Laying brick rows

The brick “lining” of the stove should be half a brick thick.

It is erected at a certain distance (up to 100 mm) from the steel body so that it does not burn out due to overheating. The greater this distance, the longer the stove will last; but if there is a need to quickly heat the brick case, the gap is reduced to a minimum of 10 mm. Seams can be made with a width of 2 to 5 mm, ideally 3 mm.

Without sufficient experience, applying such a thin layer of mortar using a trowel can be difficult, so it is better for a beginner to do it directly with his hand.

It is better to moisten the bricks before applying the mortar to improve adhesion.

Metal stove lined with bricks

Row No. 1 must be checked with a building level - it must be strictly horizontal.

In the 2nd row it is necessary to leave several holes through which cold air will be sucked into the space between the stove and the brick wall. To install such vents, it is not necessary to break off the quarters from the bricks - you can simply rotate them 90 degrees (poking them outward).

After laying the second row along the corners of the future case, it is necessary to pull the nylon cord strictly vertically - to do this, you need to drive nails into the ceiling and into the seam between the 1st and 2nd rows. These will be guidelines that will help you draw the corners without distortions.

If, when hammering a nail into the ceiling, it deviates slightly to the side, it can easily be corrected with a hammer, simultaneously checking the verticality of the stretched cord with a plumb line.

Even better is to install an ordering rail. The risks present on it will help to lay out the rows strictly horizontally, so that constant monitoring by the building level will not be required.

DIY brick solid fuel boiler

For heating private houses, a solid fuel boiler made of brick has proven itself well. You can easily make such a heat generator with your own hands if you have the necessary materials, tools, and an understanding of the intricacies of the design and production process. The availability of information allows you not to experience difficulties when assembling the boiler. Therefore, armed with a ready-made drawing, you can easily and profitably manufacture heating equipment.

Facing

Before you line a metal stove in a bathhouse with bricks, you need to prepare for work.

Preparatory activities

You can start laying only after the concrete and brick base has dried. A metal stove is installed on it, and future cladding is marked around it.

But first you need to install a fireproof shield made of any fire-resistant materials on the wooden walls around the fireplace.

Insulation of wooden walls and floors with mineralite

If you decide to prepare masonry mortar from clay, then you need to fill it with water for several days and carefully sift the sand. Since it is difficult to cover an iron stove with bricks and not stain its body with mortar, before starting laying it should be protected with paper, cardboard or film, securing them to the walls with tape.

To prevent water from the solution from being absorbed into the brick, it is soaked in water about half an hour before starting work.

Soaking the brick

Masonry

When deciding how to brick a cast-iron stove, it is better to choose half-brick masonry. A thicker screen will take longer to heat up, and a thinner screen will cool down faster.

The laying of the first row begins from the far corner, laying a whole brick

It is very important to lay it out evenly and neatly, since all subsequent rows will be aligned with it. They are laid out alternately, with an offset of half a brick. Don't jump over the row, first raising the corners and then filling the space between them.

Laying is done offset

- The permissible thickness of the horizontal seam is 8-10 mm, vertical 3-5 mm.

- The seams are filled completely with the solution, its excess is immediately removed from the surface with a trowel.

Bricks that go beyond the plane are knocked down with a hammer or mallet

During the laying process, you need to constantly monitor the verticality of the walls and corners using a plumb line or building level.

A cord stretched along the upper edge of the row will help to keep the row strictly horizontal.

Auxiliary vertical stands will make work easier

To strengthen the masonry, reinforcing mesh can be placed in the seams every two or three rows.

The photo shows the reinforcement of the masonry with metal mesh

Also, every two or three rows you should unstitch the seams until the mortar loses its elasticity, and wipe the surface from any remaining mortar with a wet rag.

Joining seams

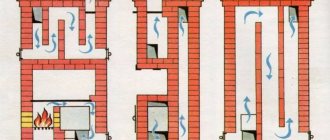

When laying out the walls, it is necessary to leave ventilation holes in them: at least two at the top and two at the bottom. Cold air will flow into the lower ones, protecting the oven from overheating, and heated air will come out through the upper ones.

Furnace ventilation diagram

- As an option, you can line the stove with bricks laid in a checkerboard pattern with holes between all adjacent elements.

- Around the doors of the firebox and ash pit, masonry should be carried out taking into account their full opening.

The brick will have to be cut if it prevents the doors from opening

Where to finish the masonry is up to you. If you have a stove with a stove or heater, it is only brought to the top of the body. You can raise it to the ceiling. Or you can make figured masonry with a vault and chimney lining, turning an ordinary potbelly stove into something like a fireplace.

Metal stove for a bath, lined with bricks up to the pipe

Option with full height masonry and pipe lining

The brick portal turned an ordinary stove into a real fireplace. Now you need to let the solution dry for at least a day. It is desirable for this to happen in natural conditions, so it is better not to heat the stove for now.

Preliminary preparation

Before laying bricks, you need to make sure the floor is in good condition. Thus, a reinforced concrete floor can withstand no more than 800 kg of weight per m2; the load on any other floor is usually calculated as 150 kg per m2. Before you cover the potbelly stove with brick, it needs to be installed on a kind of foundation made of a sheet of metal, asbestos cardboard and brick in this order: cardboard is placed on the floor, a steel sheet on top, then the brick is laid in two rows, as close to each other as possible.

If the potbelly stove has already been installed, it must be disconnected from the chimney pipe and moved away from the site of future masonry. When the floor is old and the weight of the structure cannot withstand, the logs are cut out and a cement foundation is poured, provided that the stove is installed on the first floor of the house. The stove should not stand only on the finished floor. To reduce the load on the joists, it is allowed to lay only 1 row of bricks on a sheet of metal and asbestos cardboard. The steel sheet should protrude 30 cm in front of the firebox door.

Masonry

The production of fitting brickwork is carried out “dry” without mortar. The fitting masonry is made directly on the floor close to the parallelepiped frame with gaps between the elements of 7 mm.

Upon completion, a contour of the brick cladding is outlined on the floor for further laying it with mortar. Angles must be constantly monitored horizontally and vertically.

Work begins from the corners, constantly checking their horizontalness. Nails are driven into the side seams of the fireplace to tighten and secure the cord for laying an even row of cornices without deviations. Between the brick gap is filled with mortar.

Do you need a cast iron brick?

The thermal advantages of cast iron stoves are great and undeniable, see the video below. Is it possible to improve a cast iron stove with brick lining? No way. First, cast iron is already a very good material for a stove. Lining a cast iron stove with bricks is generally the same as covering a brick stove: there will be no visible effect, but there is a lot of work and expense.

Second, cast iron is a brittle material with a large TCR. Under a brick lining, any furnace overheats beyond what is specified according to the specifications. The best structural cast iron (there is also raw cast iron for conversion into steel) will soon crack in a furnace under a brick. If a cast iron stove needs to fit into the interior, then the optimal means for this is decorative elements separate from the stove or overhead decorative elements made from cold forged parts.

Arrangement of the foundation for a metal furnace

Before laying brick over the unit, you need to thoroughly prepare and strengthen the base for it. Since metal structures are light in weight, they do not require a separate foundation for the furnace, but brick cladding will provide an additional load of tens of kilograms.

Not every floor covering can withstand such a mass. For this reason, before covering the boiler with bricks, it is imperative to dismantle the floor and arrange a separate foundation - columnar or monolithic.

Most often, a monolithic base is made. To do this, the floor under the stove is dismantled. The foundation parameters should be such that there is a gap of 10 to 15 centimeters between the future brick cladding and the metal body of the unit.

First, they dig a hole approximately 30 centimeters deep, pour crushed stone and sand onto the bottom, compact it, install reinforcement and fill it with concrete mortar. The foundation will harden in about 2 weeks.

To arrange a columnar foundation, pillars are installed at the corners of the facing box and in places of the highest load. The advantage of this base is that no drainage or waterproofing is required.

The sequence of actions during the construction of a columnar foundation is as follows:

- Markings are made at the corners of the furnace for mounting the pillars.

- Dig holes located strictly vertically, having a depth of about 50 centimeters.

- A 10-centimeter layer of sand is poured into the bottom of all holes and compacted.

- Prepare a solution of cement and sand in a 1:2 ratio; it should have the consistency of thick sour cream.

- The solution is poured over the layer of sand in a 10-centimeter layer. Crushed stone or brick chips are added to it.

- After hardening, brick pillars are laid out so that they rise 7–10 centimeters above the floor.

- Install the lower trim beam. The most reliable way would be to lay the channel around the perimeter and weld the edge.

The use of concrete pillars is allowed. You can make sure that they are vertical using a building level.

Masonry mortar

The inner surface of the brick lining of the stove can heat up to 350-400 degrees, so a regular cement-sand masonry mortar is only suitable for the screen of a sauna stove, spaced at least 7-8 cm from its body. In other cases, you need to use a clay-cement mortar, because stove clay is fragile and hygroscopic.

To prepare a solution for lining a stove with bricks, you must first sift the dry clay through a sieve with a mesh size of 1.5 mm. Next, the fat content of the clay solution is adjusted:

- A test portion of clay is mixed with mountain or ravine sand of fraction up to 1 mm in a 1:1 ratio by volume.

- Cover with water and knead until the dough becomes thick.

- Roll into a rope (sausage) approx. thick. 2 cm and length approx. 30 cm.

- Allow to dry not in direct light for 1-3 hours at a temperature of 30-15 degrees, respectively.

- Bend the tourniquet into a ring.

- If the rope is deeply cracked in several places or broken, the initial (base) solution is thin, you need to add more clay.

- The tourniquet bent smoothly or only the dried crust cracked - the base solution is greasy, you need to add more sand.

- The tourniquet cracked more or less evenly along its length to no more than 1/4 of the thickness - the fat content of the base solution is optimal.

A test portion of the working solution is prepared by replacing 1/8-1/3 of the clay with cement from M400; Usually they give 1/5 to start with. The dry mixture is gradually mixed with water, kneading until the cream becomes thick. Then check the solution for fluidity: dip a clean trowel into it and remove it, holding the nose down. There are 3 possible cases here:

- The solution drains, leaving stains on the trowel or completely exposing the metal - there is a lot of water;

- The solution drains, leaving a lumpy layer with lumps on the trowel - there is not enough water;

- The solution drains, leaving a thin, even layer of water in moderation.

Now you need to check the solution for stickiness (adhesion); This is important for laying half/quarter bricks. Take a brick, dip it in water, and apply a 3-5 mm layer of solution onto its bed with a trowel. Immediately take a dry brick and place it on a layer of solution, without pressing down, immediately lift it. The mortar should not stretch behind the dry brick; sticking of several small, match-head-sized lumps is acceptable. If the mortar follows the dry brick, the proportion of clay in the base mortar must be reduced, respectively. increase the proportion of cement.

Next, the dry brick is again placed on the mortar, tapped with the handle of a trowel and left for 5-6 minutes. They try to lift it, the wet brick should rise with it. If it remains lying or gradually comes off while hanging, you need to add more clay in the base solution and, accordingly. less cement.

Step-by-step cladding technology

- The bricks for laying are soaked in water for about 40 minutes.

- If the walls of the stove will be visible after laying, then before starting work it is advisable to wrap the stove with film so that you do not have to clean it later from any remaining mortar.

- If the stove was sold with a convection casing, it must be dismantled, since its role will now be played by the lining.

- To mark, stretch a fishing line or cord vertically along the corners of the future masonry. If the floor is wooden, you can nail two vertical bars to it on both sides of the stove. They are fixed using wooden spacers.

- Mix the solution. You don’t need to do much – half a bucket is enough.

- Brick laying begins from any convenient angle. For this, only whole material is used, which is carefully, guided by a cord or fishing line, laid flat - “in half a brick.” Each brick is carefully leveled. Excess mortar is removed immediately before it dries; the outside of the masonry is wiped with a rag; burlap is good for this purpose.

- The seams should not contain voids and be of the same thickness (5-7 mm).

- It is advisable to reinforce the second row with mesh. It is cut into strips of the required size and laid on a brick, with mortar on top. The mesh should not stick out from the seams. The corners are reinforced with pieces of wire to tie the entire row into one. The second row needs to start from the same corner, but take not a whole brick, but a half, so that the seams are offset by half a brick - this is necessary for bandaging and strengthening the structure.

- In the third or fourth row, you need to leave several holes for hot air - usually two or three are made on two opposite sides of the masonry, the size of half a brick.

- The next 5–6 rows are made continuous; dressing the seams is mandatory. Do not forget to check each row with a building level for the horizon and vertical, so as not to “fill up” the masonry. Constantly monitor the thickness of the seam.

- In the areas where the firebox and ash pan are located, the brick should not interfere with the doors opening. The bricks must first be laid without mortar, their location must be accurately determined, and, if necessary, cut to the required size with a grinder.

- The row above the door is covered with two pieces of steel strip or corner - on the outside and inside of the masonry. The laying is carried out on it.

- In the penultimate row, two more holes should be made for air circulation - as described above. In this way, it will be possible to achieve proper circulation - cold air below will flow under the heat shield and exit from above already heated.

- The work is usually completed when the masonry reaches the upper level of the furnace. Sometimes the brick is laid up to the ceiling, completely covering the chimney.

- Wait at least 48 hours for the solution to dry completely.

- After drying, the brick can be given a more beautiful and rich appearance. To do this, rub it with a stiff brush, which is moistened with a solution of laundry soap. After this, the surface of the masonry is rinsed with clean water.

If the stove is very powerful, it is covered with a special lattice method, leaving gaps between the elements of 10 cm.

For a round stove, the masonry is made round. The technology is not much different from the standard one, although placing the brick in a circle is a little more difficult. Holes for air circulation are made symmetrically on both sides of the masonry. During the work, the main thing is to maintain the same distance between the walls of the stove and the inside of the brick over the entire area.

Operating principle of a furnace with a built-in tubular heat exchanger

Brick boilers with a built-in tubular heat exchanger have a water circuit connected to the in-house heating system.

Solid or gaseous fuel burns in the combustion chamber, the heated flue gases transfer heat through the steel walls to the coolant, heating it to a temperature of 95 C.

Due to the temperature difference, the cooled flue gases are removed into the chimney and then released into the atmosphere. The heated coolant enters the heating system and moves along the internal circuit to the heating devices, where, through the radiator heating surfaces, it gives off heat to the internal air in the room and cools.

Then it returns to the brick kiln, under the influence of natural circulation caused by the temperature pressure at the inlet and outlet of network water from the brick boiler.

If a complex configuration of a tubular heat exchanger is installed in the boiler, a large hydraulic resistance may be created, which will not allow water to circulate well in the circuit.

For furnaces operating on gas fuel with a burner device, it is possible to install an automation complex with primary control sensors and weather-dependent regulation, which will ensure 100% automation of the combustion process.

Features of the stove lining installed on a wooden floor

When the bathhouse has a concrete floor, there are no questions about the arrangement of the base of the stove and the cladding around it. But with wooden flooring, before you start laying around a metal stove, you should consider a lot of questions.

First of all, it is important to decide whether a foundation is needed. To do this, the weight of the brick structure is calculated and the endurance of the wooden floor is assessed.

In some cases, it is enough to simply additionally strengthen the load-bearing logs. But the safest thing to do is to pour a foundation under the brickwork. It is up to the owner to decide what it will be: strip or pillar.

If the foundation was not laid during construction, then it will be necessary to dismantle a certain part of the floor and dig a pit, since the foundation for the furnace formwork must be located at the same depth as the base of the building itself. In size, it should be 15-25 cm wider than the furnace screen itself.

First of all, you should calculate whether the floor will support the weight of the foundation

The foundation of the stove should not be connected to the main one; if the firebox is located near a load-bearing wall, then a distance of at least 5 cm is provided between the two foundations. The gap formed between them should be filled with heat-insulating materials. The height of the stove foundation should be 10-15 cm below the floor level.

It should take about a month for the foundation to dry completely. And only after that work continues. Several layers of roofing felt or roofing felt are laid on top as a moisture-proof material. Then two rows of bricks are laid, each subsequent brick of the second row is laid offset relative to the previous one so that the seams overlap. Now the foundation for the furnace screen is ready.

Even if the floor and foundation joists seem strong and reliable, capable of supporting the weight of a brick screen, a number of preparatory work will be required. A base for installing the oven and screen is being organized. The base must be non-flammable and strong; the following materials can be used:

- A sheet of metal fixed over a thermal insulation layer;

- Two rows of brickwork that are laid on a wooden floor;

- Ceramic tiles resistant to high temperatures;

- Artificial or natural stone.

Plating methods

Stove makers use three methods:

- Continuous cladding. The method accelerates heat transfer. Rarely used, mainly for decoration.

- Creation of a heat shield. Acts as a partition. Increases the comfort of people sitting next to you in the bathhouse. Improves the level of heat transfer.

- The lining performs the function of a convector with vents. The best option for a bath. Suitable for any metal stoves. The area of the steam room is not important.

The layout of the lining will depend on its purpose and the functions of the stove. For decorative purposes, it is made in full brick. If the equipment acts as a water heater, then it must be laid in half a brick.

To correctly calculate the distance from the brick screen to the stove body, you need to add 2 cm per 1 kW of unit power.

There is no point in placing it close to the body - the lining will not perform the necessary functions.

People are also interested in:

- DIY metal sauna stove

- Brick stove for a bath

Design

This is the very first stage, during which several important points should be taken into account, especially for functional fireboxes:

- It is necessary to determine the location for the equipment in the room relative to the walls and furniture arrangement. At the same time, do not forget about fire safety: the distance from flammable surfaces to the firebox is at least 700 mm.

- The base for the equipment is recommended to be made of concrete with a height of 300 mm. The perimeter of the foundation should extend beyond the dimensions of the firebox by 250 - 300 mm on each side.

- The recommended gap between the firebox and the plasterboard structure is 50 mm.

- An air vent box should be provided.

- Podium. The design must provide air flow for heating and support the weight of the firebox.

- The thickness of the fireproof wall finishing and a technical gap of 100 mm between it and the firebox.

- To accurately determine the dimensions of the portal, you should take into account the parameters of the facing material: profiles: guide – 27×28 mm and rack – 27×60 mm). For cladding, it is recommended to use fireproof or moisture-resistant plasterboard with a thickness of 12.5 mm.

- The design of the portal and its decoration should fit organically into the interior.

The listed parameters will help you avoid installation errors.

Pros and cons of external cladding

In addition to functional and decorative advantages, several operational advantages can also be mentioned:

- You can provide space for a hob, a stove bench, or a water heating tank.

- Increasing the service life of the metal if the stove is made of metal sheets that are connected by welding.

The disadvantages can only be associated with non-compliance with brick cladding technology, due to which the masonry may fail. In addition, the outer brick layer will make the stove larger.

Important!

It is necessary to use high-quality facing bricks without chips and cracks, otherwise a crack may spread across the entire facade due to deformation.

Why enclose the heater in the steam room?

Homeowners who want to set up a steam room in their home at a cheaper price buy an iron or cast iron stove, or even order a homemade one. Heaters of the middle and highest price categories are equipped with special convection screens that protect people in the steam room from hard infrared radiation coming from the hot steel walls of the firebox.

There are 3 reasons why owners have to line the stove in their bathhouse with bricks:

- budget and homemade heaters made of metal do not have protective screens;

- the need to protect the wooden lining of the steam room from fire when the stove is installed close to the walls;

- Wood stoves with steel walls are not able to retain heat for a long time; the temperature in the steam room quickly drops after the wood burns out in the firebox.

The lining of a metal stove immediately solves 2 problems: it protects against burns from infrared radiation and accumulates heat, like a battery. Due to the good thermal capacity of the brickwork, such a screen will transfer heat to the bathhouse for a long time after the firebox has died down.

Stove cladding options in photographs

Below are ready-made options for cladding stoves that will fit perfectly into the interior of frame baths, as well as baths made of logs and blocks. The furnace firebox is located both in the steam room and in the dressing room.

How to cover a metal stove with bricks

Before proceeding directly to the lining, you should understand that the brick should not lie close to the walls of the furnace. A distance of 5 or 10 cm is considered optimal.

This air gap is necessary to compensate for the difference in heating of the materials. Rapidly heating metal in direct contact with the brickwork will cause the stove to overheat. Therefore, at the first stage you will need a pencil and a tape measure. You need to mark the boundary of the masonry. The metal sheet is screwed onto self-tapping screws or nailed in such a way that its area completely covers the masonry site.

A sheet of asbestos cardboard is attached on top of it. Its thickness must be at least 4 mm, and it must be smaller in size than a metal sheet. If the stove is not placed on a wooden floor, but on another non-combustible base, then such fire safety measures will be unnecessary. A diluted purchased mortar or a self-prepared mixture along with bricks and trowels should be brought directly to the installation site. To improve the operation of a metal stove , half a brick of masonry is enough.

It allows you to save both building materials and mortar. This method of installation implies that the spoon side will be facing the “viewer”. The bricks are laid in a row on the base lengthwise.

Each of them is connected to each other by a layer of solution. Subsequent rows of masonry are shifted relative to the previous one by half a brick. The joints of the bricks do not match, so the entire structure is strong.

With standard dimensions of building materials, the thickness of the resulting masonry will be 120 mm.

Immediately before laying, the brick is lightly wiped to remove excess moisture. The first row is made solid, without technological holes. The second row must have ventilation outlets. Their width should not exceed five centimeters.

They should be duplicated several more times. That is, continuous rows of masonry need to be interspersed with those left by “windows”. The number of rows with holes depends on the size of the stove.

Such ventilation is needed so that the heat from the hot walls does not remain inside the brick casing, but goes outside and evenly fills the room. Each row of masonry is done using a level. A portion of the mortar is added (or removed) to the brick so that the rows do not deviate from the horizontal and vertical. To level the brick, you can lightly tap it with a mallet or trowel, slightly moving it in the desired direction.

- Excess mortar that unsightly floats onto the rows must be removed immediately, so that after hardening you do not have to make unnecessary efforts to separate them from the masonry. In the place where the oven door is located, you need to make the lining in such a way that it does not interfere with opening, placing firewood, ignition and cleaning the firebox from ash. The metal angle is useful to strengthen the top side of the doorway.

What happens when you combine brick and metal?

- When adjacent to metal, brickwork is able to retain much more heat, and when heated, it will evenly heat the room for a long time. This property of brick is used by bathhouse owners, since the brick transforms hot, scalding air into high-temperature vapors that do not cause discomfort. In other words, dense heat is created.

- Brick allows you to increase the heat retention time, without additional heating of the oven. Thus, by spending money on brickwork, you will save on fuel for a long time. In addition, you will save strength and energy, and going to the bathhouse will become a real relaxation. The additional layer prevents direct contact with metal. This option makes the bathhouse safer to use.

- We must not forget that brick is a natural material. Bricks made of clay can create a unique microclimate, and when combined with metal, they heat up much more, creating a huge amount of soft steam.

The only drawback. Together, these two materials heat up much more slowly than individually. But coupled with the listed advantages, it can be written off as nothing.

In order for all the benefits to really begin to work for you, you need to treat your work with great trepidation and responsibility. After all, the functional features of the resulting boiler will depend on the correctness of your actions.

In order to line the boiler with bricks, you need to prepare tools, binder mortar and, directly, bricks. Chimney improvements should not be ignored. It can be made entirely of bricks, or it can be lined with metal. A beautiful chimney will make your home aesthetically pleasing.

Material selection

It should be immediately noted that in order to line a metal stove with brick, you need to use a material that has special characteristics. The brick must be of high quality, with high fire resistance, heat resistance, and its structure must not contain voids. High-quality fire bricks can be recognized by their red color. The lining is made with the following types of bricks:

- Silicate

- Ceramic

- Clay

- Fireclay (fireproof)

The first two types are usually used as cladding. Solid clay brick is used for laying pipes, chimneys, fireboxes, and direct lining of the body - this applies to a wood-burning stove. If you plan to use coal as fuel, it is better to lay the firebox and lining with fireclay bricks, which can withstand high temperatures of up to 1800 degrees. In addition, you can use used bricks, having first cleaned them of the remnants of the old mortar. Using embossed bricks you can create a beautiful, original screen for the stove.

The required amount of brick is calculated based on the dimensions of the stove and the area into which it is planned to expand the space around it. In addition, you need to take into account the laying of the base, which will require a row of one or two bricks. You also need to consider the installation method - on the narrow side of the brick or on the wide side. The first option is more economical, but ineffective from the point of view of the operation of the stove.

Masonry material can be prepared in four ways:

- Mortar of refractory clay with cement;

- Made of cement with adhesive for porcelain tiles;

- A solution consisting of clay and sand;

- Ready-made fireproof oven mortar based on red clay.

Experience shows that the best and simplest solution is clay-based. There are many varieties of this material, therefore, in order to guess the correct proportions, it is recommended to first mix the sample with the same amount of sand and clay, then adjust the volume of one or the other in the composition of the mass. If there is too much clay, it will crack as soon as it dries. If there is too little, it will not set well. Often brickwork is reinforced with reinforcing mesh. This is necessary in cases where the foundation is too weak to support the weight of the furnace with lining.

In addition to materials for masonry and mortar, you will also need roofing felt for the base of the stove as a waterproofing and fireproof material.

Basic criteria for choosing bricks for lining

The stove can be lined with clinker bricks.

The rules for cladding metal with bricks are prescribed in SNiP 01/21/97. "Fire safety of buildings and structures."

The document stipulates that steel boilers can be lined with the following types of material:

- silicate;

- hyper-pressed;

- ceramic;

- clinker;

- refractory.

Brick for lining a cast iron stove must have the following properties:

- maintaining characteristics under high heat;

- immunity to temperature changes;

- resistance to moisture, fungus and mold;

- long-term preservation of the resulting heat;

- mechanical strength;

- long service life;

- frost resistance;

- high heat capacity.

The best option is considered to be red and yellow fireclay. When purchasing, you must pay attention to the characteristics declared by the manufacturer and the actual condition of the stones. They should not differ significantly from each other in size, shape, or color. It is unacceptable to take goods that are crumbling in the corners and edges, have pronounced heterogeneity, foreign and burnt inclusions.

Covering a metal stove

When deciding how to line an iron stove with bricks with your own hands, you should first decide on the materials that will be needed for the work.

Choosing mortar for masonry and bricks

Masonry mortar can be of three types:

- Sand-clay. which is considered a classic of stove solutions.

- Cement mortar. to which fireclay clay (fireproof) is added.

- The cement mortar is mixed with glue. intended for porcelain stoneware.

Now let's move on to the question of what kind of brick to line an iron stove with. To do this, you should not use ordinary building bricks, but special oven or fireclay bricks. According to the production technology, this material is an ordinary ceramic brick made from fireclay - fireproof clay.

Fireclay refractory brick.

The modern market offers various varieties with a textured surface, which allow you to greatly transform a stove of a simple design, but are somewhat more expensive. Double sand-lime brick M 150 is not suitable for these purposes, since its thermal conductivity is not very good, and it cannot withstand high temperatures.

Laying brick rows

A standard metal stove is laid out very simply - half a brick in a checkerboard pattern (that is, offset by half a brick relative to the previous row).

Advice! If there is a shortage of refractory bricks (for example, fireclay), you can lay the blocks on edge, this way you will be able to save money, however, the protective screen will be thinner, and accordingly, all the properties of such masonry will be somewhat reduced.

We cover the iron stove.

The instructions for carrying out the work are extremely simple and consist of several tips:

The first row of masonry is considered the most important, because it determines the distance between the metal screen of the furnace and the brick wall. Different information sources give different recommendations on this matter, suggesting a gap of 1 to 10 cm.

When calculating the gap, one should proceed from the following considerations: too small a distance will lead to excessive heating of the metal screens, which will reduce the service life of the furnace itself. If you provide too much indentation, the brick walls will take too long to warm up. Therefore, a gap of 5 cm would be ideal.

Advice! When laying bricks, it is advisable to soak each of them in water. This allows you to strengthen the adhesion of the mortar to the surface of the brick block.

- Ventilation holes should be allowed in the masonry. This will allow air to circulate better between the masonry and the metal. In places of such “windows” the brick is laid end-to-end first (button method). So in each “window” there are two holes.

- It is advisable to lay bricks through the row with reinforcing mesh cut lengthwise, which will add strength to the structure.

Cleaning masonry from mortar

After the work is completed, it is necessary to let the masonry stand for several days. About a day later, you can start cleaning the stove from the solution, stains of which are probably present on its walls. And this procedure actually turns out to be much simpler than it might seem at first glance.

For this you can use a drill with a special attachment in the form of a metal brush. Thus, within half an hour your stove will be completely cleaned of stains. This brush leaves dark stains on the brick, and to remove them, you need to wash the stove with a household brush, which is soaked in a soapy solution.

Oven cleaned of solution.

Nuances you need to know when starting cladding

In general, the laying of bricks for cladding in terms of technology is no different from the laying of stove walls. However, when deciding to line a cast-iron or iron stove with brick, pay attention to the important points listed below.

- every 4th row of facing masonry with wire or steel strip. The firebox opening (including the opening of the remote firebox) is reinforced with a metal corner.

- During the DIY cladding process, you will need a heat insulator. Asbestos or basalt cardboard can be used as it.

- Review all purchased bricks for defects (chips, cracks, etc.). Take the time to lay out the material on the floor, adjusting brick to brick so that the pins touch with the smallest possible gap. Follow the same order when you lay the bricks on the mortar.

- The masonry mortar must match the chosen type of brick. However, there is no need to rack your brains here. Usually, when purchasing building materials, you will immediately be offered a dry mixture, which you only need to dilute with water according to the instructions.

- Watch the thickness of the seams, do not make them too wide. The thinner the seams, the better thermal conductivity the lining will have.

- Be sure to check the verticality of the corners with a plumb line, as well as the horizontality of the rows with a level.

Installation of a metal stove with a remote firebox in a log house

Let's consider the option of installing a fireproof anti-shrink wall made of LV mineralite. A special fastening method will allow installation in the log house before it shrinks, and the floating design of the fastening elements will prevent the rigid wall from deforming.

Minerit LV

Minerite

Step 1. Prepare the opening in the wall. We cut it out with a chainsaw according to the markings.

Hole in the wall

Step 2. Cover the inner surface of the opening with mineralite. We saw the mineralite sheet into three pieces. We cut out two vertical pieces based on the height of the opening minus 10 cm. We cut out the horizontal part with a length equal to the width of the opening minus 2 cm. The width of the mineralite section should be equal to the thickness of the timber or log from which the wall of the bathhouse was built.

Step 3. We nail foil to the inside perimeter, and then mineralite. First, we fix the vertical sections with nails, then the horizontal ones.

Step 4. It is necessary to make an opening in the mineralite sheets, which will protect the wall from the heat of the stove. The remote furnace firebox will pass through this opening. We take measurements of the remote firebox, then make markings with a pencil and cut the sheet so that there is 3 cm on each side between the remote channel and the sheet.

Installation of foil and mineralite. Finishing of the opening can be done both before and after installation of the main slabs of refractory material

You can do it differently - first we fix the sheet on the wall, and then we cut the opening for the remote firebox.

Mounting mineralite to the wall

The sheet is fixed, you can cut out the opening

Step 5. Drill oval holes in the sheet for self-tapping screws. When shrinkage occurs, the screws will move downward inside these holes, while the sheet will remain motionless. We fix the foil insulation on the wall (with a stapler), and then use self-tapping screws and a washer to fix the mineralite sheet (we mount the sheet on the steam room side).

Step 6. We attach the second layer of mineralite with an air gap of 3 cm. To do this, you need to purchase a mounting kit with ceramic or steel bushings.

Mounting kit

Once again, you need to drill oval holes, but be sure to make sure that the fasteners of the first and second sheets do not end up at the same point.

The photo shows a diagram of the installation of a protective screen made of mineralite. Double-layer sheathing. If the stove has an external firebox, make an opening according to the instructions

When joining two sheets at 90 degrees, we make cuts at the ends at 45 degrees for a more aesthetic appearance.

After installing the sheets, we install the stove on the base. We adjust the legs, making sure that the external channel is located exactly in the center of the opening cut in the mineralite. We take foil-coated basalt wool and place it tightly between the walls of the outlet channel and the mineralite. In this case, the foil should “look” towards the steel walls of the channel.

Adviсe

Craftsmen use different methods of installing stoves and protecting walls. So, for example, in a log bath it will be more convenient to install mineralite on a wooden sheathing. Antisepticize the 50x50 mm bars, drill holes for self-tapping screws and fix the sheathing posts exactly vertically. The mineralite will already be fixed to this sheathing with self-tapping screws.

Lathing

If you plan to cover the wall from the inside (from the steam room side) with mineralite for further finishing, for example, with a coil, and finish the portal with brick from the outside, then it is worth carrying out the work in the following sequence:

- From the side of the steam room, fix a sheet of mineralite;

- cut a hole for the outlet channel;

- secure the horizontal guides from the plasterboard profile. Fasten the strips with self-tapping screws at the top of the opening, along the bottom and exactly above the opening for the fuel channel;

- install the vertical posts of the sheathing from the profile, fix them with self-tapping screws through the shelves;

- take basalt wool and lay it between the sheathing posts;

- sew up the opening with mineralite (from the dressing room side);

- install the stove in its place;

- Now, on the side of the dressing room, fill the opening with brick (don’t forget to put insulation in the cracks), and on the side of the steam room, apply decorative finishing with stone.

Lathing and insulation

View from the steam room and dressing room

Fixed furnace portal

Walls and chimney after finishing with a coil

The process of finishing the oven itself

The work on installing the furnace does not end there. Be sure to install a water tank and a heat exchanger, if they are provided for in the design, install the chimney in accordance with fire safety rules, prepare and lay the stones in the mesh.

Requirements for facing materials

A furnace is a structure whose materials work under emergency conditions. Facing is no exception. There are certain requirements for the finishing material of the stove. He must:

- Withstand high temperatures.

- Possess the property of high heat transfer.

- Be resistant to mechanical damage.

- Have good adhesion to the fastening solution.

- Be attractive and have an aesthetic appearance.

Experts recommend lining stoves with brick, ceramic tiles (terracotta or majolica), tiles or natural stone (marble, basalt, sandstone, slate and granite). More recently, the use of soapstone and artificial stone has become popular. Some resort to the simplest methods, such as plastering or painting.

Photo gallery: beautiful stoves

You can combine different types of cladding

Painting the stove and applying patterns can be an economical decoration option. Brick finishing looks very aesthetically pleasing.

Finishing with ceramic tiles is done most often. Lining the stove with tiles will make it unique. Natural stone in the decoration of the stove looks very status

Materials and tools

When deciding how to properly line an iron stove with bricks, you first need to decide on the materials suitable for this. They must have special characteristics.

Brick

The main material for cladding must be of high quality: without voids, with high heat resistance and fire resistance.

You can choose which brick to line an iron stove in a bathhouse from two options:

Clay brick. It is used for lining the body, masonry of the firebox and chimney of a wood-burning stove. It can be ordinary, front, or with a decorative front surface.

Ordinary solid brick

Facing brick

Facing brick with decorative surface “oak bark”

Using shaped bricks you can create unique shapes

Fireproof fireclay brick. Withstands temperatures up to 1800 degrees. It is recommended to be used for masonry and lining of coal-fired stoves.

Fireclay brick

The approximate quantity is calculated depending on the method of laying (half or quarter brick) and the perimeter of the cladding. In this case, the dimensions of the furnace itself and the distance between it and the lining are taken into account. This also includes the amount required to construct the site, since it is possible to cover a metal stove with bricks only on a solid foundation.

With this type of masonry, the brick is placed on a spoon - a narrow long part

Solution

The ideal masonry mortar is made from clay and sand in certain proportions, which depend on the quality of the clay. Without experience, it is very difficult to do it. Therefore, it is best to buy a ready-made refractory mixture based on red clay.

Before covering the cast-iron firebox with brick, you just need to dilute it with water, as required by the instructions on the package.

Heat-resistant terracotta mixture

In addition to bricks and masonry mixture, masonry mesh and fire-resistant sheet materials may be needed to create a protective screen for wooden surfaces. And also roofing felt as a waterproofing material.

Tools

The following tools will be required to complete this job:

- Container for solution;

- Trowel for typing it;

- Hammer for adjusting bricks;

- Pickaxe for dividing them into parts;

- Jointing for seams;

- Ordering is a strip with divisions applied to it, the distance between which is equal to the height of one or several rows, taking into account the thickness of the seam;

- Construction level and plumb line for level control;

- Cord for controlling the evenness of horizontal rows.

Tools required for masonry A sponge or rag and a bucket of clean water will also help to remove the mortar from the front surface of the masonry.

Properties of mortar for laying a brick oven

The mortar for laying bricks in the bathhouse around the stove must have the same characteristics as the stones used to construct the screen. In addition to strong heating, the mixture will be subject to significant vertical loads created by the masonry. The composition for laying bricks under the stove in a bathhouse should not be hygroscopic or porous. Otherwise, when the temperature drops below zero, rupture and destruction of the material will occur.

The characteristics of the solution in the frozen state must correspond to the following parameters:

- frost resistance - F 50;

- moisture absorption - 7%;

- thermal conductivity - 0.48 W/(μ);

- voidness - 10%;

- fire resistance - 750°C.

Alternatively, you can purchase a ready-made mixture that contains several components that provide these parameters. It will be expensive, but the quality will be guaranteed if you act according to the manufacturer's instructions.

Types of protective screens for furnaces

For air movement and better heating of the room, the protection is located a few centimeters from the walls . Gaps are made in the lower part of the structure : gaps are left in the brickwork for this purpose, metal sheets are installed on the legs.

Reference. When using brickwork, the room warms up more slowly , but the comfortable temperature remains longer .

Such screens are placed on the sides facing the room. And to protect walls, especially wooden ones, they are sheathed .

Important! Side and front screens are used only for metal stoves. Brick structures also need protection for nearby walls

Safety regulations

To ensure proper functioning of the furnace device with a boiler, it is necessary to strictly follow the rules and safety requirements, and in addition, follow some recommendations for caring for a home-made structure. They are as follows:

- Devices in which a water circuit is installed must be under constant supervision during operation. This applies to storing firewood, as well as periodically cleaning the device from accumulated soot and ash.

- Safe operation involves constant inspection of smoke exhaust ducts. It is especially important to carry out these activities before the start of the heating season. It is necessary to check the technical condition of all furnace elements, including valves. They must be open when lighting.

- The heating system is recommended for use in winter. In the season when it is necessary to quickly and efficiently heat a large area of the room, as well as to ensure a constant hot water supply. But in the summer, it would be irrational to use a stove only for cooking food or heating water. To do this, it is better to select more economical options for heat sources.

- Due to open fire, the surface of the stove structure becomes very hot, which often causes the heat exchanger to break down.

In order to ensure liquid injection, it is recommended to equip the homemade device with a pumping unit. In addition, it is worth using special devices with which you can monitor and regulate pressure.

Features of a wood-burning heating boiler with a water circuit

A proper boiler has the following characteristics:

- Safety. The walls and door of the boiler should not heat above 150 °C.

- Ease of use. The design of the boiler does not allow “abstruse” systems or a large number of valves.

- Durability. The stove should serve without repairs for a long time.

- Controllability. The intensity of the flame is regulated not only by the amount of firewood.

- Efficiency . Make the most of the heat from fuel combustion.

In order to build a boiler, there are two ways - building a new one or integrating a heat exchanger into an existing furnace.