For a stand-alone water heater, you will need two items: energy for heat and water. In terms of energy, there are three main sources that can be used to heat water:

- Energy of sun.

- Natural gases.

- Burning wood.

Using wood to heat water is convenient and cheap. You can collect fuel in your home area, even if there is no company nearby that will supply the resource to your home.

The option is primitive, since you will have to keep the fire going all day to have access to the benefits of modernity. It is also worth considering that resource consumption in winter will be very large.

The use of solar energy is available only in areas where it is constantly available. In Russia and the CIS countries, this type of energy is little used due to climatic conditions. What remains is gas, which is everywhere, even in the most remote corners.

Boiler assembly

The unit must be assembled in the following sequence:

- First, the body is made by attaching the side walls and frames of the openings to its bottom with short seams. The bottom frame of the ash pit opening is the bottom of the housing itself.

- From the inside, corners are welded to the body, on which the firebox grate pan (grid) will be placed.

- Now you need to weld the grill itself. The corners of which it consists must be welded with the outer corner down, so that the air coming from below is evenly distributed over the two inclined surfaces of each corner.

- Next, a firebox with a heat exchanger is welded to the corners on which the grate is laid.

- The doors of the firebox and ash pan are cut from steel sheet. From the inside they are framed with a steel strip laid in two rows, between which an asbestos cord must be laid.

Next, a smoke exhaust pipe and an air duct with a flange for installing a fan are welded. The air duct is led into the boiler through a hole in the middle of the rear wall just below the grate.

Now we need to weld the mating parts of the door hinges and several 20 mm wide brackets to which the casing will be attached to the boiler body.

The heat exchanger must be lined on three sides and on top with basalt wool, which is tightened with a cord.

Since the insulation will be in contact with hot surfaces, it should not contain phenol-formaldehyde binders and other substances that emit toxic volatile substances when heated.

The sheathing is screwed to the brackets using screws.

An automation controller is installed on top of the heat generator, and a fan is screwed to the air duct flange.

The temperature sensor must be placed under the basalt wool so that it is in contact with the rear wall of the heat exchanger.

If desired, the boiler can be equipped with a second circuit, allowing it to be used as a water heater.

The circuit has the form of a copper tube with a diameter of about 12 mm and a length of 10 m, wound inside the heat exchanger on flame tubes and brought out through the rear wall.

Principle of operation

The operating principle of a gas heating boiler is quite simple. Through the return pipeline from the heating network inside the house, cooled water is supplied by a circulation pump to the input of the heating circuit heat exchanger.

At low coolant temperatures, an electromechanical valve opens, supplying fuel to the injector. The igniter ignites the gas and the combustion process begins. The boiler constantly operates on the heating circuit.

The DHW circuit begins to function when the tap on the mixer is opened. This thermal scheme of the boiler operation in the summer makes it similar to the operation of a conventional gas water heater.

How does a condensing boiler work?

The name “condensing” boiler units was acquired due to the fact that they implement a technology for obtaining additional thermal energy by modifying the aggregate state of condensate from steam located in the flue gases.

Operating principle of a condensing boiler

During the combustion of natural gas in a condensing gas boiler, water vapor is created, which in traditional units evaporates and is released into the atmosphere through a chimney.

Experts have developed an additional device in the boiler - a water economizer, in which steam in the flue gases turns into condensate, while releasing additional heat, which is transferred to the coolant in the economizer.

The temperature at which the condensate is converted is called the dew point of +55 C, and the technological process is called condensation. This temperature corresponds to the parameters of the return network water entering the boiler from the heating system. If it is more than +60 C, then the condensing boiler will work like a traditional device with low efficiency.

In addition, condensate creates a very aggressive environment containing acids. Therefore, its collection and disposal will require a special neutralization system, which the liquid must undergo before it can be discharged into the city sewer.

Condensing boiler. Photo source: allbuildingtips.com

In general, a convection gas boiler is an expensive device, however, fuel savings of up to 20% allow it to pay for itself within five years.

The principle of operation of a double-circuit gas boiler

The operating principle of a double-circuit boiler unit is designed for 2 thermal modes:

- heating;

- DHW.

In heating mode, the operation of the boiler is practically no different from a single-boiler boiler. Starting the burner involves a fairly long start-up period in order to increase the temperature in the heating circuit to operating levels. When the main mode is reached, the flow of fuel to the burner stops.

The internal air temperature sensor allows you to automatically regulate the temperature and sends a signal to open the gas when the permissible level decreases.

Modern double-circuit Baksi boilers, in addition to an internal temperature sensor, are equipped with a special weather-dependent automatic system that regulates the operation of the boiler based on the outside air temperature outside the building window. The burner increases the temperature of the heating water, the circulation of which through the pipelines of the heating system is ensured by a circulation pump. A three-way valve built into the system switches the movement of coolant through the heating circuit or into the DHW system.

Today's double-circuit heating boilers are equipped with automatic control and safety systems. In emergency situations, flame and draft sensors are capable of shutting off the gas supply to the boiler through an electromagnetic valve, thereby preventing the creation of an increased concentration of gas in the boiler room.

This mechanism not only shuts off the gas supply, but also informs others about the danger using sound and light alarms, and also starts exhaust ventilation to reduce the content of methane and carbon monoxide in the air.

Selection of heating equipment design

The combustion processes in furnaces and heating boilers are identical, but the units have differences in functionality, since the heating boiler is used not only for local heating of the zone, but also for heating the coolant transported through the heating system of the house. To ensure uniform heat transfer, it is necessary to consider the placement of the heat exchanger and maintain constant combustion of the fuel to maintain the temperature of the circulating coolant. When choosing a boiler design, you need to decide on the type of combustion.

There are two options - upper and lower combustion types:

- Bottom burning. These are units with a loading door at the top of the combustion chamber, but the combustion process itself occurs from below. It turns out that the top layer of fuel moves down as the lower layers burn. Ventilation in such boilers depends on the type of model and can be carried out from the bottom up using a fan or naturally due to draft. The second option does not require connection to the power supply network, requires a smaller volume of fuel loading, but is not highly efficient.

- Top burning. The door for loading fuel is also located in the upper part of the combustion chamber, but the units must be equipped with forced draft with the direction of air movement from top to bottom. The smoke moves down the furnace, mixes with air and burns, simultaneously heating and drying the fuel laid out in the lower layers.

It’s easier to make a wood-burning boiler with your own hands with a bottom combustion option, where you can do without a fan, which is needed to generate forced draft. There are no particularly complex components in such units, so the manufacturing and assembly process is significantly simplified.

Now, once and for all, without any registrations or SMS, you can click on the active link and continue to enjoy the game and place bets on your favorite team in a convenient mobile application.

The second nuance that you need to pay attention to is the combustion mode. There is a difference between normal mode and pyrolysis

The second option involves the decomposition of solid fuel into its components and the afterburning of all components. This means that not only coal or wood will burn, but also the gas released during the combustion process. This function reduces fuel costs and increases equipment efficiency, but you will have to take into account the installation of a second combustion chamber (afterburning), which will increase the size of the boiler and require the purchase of more materials.

You also need to take into account the type of fuel - coal, firewood, pellets. It all depends on the availability of raw materials, and the quality and duration of combustion directly depends on the power and efficiency of the constructed unit.

Types of hydrogen heating boilers and how to make them yourself

The choice in favor of more complex types of equipment can be made by a master with experience, but for a beginner it is better to take simple diagrams of understandable designs. If the calculations are made correctly, the required chamber volume is selected and ventilation is taken into account, then even the simplest unit will cope with space heating.

Manufacturing process

We manufacture the boiler body:

- We take pipes with a diameter of 150 and 130 cm, put them into one another and connect them together using a ring from a 25x25 mm angle.

- We cut a circle Ø 45 cm from a sheet of metal and weld the bottom of the inner pipe. You should get a barrel Ø 45 cm around which a water heating circuit 2.5 cm wide is welded.

- At the bottom of the “barrel” we cut a rectangular hole 15–16 cm wide and 8–10 cm high. This will be the ash pan door. We weld in the ash pan hatch, attach a door, which we will equip with hinges and a latch.

- In the upper part of the “water jacket” we cut a rectangular hole for loading fuel (the dimensions should be sufficient to make it convenient to load firewood). We weld in the loading hatch, equip the door with hinges and a latch. It is better to make double doors by laying an asbestos gasket between the sheets of metal and sealing the contact areas with asbestos cord. This will reduce heat loss from the boiler.

- We also weld an outlet pipe into the upper part of the boiler, through which completely burnt gases will exit into the chimney.

- At the top and bottom of the water jacket we weld pipes Ø 40–45 mm for connection to the heating system. We cut the thread.

- We wash all the welds well and press the boiler jacket with a pressure of at least 2 kg/cm2. We carefully check the quality of the welds and, if necessary, eliminate flaws.

Now let's start making the air distributor.

- From a sheet of metal we cut out a circle with a diameter 2–3 cm smaller than the inner Ø of the boiler, approximately 42–43 cm. In its center we cut a hole Ø 5.7–6 cm (along the Ø of the air distributor pipe).

- We insert the air distributor pipe into the hole and connect everything with a sealed seam.

- We weld pieces of a channel or corner in the form of blades onto the lower surface of a metal pancake (you can use an impeller from a fan if the thickness of the blades is suitable).

- At the other end we weld a loop through which the structure will rise and fall and adapt a damper to regulate the air supply to the combustion zone.

The air distributor is ready. We cut out a circle Ø 50 cm from a sheet of metal, in the center of which we cut a hole Ø 7–8 cm. We insert the air distributor into the boiler, thread the upper end of the pipe into the hole and tightly weld the top lid of the boiler. We attach a cable to the air distributor loop with the help of which the distributor will rise and fall through the block.

Long burning pyrolysis boiler assembly

That’s it, the long-burning pyrolysis boiler, made by yourself, is ready, you can start testing. The Stropuva or Buran boilers have the same design, only a little more complex, the reviews of which are very good.

The video shows another version of the boiler with an upper combustion chamber for pyrolysis gases. Here the separation of the fireboxes is clearly visible and even the combustion process itself is demonstrated.

There is another boiler of a similar design and operating principle. It's called "Bubafonya", perhaps you will like it more.

Assembling the heating unit

First of all, the chimney is welded to the 412 mm pancake. Then, temporary stops must be welded inside the housing at a height of 30-35 cm from the combustion hole. It can be wire or fittings. A pancake with a chimney is lowered on top of them.

Main joints

And now the most important point - you need to weld the pancake and the boiler body together. It is necessary to weld the seam on both sides and it must be done efficiently. This joint is the connection between the firebox and the water tank.

Next, a 425 mm pancake is placed on the chimney protruding from the boiler. Here it is necessary to thoroughly weld two joints: between the outer edges of the pancake and the boiler body, between the chimney and the metal circle.

Combustion compartment

The next stage concerns the combustion chamber. On the back side of the chimney, a ready-made grille made of reinforcement is inserted into the housing.

Then, several pieces are cut out from a 25 mm angle using a grinder, which are welded inside the boiler between the combustion hole and the ash pan. These will be the stops on which the grille will rest.

Lower body

And one last thing. It is necessary to weld a 425 mm pancake to the lower edge of the body, weld four legs from a 25 mm pipe with a height of 5 cm to it. Next, weld the hinges on which the firebox door is hung.

Blower valve design

The design can be different: in the form of a regular door, in the form of a gate (this is a damper that moves in the plane of the hole), in the form of a rotary damper with holes in the body. Finished products are sold that are simply welded in place.

You can weld a solid structure with your own hands and attach it to the boiler. Of all the proposed options, the simplest is either a door or a gate.

Where can I buy

You can purchase a water heater as quickly as possible at your nearest specialty store. A good option in terms of price-quality ratio is purchasing from the AliExpress online store. Mandatory long waits for parcels from China are a thing of the past, because now many goods are in intermediate warehouses in destination countries: for example, when ordering, you can select the “Delivery from the Russian Federation” option:

| HYUNDAI Instant Electric Water Heater | Electric water heater TINTON LIFE with temperature display | Stainless steel liquefied water heater |

| 2500W floating electric water heater, for bath, swimming pool | RX-21.3500W instantaneous electric water heater | Kitchen electric water heater HYUNDAI |

Is it worth designing a gas boiler yourself?

Let’s begin our analysis of options for making a gas boiler with our own hands with the fact that the fuel they process is classified as toxic and explosive substances. Gas is highly flammable. The slightest miscalculations in the design and implementation of homemade products can result in serious destruction, damage to health, and loss of property.

Therefore, we do not recommend developing a model of a gas boiler for people who do not have a technical education with a specialization in the design of gas equipment. Yes, often even experienced gas workers will not take on such a project.

The optimal solution is quite reasonably considered to be:

- Converting a solid fuel model into a gas boiler by installing a gas burner in the firebox;

- Improvement of an old but functional unit with a focus on use in a heating circuit. Supplementing the factory model with devices for heating and stimulating the movement of coolant;

- Manufacturing of a pyrolysis boiler - equipment that generates gaseous fuel as a result of processing solid fuel at the initial stage. At the secondary stage, the gas released during the combustion of wood is burned in an additional firebox.

If you still have a desire to thoroughly study the issue and invent a version of a homemade gas boiler for autonomous heating in a private house, get ready for a literal “walk through agony.” You will have to obtain permits and confirmation of the safety of the invention from a number of government supervisory authorities.

An independent craftsman will need:

- Check the boiler for compliance with safety requirements, and then obtain a confirming or refuting document.

- Obtain permits from GosTechNadzor, Fire Inspectorate of the Ministry of Emergency Situations and GorGaz.

- Apply for a patent and a certificate allowing one-time or continuous production.

This list, although not numerous, is quite impressive and can discourage any folk from inventing documents. However, it will not be able to quell the desire to modernize an existing unit by installing factory-assembled burner modules. The improvement easily combines operational safety with increased efficiency.

The most important working part in gas equipment is the burner. Installing it will turn any boiler into the type of coolant and hot water heater we require for sanitary purposes.

The ignited igniter heats the working part of the thermocouple, which eventually begins to generate current. The charge enters the gas valve coil, it acts as an electromagnet and magnetizes the washer, which closes the path of gas

Depending on the method of supplying the combustion air required for combustion to the combustion chamber, burners are divided into two main groups:

- Atmospheric. They are installed in open combustion chambers of atmospheric boilers. In them, air is drawn freely from the room in which the boiler is located.

- Fan (also known as blower). Such models are equipped with closed combustion chambers into which air is forced in a forced manner and captured from the street. To remove flue gases, they require a coaxial chimney and a fan.

Blowing designs are too complex for home creativity. They are easier and more profitable to buy. After all, purchasing all the adjustment and safety devices for operating a fan burner can be more expensive than purchasing a module ready for installation.

It is also advisable to purchase an atmospheric burner, but you can make the simplest version with your own hands. Below we will consider how and from what it can be assembled.

Recommendations for the selection and installation of pipes

To install the heating of a private house with your own hands, you first need to decide which pipes to choose for this. The modern market offers several types of metal and polymer pipes suitable for heating private homes:

- steel;

- copper;

- stainless steel;

- polypropylene (PPR);

- polyethylene (PEX, PE-RT);

- metal-plastic.

Heating lines made of ordinary “ferrous” metal are considered a relic of the past, since they are most susceptible to corrosion and “overgrowth” of the flow area. In addition, it is not easy to independently install such pipes: you need good welding skills to make a hermetically sealed joint. However, some homeowners still use steel pipes to this day when they install autonomous heating at home.

Copper or stainless steel pipes are an excellent choice, but they are too expensive. These are reliable and durable materials that are not afraid of high pressure and temperature, so if you have the means, these products are definitely recommended for use. Copper is joined by soldering, which also requires some skills, and stainless steel is joined using dismountable or press fittings. Preference should be given to the latter, especially when the installation is hidden.

Advice. For piping boilers and laying pipelines within the boiler room, it is best to use any type of metal pipes.

Heating made from polypropylene will cost you the cheapest. Of all types of PPR pipes, you need to choose those that are reinforced with aluminum foil or fiberglass. The low price of the material is their only advantage, since installing heating from polypropylene pipes is quite a complex and responsible task. And in appearance, polypropylene is inferior to other plastic products.

The joints of PPR pipelines with fittings are made by soldering, and it is not possible to check their quality. When the heating was insufficient during soldering, the connection will certainly leak later, but if it is overheated, the melted polymer will half block the flow area. Moreover, you won’t be able to see this during assembly; flaws will make themselves known later, during operation. The second significant drawback is the large elongation of the material during heating. To avoid “saber” bends, the pipe must be mounted on movable supports, and a gap must be left between the ends of the line and the wall.

Recommendation. Do not embed polypropylene products into floor screeds or wall strobes. This is especially true for pipe joints.

It is much easier to make your own heating from polyethylene or metal-plastic pipes. Although the price of these materials is higher than polypropylene. For a beginner, they are the most convenient, since the joints here are made quite simply. Pipelines can be laid in a screed or wall, but with one condition: connections must be made using press fittings, not collapsible ones.

Metal-plastic and polyethylene are used both for open laying of highways and hidden behind any screens, as well as for the installation of water-heated floors. The disadvantage of PEX pipes is that it tends to return to its original state, which can cause the installed heating manifold to appear slightly wavy. PE-RT polyethylene and metal-plastic do not have such a “memory” and easily bend as you need. More information about choosing pipes is described in the video:

The main types of homemade boilers

If you are going to make a long-burning boiler with your own hands, then you will definitely need the information from our review. In the following sections we will tell you how to make a heating unit of one design or another yourself, give several of the easiest schemes, and publish information about the most common long-burning boilers

Let's focus on the last question for now.

The time has come to consider the most current options for long-burning boilers, which we can assemble with our own hands at home. They will all eat wood. As for coal, it is more difficult to obtain, and it also leads to high temperature loads on heating units. In the following sections we will provide drawings of long-burning solid fuel boilers and provide explanatory information.

Long burning mine boiler

We can make the simplest mine boiler with our own hands. It is implemented according to a bottom combustion scheme. The basis of the unit is a capacious loading chamber, which is often called a shaft. Having a vertical design, it allows you to accommodate a large amount of firewood. As they burn, they fall down, and the combustion products are sent through the grate into the ash pan.

If we look at the diagram of a shaft furnace (boiler), we will find that the flame is raging not in the shaft at all, but in the adjacent chamber, from where the resulting heat enters the fire-tube heat exchanger. And the remaining thermal energy is sent to the chimney. The combustion here is long and is determined by the volume of the shaft - after loading a large amount of firewood here, you can safely go to bed.

Pyrolysis boiler

Let's see how a pyrolysis boiler works and how to make this unit with your own hands. The easiest way to explain the operating principle of this unit is to use the example of a potbelly stove. Here we see a volumetric combustion chamber that realizes long-lasting combustion. The resulting combustion products are sent to the afterburner chamber, into which secondary air is supplied. As a result, a large amount of heat is generated. All we have to do is retrofit the potbelly stove with a fire-tube heat exchanger.

There are dozens of drawings of long-burning wood-burning boilers built on the pyrolysis principle of operation. They differ in the location of combustion and afterburning chambers, the presence and absence of blower fans and automation, as well as methods for adjusting the intensity of the wood fuel combustion process. But in general, their operating principle is the same.

Boiler-furnaces Bubafonya

Bubafonya is a stove, and its modification is a water-heating wood-burning boiler with air supply from above, through a pressure piston. We have already written about such stoves more than once in our reviews, now it’s time to talk about units with a heating circuit. To implement the circuit, we can use three schemes:

- Installing a heat exchanger on a chimney is the easiest option;

- Build a continuous water jacket around the boiler body;

- Scald the body of the unit with the pipes through which the coolant will circulate.

Which scheme to choose is up to you. By the way, Bubafonya boilers, due to their spacious chambers, will help to realize long-term combustion lasting up to 24 hours or even more.

Long-burning boilers Bubafonya operate on wood and have an upper combustion scheme.

Boiler-furnaces Buleryan

Initially, Buleryans were (and are) convection-type ovens. They are equipped with powerful convectors, which allow you to warm up a large room in literally 20-25 minutes. Having originally appeared in Canada, these stoves reached Russia, which also boasts a harsh climate (true for some regions). Craftsmen turned stoves into boilers, having worked a little on the design of convectors - now not air, but coolant circulates through them. True, Buleryan boilers cannot boast of long-lasting combustion, since they do not have the largest combustion chambers. Some of them have the property of burning for up to 10-12 hours, some – a little longer. But you still can’t count on 24 hours. But they are characterized by high efficiency and the ability to quickly transfer heat to heating systems.

Electric boiler

This invention is not new and does not relate to space technology. Be that as it may, the essence is the same - to heat the coolant in the heating system.

We have a house, and there is also a water heating system in the house. But there is no centralized gas supply to install a gas boiler. It remains to decide how to heat this coolant. Alternatively, it could be a homemade electric boiler.

And this is a good option, since such equipment is easy to place and receive heat if there is a power supply.

Positive sides

In addition, there are other positive aspects:

- Easy to install.

- Compact sizes.

- Ergonomics.

- No special permissions are required for installation.

- Environmentally friendly - no harmful emissions into the atmosphere.

- Silence.

- Does not require an additional hood or chimney.

- There is no need for additional fuel storage facilities.

Meanwhile, there is nothing difficult here. Heating elements are placed in a special metal container. The tank is connected to the heating system. The coolant is usually ordinary water.

It is this water that is poured into the system through a metal container. All that remains is to apply electric current to the heating elements.

When exposed to current, the heating blocks become hot and transfer their heat to the water. Hot water from the tank rushes through the pipes into the heating radiators, heating the entire house.

Everything seems simple!

This is the heating circuit in principle.

It can be supplemented with such innovations as:

- system monitoring and control device,

- expansion tank,

- circulation pump.

- automatic water heating regulator.

Flaws

There are disadvantages, how could we live without them? These include:

- Dependence on power supply.

- Scale that forms on heating elements leads to a decrease in their efficiency.

- Dimensions of the expansion tank - the higher the power, the more space there is for placing heating elements.

Combined boilers for summer cottages

Boilers for summer cottages can heat up to two hundred and fifty square meters; they use solid fuel: firewood, briquettes, coal and electricity.

Combination boilers are made of metal, the body thickness of which is usually three centimeters. The boilers are painted with white powder paint, suitable for a summer residence. They work on wood. Power three, or 6 kilowatts. Easy to control - via the Remote Control. The remote control regulates the room temperature remotely. Boilers for summer cottages are easy to install, and their weight is up to 110 kilograms. The chimney is made with adapters. Do not forget to make a concrete foundation of about 100 mm. Cover the foundation with 2-3 mm sheet iron to protect the flooring.

All boilers that operate on solid fuel for heating a dacha have a damper for the chimney, a tray for collecting ash and are equipped with a poker. The firewood door is made of three metal layers, so the door does not get hot. The solid fuel boiler for the dacha is equipped with cast iron and a burner. And the modified ones even have 2 burners, which is very convenient if the boiler is in the kitchen.

Such boilers are very easy to use: they are equipped with a water jacket on four sides, which protects you from the danger of getting burned, since the temperature can be above 85 degrees. This safe device can be installed even in a room or living room.

Attractive appearance, affordable price and ease of installation - these are perhaps the most important advantages of such boilers.

Thus, the above types of heating are perfect for any dacha - the only question is the capabilities and needs of the owner of the house, because everything depends on this.

Subscribe to our newsletter for new materials:

Operation of homemade heating systems

All of the above must be supplemented with a rather important clarification. As we found out, electric boilers for heating a home are not greatly affected by surges in mains voltage. But the load on the home network is quite high. Therefore, for the device to operate, you need to worry about high-quality electrical wiring in advance.

In addition, Russian realities are such that power outages are a frequent and unpredictable occurrence. Hence the conclusion - UPS (uninterruptible power supply) must be installed. It will be able to maintain power to the heater for some time. For rural areas, a gas generator is relevant. This way, autonomy will increase, and the heating system will work until the centralized power supply is supplied.

Experienced specialists note that when installing an electric boiler there are a number of technical requirements:

- Before installing the device, the entire heating system needs careful preparation. In particular, flushing and cleaning of the entire heating circuit is necessary;

- the heating system requires the installation of a complex of safety valves with an air vent;

- It is advisable to make all connections of the boiler to the heating system only from metal;

- the temperature regime during installation work should not go beyond +100 to +40 °C;

- for two-story buildings, it is necessary to take into account the fact that only one heating boiler cannot cope with heating the entire building. The best option is to install one heater, with its own group of radiators, on each floor.

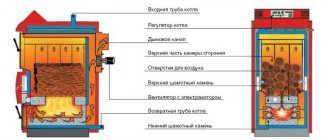

What parts does a solid fuel boiler consist of?

Before you start working on the boiler, you need to understand its operating principle. Main elements of the boiler design:

- The combustion chamber is a chamber into which fuel is placed and where the combustion process occurs.

- The heat exchanger is the main structure of the boiler through which the coolant passes and, after heating, enters the heating system.

- The body is a structure that contains all the components of the boiler.

Independent creation of heating boilers for the home is usually limited to a simple design, but nevertheless has two design options: brick and metal.

Let's consider each option in detail.

Schemes and drawings

Slow burning stove design

Construction of a pellet boiler Drawing of a solid fuel boiler

Drawing with dimensions for creating a solid fuel boiler Drawing of a Viessmann pyrolysis boiler for 25-40 kW Viessmann for 65 and 80 kW Drawing of a boiler for self-production

Slow burning oven

Drawing of a furnace in production

Simple and safe sauna boiler

What is the real efficiency of solid fuel boilers

Manufacturers of heating equipment, in particular solid fuel boilers, offer a wide range of products with different characteristics.

Based on the design of the solid fuel boiler, all products can be divided into the following groups:

- traditional heating units;

- wood boilers with pyrolysis type of combustion (gas generator);

- long burning;

- pellet

A traditional solid fuel boiler, including a homemade one, in appearance resembles a stove or potbelly stove with the most necessary elements - a combustion chamber, a door, an ash pan and a chimney. Using the ash pan, you can regulate the draft by opening and closing the damper. Such designs are considered quite reliable because they do not contain any technological elements, such as temperature sensors or thermometers, an automatic control unit or electronics. In this case, the main design element of a solid fuel boiler is a heat exchanger that transfers thermal energy to the coolant. The heat exchanger can be tubular or made in the form of a container made of solid steel sheets.

There are, however, more complex devices that can also be classified as traditional. They are equipped with baffles and throttle valves to make it easier to regulate the draft, and the hot air travels a greater distance before exiting the chimney. Such partitions significantly increase the efficiency of the boiler, since more thermal energy is transferred to the coolant, and does not just “fly out into the chimney”. You need to understand that boiler efficiency is a very important indicator.

For such boilers, you can use almost any fuel - wood, coal, pellets and even garbage. The main thing is that it is as dry as possible. In terms of performance, boilers of simple designs can hardly claim 50% efficiency, and in most cases it is only 15-20%. The problem is that the fuel burns too quickly, without having time to transfer all the thermal energy to the water in the heat exchanger. As a result, more heat is simply released into the chimney or its excess causes the coolant to boil. For example, firewood needs to be added to the firebox every hour, and coal will last for 2-4 hours, but it still burns with excess energy and large heat losses.

Boiler with pyrolysis combustion of solid fuel

The difference between this design is that solid fuel does not burn in it, as in a conventional one, but if there is a lack of primary air supply, it is “distilled” into wood (pyrolysis) gas, which is burned in a special afterburner chamber when secondary air is supplied to it. Such a presentation can be either natural or forced.

Scheme-drawing of one of the variants of a pyrliz boiler

1 — draft regulator with temperature sensor; 3 - firewood; 4 - bottom door; 5 - grate; 6 — air damper for primary air supply; 7 - ash pan; 8 — grate; 10 — cleaning; 11 - drain; 12 — thermal insulation of the body; 13 — return (coolant supply from the system); 14 — nozzle; 15 — secondary air supply; 16 — chimney damper; 17 - pipe with heated water; 18 — damper; 21 — loading door; 22 - afterburning chamber.

How does a water boiler work?

- samovar-type water boiler. In this design, the fuel burns inside a container with coolant (water). Typically this type of boiler is used in Russian baths;

- water boiler with coil. In it, the coolant flows through the pipes of a heat exchanger laid through the firebox. This type of boiler has a popular variation, in which the coil does not pass through the firebox, but directly behind it - where the combustion products come out.

Remember that home heating boilers require a thermometer to determine the temperature of the water in the system, a pressure gauge to measure pressure, and a valve that is used to relieve excess pressure (if necessary).

Testing, connection to the heating system

After assembling the main part and applying the final seam, it is necessary to check the tightness. Just pour water into it. Gross welding errors will be identified. Deeper lack of penetration will remain unknown and will appear at the most unexpected moment during operation.

To test the heating device, before connecting it to the home heating system, you need to use a pressure test pump. You can create the required pressure and identify design flaws.

Using a pressure test pump, you need to create a water pressure inside of at least 3.5-4 atmospheres. If it does not leak during testing, it will successfully operate at the standard 1.5-2.5 atmospheres of internal pressure.

A pressure test pump is expensive equipment and requires skill to use. It is impractical to purchase just once. It’s easier and more effective to contact a plumber or a specialist who installs heating equipment.

After pressure testing, the test firebox can be installed in the planned location and connected to the heating system of the house. It is necessary to include an expansion tank in the safety group. Safety group - pressure gauge showing the pressure in the system, automatic air release valve, emergency valve.

Start of assembly

What does the design depend on?

The design of the heating boiler is influenced by several conditions:

- cost and availability of materials;

- Type of fuel;

- coolant circulation method.

Heat-resistant stainless steel demonstrates the greatest durability. However, it is this that has the highest price on the market, and its processing is a rather complex task that cannot be handled without special equipment. The same applies to cast iron, which, however, costs much less than stainless steel. Traditionally, for the manufacture of heating boilers, sheet steel with a thickness of 4 mm is used - this option is relatively easy to process and, most importantly, is quite reliable and durable.

To ensure natural circulation of the coolant, it is necessary to use heating circuits and connecting fittings of large diameter, and place the storage tank at a height. If this is not possible, you will have to use a circulation pump - it will reduce the diameter of the pipes. However, the heating boiler pumping system is energy-dependent, which must be taken into account when choosing the design and functionality of the unit.

Recommendations for choosing and connecting radiators

An ordinary homeowner, going to a heating equipment store and seeing a wide selection of different radiators there, can conclude that choosing batteries for his home is not so easy. But this is the first impression; in fact, there are not so many varieties of them:

- aluminum;

- bimetallic;

- steel panel and tubular;

- cast iron

Note. There are also designer water heating devices of a wide variety of types, but they are expensive and deserve a separate detailed description.

Sectional batteries made of aluminum alloy have the best heat transfer rates; bimetallic heaters are not far behind them. The difference between the two is that the former are made entirely of alloy, while the latter have a tubular steel frame inside. This was done for the purpose of using the devices in centralized heat supply systems of high-rise buildings, where the pressure can be quite high. Therefore, installing bimetallic radiators in a private cottage makes no sense at all.

It should be noted that heating installation in a private home will be cheaper if you purchase steel panel radiators. Yes, their heat transfer rates are lower than those of aluminum ones, but in practice you are unlikely to feel the difference. As for reliability and durability, the devices will successfully serve you for at least 20 years, or even more. In turn, tubular batteries are much more expensive, in this respect they are closer to designer ones.

Steel and aluminum heating devices have one useful quality in common: they lend themselves well to automatic control using thermostatic valves. The same cannot be said about massive cast iron batteries, on which it is pointless to install such valves. This is due to the ability of cast iron to heat up for a long time and then retain heat for some time. Also because of this, the rate of heating of the premises is reduced.

If we touch on the issue of appearance aesthetics, then the cast-iron retro radiators currently offered are much more beautiful than any other batteries. But they also cost incredible amounts of money, and inexpensive Soviet-style accordions MS-140 are only suitable for a one-story country house. From the above, the conclusion suggests itself:

For a private home, buy those heating devices that you like best and are comfortable with in terms of cost. Just take into account their features and choose the right size and thermal power.

Installation of an induction heating boiler

The “inductor” consists of a core, a toroidal winding, a high-frequency generator and auxiliary elements. The first one acts as a heat exchanger: when heated, it gives off heat to water or other liquid flowing through the heater. The power wire is located around the core in such a way that eddy currents arising in the metal cause it to heat up. The element is made from a large-section copper conductor.

The winding is connected to a high-frequency pulse generator, through which a current of a given frequency is obtained. The process is controlled by an electronic unit that monitors the degree of heating and can, in the event of an emergency, shut down the device. The heater is covered with heat-insulating material and an external decorative shell. The housing protects the operator from burns and electrical injuries due to possible damage to the insulation.

Important points

The efficiency of a solid fuel heating boiler is always influenced by two factors:

- Design features of the heat exchanger

The larger the thermal contact area, the more energy per unit time will be transferred from the burning fuel to the thermal agent - water.

Options for a homemade heat exchanger in the photo

Horizontal heat exchanger made of profile pipes Horizontal heat exchanger made of sheet steel and profile pipes Homemade horizontal heat exchanger Do-it-yourself steel vertical heat exchanger for a boiler

- Completeness and period of fuel combustion

If the fuel burns inefficiently - it loses pyrolysis gas or does not have time to heat the coolant to the required temperature, there are flaws in the design. Therefore, the calculation and manufacturing process of the latter should be treated with maximum responsibility - after assembly it will be impossible to change it.

Homemade wood boiler: firebox door

The design of the boiler must be reliable and safe, and responsibility for this lies with nothing other than the body. It is made of thick (at least 5 mm) steel, preferably heat-resistant. However, the latter is noticeably more expensive than the usual one, so you should remember that the thicker the metal, the slower it will heat up. This means that in order for a medium-power boiler not to burn your hands and turn the boiler room into a sauna, the boiler body must be about 8 mm thick.

Solid fuel boiler-stove with built-in heat exchanger

The exception is designs with a cast iron top cover, which serves as a stove. The thickness and dimensions of the cast iron sheet will depend on the design parameters of the body and the operating characteristics of the boiler (but not less than 8 mm).

To organize the internal piping system of the boiler, it is necessary to use pipes with a wall thickness of 3-4 mm and a diameter of 50 mm. To ensure the coolant flow, it is necessary to provide for a narrowing (from 50 to 25 mm) of the pipelines in the direction from hot to cold, for example, from the boiler to the radiators) and expand them on the return path of the coolant.