Bimetallic radiators are very popular among consumers today. These are highly efficient heating devices that have an elegant, laconic design that fits perfectly into modern interior style. What should you pay attention to so that, under the guise of such a battery, you do not purchase a device that is similar to it only in appearance?

Design of a bimetallic radiator

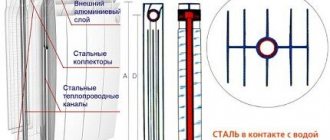

The essence of the design of bimetallic radiators is reflected in their very name. The products consist of two parts - internal pipes through which the coolant flows, and an external casing that ensures heat exchange with the outside environment. Pipes are made of stainless steel or copper. These materials fully meet the main requirement for heating pipes, namely, they are resistant to water hammer and excess pressure in the system, as well as chemical corrosion at high temperatures. The radiator body is made of aluminum: it heats up quickly and conducts heat well; its thermal conductivity coefficient is 230 W/(m‧⁰С). For reference: for cast iron this figure is approximately 60 W/(m²‧⁰С), for steel - 50 W/(m²‧⁰С).

Average service life of radiators of different types

| Battery type | Resistance to water hammer | Corrosion resistance | Duration of use, years. | ||||

| Steel | weak | low | 15-20 | ||||

| Aluminum | average | high (if additional protection is available) | 20-25 | ||||

| Bimetallic | high | high | 25-30 | ||||

| Cast iron | average | high | 25-35 | ||||

In addition to the quality of the raw materials used and compliance with the technological process regulations, other factors also influence the lifespan of radiators. Among them are:

- correct installation;

- regularity of maintenance;

- working pressure value;

- maximum permissible temperature in heating networks;

- composition and quality of coolant transported through pipes.

The operating pressure depends on the heating characteristics. In autonomous networks, which are used to maintain a comfortable temperature in the premises of private houses, it varies from 3 to 5 atm. The pressure in central heating systems of multi-storey buildings is about 8-16 atm. To ensure long-term use of radiators, their operating pressure must exceed the same parameter in the network by at least 2 atm. The composition of the coolant also differs. In autonomous networks, antifreeze solutions can be used, and water for central communications is usually subjected to chemical treatment.

In addition, the duration of use of batteries installed in apartments with central heating is negatively affected by water hammer in the pipeline. They occur due to pressure changes and often occur when utilities are started at the beginning of the heating season. Since different materials are used for the production of radiators, their level of resistance to external influences, reliability and durability differ significantly. Some manufacturers achieve improved technical parameters and increased service life by introducing new technologies and methods of metal processing.

Criterias of choice

1. The main criterion for choosing bimetallic radiators is the material they are made of:

the “filling” should be made exclusively of stainless steel or copper, and the body should be made of aluminum.

The fact is that if you do not go into these details when purchasing a device, there is a risk of purchasing a so-called semi-bimetallic battery, which is significantly inferior to the “original” in reliability and durability.

In such devices, vertical pipes can be made of stainless steel, and horizontal pipes of aluminum, or vice versa.

As a result, the radiator will show all the disadvantages inherent in purely aluminum models, such as: low resistance to temperature changes, fear of water hammer and pressure surges in the system, susceptibility to corrosion. In addition, the combination of two metals in the manufacture of the core causes another problem: due to the difference in temperature expansion of the materials in the connecting nodes, there is a high probability of leaks. It is impossible to distinguish semi-bimetallic radiators from real bimetallic ones by appearance.

Thanks to this similarity, they attract buyers with a lower price. By the way, the weight of the product will help you not to be deceived with your choice: a battery with an entirely steel core will be much heavier than one in which it is partially made of aluminum.

2. You should also pay attention to the pressure,

during which the device underwent pressure testing - it should be sufficient for the radiator to easily withstand peak loads in the heating system.

So, for installation in a centralized heating network, you can safely use batteries pressurized at a pressure of 35 atm. The maximum coolant temperature

for bimetallic radiators ranges from 90 to 135⁰С, depending on the model, while in reality the coolant in systems does not always heat up even to the standard 70⁰С.

Bimetallic radiators have a laconic design, have streamlined shapes and smooth lines of protrusions, they do not have parts that can cause injury. Color options - from dazzling white and ivory to noble gray and deep graphite

3. In quality products, the wall thickness of steel or copper pipes

should be at least 3–3.5 mm, and

the thickness of the shell fins

should be at least 1 mm, otherwise the radiator will have low mechanical strength and reduced heat transfer.

If, when you try to bend the edge with your fingers, it easily gives in to force, or even tends to crack, it means that a low-quality alloy was used for the casing, and the device can be damaged by any impact. To increase heat transfer, models of some brands are equipped with additional fins. 4. Experts recommend choosing sections with a width and depth of fins of at least 80 mm

- these are the optimal parameters for the greatest heat transfer effect.

Installing gaskets in the radiator

5. When purchasing a prefabricated sectional model, try to evaluate the quality of the mounting nipples and gaskets.

The first should be made of high-strength steel and have an impeccable thread (without scoring, distortions, etc.), and the second, usually made of rubber or silicone, should have medium hardness and good elasticity.

6. Important installation characteristics of the radiator - center distance

between the inlet and outlet openings (it can be 200, 300, 350, 500 and 800 mm), as well as

the connection diagrams to the heating network provided for by the design of the device.

We especially note that despite the simplicity of installation, which, by strictly following the instructions, the consumer can handle independently,

some manufacturers only allow professional installation of their equipment, stipulating this condition in the warranty documents.

Diagonal connection of a radiator

If calculations show that a room requires a radiator with ten or more sections (for example, it is located in an old house, or on the ground floor, or is simply large in size), then it is recommended to connect such a device according to a special diagram. Otherwise, due to the large length of the channel through which the coolant flows, the equipment will operate with reduced heat transfer. The problem is solved by diagonally connecting the upper inlet pipe to the lower outlet pipe, which makes it possible to achieve the calculated heating efficiency.

7. Pay attention to what coolants the radiator can operate on.

Some models allow the use of any liquid with varying degrees of chemical aggressiveness; others, in addition to water and antifreeze, also require the use of steam and oil, while others only need specially prepared water with a certain pH level.

Characteristics of steel radiators

The least durable heating devices include steel radiators, whose service life ranges from 15 to 20 years. They are characterized by low resistance to corrosion, leading to deformation and destruction of products. Heating devices made from low-quality metal are especially susceptible to rust.

Radiators made of stamped steel sheets can withstand pressure of no more than 8.5 atm. Exceeding this parameter contributes to the destruction of welded joints and failure of products. Damage can also occur as a result of water hammer, so it is recommended to install steel batteries in autonomous networks that are used to heat private houses.

Features of aluminum batteries

Aluminum radiators are also used in heating systems that are not connected to central communications. Operating such batteries in apartment buildings can damage the metal. They are characterized by the following:

- good heat dissipation;

- light weight;

- the ability to select a heating device with the required number of sections;

- variety of shapes and sizes;

- heat distribution by convection flow, which is created due to the shape of the ribs.

However, aluminum radiators are not able to withstand high pressure: their maximum is 8 atmospheres in the current mode and 16 during pressure testing. They are characterized by low resistance to hydraulic shocks and are sensitive to the composition of the coolant. With an increased level of acidity in the working environment, there is a high probability of corrosion. It can also occur when there is no water in the system, so it is not advisable to drain it.

By controlling the pH level of the coolant and maintaining the pressure within the specified limits, aluminum batteries will last about 20 years. Installing products in central networks is not advisable because they will soon need to be replaced, which will lead to additional costs.

Which brand of bimetallic radiators is better?

Italy

Let's start with Italian manufacturers. First of all, this is the Sira company, whose specialists invented bimetallic radiators. You can also mention the brands Global Style and Radena. All these products have a price per section from 700 to 1500 rubles. Elegant and high-quality finishing, interesting design, compactness and lightness - that’s what radiators from Italy are. Modern technologies allow them to work for at least 20 years. Specifications:

- Sectional thermal power – from 120 to 185 watts;

- hot water temperature limit – 110 degrees;

- operating pressure – up to 35 bar.

Russia

Let's not forget about domestic producers. One of the most famous is Rifar. This company from the Orenburg region produces heating devices with prices ranging from 500 to 900 rubles per section. Specifications:

- Sectional thermal power – from 100 to 200 watts;

- hot water temperature limit – 135 degrees;

- operating pressure – up to 20 bar.

Let us note the patented radiator RIFAR MONOLIT, which is often called one of the best domestic devices. It is tested at a pressure of 150 bar. Specifications:

- Sectional thermal power – from 134 to 196 watts;

- hot water temperature limit – 135 degrees;

- operating pressure – up to 100 bar.

Other countries

Here we can note the radiators of the South Korean company MARS. Their core is not steel, but copper. Price – from 400 rubles per section. Stated characteristics:

- Hot water temperature limit – 130 degrees;

- working pressure – up to 20 bar;

- sectional heat dissipation – 167 watts.

Polskaya also produces bimetallic radiators with a copper core. The manufacturer guarantees 25 years of operation. Specifications:

- Working pressure – 15 bar;

- hot water temperature limit is 110 degrees.

Well, a few words should be said about Chinese manufacturers. Their radiators are significantly cheaper than well-known brands, as they do not boast of careful finishing and beautiful design. In principle, if you have a very modest budget, you can take a “Chinese” one, given that it can withstand less pressure.

Table. Comparative characteristics of some manufacturers and models of bimetallic radiators

| Brand, country of origin | Model | Distance between axes, mm | Dimensions, H/W/D (sections) | Maksim. working pressure, bar. | Thermal power, W | Water volume in section, l | Weight, kg | Max. temp. heating agent |

| Italy | STYLE 350 STYLE 500 STYLE PLUS 350 STYLE PLUS 500 | 350 500 350 500 | 425/80/80 575/80/80 425/80/95 575/80/95 | 35 | 125 168 140 185 | 0,16 0,2 0,17 0,19 | 1,56 1,97 1,5 1,94 | 110 |

| Italy | BiLiner Inox 500 BiLiner 500 | 500 | 574/80/87 | 20 | 171 | 0,2 | 2,01 | 90 |

| Germany | TENRAD 350 TENRAD 500 | 350 500 | 400/80/77 550/80/77 | 24 | 120 161 | 0,15 0,22 | 1,22 1,44 | 120 |

| Russia | RIFAR Forza 350 RIFAR Forza 500 RIFAR MONOLIT 350 RIFAR MONOLIT 500 | 350 500 350 500 | 415/90/80 570/100/80 415/100/80 577/100/80 | 20 20 100 100 | 136 202 136 194 | 0,18 0,20 0,18 0,20 | 1,36 1,84 1,5 2,0 | 135 |

| China | Gordi 350 Gordi 500 | 350 500 | 412/80/80 572/80/80 | 30 | 160 181 | 0,21 0,3 | 1,4 1,7 | 110 |

| Italy | Gladiator 200 Gladiator 350 Gladiator 500 | 200 350 500 | 275/80/80 423/80/80 | 30 | 90 140 185 | 0,1 0,13 0,42 | 0,65 0,85 1,6 | 110 |

If you notice an error, a non-working video or link, please select a piece of text and press Ctrl+Enter .

0

Durability of cast iron radiators

The most durable heating devices are cast iron, which usually perform their functions for 25-35 years. The service life of some products can reach up to 50 years. This service life is due to the following characteristics:

- resistance to corrosion;

- low sensitivity to coolant quality;

- ability to maintain its parameters at temperatures reaching 130 °C.

Due to the properties of the material, cast iron radiators cool more slowly than similar products made of aluminum or steel. However, they are not designed for pressures above 9 atmospheres and therefore cannot be used when installing central communications. In addition, cast iron is a brittle metal and is susceptible to destruction under the influence of hydraulic shocks. Heating devices made of cast iron can last as long as possible if protection against sudden pressure changes is provided, and its value in normal mode does not exceed permissible values.

Advantages and disadvantages

Batteries made from silumin, along with positive characteristics, have a number of disadvantages. Both should be considered.

pros

The advantages of products of this type include the following:

- silumin, retains all the positive characteristics of aluminum, while imparting additional strength to the metal;

- high heat transfer. Almost instantaneous heating of the surface of the heating panel. In a few minutes the battery reaches maximum heating;

- the optimal dimensions of the products allow them to be compactly placed under the windows, without going beyond the width of the window sills;

- the sectional design of the batteries allows you to shape the dimensions of the heating panels in each individual case;

- affordable prices for non-ferrous metal batteries for the average consumer.

Minuses

The disadvantages of silumin products include the following:

- fragility of the metal, which is fraught with destruction due to pressure drops and water hammer in the heating system;

- along with rapid heating, the batteries also cool quickly, which negatively affects the heating of the entire room;

- during the summer season, the coolant cannot be drained from the system as there is a risk of internal corrosion;

- The risk of corrosion is much higher for simple aluminum products than for anodized models.

Service life of bimetallic batteries

Bimetallic models are less durable than their cast iron counterparts: their service life averages from 25 to 30 years, and manufacturers usually provide warranties for 10 years. This service life is achieved due to the following factors:

- good strength indicators, which are obtained due to the design features, which include the presence of a steel core;

- ability to withstand at least 20 atmospheres;

- high level of resistance to hydraulic shocks.

Bimetallic radiators are characterized by good heat dissipation, aesthetic appeal and low weight. The availability of products with different axial distances provides wide installation options. They are resistant to corrosion and are not sensitive to the composition of the coolant.

Bimetallic heating devices are able to maintain their functions for a long time both in autonomous networks and in centralized systems of high-rise buildings. However, it is more rational to use products when laying communications in multi-apartment buildings, where they show maximum efficiency throughout their entire service life.

Heat dissipation

In order to choose the right heating devices, it is important to decide which radiators are warmer. According to this indicator, aluminum radiators have an absolute advantage. This is due to the high thermal conductivity of aluminum. Thanks to this, one section can produce up to 200 W of thermal energy. Another important advantage is the low thermal inertia, due to which the room warms up very quickly after starting the heating system.

Bimetallic radiators are inferior to aluminum ones in terms of heat transfer. Heat loss is explained by the presence of a steel core, which has lower thermal conductivity. As a result, heat transfer can decrease by up to 20%. The thermal inertia of these radiators is also slightly higher.

Thus, if you evaluate which heating radiators are better (aluminum or metal) in terms of thermal efficiency, then the choice will be in favor of the first option. However, this indicator is not the only one that needs to be taken into account when choosing.

Lammin Product Benefits

Lammin sells bimetallic and aluminum radiators of the Eco and Premium series of its own production. The warranty period for the first products is 7 years, and for the second - 10. They meet the requirements of European standards and are adapted for use in Russian conditions. High quality heating devices is achieved through the use of modern production lines and the introduction of special developments.

Bimetallic batteries are ideal for heating offices, apartments in multi-storey buildings and industrial premises. They are insensitive to the composition of the coolant, since the design does not allow contact between aluminum and the medium transported through the pipes. Aluminum models are produced using injection molding from a unique alloy and are used for the installation of autonomous heating networks in private homes and country cottages. They are characterized by increased strength and reliability. A protective coating on the inner surface protects the metal from corrosion.

Cons of aluminum radiators

Any product has some pros and cons. Consumers have to weigh the pros and cons when they compare the differences between heating radiators.

The disadvantages of aluminum radiators are the following:

- high demands on the coolant: it should not contain acids or alkalis;

- all aluminum radiators must have air venting devices in order to promptly remove air pockets;

- aluminum radiators are connected to the heating system only using aluminum pipes;

- weak points - connections of sections that can leak under load;

- heat is distributed unevenly, the hottest places are the radiator fins;

- The service life of an aluminum product is about 15 years.

If you handle the aluminum product carelessly during installation, it can be damaged, since the material is quite fragile. Therefore, this work should be done by a professional. The listed disadvantages help to understand the difference between an aluminum radiator and a bimetallic radiator.