Due to its relative cheapness and good characteristics, polystyrene foam remains a fairly popular thermal insulation material. Let's look at how to properly insulate with foam plastic, what you need to know about synthetic boards and granules. Let's get acquainted with the features of installation technologies and subsequent finishing works. Read to the end and you will know what questions to ask specialists when discussing work for your home.

Expanded polystyrene granules - the same foam Source tsmos.ru

Overview of the material

Before insulating a house with polystyrene foam, you need to find out which material is suitable for which structures. EPS is supplied to the trading floors of the construction market in the form of slabs of different densities and in bulk. Each option belongs to the group of polymers with a foamed structure.

The table presents a number of basic technical characteristics characteristic of the group of foam materials for home insulation.

| Parameter | Meaning | What is important for a builder |

| Density | 15-40 kg/cub.m | The low weight of a cubic meter of insulation is considered one of the main advantages. This is justified by the relatively insignificant load of the material on the load-bearing structures of the building, which practically does not limit the scope of application of PPS. |

| Thermal conductivity | 0.038-0.042 W/m*K | The values are close to the average compared to thermal insulation products, which are often used in construction. |

| Water absorption | 0,02 | Extruded polystyrene foam has an indicator as close as possible to zero. This justifies the use of the material as an independent and additional waterproofing layer. |

| Vapor permeability | 0,05 | A low coefficient indicates poor breathability of PPP. This property is important to take into account especially during interior work, as it affects the microclimate in the room. |

| Working temperature | -50-+75 degrees Celsius | Foams are synthetic in nature, so when heated they can release toxic substances. Therefore, insulation is rarely used indoors with high thermometer readings. |

| Operational period | 60 years (outside 20 to 40 years) | The time period can be reduced if the rules for installation and operation of materials are not followed. |

Extruded foam Source myremontnow.ru

Experts recommend paying attention to the chemical composition before purchasing polystyrene foam for insulation. It is desirable that it contains fire retardant additives and non-flammable carbon dioxide. This is justified by the fact that PPS is unstable to open fire. When purposefully igniting foam plastic, the effect of fire retardants may not be noticed, but in general, thanks to them, the fire takes longer.

The advantages of the material, in addition to good thermal insulation properties and water resistance, include noise absorption and inertness to corrosion and biological activity. Foam boards and granules are often used to improve the acoustic environment in a building. The material is also easy to cut, which is important for installation work. But it is worth considering that foamed polystyrene can crumble and cannot withstand mechanical load and is deformed.

PPP and dew point

Insulation tends to shift the dew point outward. Let's consider three design options without insulation and with insulation with polystyrene foam. In the absence of finishing, the walls are the only material that is located between spaces of different temperatures. Due to changes in thermometer readings, the following occurs:

- heat loss;

- condensation indoors;

- the operational life of the monolith or log house is reduced.

If the dew point in a log house without finishing is poorly calculated, then there is a possibility of condensation Source remontnik.ru

See also: Catalog of companies that specialize in insulating houses

When insulating walls internally, the dew point shifts towards the contact between the base and the PPS. Heat leakage is significantly reduced, but the issue of dampness remains. Because of this, there is an increased risk of the appearance and spread of mold, mildew, and bacteria.

The optimal solution is to insulate external walls with polystyrene foam. In this case, the dew point is closer to the surface on the front side of the structures. As a result, the risks of heat loss and condensation accumulation are minimized.

We attach the starting profile

Having studied the project, we calculate the location of the lower border of the walls, which should be insulated with foam plastic. Now we take a hydraulic level, measuring this boundary at all external and internal corners of the house. We pull the cord along these points. It is along this line that we have to install the starting profile on which the bottom row of slabs of heat-insulating material will be supported. Otherwise, until the glue dries, the slabs may move.

We select the size of the starting strip according to the width of our heat insulator. We fasten it with six-millimeter dowel nails, placing them every 30 or 35 centimeters. The expansion element for the dowels is driven nails, onto which washers should be placed. The joints of the starting strip at the corners of the house are made either with an oblique cut or using a corner connector.

To prevent temperature fluctuations from deforming the structure, we place plastic connecting elements at the ends between the base profiles. Overlapping profiles are not permitted.

To be on the safe side, check the level of fastening of the starting profile.

External insulation technology

You can insulate walls with foam plastic on your own, since the technology for installing lightweight insulation is simple and does not require special skills or tools. However, before starting work, it is important to learn about the features that are associated with facades, internal walls and openings for windows and doors. There are also some nuances in subsequent finishing.

Preparatory stage

Any installation and repair work begins with preparing the base. It must be clean, “healthy” and, in the case of slab foam, even. The procedure at this stage looks like this:

- removal of old decorative coating;

- removing weak elements;

Peeling pieces of plaster must be removed Source krysha-expert.ru

- bridging cracks;

- “treatment” of affected areas (mold, mildew, rust) followed by prevention;

- priming of defects and repairs;

- treating the working surface with a primer;

- leveling the walls (differences of up to 1 cm per linear meter are acceptable) and forming corners.

Before insulating the facade with polystyrene foam, it is recommended to impregnate the dry and even base twice with a primer. In this case, for the second layer it is permissible to dilute the primer with water. The main thing is not to exceed 10%, so as not to reduce the quality of the original product.

Installation work

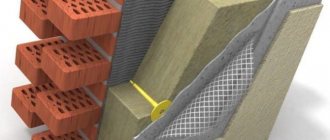

As a rule, to insulate vertical structures, craftsmen use a slab version of PPS. There is no need for lathing here, but the fastening must be combined. That is, first a special adhesive solution is applied and the position of the canvases is adjusted to create an even plane. To prevent the insulation from slipping, you must first secure a support strip under the first row. This can be a beam or a metal profile. If you lay the first row unevenly, then subsequently all the joints will turn out to be uneven.

Then, after the composition has hardened (after about three days), additional fixation is carried out with plastic dowels (“umbrellas” or “fungi”) with a wide cap.

Special dowels for insulation Source allegroimg.com

Preparing the wall surface

In order for the thermal insulation to be of high quality and last a long time, the surface to be insulated must be well prepared. This process is quite lengthy, and you will have to put in a lot of effort. But the result is worth the effort and time spent.

If you are insulating a new house, then you do not need to do some things.

#1. The first step is to remove everything from the external walls that could interfere with the work. These are drainpipes, ventilation grilles, air conditioners, spotlights and wires. If the brick house is old enough, then on its facade there may be decorations framing the cornices and windows. They will have to be sacrificed by carefully knocking them down.

#2. If there is plaster on the walls, we will check its strength by tapping the surface. We check all unevenness and slopes using a plumb line, rule or cord of sufficient length. We will mark all errors with chalk so as not to miss a single flaw. As a rule, upon inspection it turns out that the walls are far from ideal. Not only are they not very even, but in some places the plaster is held to its word of honor.

Do not undertake insulation if you discover these shortcomings. First, remove these pieces of plaster, and then work with a chisel, knocking down the concrete beads and excess mortar between the bricks.

#3. If the façade has been painted with oil paint, it cannot remain on it. In this case, you will have to peel off the paint. Because of this, the adhesive properties of the surface are reduced. Well, perhaps everyone knows that it is necessary to remove mold, grease and rust, as well as salt deposits.

#4. If there are large enough unevenness and cracks on the walls (more than 2 millimeters), then they must be primed. To do this, use a deep penetration primer using a special brush called a paint brush. It will allow you to do this work faster and more accurately. When the primer has dried well, you can apply cement putty for exterior use and fill the cracks.

#5. In the case where the unevenness is very large - more than 1.5 centimeters - we also prime them first. And then we put up beacons along which we apply the plaster composition.

#6. The walls are covered with a brick primer once, with cellular concrete 2 times. You can apply it with a large brush or roller.

Sometimes part of the communications is left on the surface of the wall, covering them with insulation. In order not to damage them when driving in dowels for fastening polystyrene foam, you need to draw up a detailed plan for their location.

PPS or EPPS

The starting raw material for the materials is polystyrene. The final product can vary greatly in density, hardness and structure. This is explained by the plate production technology:

- Foaming . Expanded polystyrene is characterized by lower weight due to the high air content in the pores and granules. The advantage is the low price, the disadvantage is that it retains heat worse with the same thickness of the slab.

- Extrusion . EPPS has less moisture-absorbing ability and higher density, strength and hardness. With identical sheet thickness, the thermal conductivity is lower. Against the background of the advantages, only one disadvantage stands out in the group of materials - high cost.

Craftsmen also note the low adhesion of extruded insulation due to the dense and smooth surface. To improve the situation, the boards are passed with a float or a needle roller (with metal spikes) to bend the drywall. Also, such products are characterized by a stepped shape of the mounting edges. This is a practical approach from manufacturers, thanks to which there are no cold bridges and the joints between individual sheets are strengthened.

Production line for extruded polystyrene foam Source ros-tenders.ru

Types of decorative finishes

When finishing the facade with foam plastic is finished, it’s time to start decorative cladding of the building. It is recommended to decide on the material before you start insulating the facade, but if you haven’t done this yet, then it’s time to start.

Preparing the decorative layer

Primer of walls

The most popular options:

- A simple option is facade plaster (huge selection of colors, water resistance, vapor permeability, simplicity, durability). It happens: mineral, acrylic, silicate, silicone.

- Vinyl siding is inexpensive, easy to install, and one of the most popular coatings.

- Facade panels with patterns. They are made of plastic, metal, wood, aluminum, stone, brick, tile. Installed on the façade sheathing.

- Decorative ceramic tiles - durable, fire-resistant, large selection of colors and sizes.

- Concrete tiles - durability and strength at low cost.

- Facing bricks (ceramics, clinker, hyper-pressed, silicate).

- Artificial or natural stone (marble, sandstone, dolomite, limestone, quartzite).

- Sandwich panels – aluminum, plastic, steel, magnesite sheets. Filling: cotton wool, polystyrene foam.

- Porcelain tiles (high frost resistance, water resistance).

- Facade cassettes are galvanized steel coated with polymer of various shapes.

Applying facade plaster

You can also distinguish wooden (the more common name is lining), foam, metal (it weighs a lot, you need to take into account the load), and cement siding.

Before installing any type of siding, you must first install a ventilation structure into the walls.

Which material to choose depends on personal preference and cost.

Formation of invoice

What do you need for work?

Before proceeding with the installation of foam plastic, the necessary materials and tools are purchased and prepared.

Materials:

- Styrofoam;

- Adhesive composition suitable for the material;

- Polyurethane foam;

- Dowels;

- Primer and plaster;

- Construction mesh for reinforcement;

- Starting bar.

Tools:

- Drill (it’s good if you have a mixer attachment);

- Notched trowel for applying adhesive;

- Regular spatulas;

- Construction knife;

- Container for diluting glue;

- Roulette;

- Level;

- Drill;

- Graters with teeth of various sizes.

It is important to purchase the “correct” polystyrene foam to insulate walls. To do this, its density should be about 25 kg per cubic meter

The thickness of the slabs should be at least 8 cm, most often 10 is used.

You can attach the foam with glue or dowels. But as practice shows, both are better. The pasted sheets are fixed in several places with nails for greater strength.

If desired, a starting profile profile is installed at the bottom of the wall, which serves to secure the position of the sheets and prevents them from sliding during installation. It also prevents damage to the foam by rodents, so if there is a problem with uninvited guests visiting, then it is better to use it.

Where can I use it?

A universal material that can be used to insulate any surface:

- Roofs and walls.

- Floor and plinth.

- Industrial buildings and residential buildings.

This is one of the simplest methods of insulation, which is why many people use foam plastic. The house will become comfortable and warm, and the insulation itself is very reliable. The installation work itself and the material are inexpensive, so if you wish, you can hire a team of workers for these purposes.

To insulate walls, foam sheets are more often used, and crumbs or balls are used for the roof. The floor and base are often insulated with extruded polystyrene foam.

Hundreds of ideas for using facade decor

Columns and pilasters, all kinds of profiles and stones, as well as fences (balustrades), bas-reliefs, rosettes and various stucco moldings can be used in the decorative cladding of the facade. There are a great many ideas for decoration. You can choose a simple option based on a ready-made design project - or order an individual design.

Examples of our work

Decoration can be carried out in any architectural style:

- Classic - with pediments, sandriks, pilasters, complex stucco molding.

- Gothic - with bas-reliefs, openwork vaults, carved decorations.

- Neoclassicism is a combination of classical, Gothic elements with antique columns and half-columns.

- Baroque - with an abundance of lush stucco, the use of rosettes and panels.

In most cases, new houses are decorated in the spirit of classicism, which is characterized by restrained conservative features. After cladding, the facades look beautiful and fashionable.

Attaching to wood

Polystyrene foam is attached to wood in different ways.

- It has long been known that wood must “breathe”, otherwise rot will appear. Only thanks to the air flow, the tree retains its characteristics for many years.

To protect the wooden wall from rotting, foam plastic is laid with a ventilation gap. For insulation, a lathing is made from wooden blocks. The slabs are inserted between the bars. A vapor barrier layer made of foil film protects the insulation from condensation.

- Special metal nails can securely hold slabs on wooden surfaces. Unfortunately, cold bridges appear at the fastening points, so high-quality putty is required.

When plastic nails , the thermal insulation of the slabs is improved.

- Fastening with adhesives is simple and reliable. The main thing is to choose the right glue that is resistant to changes in ambient humidity and temperature. A solution containing cement and glue has worked well.

Classes and grades of foam plastic

Foam classes

There are only two classes of foam: pressed and non-pressed. From the names it is clear that these materials have different production methods. The first is made using pressing equipment, the second - by sintering at high temperatures. But this production line also uses pressing equipment. However, the classification is what it is.

Expanded polystyrene suspension pressless

Which class the foam belongs to can be determined visually. Bespressovy is a complex of fairly firmly glued round and oval granules. The structure of this material is porous, the strength depends on the density.

Pressed polystyrene foam

Pressed sheet has the appearance of a fairly smooth sheet, the density of which varies and depends on the brand of the product. This material has excellent technical and performance characteristics.

Foam brands

Foam brands

Polystyrene foam produced using the non-press method is designated by the abbreviation PSB. Press - PS. The product name may also contain other letters, each of which indicates a feature of this product.

- A – the canvas has the correct geometric shape of a parallelepiped and a smooth edge;

- B – the edge of the product has an L-shaped cut;

- P – cutting of the blades is done with a hot string;

- F - façade or made using special forms;

- C – self-extinguishing;

- N – the product is suitable for external use.

The numbers in the name of the PPP indicate its density.

Brands of pressless foam

PSB-15

The most inexpensive product with a high degree of fragility. Used as a thermal insulation and packaging material, it crumbles easily and has low hygroscopicity. Traditionally used for insulating balconies and loggias, country houses, containers and outbuildings.

Foam plastic PSB S-15

PSB-25

Foam plastic of different brands

This brand of foam plastic is often supplemented with the letter “F”, so the material is recommended for insulating facades. Due to its higher density than PSB-15, it is used for the manufacture of landscape and interior decorative elements.

PSB-35

Expanded polystyrene PSB-S-35

A universal material with a wide range of applications. It is used for insulation of utilities, heat and gas mains, production equipment, thermal insulation of roofs and attics. Involved in the production of multilayer panels (including reinforced concrete) as a thermal insulation gasket.

PSB-50

Characteristics of polystyrene foam PSB-S 50

This material has the highest density among non-press foams. Demanded as a heat and sound insulator for objects of any purpose. It is able to provide high-quality protection from the cold, therefore it is used in the construction of underground communications, garages and parking lots, and in road construction.

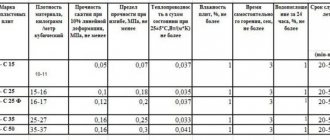

Characteristics of brands of pressless foam.

| Index | PSB-15 | PSB-25 | PSB-35 | PSB-50 |

| Compressive strength at 10% strain (MPa) | 0,04 | 0,08 | 0,14 | 0,18 |

| Density (kg/m3) | 15,0 | 15,1-25,0 | 25,1-35,0 | 35,1-50,0 |

| Thermal conductivity (W/mK) | 0,1 | 0,43 | 0,38 | 0,38 |

| Water absorption during the day in% of the total volume | 4 | 3 | 2 | 2 |

Pressed foam brands

Durable and rigid press (tile) foam is a closed-cell plastic. It is a radiotransparent material. It has found wide application in all sectors of industry and agriculture. PVC foams, which contain polyvinyl chloride resin, are produced using the pressing method.

Brands PS-1, PS-2, PS-3, PS-4.

They have a closed-porous structure, the degree of hygroscopicity is close to 0. They are extremely resistant to atmospheric influences. Self-extinguishing, petrol and oil resistant.

High-hardness foam PS-1-350

PS-1-150

They are used in radio electronics as a material that is unstable to electrical breakdown, as well as for the manufacture of containers and floats for aggressive liquids.

For insulation of building facades, pressless foam plastics of different densities are in demand. In order to buy truly high-quality material, you need to know how you can independently check the information of the manufacturer and seller.

Polystyrene foam of increased hardness PS-4-40

Among the largest Russian producers of foam plastic are the following companies:

- "Styroplast" (Chekhov);

- "Omegaplast" (Moscow);

- "Gamma Center" (Kolomna);

- "Kavminprom" (Mineralnye Vody);

- "Stavpolyester" (Stavropol);

- "Rosplast" (Moscow).

Prices for various brands of polystyrene foam

Styrofoam