Bimetallic heating radiators

The comfort of a house or apartment in winter greatly depends on how warm the room is. I want to return to a warm and cozy home, and since our heating season lasts six months, the issue of choosing and installing suitable radiators must be decided seriously and carefully. In order to keep the house warm, you need to carefully consider the entire heating system, especially for a country house. As long as everything is done correctly and functions well, it will be warm in winter.

You need to approach this matter seriously and competently, taking into account all the nuances of construction, climate and much more. Now the market is literally flooded with various types of heating devices and radiators. Surely, many people associate the concept of “radiator” with heavy cast-iron batteries, although their quality is far from the best at the moment. One of the types of batteries, the characteristics of which we will analyze, are bimetallic heating radiators.

Types and characteristic features of bimetallic heating batteries

The name of the product is associated with the use of two manufacturing materials - steel and aluminum. The inner side of the radiator is made mainly of steel, and sometimes of copper, since both materials withstand the effects of heated coolant. On the outside of the device there is a ribbed casing made of aluminum, which has high thermal conductivity. Using stainless steel nipples and temperature-resistant rubber gaskets, the radiator sections are interlocked.

Radiators according to their structure are divided into two groups:

- Bimetallic;

- Semi-bimetallic.

A distinctive feature of semi-bimetallic models is the minimal amount of steel used for the cores, and in bimetallic products all frame pipes are made from steel.

Semi-bimetallic products are not always suitable for central heating systems, which most often contain low-quality coolant with a high alkaline content.

Therefore, there is a high chance of corrosion and damage. These models are primarily suitable for autonomous heating systems.

Weight and heat dissipation

There are two stereotypes about bimetallic radiators:

- They are light and do not heat well;

- They are heavy and keep you warm.

This seems stupid, but in fact everything is true. The lighter the radiator, the less energy it can take from the coolant. Accordingly, it will release less heat into the room. And vice versa - the more aluminum in the radiator, the more thermal energy the water or coolant gives to it. And it warms better.

It's just that different people encounter different makes and models. Some options are made lightweight, but have poor heat dissipation. And some are heavy, but produce more kilowatts of heat.

Many manufacturers artificially increase the heat output of bimetallic radiators. Sometimes the numbers differ by 1.5-2 times. To know the actual heat transfer of bimetallic heating radiators, you can read the article “How many real kW of heat are in one radiator section.”

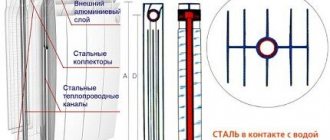

Construction of bimetallic heating radiators

Bimetallic radiators are characterized by the presence of a shaped ribbed casing, with high heat transfer due to the aluminum alloy. The pipes under the frame constitute a heating circuit.

Based on this, there are two types of radiators:

- Sectional;

- Monolithic.

As already noted, products of the first type are presented in the form of sections connected to each other, but the joints between the plates may not always be sealed, so after a while the radiator may begin to leak coolant. In this regard, monolithic products that are made from a solid manifold filled with aluminum are much more practical.

What is a bimetallic radiator in cross section?

For monolithic radiators, an alloy of copper and aluminum is used, and in sectional radiators, copper is replaced with steel. In general, steel is characterized by low heat transfer, and aluminum is characterized by sensitivity to corrosion and fragility, thus, the disadvantage of one metal is offset by the advantage of the other, due to which this alloy is more durable and effective.

That is why sectional radiators have some specifics:

- Their service life is no more than 25-27 years;

- The maximum pressure they can withstand does not exceed 35 atmospheres;

- Sectional heat output varies from 100 to 200 watts.

Monolithic radiators are also characterized by a number of features. The service life exceeds 50 years, can withstand pressure of about 100 atmospheres, heat transfer is 100-200 watts.

Thus, monolithic structures are more effective than sectional ones, however, their significant disadvantage is the relatively high price; moreover, the solid structure cannot be changed, i.e. remove or add sections.

Specifics of the design of a bimetallic heating radiator

Sections of bimetallic type products are connected in a universal way, which eliminates the possibility of coolant leakage.

In addition, these models allow the use of various coolants:

- Steam;

- Oil;

- Water;

- Antifreeze.

The coolant temperature can reach up to 135 °C, while the thermal efficiency per section is about 196 Watt. It is important to note that the wall thickness of the steel manifold is exactly the same as that of conventional water pipes.

In general, the design of bimetallic radiators is as follows:

- The steel core (frame) of the radiator, which also transports the coolant.

- The fins of the product are made of aluminum and are designed to ensure heat transfer from the radiator.

The use of two metals provides the device with strength, high heat transfer and resistance to corrosive processes.

Design and principle of operation

Bimetallic radiators made of a pipe made of steel and an aluminum body. Steel serves as protection against corrosion, and aluminum helps to quickly warm up the room. It is this combination of metals that makes it possible to use modern radiator models for a very long time.

Bimetallic radiator design

Thanks to the steel pipe through which the hot coolant flows, pressure drops are not a problem. And the steel-to-steel connection can withstand the pressure of high performance. The copper used in such products also increases the resistance of the heating system to electrochemical influences.

Aluminum is a good conductor of heat, which is why it is used to make radiators. The aluminum surface of the bimetallic radiator is capable of heating up in a short period of time and also quickly cooling down if necessary, making it possible to regulate the desired temperature in the room.

Bimetallic radiator design

The high heat transfer of aluminum allows the use of a minimum amount of hot coolant, and, therefore, it becomes possible to produce radiators of small sizes. Bimetallic batteries can be installed in niches or used to heat a (small) room.

Operating principle of bimetallic radiators

Bimetallic radiators are mounted using welding or fittings. For high-quality installation, it is best to turn to professional plumbers, although if you have the installation skills and necessary tools, you can do it yourself. When connecting a radiator, it is recommended to use polypropylene pipes reinforced with fiberglass or aluminum.

The entire process of installing bimetallic radiators into the heating system of the whole house has a number of features:

- Radiators are mounted in place of the previous batteries, with appropriate surface preparation.

- The batteries are installed in the center, under the windows at a distance of 55 mm from the top of the window sill.

- The distance between the floor and the bottom edge of the radiator can be 60-120 mm, and the distance from the device to the wall should be about 20 mm.

- In advance of installation, you need to install Mayevsky taps on the radiators, which will allow you to remove excess air from the heating system.

- In addition, it is necessary to install fittings and adapters at the junction of the radiator and pipes.

- It is necessary to drill holes under the brackets, which are secured with dowels with nails and cement mortar, if necessary. Dowels must ensure free placement of hooks between horizontal collectors.

- At the end of the installation, the water riser is equipped with special taps, and then the pipes that connect the heating batteries to the riser are connected.

Installation of equipment

The installation of bimetallic heating radiators must be carried out in accordance with the instructions given by the manufacturer. And, of course, the installation must be carried out by a specialist who has a license to carry out this type of work.

Before installing batteries, wash the communications.

A valve will need to be installed on each battery; it can be either manual or automatic and designed to release air from the radiator. To prevent the valve from becoming dirty, special filters are installed on the supply risers to protect against dirt.

Aluminum or bimetallic radiators?

Radiator installation procedure:

- Mark the mounting locations for the brackets;

- Attach the brackets using dowels or cement mortar;

- Connect the battery to the supply lines, this is done using a tap or thermostat;

- Install an air bleed valve at the top of the radiator.

The bimetallic heating radiator must be installed so that the horizontal sections of the heads lie directly on the brackets. It is undesirable to cover radiators with various screens and cabinets, as the operating conditions of the equipment may worsen.

Bimetallic type heating radiator design

Before purchasing heating equipment of this type, you need to calculate the number of sections required for high-quality heating of the entire room. To make this calculation, you need to multiply the area of the room by 100, and divide the resulting amount by the power of one battery, i.e. section.

It is important to take into account a number of additional nuances:

- Availability of double-glazed windows in the room and their quantity;

- Ceiling height;

- How is the room located in relation to other rooms?

- If the radiator is installed in an apartment in a multi-storey building, you need to take into account the floor on which it is located;

- Average temperatures in the cold seasons for a specific area;

- The total number of external walls (the number of radiator sections depends on their number);

- The total power of radiators per square meter of room area, in accordance with established standards.

Also, in advance of purchase and installation, it is necessary to check the devices for compatibility with the heating system of the whole house (autonomous heating or central heating). In this case, it is necessary to take into account: heat transfer coefficient, hydraulic pressure indicators, values that are the maximum permissible for the coolant in the system. It is especially important to take this into account if the devices are connected to central heating, since the autonomous system can be adjusted to specific radiators and designed according to individual orders.

Many models are quite versatile and ergonomic, since they have a thermostat through which you can adjust the temperature manually. In addition, all products have an aesthetic appearance, so they are perfect for any interior.

Currently, the following Russian and Italian companies producing bimetallic heating radiators are more popular::

- Sira (Italy);

- Rifar (Russia);

- Global (Italy);

- Royal Thermo (Italy).

Italian products are created in accordance with international standards and even adapted to the Russian heating system. Also, foreign models are characterized by a long service life, high strength and reliability. However, these radiators are expensive, and some models are made for closed heating systems and will not be suitable for central heating.

Domestic models are no less worthy and are quite capable of competing with foreign production. For example, products from the Russian company Rifar are equipped with thermostats, as well as air vents, and in addition to this, they are comparatively cheaper than Italian devices. In addition, domestic manufacturers produce stylized models of various shapes (rounded).

Popular manufacturers

Three manufacturers have gained the most popularity on the Russian market: Global, Sira, RIFAR.

Heating devices from Sira group appeared on the Russian market about 20 years ago. Three types of height sizes are available: 30, 50, 80 cm . Each section has two vertical channels, connected to each other using threads, which allows you to add or remove sections at any time. is required for assembly . The cost of one section is from 700 rubles.

Global offers devices with a height of 35 and 50 cm. When connecting sections, special steel nipples and paronite gaskets , which significantly reduces the possibility of leaks. An installation kit is provided with the radiators. There are several design options: Global Style is conservative, Global Style Plus is elegant, Global Style Extra is simple. The cost of one section is from 620−670 rubles (depending on height).

Sira radiators are not suitable for a house in which the heating system was installed more than 30-40 years ago, since the diameter of the vertical sections is only 5-6 mm. For older houses, Global devices with a diameter of 10 mm are more suitable.

The domestic manufacturer RIFAR recently released a new MONOLIT with non-separable channels welded into a single system. This design completely eliminates the possibility of leakage. The main feature is the ability to use coolant with a temperature of 135°C. The cost of one section is from 610−620 rubles.

Bimetallic radiators are ideal for Russian conditions. They easily withstand the abundance of impurities in the coolant and frequent, sudden pressure surges . Aluminum radiators deteriorate much faster. Steel appliances are, of course, more durable, but they are heavy and rust.

Characteristics of bimetallic heating radiators (video)

To summarize, we can say that bimetallic radiators are a worthy replacement for old, cast-iron batteries. They are well suited to both central heating systems and autonomous heating systems. Structures of this type are characterized by long service life, strength and reliability, as well as high heat transfer due to the combination of materials such as aluminum and steel.

Comments

0 Olga 01/06/2018 06:28 When they were doing the repairs, we replaced the old cast-iron batteries with semi-bimetallic ones; we chose these because the heating was central and not autonomous, as I now understand they did the right thing.

We are very pleased, the rooms have definitely become warmer, and they look nicer. Quote

Update list of comments RSS feed of comments for this entry

Specifications

In the technical characteristics of radiators, first of all, I would like to note the durability of bimetallic heating batteries, the service life of which is from 20 to 25 years. The surface of the bimetallic radiator has a high-strength coating, thanks to which they retain their original appearance throughout the entire period of their operation. You also don't have to paint them. Such radiators for the heating system practically do not clog due to the relatively smooth steel surface. Thanks to these advantages of radiators, they can be used for any heating system without fear of the chemical composition of the water and its purity.

It is very easy to install radiators with your own hands and during operation, no difficulties are noted. During repairs, they can be easily dismantled and, if necessary, installed back.

Companies producing bimetallic batteries present a wide range of new generation heating systems. The beautiful and modern design of the units allows them to be used in any room

Bimetallic radiators have high technical characteristics and a relatively reasonable cost.