The leading trends in modern construction are the construction of houses with maximum energy efficiency. That is, with the ability to create and maintain comfortable living conditions with minimal energy costs. It is clear that many of our builders, who are constructing their residential properties on their own, are still far from achieving such indicators, but it is always necessary to strive for this.

Thermal conductivity of building materials

First of all, this concerns minimizing heat losses through building structures. This reduction is achieved by effective thermal insulation, performed on the basis of thermal engineering calculations. Design should ideally be carried out by specialists, but often circumstances force homeowners to take such matters into their own hands. This means that it is necessary to have a general understanding of the basic concepts of building heating engineering. First of all, what is the thermal conductivity of building materials, how is it measured, and how is it calculated.

If you understand these “basics”, then it will be easier to seriously, with knowledge of the matter, and not on a whim, to deal with the issues of insulating your home.

Thermal conductivity.

So what is thermal conductivity? From a physics point of view, thermal conductivity

– this is the molecular transfer of heat between directly contacting bodies or particles of the same body with different temperatures, in which the energy of movement of structural particles (molecules, atoms, free electrons) is exchanged.

To put it simply, thermal conductivity

is the ability of a material to conduct heat. If there is a temperature difference inside the body, then thermal energy moves from the hotter part of the body to the colder part. Heat transfer occurs due to the transfer of energy when molecules of a substance collide. This happens until the temperature inside the body becomes the same. This process can occur in solid, liquid and gaseous substances.

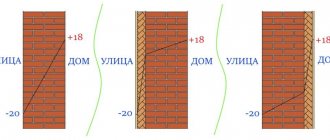

In practice, for example in construction for the thermal insulation of buildings, another aspect of thermal conductivity is considered, associated with the transfer of thermal energy. Let's take "abstract house" as an example. In the “abstract house” there is a heater that maintains a constant temperature inside the house, say, 25 ° C. The temperature outside is also constant, for example, 0 °C. It is quite clear that if you turn off the heater, then after a while the house will also be 0 °C. All the heat (thermal energy) will go through the walls to the street.

To maintain the temperature in the house at 25 ° C, the heater must be constantly running. The heater constantly creates heat, which constantly escapes through the walls to the street.

Warm designs

To increase thermal thermal resistance, modern materials should be used in which thermal conductivity rates are as low as possible. The number of such materials is now increasing. The following became popular:

- Wooden structures. They are considered an environmentally friendly material, which is why many people prefer to build using this particular component. Any type of cultivated wood can be used: log house, log, timber. More often they use pine, spruce or cedar, whose conductivity indicators are quite low compared to other materials. It is necessary to provide protection from atmospheric influences and pests. The material is covered with an additional layer that protects against negative factors.

- Ceramic blocks.

Example of protection against external air

- Sandwich panels. Recently, this material has become increasingly popular. Main advantages: low cost, high resistance to cold. The material has many air cells, sometimes a “foam” structure is made. For example, some types of panels have vertical air channels, which provide good protection from the cold. Other components are made porous so that the large amount of trapped air helps cope with the incoming cold.

- Expanded clay concrete materials. Their use will also reliably protect your home from the cold.

- Foam blocks. The structure is made porous, but this is achieved not by simply wedging in air layers, but by performing a chemical reaction. Sometimes a porous material is added to the cement, which is covered on top with a hardened solution.

Coefficient of thermal conductivity.

The amount of heat that passes through the walls (and according to science, the intensity of heat transfer due to thermal conductivity) depends on the temperature difference (in the house and outside), on the area of the walls and the thermal conductivity of the material from which these walls are made.

To quantify thermal conductivity, there is a coefficient of thermal conductivity of materials . This coefficient reflects the property of a substance to conduct thermal energy. The higher the thermal conductivity coefficient of a material, the better it conducts heat. If we are going to insulate a house, then we need to choose materials with a small value of this coefficient. The smaller it is, the better. Nowadays, the most widely used materials for insulating buildings are mineral wool insulation and various foam plastics. A new material with improved thermal insulation properties – Neopor – is gaining popularity.

The thermal conductivity coefficient of materials is designated by the letter ? (Greek small letter lambda) and is expressed in W/(m2*K). This means that if we take a brick wall with a thermal conductivity coefficient of 0.67 W/(m2*K), a thickness of 1 meter and an area of 1 m2, then with a temperature difference of 1 degree, 0.67 watts of thermal energy will pass through the wall energy. If the temperature difference is 10 degrees, then 6.7 watts will pass. And if, with such a temperature difference, the wall is made 10 cm, then the heat loss will already be 67 watts. More details about the methodology for calculating heat loss in buildings can be found here.

It should be noted that the values of the thermal conductivity coefficient of materials are indicated for a material thickness of 1 meter. To determine the thermal conductivity of a material for any other thickness, the thermal conductivity coefficient must be divided by the desired thickness, expressed in meters.

In building codes and calculations the concept of “thermal resistance of a material” is often used. This is the reciprocal of thermal conductivity. If, for example, the thermal conductivity of foam plastic 10 cm thick is 0.37 W/(m2*K), then its thermal resistance will be equal to 1/0.37 W/(m2*K) = 2.7 (m2*K)/ Tue

Necessity of calculations

Why is it necessary to carry out these calculations, is there any benefit from them in practice? Let's take a closer look.

INTERESTING: How to cover the roof of a private house?

Assessing the effectiveness of thermal insulation

Different climatic regions of Russia have different temperature conditions, so each of them has its own standard indicators of heat transfer resistance. These calculations are carried out for all elements of the structure in contact with the external environment. If the structural resistance is within normal limits, then you don’t have to worry about insulation.

If thermal insulation of the structure is not provided, then you need to make the right choice of insulating material with suitable thermal characteristics.

Heat loss

Heat losses at home

An equally important task is to predict heat losses, without which it is impossible to properly plan a heating system and create ideal thermal insulation. Such calculations may be necessary when choosing the optimal boiler model, the number of radiators required and their correct placement.

To determine heat losses through any structure, you need to know the resistance, which is calculated using the temperature difference and the amount of heat lost from one square meter of the enclosing structure. And so, if we know the area of the structure and its thermal resistance, and also know for what climatic conditions the calculation is being made, then we can accurately determine the heat losses. There is a good calculator for calculating heat loss at home (it can even calculate how much money will be spent on heating, approximately of course).

Such calculations in a building are carried out for all building envelopes interacting with cold air flows, and then summed up to determine the total heat loss. Based on the obtained value, a heating system is designed that should fully compensate for these losses. If the heat losses are too large, they entail additional financial costs, and not everyone can afford this. In this situation, you need to think about improving the thermal insulation system.

Separately, we need to talk about windows, for which the heat transfer resistance is determined by regulatory documents. There is no need to do the calculations yourself. There are ready-made tables in which resistance values are entered for all types of window and balcony door structures. Thermal losses of windows are calculated based on the area, as well as the temperature difference on different sides of the structure.

The calculations above are suitable for beginners who are taking their first steps in designing energy-efficient homes. If a professional gets down to business, then his calculations are more complex, since many correction factors are additionally taken into account - insolation, light absorption, reflection of sunlight, heterogeneity of structures, location of the house on the site, and others.

Thermal conductivity coefficient of materials.

The table below shows the values of the thermal conductivity coefficient for some materials used in construction.

| Material | Coeff. warm W/(m2*K) |

| Alabaster slabs | 0,470 |

| Aluminum | 230,0 |

| Asbestos (slate) | 0,350 |

| Fibrous asbestos | 0,150 |

| Asbestos cement | 1,760 |

| Asbestos cement slabs | 0,350 |

| Asphalt | 0,720 |

| Asphalt in floors | 0,800 |

| Bakelite | 0,230 |

| Concrete on crushed stone | 1,300 |

| Concrete on sand | 0,700 |

| Porous concrete | 1,400 |

| Solid concrete | 1,750 |

| Thermal insulating concrete | 0,180 |

| Bitumen | 0,470 |

| Paper | 0,140 |

| Light mineral wool | 0,045 |

| Heavy mineral wool | 0,055 |

| Cotton wool | 0,055 |

| Vermiculite sheets | 0,100 |

| Woolen felt | 0,045 |

| Construction gypsum | 0,350 |

| Alumina | 2,330 |

| Gravel (filler) | 0,930 |

| Granite, basalt | 3,500 |

| Soil 10% water | 1,750 |

| Soil 20% water | 2,100 |

| Sandy soil | 1,160 |

| The soil is dry | 0,400 |

| Compacted soil | 1,050 |

| Tar | 0,300 |

| Wood - boards | 0,150 |

| Wood - plywood | 0,150 |

| Hardwood | 0,200 |

| Chipboard | 0,200 |

| Duralumin | 160,0 |

| Reinforced concrete | 1,700 |

| Wood ash | 0,150 |

| Limestone | 1,700 |

| Lime-sand mortar | 0,870 |

| Iporka (foamed resin) | 0,038 |

| Stone | 1,400 |

| Multilayer construction cardboard | 0,130 |

| Foamed rubber | 0,030 |

| Natural rubber | 0,042 |

| Fluorinated rubber | 0,055 |

| Expanded clay concrete | 0,200 |

| Silica brick | 0,150 |

| Hollow brick | 0,440 |

| Silicate brick | 0,810 |

| Solid brick | 0,670 |

| Slag brick | 0,580 |

| Siliceous slabs | 0,070 |

| Brass | 110,0 |

| Ice 0°C | 2,210 |

| Ice -20°С | 2,440 |

| Linden, birch, maple, oak (15% humidity) | 0,150 |

| Copper | 380,0 |

| Mipora | 0,085 |

| Sawdust - backfill | 0,095 |

| Dry sawdust | 0,065 |

| PVC | 0,190 |

| Foam concrete | 0,300 |

| Polystyrene foam PS-1 | 0,037 |

| Polyfoam PS-4 | 0,040 |

| Polystyrene foam PVC-1 | 0,050 |

| Foam resopen FRP | 0,045 |

| Expanded polystyrene PS-B | 0,040 |

| Expanded polystyrene PS-BS | 0,040 |

| Polyurethane foam sheets | 0,035 |

| Polyurethane foam panels | 0,025 |

| Lightweight foam glass | 0,060 |

| Heavy foam glass | 0,080 |

| Glassine | 0,170 |

| Perlite | 0,050 |

| Perlite-cement slabs | 0,080 |

| Sand 0% moisture | 0,330 |

| Sand 10% moisture | 0,970 |

| Sand 20% humidity | 1,330 |

| Burnt sandstone | 1,500 |

| Facing tiles | 1,050 |

| Thermal insulation tile PMTB-2 | 0,036 |

| Polystyrene | 0,082 |

| Foam rubber | 0,040 |

| Portland cement mortar | 0,470 |

| Cork board | 0,043 |

| Cork sheets are lightweight | 0,035 |

| Cork sheets are heavy | 0,050 |

| Rubber | 0,150 |

| Ruberoid | 0,170 |

| Slate | 2,100 |

| Snow | 1,500 |

| Scots pine, spruce, fir (450…550 kg/cub.m, 15% humidity) | 0,150 |

| Resinous pine (600…750 kg/cub.m, 15% humidity) | 0,230 |

| Steel | 52,0 |

| Glass | 1,150 |

| Glass wool | 0,050 |

| Fiberglass | 0,036 |

| Fiberglass | 0,300 |

| Wood shavings - stuffing | 0,120 |

| Teflon | 0,250 |

| Paper roofing felt | 0,230 |

| Cement boards | 1,920 |

| Cement-sand mortar | 1,200 |

| Cast iron | 56,0 |

| Granulated slag | 0,150 |

| Boiler slag | 0,290 |

| Cinder concrete | 0,600 |

| Dry plaster | 0,210 |

| Cement plaster | 0,900 |

| Ebonite | 0,160 |

Brick

Brick is a popular material both for the construction of houses and for the installation of enclosing structures. Its thermal conductivity characteristics are available in the table:

| № | Material | ρ0, kg/m³ | λ0, W/(m °С) | λ (A), W/(m °C) | λ (B), W/(m °C) | μ, mg/(m h Pa) |

| 1 | Clay ordinary on cement-sand mortar | 1800 | 0,56 | 0,7 | 0,81 | 0,11 |

| 2 | Clay ordinary on cement-slag mortar | 1700 | 0,52 | 0,64 | 0,76 | 0,12 |

| 3 | Clay ordinary on cement-perlite mortar | 1600 | 0,47 | 0,58 | 0,7 | 0,15 |

| 4 | Silicate on cement-sand mortar | 1800 | 0,7 | 0,76 | 0,87 | 0,11 |

| 5 | Trepelny on cement-sand mortar | 1200 | 0,35 | 0,47 | 0,52 | 0,19 |

| 6 | Same | 1000 | 0,29 | 0,41 | 0,47 | 0,23 |

| 7 | Slag on cement-sand mortar | 1500 | 0,52 | 0,64 | 0,7 | 0,11 |

| Hollow brick brickwork | ||||||

| 1 | Ceramic hollow core with a density of 1400 kg/m³ (gross) on cement-sand mortar | 1600 | 0,47 | 0,58 | 0,64 | 0,14 |

| 2 | Ceramic hollow core with a density of 1300 kg/m³ (gross) on cement-sand mortar | 1400 | 0,41 | 0,52 | 0,58 | 0,16 |

| 3 | Ceramic hollow core with a density of 1000 kg/m³ (gross) on cement-sand mortar | 1200 | 0,35 | 0,47 | 0,52 | 0,17 |

| 4 | Silicate 11-hollow on cement-sand mortar | 1500 | 0,64 | 0,7 | 0,81 | 0,13 |

| 5 | Silicate 14-hollow on cement-sand mortar | 1400 | 0,52 | 0,64 | 0,76 | 0,14 |

Building blocks

The high heat transfer resistance of all building blocks is achieved due to the presence of air chambers or a foam structure in their structure. For example, some ceramic and other types of blocks have special holes that run parallel to the wall when laying. In this way, closed chambers with air are created, which is a fairly effective measure of preventing heat transfer.

In other building blocks, the high heat transfer resistance lies in the porous structure. This can be achieved by various methods. In foam concrete aerated concrete blocks, the porous structure is formed due to a chemical reaction. Another method is to add porous material to the cement mixture. It is used in the production of polystyrene concrete and expanded clay concrete blocks.

The nuances of using insulation

If the heat transfer resistance of the wall is insufficient for a given region, then insulation can be used as an additional measure. Insulation of walls is usually done from the outside, but if necessary, it can also be used on the inside of load-bearing walls.

Today there are many different insulation materials, among which the most popular are:

- Mineral wool.

- Polyurethane foam.

- Expanded polystyrene.

- Extruded polystyrene foam.

- Foam glass, etc.