costs, etc.

Foam blocks have low thermal conductivity - 0.2 - 0.4 W/m*ºK. This characteristic is several times better than the thermal conductivity of sand-lime brick. Therefore, some doubt the advisability of insulating walls.

In fact, facade insulation is necessary for the following reasons:

- Foam concrete blocks, due to their porosity, have a high vapor permeability rate. If insulation is not performed, the dew point will be inside them, which will lead to a decrease in the service life of the building.

- Insulation will significantly reduce energy costs for heating.

Important! Thermal insulation of a foam concrete house is not something you should skimp on!

You can avoid insulation if the building is not planned to be used in winter. However, the outside of the walls will still have to be finished, since the negative effects of moisture will soon ruin the walls.

Outside or inside: which is correct?

Thermal insulation measures are usually carried out outside. Internal insulation will complicate the installation of hanging structures on the walls.

The thermal insulation layer can be installed both from the inside and outside, but the first option is usually chosen for the following reasons:

- When performing thermal insulation work inside, the usable area of the room is significantly reduced, while external insulation does not affect the internal dimensions in any way.

- This allows you to extend the service life of load-bearing structures. This way they are reliably protected from adverse weather influences.

- If insulation is done inside the house, then the wall outside remains cold and moisture penetrates into it. When insulating from the outside, moisture does not collect inside the wall.

What is the best time to carry out work?

A certain amount of time must pass before the outside of the house can be insulated. After all, at the factory, immediately after production, foam blocks are sent into sealed packaging and delivered to the construction site. Provided that the building is erected quickly, the blocks still retain their original moisture level upon completion of construction. And if you insulate it right away, the blocks will absorb all the water and steam.

Because of this, vapor permeability decreases and in cold weather, when heating devices are turned on inside the building, the moisture inside the walls moves to where the partial pressure is lower (in the direction of the house, that is). When moisture reaches the interior, it collects on the surface and the wall becomes damp. The foam blocks freeze, the insulation actively rots and the performance characteristics of the entire building deteriorate significantly.

After completion of construction, it is advisable to cover the facade with film and allow all moisture to evaporate for 3-5 months, which depends on the humidity/ambient temperature.

It is ideal when a house is built in the spring and insulation is carried out at the end of summer. Then the foam blocks have time to dry completely and the efficiency of further work increases.

Materials: what is better to use?

There are several materials that are most often used for insulation:

- Mineral wool. It has excellent vapor permeability, but shrinks if installed incorrectly. Some types of this insulation can only be installed using protective equipment. This type of insulation must be securely closed, since wind and other external influences can spray small particles. Capable of accumulating moisture, so it cannot be installed in bad weather. The most popular type of mineral wool is stone (basalt) wool.

- Polystyrene foam or polystyrene foam. They are excellent thermal insulation materials, although they do not have vapor permeability. They do not shrink, are not afraid of cold weather, have a water-repellent effect and are a sound insulator. But polystyrene foam does not tolerate exposure to direct sunlight, which means that it must be covered with decorative materials. In addition, mice love polystyrene foam, and if they make their nests in this thermal insulation layer, their quiet life will end. Penoplex insulation will avoid these disadvantages, but will cost much more.

- Polyurethane foam. Another material that is often used for insulation. The advantages include excellent adhesion to any surface, no need for leveling the wall, priming and construction of the frame, ease of transportation, light weight, it does not weigh down the walls and roof, improved thermal insulation and strength characteristics of the wall during installation, improved sound insulation, resistance to temperature changes , seamless, no fasteners required. Disadvantages include fear of exposure to sunlight, ultraviolet radiation destroys the material, and fire hazard during prolonged exposure to high temperatures.

Typically, a material is chosen that does not block air circulation through the walls of a foam block house. Therefore, it is better not to use polystyrene foam and penoplex.

The cheapest option that meets this requirement is mineral wool insulation.

Insulation with this material should be carried out strictly according to technology, taking into account its characteristics.

An important requirement for thermal insulation materials for outdoor use is good vapor permeability. The walls will become damp if moisture cannot escape.

Let's start from the roof

It is better to start this type of work from the roof. After all, it is through it that significant heat loss can occur. They occur if the floors are not insulated.

You can insulate a house from above in various ways. In particular, if you want to arrange a living space in the attic, you will have to insulate the inside of the roof. At the same time, the price of the work carried out will, of course, increase.

The roof of the attic floor must be insulated

If you do not have such plans, then it is quite possible to get by with insulating only the ceiling, that is, the attic floor.

For this purpose, cardboard must be laid in several layers between the beams. You need to pour a thick layer of sawdust on it. Instead, you can put mineral wool. But, in this case, you will have to attach a waterproofing film over it.

In the photo - thermal insulation of the attic floor using mineral wool

To get a good result, you need to ensure that the insulating material covers the entire surface of the attic floor. If mineral wool is used, it should also cover the beams themselves. In addition to this, boards must be laid on top of the thermal insulation layer so as not to damage the insulation when walking.

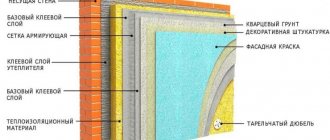

The use of foam plastic or penoplex and plastering using “wet” technology

This technology makes it possible to carry out insulation and finishing work on foam block walls as economically as possible . The principle is to stick the insulation material and then plaster the surface.

For work you will need the following tools:

- screwdriver;

- a bucket or other container for glue;

- a “comb” spatula for applying the adhesive mass;

- wide spatula for plastering;

- hammer, construction knife;

- roller, brush;

- glasses, respirator, gloves;

- hammer drill, electric drill;

- building level, tape measure.

Materials you will need:

- foam boards;

- fiberglass mesh;

- perforated profile;

- special umbrella dowels for foam concrete;

- dowels for mounting the profile;

- foam glue;

- deep penetration primer;

- mixture for plastering work.

Preparatory work

Before starting the main work, all communication cables, drains, ventilation should be removed, and wastewater should be removed. The surface of the walls is cleaned of dirt and then thoroughly dried.

It is advisable to carry out insulation during the dry period, when the foam concrete blocks are completely dry without moisture inside. All cracks and crevices should also be repaired. If the damage is extensive, it is necessary to consider strengthening structural elements or strengthening the foundation.

The cleaned walls are treated with a primer composition intended for external use, deep penetration. It is advisable to repeat the procedure 2 times. Priming is necessary for adhesion of the heat-insulating material to the foam blocks.

Attaching the supporting profile

The profile is needed to support the foam so that it does not slide down. It also protects against rodents entering the insulation. The profile is fixed around the perimeter of the base with dowels or self-tapping screws. Work is carried out strictly according to the level.

Laying slabs

According to the instructions on the package, the adhesive composition is prepared. Using a notched trowel, glue is applied to the slabs from the back side of the material. The layer should evenly cover the entire surface of the foam plastic (or penoplex) plate.

If the walls are not too smooth, the glue can be applied to the material in “patches”, but in this case it is necessary to pass the solution along the perimeter from the edge of each slab. The boards are glued starting from the bottom in a checkerboard pattern. Strongly protruding parts are removed.

Fastening slabs with “umbrellas”

A day or two after gluing the slabs, it is necessary to supplement the fixation of the slabs with umbrella-type dowels. The holes are drilled approximately 1.5 cm longer than the dowel length. They are fastened in the corners and in the center of the slab.

Plastering works

To protect the insulation and give a finished look, the wall surface is plastered. A fiberglass mesh with a layer thickness of 3-5 mm is glued on top of the insulation for reinforcement. The mesh must be completely immersed in the adhesive composition.

After the mesh has dried and smoothed, a layer of primer is applied to the surface. After it has dried, you can begin finishing.

By following the sequence described above, you can independently insulate a house made of foam blocks from the outside with polystyrene foam and plaster the facade using the “wet” method.

Expanded polystyrene and its characteristics

Expanded polystyrene is a white substance that consists of individual elastic granules firmly welded into one whole. It is produced by foaming polystyrene; the structure of the foam block consists of 90 percent air. In current construction, this heat insulator claims to be one of the leading places in popularity - it is used for insulating brick, wood and aerated concrete buildings.

Polystyrene foam is one of the best options

Expanded polystyrene has the following characteristics:

- high degree of thermal insulation due to low thermal conductivity coefficient;

- small weight with large dimensions - it allows you to transport it without problems and refuse to use special installation and loading equipment;

- hydrophobicity – does not allow water to pass through or retain;

- moisture resistance – the insulating properties do not disappear even after a long stay in a humid environment;

- environmental friendliness - polystyrene foam is harmless to the environment and human health. This property is taken into account when choosing it for the production of food packaging;

- good workability - polystyrene foam can be cut with a sharp knife, it is easy to make holes in it and is convenient to glue;

- frost resistance – does not lose its properties at low temperatures;

- durability;

- non-flammability;

- affordable price is a factor that significantly affects the cost of thermal insulation.

Expanded polystyrene is sold in the form of slabs of various thicknesses and sizes. The thickness of the insulating layer depends on the required degree of insulation, climatic conditions in the region and other similar factors. The number of slabs is calculated based on the total area of the walls that need to be insulated.

It is quite easy to work with these plates, since they have strict geometry and, if necessary, are easy to cut

Using mineral wool boards for siding

Another insulation option is a “ventilated facade”. It consists of fixing mineral wool and covering the walls with siding or facade panels with a gap for ventilation.

All work can be divided into several stages.

The work does not require special qualifications; everything can be done with your own hands.

Surface preparation

The wall made of foam blocks is cleaned of dust and other contaminants. If there are significant irregularities, they should be eliminated. This should not be difficult, because foam blocks are easy to process.

All interfering elements are dismantled. For example, wall mounts. The surface must be clean.

By stretching the line diagonally from the upper corners to the lower, the differences in the wall are determined. This will allow you to find out at what height the sheathing will be mounted.

Installation of sheathing and mineral wool slabs

To do this, you can purchase either a metal profile or a wooden beam . Both options will do.

Important! The wooden beam should be treated with antiseptics before fastening, so it will last much longer.

Sequencing:

- The beam is attached along the perimeter of the wall. The distance between the bars (or profiles) must be less than the width of the insulation boards in order for the insulation to fit tightly, without gaps.

- The lower transverse beam is fixed. It is needed to support the first row of slabs, and will also protect the insulation from penetration by rodents from below. Window and door openings are sheathed with timber around the perimeter.

- After installing the sheathing, the vapor barrier material is attached with a stapler. For example, polypropylene or polyethylene film, foil vapor barrier, etc.

- The insulation is installed and secured with umbrella-type dowels. It is advisable to make more than one layer so that the next layer overlaps the joints of the previous layer. The installation of the slabs begins from the bottom with gradual movement to the top in a checkerboard pattern.

- A waterproof film is stretched over the insulation. Serves to protect mineral wool from getting wet. It is also attached with a stapler.

Important! You cannot make holes for dowels with an impact hammer. Switch to the drill. Drilling should occur without impact, because foam concrete is very fragile.

Siding installation

Insulation of walls made of foam blocks from the outside ends with the installation of siding:

The counter-lattice is installed and the siding is attached to it with self-tapping screws. You cannot screw in the screws all the way; you must leave a gap of approximately 2 mm.

It is needed to ensure that the material does not warp during expansion. The panel has holes for connection. The self-tapping screw is screwed into its center. No holes are made in the panel itself.

You can cut siding panels with a regular hacksaw with a fine tooth.

How to insulate a foam block house from the outside with your own hands

Preface .

In this article we will look at how to independently insulate a foam block house from the outside under siding and under plaster. For many owners of foam block houses, the thermal insulation of the room comes to the fore. We will tell you about the technology of using mineral wool, polystyrene foam or penoplex when insulating a foam block facade; at the end of the article, watch the video instructions for insulating the facade of a foam block house with mineral wool. Photo. Advantages of a foam block house

By the term “foam block”, private developers mean blocks made of foam concrete or gas silicate. This material is used today for the construction of low-rise buildings. The foam block itself is a thermal insulation layer. Previously, we told you how to insulate a house made of gas silicate with your own hands. Today we will look at the issue of independently insulating a foam block façade from the outside.

Due to their porous structure, foam concrete blocks provide excellent adhesion to any finishing material (plaster, putty). Many owners of country houses made of foam concrete blocks often resort to insulation. Is it worth it to insulate a foam block from the outside and how to properly insulate a foam block house for the winter? Read this article about the best materials to use when carrying out work.