Where does the heat go?

Heating devices in buildings are installed under the windows.

The goal is to warm the air inside and create a thermal curtain that prevents the penetration of cold from the street.

Heat spreads from a heated object to a cold one.

The wall temperature is lower than that of the radiator.

In the cold season, the surface behind it heats up to 35-40 °C.

Instead of heating the air inside a warehouse or office, some of the energy is used to heat the external walls.

Video description

How to reduce battery heat dissipation

Contact utility companies

Problems in high-rise buildings are resolved by the management company. According to the rules, residents should not directly contact workers servicing the heating network. It is better for the inhabitants of the problem apartment to write a statement to the Criminal Code. If the complaint is not considered, then they further contact Rospotrebnadzor and the housing inspectorate.

The appeal will be investigated if the problem of too high a temperature is observed in other residents. In high-rise buildings, people on the lower floors often suffer from the heat, while those on the upper floors freeze. Utility workers turn up the heating as much as possible, which leads to discomfort.

The management company must carry out balancing. After correction, the temperature of all residents should return to normal. If the weather forecast predicts a sharp cold snap in the coming days, workers may ignore the request.

Heat reflector behind the battery

- Effective operation of the heat-reflecting screen behind the radiator can be achieved by simultaneously following the following rules:

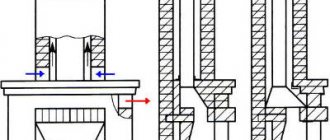

- The screen itself should not block the heat transfer path from the battery to the room. There are only two such paths. These are flows of warm air going upward and heat radiation in the infrared range.

- To eliminate the ineffectiveness of heat transfer in the first case, the boxes must structurally ensure unhindered air circulation in the upward direction. To do this, they must have the necessary inputs at the bottom. At the same time, the upper horizontal line should not be continuous.

- To carry out warm air flows, it is worth making heat-reflecting screens with lattice front parts (with the exception of those made of metal).

The heating of an external wall with a fixed battery becomes much less due to the fact that similar screens are mounted between it and the wall.

The principle of operation of the heat-reflecting screen behind the radiator

In most apartments and residential buildings, heating radiators are installed under window openings. The section of the wall behind them is always heated the most intensely. Experts say this part can heat up to 35-40°. Essentially, precious heat is wasted on heating the outer wall of the building instead of making the room temperature higher.

The problem of heat loss can be solved in a simple way - install a heat shield on a section of the wall directly behind the radiator

Even greater heat losses are observed in cases where the radiator is mounted in a niche. It is thinner than the wall surface. This means that cold air penetrates into the rooms in huge quantities through it.

It is undoubtedly impossible to put up with this state of affairs. And it's not necessary. The problem of heat loss can be solved in a simple and elegant way - by installing a heat shield on a section of the wall directly behind the radiator.

The heat-reflecting device we are interested in not only retains heat. It, in addition, protects the batteries from the penetration of dust and moisture particles into them from behind the wall (through small cracks).

Visually, factory-made heat-reflecting screens look attractive. This makes it possible to use them to decorate nondescript areas of the wall behind the heating radiators.

Theoretically, they can be made from any type of reflective material, combining it with a heat-insulating product. The main thing here is to meet one condition. The reflective material must have a minimum (up to 0.05 W/m*°C) thermal conductivity index.

Foil fully meets this condition. But you cannot use it yourself. The foil, which is a metallized product, will have to be attached to the wall. It will heat up and immediately transfer heat to the wall.

Therefore, it is imperative to create a special layer between the wall surface and the foil. Important! The layer should be thicker than the metallized product.

- Let's consider what materials are used for such screens:

- foil;

- penofol;

- Porilex with foil.

It is important! The main thing is that the material from which the reflective screen is made has a low thermal conductivity coefficient, approximately 0.05 W/m*°C.

If you use only foil for these purposes, then you should take into account that this metal heats up and if it has contact with the wall, then all the heat will transfer to it. And to prevent this from happening, it is necessary to make a layer between them (foil and wall), which should be thicker than the foil and have low thermal conductivity.

For this purpose, penofol is used, which is a foam base or Porilex with foil. Moreover, the thickness of the screen should be 3 - 5 mm.

Also, the heat reflector behind the battery can be made from rolled foam. This is a three-millimeter material that is created specifically to redirect heat indoors.

The most common and cheapest material for insulation is polyethylene foam. 4 mm of this material replaces a 10 cm layer of mineral wool. The polyethylene is attached to the wall with an insulating layer, and the side with foil is attached to the heating battery.

- Advantages of a heat-reflecting screen behind the radiator:

- The heat-reflecting element allows you to redirect heat inside the room, rather than heating the exterior walls. Due to this, you can increase the temperature in the room, while saving on heating costs.

- Such radiators can be decorative, that is, thanks to this, nondescript places under the batteries are emphasized.

- Radiators do not become clogged with dust due to suitable cold air from below, and they become easy to clean.

- The main advantage is the supply of warm air into the room, as well as the prevention of moisture penetration.

Foil behind the radiator

A heat-reflecting screen with aluminum foil behind the heating radiator completely insulates the walls from heat, which helps reduce heat loss and increases the efficiency of the heating system by 20%.

A heat-reflecting screen with aluminum foil behind radiators and central heating radiators completely insulates the walls from heat, which helps reduce heat loss and increases the efficiency of the heating system by 20%.

The room temperature rises by 2-3°C. Thermal waterproofing of the roof. Can be used as insulation under heated floors only with polyethylene film (to protect the foil from oxidation in the aggressive environment of cement-sand mortars).

90% of the heat is reflected from the foil, and the thermal insulation layer makes it difficult to lose heat. To achieve the greatest effect and retain heat, you can use double-sided foil, that is, the insulating material will be the middle link, and the outer sides of the material are made of foil, but this is unnecessary.

Such material is secured with glue, but it will be better if there is a layer of air under such a screen that will replace the heat insulator. To do this, use a grid on which a screen sheet is attached, and the thickness of the recommended layer is 10 mm.

By installing foil behind the radiator, near the outer wall, you can increase the air temperature in the room by 2 degrees.

- The foil is installed according to the following rules:

- The thickness of the insulating layer must be at least 5 mm.

- The reflective side of the screen should be facing the battery.

- If the foil does not have a self-adhesive layer, then you can attach it using the staples of a construction stapler.

In addition to reflecting heat, such a screen can perform a vapor barrier function, that is, protect the wall from moisture penetration into it.

The size of such a reflective screen should be larger than the size of the heating radiator. Of course, to install such a screen behind heating radiators, you do not need to contact any company; you can do it yourself.

A heat-reflecting screen with aluminum foil behind radiators and central heating radiators completely insulates the walls from heat, which helps reduce heat loss and increases the efficiency of the heating system by 20%. At the same time, the room temperature rises by 2-3°C.

Thermal waterproofing of the roof. Can be used as insulation under heated floors only with polyethylene film (to protect the foil from oxidation in the aggressive environment of cement-sand mortars).

Heat Reflective Film for Batteries

Thermal reflective film is a rolled material on a woven or non-woven base that reflects infrared radiation towards the source.

First of all, you should decide on the place of its application. So, to create a heat-reflecting screen behind the battery, you need to remember that the thermal conductivity of aluminum is very high.

In order not to heat the wall behind the radiator, but to reflect the heat into the room, there must be an insulating layer between the film and the wall. The ideal choice in this case is films based on polyethylene foam.

Thermal reflective film Ondutis R Termo is perfect for reducing heating costs. Thanks to its characteristics, it provides up to 80% heat reflection. As a result, instead of heating the walls, thermal energy is used exclusively for heating the premises.

The low weight of the Ondutis R Termo vapor barrier (70 m2/g) allows it to be used for insulating light frame structures, and the vapor permeability of up to 10 g/m2 per day provides maximum protection of the insulation from steam, even in a Russian bath. At the same time, the film does not lose its properties when temperature changes from −40 to +120 degrees.

Reflective screen for radiator

Household heating radiators emit a non-directional flow of thermal energy and, at the same time as heating the air in the room, warm up the wall on which they are mounted. By installing a simple heat reflector behind the battery in the area where the battery is suspended, you can significantly reduce heat loss and, with the same energy consumption, raise the room temperature by 2-4 degrees.

The heat reflector screen is ideal for insulating the space behind radiators and radiators, loggias and balconies. This flexible, thin, durable and lightweight material based on aluminum foil has excellent thermal insulation properties.

The principle of operation is very simple - the screen reflects up to 90% of the heat.

You may have noticed that the wall located behind the radiator is always warm. This suggests that the heat from the battery simply goes to nowhere - to heat the street.

For example, such a simple procedure as insulating the area behind the radiator can increase the temperature in the house by 3-6 C, and increase the efficiency of the radiator by up to 42%. Consequently, significantly reduce the cost of heating the premises, be it gas or electricity.

Theoretically, heat shields for radiators can be made by combining any heat-insulating material and reflective foil (for example, polystyrene foam or mineral wool boards).

But at the moment, the most effective and convenient is polyethylene foam with closed air pores, produced in the form of rolls with one-sided or double-sided coating of aluminum foil. The thickness of this material is only 5-10 mm.

Without taking into account the reflective effect, the thermal conductivity of one layer of foamed polyethylene is 0.05 W/m °C. At the same time, the total heat-reflecting efficiency exceeds foam concrete by 12-20 times, mineral wool and expanded polystyrene by 4-12 times.

- The most well-known brands in this product category are: “Penofol”, “Izospan”, “Alumofol”, “Porilex”. All of them are available in three versions, distinguished by the foil method:

- type A: one-sided;

- type B: double-sided;

- type C: single-sided with self-adhesive backing.

What materials are reflectors made of?

Theoretically, they can be made from any type of reflective material, combining it with a heat-insulating product. The main thing here is to meet one condition. The reflective material must have a minimum (up to 0.05 W/m*°C) thermal conductivity index.

Foil fully meets this condition. But you cannot use it yourself. The foil, which is a metallized product, will have to be attached to the wall. It will heat up and immediately transfer heat to the wall.

Therefore, it is imperative to create a special layer between the wall surface and the foil.

Important!

The layer should be thicker than the metallized product.

- Most often, the following are used to make a heat insulator:

- rolled foam;

- penofol (foamed polyethylene).

Polystyrene foam in rolls is a cheap material. Moreover, its heat-protective potential is 1.5 times higher than that of the well-known insulator - mineral wool. Foamed polyethylene is 2–2.5 times more effective than mineral wool. It has been proven that 4 mm of penofol provides the same amount of thermal insulation as 10 mm of mineral wool.

You can make your own reflector of the heat coming from the battery. To do this, you need to purchase foil and heat-insulating material separately and fasten them together with tape. But it’s easier to purchase a ready-made heat-reflecting product.

They are produced under well-known brands - Izospan, Porilex, Alumofol, Penofol. It will be easy to choose a product that is suitable for the price.

- Thermal reflective products from different companies differ slightly from each other. Let's consider the possibilities of foil materials using Izospan screens as an example. These products are especially in demand by domestic consumers. The construction market offers several types of Izospan heat-reflecting devices:

- FX. The function of a heat insulator is performed by foamed polyethylene, and the role of a reflective film is played by a lavsan coating.

- F.S. Products with a polypropylene (PP) non-woven base to which a metallized polypropylene film is attached.

- F.D. Analogous to the FS model. But the heat insulator is made of woven PP fabric.

Experts recommend using Izospan FX. It has an affordable price, does not contain toxic and harmful compounds, and does not deform when heated. However, you can use other varieties of Izospan.

Believe me, the effect of using them will be no worse. Let us immediately note that decent performance characteristics are inherent in heat-reflecting films from other manufacturers. There is no need to focus specifically on Izospan.

Wall cladding methods

Finishing the wall behind the battery can be expensive or cheap, but in both cases it is not done quickly.

Battery repair steps:

- We remove the battery, otherwise it is impossible to fully seal the surface. When removing it yourself, first turn off the water supply valve and return valve.

- There is water in the radiator; when unscrewing it from the taps, place a low bucket or, better yet, a wide basin. The battery is removed from the mount when the water has completely drained. It’s safer to call a technician, because if the heating is on and the ball valve on the jumper is old, it’s dangerous.

- In order not to spoil the clean floor and carpets, you should stock up on large pieces of film and cover the entire path from the front door to the radiator.

- Next, we inspect the wall for defects and prepare it. We remove the bumps of old plaster and paint with a hammer and chisel, paying attention to the place where the baseboard is, it should be as even as possible.

- We remove debris and fill small cracks with putty. Once they have dried, we completely level the niche with plaster.

- The dried plaster is primed 2 times, the layers dry for 2 hours.

The radiator has been removed, the wall has been prepared, now you can choose the finishing method, and there are many of them. By the way, there are “dry” finishing options behind the battery, for which the surface does not need to be leveled, you just need to remove the protrusions and prime it.

We putty and glue wallpaper

Let's continue the topic of plaster. The method is expensive and time-consuming: you need to buy a lot of materials, and the plaster takes up to a week to dry. Beacons are not placed in the starting layer; this is a small surface; it is quite possible to level it without beacons.

After drying (up to approximately 5 days), we prime the wall, let it dry and apply the finishing coat. To save time, it is better to buy a bucket of ready-made putty. The dried surface is sanded with a sharp spatula, this way there is less dust in the room. Cut out the required pieces of wallpaper, take special glue and paste over it. They start gluing from two opposite sides, so that the joint of the pieces is in the middle, behind the battery. Next, measure out the pieces of plinth, drill holes in the hay for the fastening and install it.

Installing drywall

Finishing the wall behind the battery also means finishing the wall with plasterboard. The method is well suited in a house with plasterboard walls, it’s less hassle: at the same time you make the sheathing under the gypsum board for the battery. This is also possible with brick walls. They make a metal frame on which the sheets will be attached. GCR withstands exposure to warm temperatures very well, does not crack over time and has low heat transfer.

In this regard, it is perfect for finishing the space behind and around the battery. If you install insulating material between the wall and the gypsum board, then 10-30% of the heat will remain in the room. You just need to remember to drill holes in the drywall so that warm air from the radiator can enter the room. The joints between the sheets are pasted over with a thin mesh and puttied. A thin layer of finishing mixture is used to level everything flush with the wall. When everything was dry, all that was left was to paint the wall.

To increase operating efficiency, a heat-reflecting film is glued behind the rear wall of the radiator

There are also special heat reflectors that direct warm air into the room, but not everyone has proven the effectiveness of such a device.

We glue plastic panels or ceiling tiles

This option is the most budget-friendly, but it allows you to give the area under the battery a well-groomed look and even well insulate the thin wall where the niche is located. We are talking about the use of modern material - foiled polyethylene foam. It is mainly used for thermal insulation. It comes with double-sided aluminum coating and single-sided, with denser polyethylene inside and regular, self-adhesive and not. The simplest one is also suitable for finishing a niche.

Rarely does anyone glue ceiling tiles anymore, but they do exist as a finishing option.

Before pasting, the wall is also prepared, but not as thoroughly as in the case of plaster. We knock down the unevenness, remove the dust with a rag, seal small cracks with a solution of alabaster and sand, it dries quickly and you can continue working. You need to carefully measure the size of each wall with a tape measure so as not to spoil the penofol. Next we glue the insulation. We use universal acrylic-based mounting adhesive and a mounting gun. It sticks perfectly, and temperature does not affect it in any way.

They start gluing from the widest wall behind the radiator, then seal the top wall and the sides. The insulation can be covered with white or wood-like plastic panels using the same glue. The panels must be chosen the same width as the window sill protruding above the niche, so as not to cut it in this place. If necessary, the side parts are trimmed along the plank. External and internal corners are trimmed with special plastic strips to match the panels. Instead of a plinth, you can use a special strip with two sides into which panels are inserted.

The battery, like the wall behind it, can be designed as a design element, but then the wall behind it must be perfect

The second cladding option will be polystyrene foam ceiling tiles. It is easy to cut out pieces of the desired size from them, they are sold in a variety of colors, smooth and embossed. They begin gluing from the bottom up, so that whole pieces of tile are visible in a visible place. It is better to decorate the window sill with a ceiling plinth at the first stage, and then “pull” the tiles to it. Here you can also use corner strips. The tiles near the floor can be glued at the joint to the baseboard, or you can remove it, veneer it and attach the baseboard back. In addition to decoration, ceiling tiles have good thermal insulation characteristics.

Scope of application

Reflective thermal insulation is applicable to all surfaces without dirt and dust, suitable for complex structures with corners, bends and differences. Insulating walls from the outside can achieve maximum effect by creating an air gap of 20 mm on the foil side.

The material is effective for multi-story and single-story frame houses, and it will increase the resistance of the walls without increasing their volume. Installation is carried out end-to-end without overlaps, and the seams are taped with foil tape.

Application from inside

If you want to insulate the room from the inside, then there are two options. The first option is to make 2 air gaps between the external wall and the material, between the insulation and the cladding (for example, drywall). In this case, TIM with double foil is used.

The second option is to create one gap between the external wall and the insulation, for which material foiled on one side is used. The foil is turned indoors.

Roof insulation

Reflective TIMs mounted on the roof provide not only thermal but also vapor insulation. The under-roof space is also protected from moisture.

Reflective film is especially effective when insulating the ceiling of a bathhouse.

Piping and ventilation

Pipes require insulation with double-sided foil. If the pipes have a diameter less than 159 mm, then there is no need to create an air gap between the TIM and the pipe. If the pipes have a larger diameter, then a gap is required. The air gap is arranged as follows:

- The first option is to attach rings made of foil film to the pipe with a distance of 300-400 mm from each other. And on top of the rings the pipe is wrapped with insulation;

- the second option is to lay wooden blocks with a cross-section of 10 by 10 mm or 20 by 20 mm along the pipe, after which insulation is wrapped on top of them.

The joints must be sealed with aluminum tape. Insulating ventilation ducts will eliminate heat loss and provide sound insulation.

How to insulate heating pipes - a simple answer to a complex question

For the heating system to be effective, insulation is required not only by the design of the house or apartment, but also by the piping system. Insulation work should be carried out with pipes passing outside the house, under the floor or running through cold rooms. Insulated heating pipes will avoid heat loss, and they are also not afraid of freezing and accidents.

Types of insulation materials

The main widespread materials for pipe insulation are:

- foamed polyethylene;

- mineral wool;

- polyurethane foam;

- expanded polystyrene;

- paint insulation.

Let's consider these options in more detail.

Polyethylene

Foamed polyethylene is a soft material. The insulation is easy to use; you can simply cut it to create the necessary pieces.

It is held together with construction tape, the joints are hidden by a thicker strip of polyethylene.

This is what foamed polyethylene looks like

Mineral wool

Mineral wool is an excellent material that has a low degree of thermal conductivity and is also non-flammable. It is widely used in pipeline insulation. The main disadvantage of mineral wool is its high cost.

The advantage of mineral wool is its durability

Polyurethane foam

Heating pipes can be insulated with polyurethane foam. This insulation is installed by spraying the composition.

A man sprays in a special suit

The sprayed mass turns into a hard and durable material that can protect pipelines from heat loss.

This type of insulation should not be exposed to sunlight. If polyurethane foam is used outdoors, it must be protected by wrapping it with roofing felt or aluminum foil.

Expanded polystyrene

Expanded polystyrene is represented by two shells that follow the shape of the pipe. Fastening is carried out using special grooves on the insulation structure.

It is recommended to additionally fasten the joints with glue or other materials during installation.

In the photo - polystyrene foam

Special paint

Insulation can be done with special heat-insulating paint.

A layer of such insulation can replace other materials. The paint is resistant to high temperatures, its use does not require room ventilation, and is an environmentally friendly material.

Paint is an excellent solution for insulating heating pipes in an apartment. It does not take up much space and does not require specific conditions.

How to insulate heating pipes in the floor?

The "Warm Floor" system is often used in private homes. It makes no sense to completely insulate such pipes, since residents must receive heat from the floor.

Here the bottom is insulated under the pipes so that heat does not escape into the soil. It is necessary to use the basic available insulation materials. In the case of conventional heating pipes installed in the floor, you can use the standard insulation method.

We hope that the article was useful to you. We will be very grateful if you share it on social networks with your friends and colleagues. The buttons for this are a little lower.

Advantages of a heat-reflecting screen behind the radiator

- The heat-reflecting element allows you to redirect heat inside the room, rather than heating the exterior walls. Due to this, you can increase the temperature in the room, while saving on heating costs.

- Such radiators can be decorative, that is, thanks to this, nondescript places under the batteries are emphasized.

- Radiators do not become clogged with dust due to suitable cold air from below, and they become easy to clean.

The main advantage is the supply of warm air into the room, as well as the prevention of moisture penetration.

Where can the refrigerator be placed?

When planning to purchase a new refrigeration unit, you need to take care of the location of the device. For a small kitchen, it is recommended to choose a small-sized refrigerator model. It’s better to purchase a separate freezer and refrigerator. In this case, one part can be placed on the work surface, and the other in any free space in the kitchen. But remembering that the refrigerator cannot be located near a heating device, it is prohibited to place it near the oven.

A good option for small kitchens is to purchase built-in appliances, shown in the photo. This will save free space and protect equipment from heating and rapid breakdown.

Built-in refrigerator in the kitchen interior

If the kitchen is very small, and it is not possible to place a refrigerator in this room, you can consider placing large equipment in the pantry or hallway.

Heat-reflective polyethylene foam screen

Substances have different abilities to conduct heat.

To prevent energy consumption, the heat-reflecting screen must have low thermal conductivity - no higher than 0.05 W/(m*K).

Heat-reflective polyethylene foam screen

It is not recommended to use structures made of flammable substances with a loose structure indoors.

For example, mineral wool, which releases formaldehyde and microscopic dust, is not suitable for the screen.

Although its thermal conductivity coefficient is suitable - 0.039 W/(m*K).

Heat-reflecting screens made of insulating materials based on polyethylene foam have proven themselves to be the best:

- penofol,

- Porilexa,

- isolona,

- stizol,

- tepofol.

They are hypoallergenic and safe for human health.

The thermal conductivity of different types of polyethylene foam ranges from 0.029 to 0.032 W/(m*K).

Four millimeters of such a barrier will retain as much heat as 10 centimeters of mineral wool.

For insulation between the wall and the heating device, a layer of 3-5 millimeters is enough.

Mandatory condition: the heat-insulating screen behind the radiator must be duplicated with aluminum.

Operating principle

There are several main ways to transfer heat from one coating to another:

- thermal conductivity, which is the ability to conduct heat;

- convection, during which heat is transferred through the air;

- radiation associated with the release of heat waves by heated bodies.

These processes are associated with heat loss, which can reach several tens of percent. To maximize the thermal insulation effect, you need to reduce them. This can be done using heat-reflecting screens with a foil surface. This type of insulation works according to all the principles of heat transfer and inhibits heat loss processes.

Why do you need foil?

The coefficient of reflection of thermal radiation of polished aluminum is higher than that of other metals.

This means that maximum heat will return inside the room.

You should not use screens with a double-sided metal backing.

The layer of foil on the side of the cold wall does not carry a functional load - it simply has nothing to reflect.

Unscrupulous sellers in construction markets deceive customers by talking about new metallized coatings with fantastic characteristics.

These are fairy tales.

Any polished metal refracts heat rays, but the reflection coefficient is negligible and does not affect thermal efficiency.

The cost per square meter of a thermal reflective screen with aluminum foil is more expensive than with a metallized film.

The difference is small - 5-10 rubles.

Pros of a heat reflective screen

Important Features

By choosing modern material, the owner of the premises receives certain advantages. They are largely due to the high characteristics of the insulator itself.

Gaps between the film can be sealed with aluminum tape

When using this solution during the cold season, heat loss is eliminated. In summer, there is no excess thermal energy in the rooms of the building. As a result, a small amount of resources has to be spent on maintaining an optimal microclimate. Reflective insulation works on the principle of a thermos, preventing the penetration of thermal energy along a given vector.

One of the features of foil insulation is its complete waterproofness. This statement is especially true for models made from polyethylene foam. Aluminum foil is not subject to combustion. Therefore, the use of such a layer together with foam plastic or foamed polyethylene provides increased fire safety.

Read also: about non-flammable fireproof insulation.

In terms of physical parameters, reflective insulation has the same properties as the base layer. The material that is created on the basis of foamed polyethylene has the smallest thickness. Models made from mineral wool with the addition of a layer of foil are thicker.

How reflective insulation behaves in fire:

Advantages and disadvantages

Any material used in the construction industry becomes popular if it has a set of unique positive qualities that are in demand among consumers. In the case of reflective type insulation, there is no shortage of them.

Experts highlight the following advantages:

- The material meets hygienic standards, since the main components in its production are polyethylene and foil.

- This solution is able to reflect up to 97% of thermal energy.

- Polyethylene foam, which contains air bubbles in its structure, allows for additional thermal resistance.

- High fireproof properties. Experts classify the material as highly flammable.

- Rolls of reflective insulation are lightweight and compact in size. Therefore, there are no problems with storage, they are convenient to transport.

- When using material to insulate surfaces, heating costs are reduced. The cost savings for the owner of the structure are much higher than with other solutions.

The main disadvantage of reflective insulation is its softness. After installation, finishing work is not carried out using plaster and ordinary wallpaper. Another disadvantage is that easy fastening is only possible when using materials with an adhesive backing.

Other models must be installed using a suitable fastening compound. When a material is nailed to a surface, it reduces its thermal insulation properties. When insulating facade walls, it can only be used as an additional layer, acting as a protection against moisture and reflecting heat.

Pros of a heat reflective screen

The heat-reflecting screen behind the radiator solves two issues:

- increases heat transfer - the main goal,

- reduces heat loss.

All this at minimal cost.

Areas behind heating appliances get hotter than others.

Being an additional insulation, the screen restores their thermal conductivity along with the rest of the wall.

The idea is not new.

It has been tested in practice many times and discussed in specialized literature.

The effectiveness of heat-reflecting screens is indicated by

- Umnyakov N.P. – reference guide “How to make a home warm” and

- German engineer Inolf Tiator is the author of the manual “Heating Systems” (original title “Heizungsanlagen”).

In their opinion, a heat-reflecting screen behind the radiator can reduce the heat loss of a 0.51-meter thick brick wall by 35%.

Disadvantages of a heat-reflecting screen

Materials and designs of gratings

There are a lot of design options for decorative fences and materials for their manufacture. For example, when finishing and decorating the load-bearing surfaces of an apartment or house using sheets of dry plaster (plasterboard, etc.), owners can hide heating devices behind screens made of these materials. However, more often grilles for heating radiators are manufactured industrially. Such fencing products have a more attractive and varied design and façade perforation pattern. Gratings are classified according to the types of materials used:

- made of metal;

- made of wood;

- from fiberboards (chipboard, MDF, fiberboard);

- from sheet glass, special types of tempering;

- from plastic materials;

Indoors, radiator batteries can be located in different ways: to be deeply recessed in window sills and other niches, to protrude up to half from such niches, to be installed or hung on the wall surface, protruding outward. Screens for masking such radiator installations are generally divided into the following design groups:

- attached structures of perforated screens, having a box-like shape with sides and a table top, are used to hide the heating device against the wall;

- a flat-shaped screen panel with perforations, without side walls and an upper table top, installed in the plane of the outer wall of the niche, covers a battery of radiators deeply recessed in such a niche;

- perforated design of the hanging screen for masking radiators in window sill niches, helps to hide heating devices installed flush with the plane of the wall or slightly protruding beyond it. The designs of such hanging grilles may have special covers.

Natural wood never goes out of style

Screening structures made of natural wood are very popular. True, this material is used more for radiator grilles made to order according to individual sizes and designs. In this case, the characteristics of the type of wood used, its resistance to warping and drying out under the influence of humidity and temperature changes must be taken into account. The use of protective coatings can improve the durability of the material, taking into account operating conditions, and increase the duration of trouble-free operation. The design of wooden gratings, openings in the façade, installation height and other features must take into account the low thermal conductivity of the material. The cost of such screens and boxes varies over a wide range, taking into account all the listed nuances. But their indisputable advantage is environmental cleanliness and naturalness. Even the simplest serial prefabricated wooden structures easily decorate the interior of the simplest room, making it more comfortable and warm. In small rooms, attached structures often serve as furniture. As for more expensive and exquisite carved products, their use is allowed by almost all the most expensive and luxurious design styles.

Practicality and efficiency of metal gratings

The most practical and common are gratings made of metal. As a rule, the front part of a metal structure is made with perforation. Its holes can form the most bizarre, sophisticated and intricate patterns. The advantage of metal shielding structures is the high thermal conductivity of the material. When the temperature of the heating device increases, the metal does not block the resulting IR thermal radiation; for this, the inner surface is painted black. On the outside, such a grille can have a high-quality coating of any desired color. Metal products do not emit harmful substances, like plastic, and do not dry out or warp like wood. A thin-walled box or screen can be easily hung or installed in a niche, without requiring special skills and knowledge. Made from forged metal, lattice or fencing, they look impressive and rich. Often, highly artistic grilles are made for individual orders, combined from metal and wood, metal and glass, etc. However, the cost of such works is high.

Disadvantages of a heat-reflecting screen

The area behind the radiator is no more than 5% of the entire area of the external wall of the room.

The main heat losses occur through infiltration and windows.

Against this background, the improvement in heat transfer over an area of half a meter is negligible.

But if you add up the reduction in heat loss throughout the entire building, the amount of savings will be significant.

For uninsulated walls with low thermal resistance, a heat-reflecting screen is useless.

Heat losses are so large that improving heat transfer in an area of 0.5 sq.m. It won't even be noticeable.

Heating system inspectionfrom RUB 15,000.

Tasks and materials

Most often, grilles are installed on heating radiators for decoration - not all heating devices look attractive, but the grilles are sometimes made very beautiful. The second task that battery screens often perform is to cover sharp and hard edges. This is relevant in families with children, especially if old-style cast iron radiators, the “accordion” type, are installed. Their shape is dangerous, and their appearance is unattractive; they would only be suitable in loft-style rooms.

Grates for heating radiators are made from different materials:

- Metal screens for batteries are produced in large quantities. They are made from thin sheet steel, which is then coated with paint. For the most part, they don't cost much, but they also look average. The service life depends on the quality of the paint. Powder enamels are preferable. They last longer, maintaining their attractiveness for decades. From the point of view of the effect on heating, metal screens for radiators are the best choice. The metal heats up quickly, and then it begins to radiate heat. So the option is inexpensive (usually) and does not greatly affect the temperature in the room (if there is perforation).

- Forged grilles are very beautiful. But the forging is too delicate, so some kind of background is required, and it is often made contrasting in order to highlight the forged elements more clearly. To ensure normal air circulation, it makes sense to make the “background” from a perforated metal sheet.

- Wooden grilles and screens. Wood has always been and remains a premium material. The high plasticity of the material allows them to be made in different styles and shapes. And although there are inexpensive products made from wood, they look very good. But, as mentioned above, a radiator covered on all sides with wood transfers little heat to the room.

- MDF and HDF. For production, laminated sheet materials are used. Staz should say that no binders are used in the production of MDF and HDF. The softened wood fibers are pressed, releasing lignin, a natural binder found in wood. Lignin is what glues fibers together. So both of these materials are absolutely safe. While we know products made from MDF more or less well, HDF is an unfamiliar material for many. It differs from MDF only in the pressing conditions. It is molded under higher pressure, as a result it is very thin (3-4 mm), but more dense and uniform. HDF holds its shape well, which is why openwork grilles for heating radiators are often made from HDF. From the point of view of their effect on heating, they are slightly better than wood - the layer is thinner, and there are usually more perforations.

- Plastic. Plastic products are most often used in bathrooms and toilets. This material is the most hygienic; it can be washed an unlimited number of times. For production, heat-resistant plastic is used, which is not afraid of heating up to 60-80°C. If the grill slats are installed at an angle, as in the photo, the heating will work efficiently. Air flows through the cracks unhindered. It all depends on how the lid is made.

- Glass screens for radiators appeared several years ago. They are not ideal from a heating point of view, but they have an attractive appearance. They are made from special tempered glass, frosted or patterned.

Used in the manufacture of decorative grilles for radiators and more exotic materials. For example, bamboo and rattan. Such products are more demanding for interiors and are rare.

Rattan screen on wooden frame

There are also combined grilles. Most often there is a wooden frame on which some kind of decorative mesh is stretched. Bamboo and rattan wickers are most often attached to such a frame. MDF and HDF panels are usually mounted on a wooden frame.

Installation recommendations

The screen is mounted on the wall behind the heating device.

The reflective layer turns towards the heat source.

It is important not to allow the radiator and foil to come into contact so as not to interfere with heat transfer.

Russian manufacturers consider a gap between them of 1-2 centimeters sufficient, foreign manufacturers – no less than 4-6.

The air gap is part of the thermal insulation barrier.

The thermal conductivity of air depends on temperature and ranges from 0.0259 to 0.0915 W/(m*K).

There is no point in installing a heat-reflecting screen behind the radiator if it is mounted close to the wall. Insulation pressed end to end will actively collect dust, but will not affect convection in any way.

Ideally, a gap between the wall and the heating system should be provided at the design stage.

Then you will have room to maneuver.

Recommendations for installing thermally reflective screens

Installation stages

The most reasonable thing is to provide for the installation of a heat-reflecting screen at the construction stage - after rough finishing, before installing the heating.

If the repair is completed and the radiator is in place, you will have to remove it.

The size of the screen must correspond to the working surface of the heating device.

Then it will be invisible and will not spoil the interior.

In production areas where aesthetics are not important, it is worth increasing the area by 10 percent to ensure maximum reflective effect.

The wall under the window is cleaned of dirt and crumbling plaster, defects are puttied, irregularities are removed with sandpaper.

You can start installation.

The heat-reflecting screen behind the radiator is attached with wallpaper glue, “liquid nails” or furniture nails.

If there is enough space, a more reliable option is a lattice base made of thin wooden slats.

Additionally, we obtain a layer of air between the wall and the thermal insulation sheet.

It will have a positive effect on heat transfer.

The radiator returns to its place.

It is important to adjust the position of the device so that a distance of one and a half centimeters (minimum) is maintained between the foil covering and the back side.

If possible, make the gap larger.

The heat-reflecting screen does not require special care.

Unusual decoration

Following standards is not always the best solution, especially if you are an adherent of an original approach to everything. You can simply and easily close a heating radiator using somewhat unusual approaches. You just have to show your imagination, and the batteries will be hidden in a unique way.

- Battery-fireplace. This is a pretty interesting idea. First, the battery is covered with a mesh screen. Now we take several different picture frames. We will place one in the front part and secure it. We cut the other into pieces to decorate the top and sides. You can put a red backlight behind the screen, and install fireplace accessories next to it for authenticity.

- Frame. You can use a picture frame to decorate radiators. How? You can cover it with fabric and secure it like a regular screen. It is better to take the same fabric as is present in the interior.

- Blinds. You can use blinds to cover the radiators. These blinds are hung on a metal frame above them.

- Drywall. This is a truly universal material that craftsmen love so much - after all, almost anything can be made from it. And if you try, that’s all. Therefore, you can give free rein to your imagination to hide the batteries and create something original here.

- Curtains, screen, painting. If you do not have enough time or finances to implement the above methods, then you can sew the most ordinary curtains. They will be the ones who will be able to temporarily cover the batteries until you come up with something more serious. You can also put a screen. Or you can simply paint the radiators to match the color of the interior.

Connection

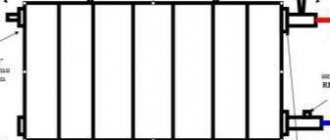

Due to the connection scheme, heat transfer may deteriorate, losses sometimes reach 25%. Connection is possible in several options.

- Lateral - the outer sections will be colder than the central ones. The more segments are installed, the worse the outer ones heat up.

- Diagonal. If the water supply is from below and goes into the upper pipe, then the radiator does not warm up completely. The correct method would be in which the liquid is supplied from above and goes down; this scheme is recommended for long samples (more than 15 segments).

- Bottom – heating distribution occurs evenly. In addition, this variety has the most aesthetic appearance, since the feeding elements are almost invisible.

You can correct the situation with unheated areas without running additional pipes around the battery by installing plugs in place of the radiator plug in front of the last section at the top or bottom (depending on which connection is used). Then we get a diagonal scheme with effective heat transfer.

To learn more about different connection methods and compare them, as well as how to increase the efficiency of the radiator, watch the video.

Preparing to create a drywall box

Using drywall you can easily and quickly hide a heating radiator. Not everyone knows how to cover a battery with drywall with their own hands. To do this, you must have minimal skills in repair and construction work and follow the instructions.

To make a plasterboard box you will need the following:

- measuring instruments: corner, tape measure, ruler;

- marker (pencil);

- heat-resistant plasterboard (thickness 12 mm);

- liquid nails, dowels, screws (for fastening);

- level;

- metal profiles of two sizes (27x28 and 60x27);

- screwdriver, pliers, hammer drill, screwdriver;

- serpyanka (construction self-adhesive mesh).

- Before hiding the heating radiators (pictured), you need to choose which installation method the markings will be used for:

- a box when only the radiator itself and 15-20 cm of space outside it are covered;

- wall, when plasterboard covers the entire wall at which the battery is installed, or the hole between the window sill and the floor, if the battery is located under the window.

Profile lathing for the battery box

We attach plasterboard to the profile

The second method requires the use of more materials.