Chemical flushing of industrial boilers is a procedure that is necessary to maintain their performance and energy efficiency. With its help, deposits that form during its operation are removed from the internal surfaces of the boiler. Thanks to this, the efficiency of heat exchange is restored and the risk of unit breakdown is reduced. On the HitEnergy website you can order descaling of industrial boilers at a very attractive cost.

In the video we will talk about chemical cleaning of industrial boilers, give step-by-step instructions, clearly show the washing process, talk about possible pitfalls, and reveal the secrets of the right cleaning agent. In doing so, we will refer to regulations and our own practical experience.

Chemical flushing of an industrial boiler - video instructions

Cleaning chemicals

Among them are the most common types of funds:

- adipic acid;

- hydrochloric acid;

- sulfamic acid.

You should never forget that these are aggressive substances, so you should always be careful when working with chemical solutions. (Read about the features of chemical boiler flushing in this article)

Expert advice: the concentration of acidic solutions for washing should be 1% per 1 mm of scale layer!

Watch the video in which an experienced user explains how to descale a gas boiler yourself:

Sequence of work

Flushing boiler equipment must occur in a strictly defined order, the main stages of which are the following important points:

- complete shutdown of the boiler and cooling;

- draining technical fluid from the system;

- filling the boiler unit with a chemical solution using a special device;

- cyclic circulation of solution in the system;

- draining the used product;

- flushing boiler equipment with industrial water;

- disposal of all waste.

In fact, all stages of work do not pose any particular technical difficulties, but for a better understanding it is worth looking in more detail at what devices are used to carry out the entire washing process.

You may be interested in an article on how to clean a gas boiler.

Read an article about the features of cleaning solid fuel boilers here.

SP-OM

The complex product of the SP-OM brand is used for flushing heating systems, heat exchangers, boilers and any other heat exchange equipment. Can be used in open and closed heat exchange circuits. "SP-OM" does not destroy aluminum and polymer elements of the system, as well as rubber gaskets. It has proven itself well on an industrial scale. There are various brands of SP-OM designed for specific operating conditions. Manufacturer's website - https://spomcom.ru/

SP-OM Pros

- effective removal of scale, rust and other deposits;

- wash-in-place;

- does not corrode rubber gaskets and seals;

- prevents corrosion of ferrous metals;

- may further include a corrosion inhibitor;

- Can be used with aluminum parts.

Minuses

Consultation and services of a flushing specialist may be required.

SP-OM

Metalin T is a product made on the basis of hydrochloric acid. Removes heavy lime deposits, rust products and organic matter in heating systems made of steel or non-ferrous metals. It is a non-flammable substance. After adding an alkaline neutralizer, the waste is allowed to be drained into the sewer. Packaged in concentrated form in containers from 1 to 30 liters.

Metalin T Pros

- non-flammable;

- quick cleansing.

Minuses

- after neutralization with alkali, discharge into the sewer system is allowed;

- not used for treating surfaces made of aluminum and its alloys.

Used in the treatment of pressure boilers, tubular heat exchange devices, boilers, condensers, pipelines in industry and domestic conditions. Removes various types of contaminants, in particular limestone and corrosive deposits. Ideal for washing plastic, metal and rubber pipes. Cleans carefully and does not have a negative effect on the structure of the seals. Not recommended for cleaning systems with surfaces made of aluminum and derivative alloys. Preliminary testing on treated stainless steel surfaces is also recommended.

SYNTILOR Watesup Pros

- does not affect the structure of metals;

- concentrated product;

- high efficiency even at low operating temperatures (20–35°C);

- does not damage seals and rubber gaskets;

- contains an inhibitor.

Minuses

Heating system cleaner SYNTILOR Watesup

Deoxyl-3

Deoxyl-3 is an acid-type product for chemical cleaning of pipelines in heating and water supply systems. It is packaged as a concentrate in 20 liter containers. The liquid is not flammable and belongs to toxicity class 3. For a greater cleaning effect, it is advisable to use the Deoxyl NO additive together with the drug. Foaming is neutralized by the Foral PG additive. The liquid is quite aggressive, so when working with it it is recommended to protect the skin and respiratory organs with protective equipment. Use strictly according to label instructions.

Deoxyl-3 Pros

- completely removes scale-corrosion deposits regardless of the design features of the equipment;

- biodegradable;

- after washing, the spent working solution can be drained into the sewer;

- The composition includes various inhibitors that prevent metal etching and the appearance of corrosion. Inhibitors not only remove deposits, but also protect the metal.

Minuses

The liquid is aggressive (work with it only with protective equipment).

Which system flushing products would you choose or would you recommend purchasing?

Deoxyl-3

44.44% ( 4 )

Save your voting results so you don't forget!

To see the results you need to vote

The most popular brands of double-circuit wall-mounted boilers

Ariston double-circuit boilers serve not only for heating, but also for supplying hot water to the house. But to install such boilers, the pressure in the pipes must be quite high. Such a boiler is not suitable for economical use of hot water. Such installations are not for large houses and they need to be located as close as possible to the water intake point. In this case, it is necessary to take into account the features of washing and maintenance. How to flush a Baxi gas boiler? By the way, Baxi and Arderia are one of the most popular brands of such equipment.

Wall-mounted boilers are more compact, but less powerful. Below are the most convenient and efficient brands of wall-mounted boilers.

Baxi

The Baxi boiler opens the gas boiler rating. Model 5 24F. It has a good camera, which makes it safe. All combustion waste is sent to a special waste pipe. Gas leaks are excluded. The burner is made of durable steel, the air vent of the pump is automatic. This is a wall-mounted, double-circuit, flow-through boiler. With small dimensions, it is able to heat a house of up to 200 square meters. meters. How to flush the heat exchanger of a Baxi gas boiler? You can do this yourself, or you can call a special service; this company has many authorized service centers. For relatively little money, the consumer receives a powerful, small gas boiler. The disadvantage is that the board is susceptible to voltage surges. Therefore, together with the purchase of a boiler, it is better to immediately buy a voltage stabilizer. At the same time, the boiler has a discreet design that will not spoil the overall interior of the house.

Navien

Double-circuit wall-mounted Navien competes with analogues due to its good assembly and long service life. Is it possible and how to wash the heat exchanger with hydrochloric acid of a Navien boiler? It is better not to use a solution of such a strong acid. It greatly damages surfaces, literally etching them. This boiler is also equipped with an anti-freeze system and tolerates even low temperatures well. The circulation pump automatically turns on immediately as soon as the room temperature drops by ten degrees. As soon as the water temperature in the system drops to 6 degrees, the boiler turns on again and heats the water to twenty degrees. It works even at low pressure and uses gas economically. There is a remote control and a voice assistant. Does not respond to pressure changes in pipes and voltage changes. But it is quite noisy, the machine sometimes malfunctions, and the hot water pressure is low.

Ariston

Another popular brand of household appliances is the Ariston boiler. It is equipped with an expansion chamber, a circulation pump and a closed safe combustion chamber. This is the most convenient boiler. Everything in it is made for simplicity and accessibility - a large display, large buttons. Uses little gas and is quiet. There is a frost and scale protection system.

What acid should I use to flush a gas-mounted boiler of this type with a built-in anti-scale system? A light preventive rinse using acetic acid is suitable here. The disadvantages of such a convenient boiler are the price and expensive repairs. But you have to pay for quality.

Vaillant

The Vailant boiler has a closed gas chamber, which eliminates gas leakage. The wall-mounted design of the boiler significantly saves space in the house. The heat exchanger from this manufacturer is made of good, high-quality copper. The use of this material significantly increases the service life of the device and maintains its efficiency level at 93 percent.

Beretta

The efficiency of such boilers fluctuates at 92 percent. The Beretta boiler is equipped with a closed chamber and has an anti-freeze system. It is easy to operate. More expensive models also include protection against pressure drops in pipes.

Arderia

The country of origin of Arderia boilers is South Korea. The quality is even better than well-known European brands, and they are cheaper, because... on the market relatively recently. The heat exchanger in this boiler is made of two durable materials - copper and steel. Everything here is thought out for the safety of users. There is a built-in voltage stabilizer and protection against gas pressure drops.

How to clean a boiler from scale with your own hands?

The process is not very complicated, but rather painstaking. Because you will have to disassemble the boiler. After all, how to clean a boiler from scale with your own hands? You will have to remove the heat exchanger from the system and clean it, first of all. The design is complex; you will have to disassemble it, remove the cover, and disconnect a large number of pipes. Therefore, it is not worthwhile to clean a gas boiler from scale without the appropriate qualifications. But you can find detailed instructions on the Internet on how to flush boiler equipment.

We use citric and hydrochloric acid

If, after all, the boiler is disassembled independently, then the question arises: how to flush the heating boiler at home? As already noted, the simplest means of acid. Lemon is in every kitchen; the situation with salt is worse, but you can buy it too. Since such an acid is strong, it must be diluted in a ratio of 1 to 10. But it is better to use more gentle acids. Because the salt one is very strong, “it will devour everything.”

How to flush the heat exchanger of a gas boiler with citric acid? Again, only after disassembling the equipment, because running the boiler at idle speed, like a washing machine, will not work. Citric acid, however, will be rather weak for such equipment, even if it is diluted at the rate of three tablespoons per liter.

We wash the secondary heat exchanger of the gas boiler

Since the boiler is a double-circuit Beretta, that is, there is a primary heat exchanger and a secondary one. How to flush a double-circuit gas boiler? Gradually, it will not be possible to wash both phases at once. Therefore, first you need to treat the most contaminated circuit, and then the less contaminated one. To do this, disconnect the boiler from electricity, turn off the gas, remove the lid, remove the expansion chamber, and now access to the wall-mounted heat exchange circuits is gained. If the scale layer is small, you can simply rinse it with a solution of vinegar or citric acid manually. If the layer is dense, then a pressure pump will be required to clean the gas boiler from scale, which will drive a stronger cleaning agent through the system. Well, in the most severe cases, the heat exchangers will have to be removed.

Cleaning the DHW circuit

If you neglect to clean the boiler system, its efficiency will very quickly be halved, and to heat the same room you will have to turn on the system at full power all the time. Moreover, cleaning is also necessary for high-quality softening, although much less frequently. Without softening, the boiler will have to be cleaned on average two or three times a year. Boiler equipment should be cleaned after the end of the heating season.

How much does the washing service cost?

The service is actually quite inexpensive. Starts from 3000 rubles! The rest depends on the power, model and degree of contamination. Spending even 5-6 thousand once a year for high-quality cleaning of the heating system is inexpensive. Moreover, the pros will do both chemical and hydraulic flushing. And after them, the surfaces of the Baxi boiler and heat exchanger will sparkle clean, like new.

Instructions for flushing the heating system

Pneumatic pulse cleaning scheme

There are 2 main methods for flushing the heating system, namely:

- using special hydropneumatic equipment;

- using chemical reagents.

Flushing using the hydropneumatic method

Hydropneumatic flushing of heating systems - instructionsHydropneumatic flushing of heating systems - instructions

This method is actively used by domestic housing offices and is quite effective. You just need to do everything in accordance with technology.

The principle is extremely simple: first, water is discharged from the system, then it is supplied back. A special pneumatic pump is used to “adjust” the water flow. As a result, under the influence of a fairly powerful pressure, scale and other deposits peel off, and when the water is drained, they are removed from the system.

To carry out this procedure yourself, you will need a pneumatic pump capable of pumping a pressure of more than 6 kg/cm2.

The sequence of actions is as follows.

Before starting work, you need to turn off all the taps. The end fittings are unscrewed using a wrench.

First step. We close the return valve.

Heating system line diagram

Second step. We connect the pneumatic pump to the valve installed after the valve.

Third step. We reset the return line.

Fourth step. Let the pneumatic pump build up pressure above 6 kg/cm2, and then open the valve to which it is connected.

Fifth step. We close off all the risers one by one. We do this so that no more than 10 risers are blocked at one time. Compliance with this rule will make the washing procedure as effective as possible.

Sixth step. We switch the system to reset in the opposite direction. To do this we do the following:

- close the discharge and close the valve connected to the pump, and turn off the device;

- close the open valve, and then open a similar one on the “return”;

- we reset the heating system. To do this, connect the pneumatic pump to the valve in the opposite direction, then open the valve and turn on the pump. The liquid will move in a different direction.

You can determine the required duration of rinsing by eye. Has clear clear liquid started coming out of the system? We can finish! Return the gates and valves to their original positions and turn off the pump.

Prepare a suitable container to collect dirty water. If you wish, you can connect a hose to the battery and ensure that the dirty coolant is discharged into the sewer.

Chemical wash

Chemical pipe flushing diagram

This method can be used only in two cases, namely:

- if it is necessary to clean a heating system with natural circulation, built using steel pipes. It is advisable to use chemical reagents in situations where, for any reason, there is no desire to flush the entire system. Most often, blockages are deposited in heat exchangers. The system can silt around the entire perimeter. In the second case, chemical washing will not be of much use;

- if it is necessary to restore the old heating system. Over decades of operation, pipes can become clogged and overgrown so much that the power of the pneumatic pump will not be enough for effective cleaning. It would, of course, be possible to use a more powerful pump, but no one can guarantee that the pipes will not burst under such pressure.

Wash reagent

The principle of flushing is simple: instead of coolant, a special solution containing acid and alkali is poured into the system. Then the mixture is circulated for 2-3 hours (if it is not the natural circulation line that is being cleaned, you will need to connect a pneumatic pump for this), after which it is drained and the pipes are filled with standard coolant.

Reagents for flushing and protecting heating systems

Never use such chemical mixtures to clean aluminum pipes. If the products remain intact after such washing, they will serve significantly less.

It is recommended to carry out mandatory flushing of the system of a private home at least once every 7 to 10 years.

At what thickness of scale are boilers flushed?

1. As a rule, water-heating water-tube boilers are washed when their heating surfaces are contaminated by 800-1000 g/m2 or more, or when the hydraulic resistance of the boiler increases by 1.5 times compared to the hydraulic resistance of a clean boiler (according to RD Inter RAO).

2. Fire tube boilers, the manufacturer recommends cleaning them in accordance with the regulations of the country in which they are operated.

3. Washing of drum-type steam boilers: DE and DKVR is carried out when the scale thickness is more than 0.5 mm.

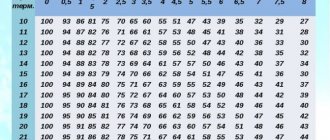

Appendix 2

Consumption of reagents for boiler alkalization

| Boiler type | Water volume, m3 | Reagent consumption, kg, at dosage, kg/m3 | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | ||

| TP-80 | 115 | 115 | 230 | 345 | 460 | 575 | 690 | 805 |

| TP-82 | 115 | 115 | 230 | 345 | 460 | 575 | 690 | 805 |

| TP-10 | 88,2 | 88 | 176 | 265 | 358 | 441 | 529 | 617 |

| TP-12 | 85 | 85 | 170 | 255 | 340 | 425 | 510 | 595 |

| TP-15 | 87,4 | 87 | 175 | 262 | 350 | 437 | 524 | 612 |

| TP-230-2 | 71,6 | 72 | 143 | 215 | 286 | 385 | 430 | 501 |

| TP-170-1 | 56,7 | 57 | 113 | 170 | 227 | 284 | 340 | 397 |

| TP-200-2 | 67 | 67 | 134 | 201 | 268 | 335 | 402 | 469 |

| TP-150-1 | 52 | 52 | 104 | 156 | 208 | 260 | 312 | 364 |

| PK-10, PK-10-2 | 61 | 61 | 122 | 183 | 244 | 305 | 366 | 427 |

| PK-14, PK-14-2 | 63 | 63 | 126 | 189 | 252 | 315 | 378 | 441 |

| PK-19, PK-19-2 | 57 | 57 | 114 | 171 | 228 | 235 | 342 | 399 |

| PK-20, PK-20-2 | 58 | 58 | 116 | 174 | 232 | 290 | 348 | 406 |

| BKZ-220-100F | 66 | 66 | 132 | 198 | 264 | 330 | 396 | 462 |

| BKZ-210-100F | 64 | 64 | 128 | 192 | 256 | 320 | 384 | 448 |

| BKZ-160-100F | 48 | 48 | 96 | 144 | 192 | 240 | 288 | 336 |

| BKZ-75-89-FB | 30 | 30 | 60 | 90 | 120 | 150 | 180 | 210 |

| TsKTI-75-39F | 30,4 | 30 | 61 | 91 | 122 | 152 | 182 | 213 |

| BKZ-75-39SL | 32,6 | 33 | 65 | 98 | 130 | 163 | 196 | 228 |

| BKZ-50-39F | 21,2 | 21 | 42 | 64 | 85 | 106 | 127 | 143 |

| TP-35U | 13,3 | 13 | 27 | 40 | 53 | 67 | 80 | 93 |

| TS-35U | 13,07 | 13 | 27 | 39 | 52 | 65 | 78 | 92 |

| TP-20-U | 9,33 | 9 | 19 | 28 | 87 | 47 | 56 | 65 |

| TS-20-U | 10,73 | 11 | 21 | 32 | 43 | 54 | 64 | 75 |

| DKVR-10-15 | 8,6 | 9 | 17 | 26 | 34 | 43 | 52 | 77 |

| DKVR-6.5-13 | 7,5 | 8 | 15 | 33 | 30 | 38 | 45 | 60 |

| DKVR-4-13 | 5,4 | 5 | 11 | 16 | 22 | 27 | 32 | 49 |

| DKVR-2.5-13 | 3,6 | 4 | 7 | 11 | 14 | 18 | 22 | 32 |

Why flush your heating system?

Over time, deposits form on the internal surfaces of the heating system. In the heat exchanger they lead to overheating of the boiler, in the pipes they lead to a slowdown in the circulation of the coolant. Timely flushing allows you to remove deposits and avoid accidents in the future.

The main reasons for the appearance of deposits:

- Water with a high content of hardness salts;

- Using antifreeze, mixing different antifreezes;

- Frequent replenishment of coolant due to leaks;

- Lack of maintenance to spot problems early.

If it is possible to refuse antifreeze, it is better to do so. You can also think about organizing a water treatment system.

The heat exchanger burst. Why does a cast iron boiler collapse?

Possible signs:

- The boiler, heated floors, radiators do not heat up or heat up worse;

- Interruptions in the operation of the circulation pump;

- Increased fuel consumption;

- Frequent boiler shutdowns.

At the first signs, you need to contact a specialist. If the problem is deposits, flushing will be required.

How to evaluate the result of acid washing?

The result of acid washing can be assessed by the actual state of the internal heating surfaces of the boiler after washing.

For these purposes, we use photography, video equipment, and video endoscopes, thanks to which it is possible to “look inside” the boiler.

Pictured: ICI GX 3000 boiler before flushing

Pictured: ICI GX 3000 boiler after flushing

Chemical flushing of a gas boiler

When chemically flushing a boiler, plaque and scale are removed from contaminated surfaces of boiler equipment and heat exchanger fragments, thanks to treatment with various chemical compounds and reagents. Most often, acid is used for washing boilers, which effectively removes carbonate scale, which is formed when magnesium and calcium salts and ferric iron combine and settle on the surface of the heat exchanger. Chemical washing is a standard, simple procedure that you can do yourself at some intervals. This flushing usually does not require disassembly of the structure.

Chemical cleaning of a gas boiler.

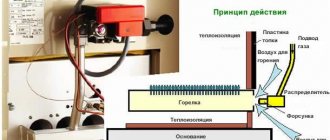

To carry out chemical flushing, you will need a chemical reagent and special equipment called a booster for flushing the heat exchanger. A booster is a device that consists of a tank for a cleaning agent, a pump and a heating element. During the procedure for flushing a gas boiler using a booster, a warm solution is first prepared and introduced into the heat exchange system (for acid flushing).

Thanks to the device, the cleaning reagent circulates and the waste liquid is removed. The acid chemical wash booster can be used on any type of gas boiler and is capable of effectively cleaning any type of boiler equipment. The main difference between a booster and installations that clean steam systems is that the booster does not need to use a heating element, since the cleaning liquid can be heated by the heat exchanger itself.

However, this is unsafe and not as effective, so it is recommended to use boosters that have heating elements, which allows you to use a solution of the same temperature and act on different parts of the heat exchanger with the same efficiency.

Gas boiler system diagram.

Acid washing is used to remove carbonate scale or ferric scale. The main reagents that are included in these solutions are sulfuric or hydrochloric acids; phosphoric or nitric acids are less commonly used. The reagent is selected depending on the type of contamination and the abundance of scale; the materials from which the heat exchanger and boiler are made are also taken into account.

Do-it-yourself flushing of a double-circuit gas boiler is carried out in two stages. At the first stage, an active reagent that has acidic properties is used. Using a reversible pump, it is necessary to create a powerful flow of solution, eroding the layer of deposits that would be affected by the acid.

The procedure takes from 2.5 to 6 hours, depending on how dirty the surfaces of the gas boiler are. When deposits and scale have dissolved, it is necessary to remove the active solution and fill the heat exchanger with a solution that neutralizes the acid residue. If the heat exchanger is made of cast iron, then due to the likelihood of the opposite effect, it is better not to flush the boiler with your own hands.

What are the methods for flushing a steam boiler?

Steam boilers and heat exchangers belong to the category of industrial units with significant dimensions and large internal volume. This feature has its advantages and disadvantages from the point of view of the steam boiler cleaning procedure. There are special requirements for equipment for cleaning steam boilers and heat exchangers for them. At the same time, washing is not limited to just one method.

Depending on the wishes of the customer and the level of contamination, we can use the following methods for washing steam boilers.

- Hydrodynamic. Water is supplied to the system under high pressure, as a result of which coarse salt deposits are destroyed and coarse particles are removed. This type of flushing is capable of partially restoring normal circulation of the medium inside the boiler.

- Hydropneumodynamic. The steam boiler is flushed with an air-water slurry, which is supplied under pressure into the pipe cavity. The presence of air bubbles creates micro-water hammers, thereby increasing the degree of cleaning of the steam boiler and heat exchangers from deposits.

- Chemical. The destruction of salts is carried out through their transfer from an undissolved to a dissolved state, by exposure to special means for washing steam boilers.

It is worth noting that each of these methods of cleaning steam boiler heat exchangers individually does not give a 100 percent result. To achieve maximum results and completely remove all deposits, we recommend combining cleaning methods. For example, hydropneumodynamic cleaning with chemical washing of steam boilers works well.

Flushing the boiler from scale: consequences of ignoring

Modern mains use ordinary hard water, which quickly leads to the inside of the equipment being covered with scale. Boilers must be cleaned on a regular basis. If cleaning is not done on time. The consequences can be the most unpredictable, but definitely unpleasant.

The design of the gas boiler is such that the coolant coming from the return line cools the cavities of the heating elements located inside. The coolant cannot effectively cool the elements if they are covered with a thick layer of scale. If the boiler constantly overheats, it will soon stop working altogether.

What will happen if you ignore flushing?

- Scale consists of mineral deposits that do not promote thermal conductivity. Scale causes the water to heat up slowly, which requires significantly more electricity. A thick layer of scale leads to increased gas consumption, which increases the price of using the boiler.

- Scale can lead to boiler failure due to difficult coolant passage. This increases the load on the circulation pump, which leads to its rapid breakdown.

Before flushing the boiler, it is important to pay attention to what kind of liquid flows through the line. The need for frequent flushing will be due to very hard and contaminated water. In order to reduce the frequency of cleaning, it is necessary to use antifreeze - it is important that it is not expired

In order to reduce the frequency of cleaning, it is necessary to use antifreeze - it is important that it is not expired

Boiler cleaning methods

There are two ways to flush the boiler from scale and dirt:

- Collapsible is a method that requires disassembling the unit. When using it, contaminated boiler parts are dismantled. These components are then either placed in a container of reagent for several hours and cleaned mechanically, or another cleaning method is used. It all depends on the degree of pollution. Then the elements are put back into place.

- In-place - cleaning is carried out without dismantling parts, directly on site. This procedure is best done with a booster.

Cleaning in place is carried out as follows:

- the boiler is switched off from the fuel supply;

- cools down;

- water is drained;

- the device is disconnected from the heating system;

- the booster is connected;

- pumping of the liquid reagent begins (2-6 hours);

- at the end of this process, the cleaning liquid is drained;

- the boiler is washed with water;

- dried;

- reconnects to the heating system.

For best results, repeat the procedure several times.

Dismantling and cleaning parts

When choosing a dismountable method, in order to prepare a gas boiler for cleaning, you should disassemble it:

- shut off the gas supply;

- disconnect the wires from the gas valve;

- unscrew and remove the boiler door;

- disconnect the wire leading to the piezoelectric element;

- detach the thermocouple and nozzles (be sure to mark the depth of immersion of the nozzles into the burner);

- disconnect the fuel supply pipe;

- take out the burner, unscrew the nuts and remove the top cover.

Key points for cleaning parts:

- Igniter. In order to clean it, you need to turn off the gas, remove the igniter, clean it with a metal brush, blow it out, and put the igniter in place.

- Burner and nozzles. To clean them, you need to turn off the gas supply, remove the burner from its place, mark the location of the nozzles, then carefully unscrew and clean the nozzles with a brush and the burner with a brush. After this, it is advisable to blow out the burner hole using pumping equipment that is at hand, then the nozzle should be inserted back, focusing on the mark, after which the burner is installed in its place.

- The heat exchanger requires cleaning both inside and outside. Water circulates inside, and the main blockages are located there. From the outside, the heat exchanger becomes contaminated with soot, which negatively affects its operation. You can clean the device from soot mechanically; a scraper, a metal brush, or pipe cleaners are suitable for this.

Important! When cleaning, do not use tools with sharp edges, otherwise you may damage the boiler parts. Heat exchanger cleaning steps:

Heat exchanger cleaning steps:

- gas supply is turned off;

- the heat exchanger is removed;

- cleaning is carried out with any mechanical tool;

- the heat exchanger is installed in place.

What is a heat exchanger

A gas boiler has an element in its design that is located above the firebox and consists of connected tubes. The coolant circulates in them. Its location is not accidental; combustion of gas in the boiler must heat the coolant, which is located in the heat exchanger.

The coolant is water. It heats up and passes further through the system. But untreated water contains many impurities that can settle in the tubes when heated. Most often these are salts and lime particles. If there is a lot of contamination, water has difficulty passing through the tubes, which leads to malfunctions.

Composition of the preparation for flushing the heat exchanger

Modern detergents have a variety of chemical compositions, making it possible to choose the best option for devices made of different materials. The concentrate includes:

- organic acids and a complex of reagents - an active substance for descaling;

- acid corrosion inhibitors – a means that prevents damage to device elements and reduces the likelihood of the onset of chemical destruction.

Additionally, the product may contain defoamers and components to prevent layering.

The formulation of the washing solution provides for loosening carbonate contamination and converting it into a soluble state, as well as creating a protective film to prevent corrosion of the metal. Manufacturers have thought about changing the color of the liquid during the washing process to control the process.

Main types of contamination and optimal cleaning mixtures:

- Scale deposits and metal deposits are effectively destroyed by phosphoric, citric and nitric acids.

- For iron oxide, experts advise using an inhibited mineral solution of high acidity, for organic compounds - sodium alkali, for mineral contaminants - nitric acid.

- To combat grease stains, special solvents are offered on the market.

Alternatively, a mixture of sodium carbonate and caustic soda can be used to remove contaminants. It is less harmful to humans, but does not fight all types of deposits, and is optimal for removing biological contaminants, fats and oils.

Basic types of flushing

Scale hits the heating system multiple times:

- reduces the flow area of the pipes and heat exchanger, as a result of which the efficiency of the system drops sharply, and in some areas the pressure increases significantly;

- for the same reason, it forces the circulation pump to work with overload, which shortens its service life;

- Having the properties of a heat insulator, it worsens heat transfer, which also negatively affects efficiency and can lead to burnout of the heat exchanger.

Therefore, removing scale is included in the mandatory list of heater maintenance work. The DHW circuits of 2-circuit boilers are especially affected: here ordinary water from the pipeline is heated, in contrast to the prepared coolant, which is saturated with salts.

Signs of scale buildup on pipes and heat exchanger:

- clicking sounds are heard;

- gas consumption has increased;

- insufficient water heating;

- significant pressure drops (in heating systems).

There are two types of washing:

- regular or planned. Performed at certain intervals in order to prevent emergency situations. Does not require disassembly of the equipment and can be performed by the user himself. Typically, scheduled flushing is carried out every few years. For systems operating year-round, the time intervals between flushing are reduced;

- repair It is carried out at a critical thickness of the scale layer, when further operation of the boiler does not produce any effect or may result in an accident. It involves disassembling the equipment, therefore the participation of specialists is recommended.

Regular washing is carried out chemically using a special device - a booster.

Steam boiler flushing

During the operation of steam boilers, deposits of calcium, magnesium, iron, and silicon salts inevitably form on their internal walls.

The result of the presence of these chemical compounds inside the pipes and heat exchangers of the boiler is a decrease in the efficiency of its operation, and in some cases, equipment breakdown and failure occurs. Despite the similarity of the procedure for flushing a steam boiler with a household one, there are certain nuances related to the nature of the deposits. High temperature and pressure lead to the formation of complex compounds:

- Calcium sulfates;

- Hydroxyapatites;

- Magnesium-iron hydrosilicates;

- Iron phosphates.

It is impossible to destroy deposits of these substances using improvised means. Therefore, cleaning a steam boiler should be carried out by professionals who know which product is best suited for each specific case.

Our company uses equipment for washing steam boilers from the best brands, of which we ourselves are suppliers. We have been working since 2011 and have successfully completed thousands of projects in Moscow, other regions of Russia and neighboring countries. Our experience and knowledge allow us to cope with deposits inside steam boilers of any complexity.

Chemical flushing of gas boilers and heat exchangers

We will carry out an urgent inspection of the insulating flange and insulating connection and issue a certificate within 1 day.

An integral condition for high productivity and full functioning of boiler equipment is regular flushing. Both domestic and industrial boilers are usually subjected to chemical flushing. Minimizing the corrosive effect on metal parts is possible only with proper monitoring of the condition of the boiler unit. If you neglect to regularly clean the system, the heating performance of the boiler will decrease, and scale will form on its internal surface.

Chemical flushing is the most effective cleaning method that allows you to maintain boiler performance at the proper level.

Estimated cost of services

| from 1,000l to 2,500l cost 30,000₽-70,000₽ |

| from 2,500l to 5,000l cost 70,000₽ – 95,000₽ |

| from 2,500l to 5,000l cost 95,000₽ – 105,000₽ |

| from 5,000l to 10,000l cost90,000₽-180,000₽ |

| from 10,000l to 20,000l cost 155,000₽ – 300,000₽ |

| from 20,000l to 50,000l cost 270,000₽ – 800,000₽ |

The cost of work is determined based on the boiler model, location, heat exchange surface area, water volume and degree of contamination.

| from 1,000l to 2,500l cost 30,000₽-75,000₽ |

| from 2,500l to 5,000l cost 75,000₽ – 95,000₽ |

| from 2,500l to 5,000l cost 95,000₽ – 120,000₽ |

| from 5,000l to 10,000l cost 120,000₽-180,000₽ |

| from 10,000l to 20,000l cost 180,000₽ — 300,000₽ |

| from 20,000l to 50,000l cost 300,000₽ – 750,000₽ |

The cost of work is determined based on the boiler model, location, heat exchange surface area, water volume and degree of contamination.

| From 17,500 ₽ |

The cost of work is determined based on the heat exchanger model, location, heat exchange surface area, and water volume.

What explains the need to flush boiler and heat exchange equipment with chemical reagents?

In practice, the quality of water for heating networks does not meet established standards. Failure to comply with the regulations when putting the system into operation starts the process of deposition of excess salt and other impurities on the surface of the pipes. In this regard, the hydraulic regime is disrupted, the useful volume of the networks is reduced, which leads to a complete imbalance and threatens the integrity of the system. It is not possible to carry out mechanical cleaning of pipes and equipment due to the lack of technical potential, so chemical flushing becomes perhaps the only and most effective method of cleaning the system.

Stages of flushing boiler equipment:

4. Drawing up a report on the work done.

Chemical washing of a boiler with a sludge level of more than 1500 g/m or with a content of silicic acid (sulfates) in deposits above 10% is carried out in two stages with preliminary alkalization before the acid stage. If the amount of sludge on the working surface of the boiler unit is more than 3000 - 4000 g/m, alternating acid and alkaline processing stages is required.

In certain cases, acid washing of the boiler should be preceded by mechanical (hydrodynamic) washing of sludge-filled areas, which allows to get rid of porous and uncemented deposits. In this case, the duration of cleaning and the amount of chemicals required for effective washing are significantly reduced.

Basic requirements for the chemical washing process: - use of safe detergents to avoid damage to the surfaces of the boiler unit;

— the ability to effectively remove deposits without the formation of insoluble compounds.

Flushing heat exchangers

Chemical washing of the heat exchanger is carried out in several stages:

- Introduction into the heat exchanger of a solution with active substances, which, when reacting with deposits on the internal surfaces, break them down and remove them from the unit.

- Washing the plates of heat exchange equipment with water to remove residual reagent. In case of ineffective flushing, active substances may react with the coolant, which will lead to equipment damage.

- Alkaline washing of internal surfaces.

- Hydraulic testing of newly commissioned heat exchange equipment.

https://youtube.com/watch?v=mnMmg4LfAVo

https://youtube.com/watch?v=9pz52JApBa4

https://youtube.com/watch?v=jMnn-iZPzNo

Examples of boiler surface contamination

Samples of extreme contaminants extracted from the water part of the boiler heating surfaces

Boiler water path - scale deposits before and after boiler flushing

Smoke pipes

Connection between flame tube and tube sheet

How to determine the thickness of scale in boilers?

1. To determine the degree of contamination of the pipes of water-heating water-tube boilers (ZIO, NR, PTVM, KVGM), control cuttings are made. To do this, pipe samples with a length of at least 0.5 m are cut out.

In the photo: control cutting from the PTVM-50 hot water boiler

The number of these samples should be sufficient (but not less than 5-6 pieces) to assess the actual contamination of the heating surfaces. It is mandatory to cut samples from the screen pipes in the area of the burners, from the top row of the upper convective package and the bottom row of the lower convective package.

These areas are the most temperature-stressed, so they are likely to experience accelerated scale formation. The need to cut an additional number of samples is specified in each individual case depending on the operating conditions of the boiler.

2. In fire tube boilers, for these purposes, the top hatch is opened or, for example, the safety valve is removed (if there is no hatch) and the smoke pipes are inspected. In high-power boilers, it is possible to get inside the boiler and conduct a visual inspection. If this is not possible, a video endoscope is used for these purposes.

Pictured: inspection of the LOOS UL-S 10,000 fire tube boiler before flushing

3. The easiest way to determine the thickness of scale in steam boilers. To do this, you just need to open the upper and lower drum and carefully examine the convective pipes at the top and bottom.

In the photo: scale in the boiler DKVR-10/13

Estimated cost of services

The cost of work is determined based on the boiler model, location, heat exchange surface area, water volume and degree of contamination.

The cost of work is determined based on the heat exchanger model, location, heat exchange surface area, and water volume.

What explains the need to flush boiler and heat exchange equipment with chemical reagents?

In practice, the quality of water for heating networks does not meet established standards. Failure to comply with the regulations when putting the system into operation starts the process of deposition of excess salt and other impurities on the surface of the pipes. In this regard, the hydraulic regime is disrupted, the useful volume of the networks is reduced, which leads to a complete imbalance and threatens the integrity of the system. It is not possible to carry out mechanical cleaning of pipes and equipment due to the lack of technical potential, so chemical flushing becomes perhaps the only and most effective method of cleaning the system.

Flushing the hot water boiler

For water-tube hot water boilers KV-GM and PTVM, chemical flushing is the only method for removing scale. These boilers do not have access to screen and convection pipes, so the only way out is to circulate the flushing solution in the boiler and dissolve the scale.

In the photo: washing of KV-GM-7.56 hot water boilers by our company, in 2022

Chemical washing is used for any brands of hot water boilers: KVA, KVG, KV-GM, PTVM and others. Our company performs flushing of hot water boilers of any capacity.

How often should the heat exchanger be cleaned?

Maybe they are all right, but the most realistic option would be that the heat exchanger should be flushed when the following signs begin to appear:

- the burner in the gas boiler is on all the time;

- the circulation pump operates with a characteristic hum, which indicates overload;

- heating of radiators takes much longer than usual;

- Gas consumption has increased significantly with the same operation of the boiler unit;

- weak pressure of hot water in the tap (this symptom is applicable for double-circuit boilers).

All these points strictly indicate that problems have arisen in the functioning of the heat exchanger, and this, in turn, means that it is necessary to start flushing.

Specialist note: irregular cleaning of the device will reduce the efficiency of the gas boiler.

Useful tips

Of course, using and cleaning gas boilers is a little easier than solid fuel units, which often have to be cleaned of tar or tar. However, gas models still require careful handling and timely flushing.

Experts do not advise taking on this task if you are not confident in your abilities, because mistakes cannot be made in this case.

Pay attention to your kettle, in which you usually boil water. If there is a noticeable coating on it, which reappears after each new cleaning, then this means that the heat exchanger in your boiler needs to be cleaned at least once every 2 years. If there are no deposits on the kettle, then you can get by with just one cleaning every 3 years.

When cleaning the boiler, never rub the plates with pressure or unnecessary force. Do not use rags, brushes or sponges. This is due to the softness of the records - they can be easily damaged

If there are no deposits on the kettle, then you can get by with one cleaning every 3 years. When cleaning the boiler, never rub the plates with pressure or unnecessary force. Do not use rags, brushes or sponges. This is explained by the softness of the records - they can be easily damaged.

- Experts and users more experienced in these matters advise beginners to film the entire process of disassembly (if you are disassembling the unit) and cleaning on video or take photos. Based on the footage, it will be easier for you to put the equipment back together, and most likely there will be no extra parts left.

- When cleaning the heat exchanger, it is not recommended to use tools that have sharp edges. Such objects can damage important parts of the heating unit.

- When working with acids that clean the heat exchanger of deposits, it is recommended to wear rubber gloves and a mask. Follow safety precautions. Make sure that chemicals do not come into contact with the skin or mucous membranes.

- If you decide to hydrostatically clean the heat exchanger, then you should keep in mind that under no circumstances should the critical pressure level be exceeded. Otherwise, pipes may burst.

- Do not try to make the burner hole wider by using a thick needle. Of course, after this it will be easier to clean this element, but the performance of the equipment itself may deteriorate.

- The brush is perfect for cleaning internal surfaces of any shape. It is recommended to use a tool with a longer handle - with such a device it will be much easier to reach all contaminated areas.

When assembling the pilot burner, it is important to remember one important rule: the tip of the thermal paste should be located opposite the area where the flame ignites. If you decide to clean the heat exchanger using a chemical method, then you should consider that high-quality reagents usually have a high cost

If a turbocharged boiler is installed in your home, then at the bottom you will see debris drawn into the inside of the air duct. It also needs to be removed

To do this, just use a vacuum cleaner. Some experts argue that regularly using hydrochloric acid to clean the exchanger can cause brittleness and severe wear on the metal. This must be taken into account when choosing the appropriate washing method.

- A common signal for cleaning the heat exchanger is a decrease in water pressure. If you notice this change, you should start cleaning the equipment as soon as possible.

- It is also necessary to start cleaning the equipment if the circulation pump begins to operate too noisily. This will indicate that this part is working under heavy load.

- You can use the non-dismountable method of washing only if your heating equipment does not have too serious and old contaminants. In addition, this method is not suitable for removing dirt caused by corrosion.

- After washing the unit, which you have not previously disassembled, you should neutralize and dispose of the cleaning solution immediately after carrying out all the necessary procedures.

If water flows freely, this will indicate that the inside of the pipe is free of debris. Once you have finished cleaning the necessary parts, reassemble everything in reverse order. Be sure to remove any contaminants from the inside of the boiler. Then run the equipment at full power - this must be done to make sure there are no leaks and the equipment is working properly.

To learn how to flush the heat exchanger of a gas boiler, see the following video.

What is a heat exchanger

This was done so that the thermal energy obtained from burning gas passes through it and, accordingly, heats it up.

Thus, hot water passes through the heat exchanger, which may contain various impurities in the form of metal salts and lime particles. These chemicals constantly deposit on the inner walls of the pipes, forming a coating. (Read this article about cleaning a heating boiler from scale.)

Over time, this type of pollution only increases, as a result of which the movement of water through the heat exchanger becomes difficult, which leads to failures of the entire boiler unit as a whole.

Therefore, it is very important to flush the gas boiler regularly.

Why us

Our company is officially registered. We have the necessary documents to provide steam boiler cleaning services to enterprises of any form of ownership and field of activity. We cooperate with both private entrepreneurs and large factories. We work with all forms of payment: cash, non-cash, bank transfers.

To order or find out more about flushing our company’s steam boilers, just contact us in any convenient way specified in the contacts.