Until recently, the main disadvantage of solid fuel boilers was the need to manually load fuel and constantly monitor the operation of these devices. Modern equipment with the help of automation units has solved the problem of adjusting the temperature and burning rate of fuel; they are equipped with special systems for uninterrupted supply of energy carriers.

Wood briquettes for the boiler

At the moment, the production technology has been changed. Consumers began to be offered cylindrical fuel, up to several centimeters long, which made it possible to use wood fuel briquettes in automatic boilers.

How and from what are wood briquettes made?

Heating wood briquettes for boilers are produced in three different ways, each of which has its own characteristics and markings:

- Rectangular RUF briquettes - received the marking due to the fact that the first compressed fuel was created on equipment manufactured by the German manufacturer RUF. In shape, the finished product resembles a small brick. The production principle is based on pressing sawdust and waste using hydraulic presses at a pressure of 300-400 bar.

Cylindrical briquette – pressing of briquettes for solid fuel boilers of this type is carried out using hydraulic or shock-mechanical equipment. When pressing, the pressure increases to 600 bar. The disadvantage of the cylindrical type of fuel is the fear of moisture and susceptibility to mechanical damage.

Pini&Kay – pressing of wood briquettes for heating boilers is carried out using mechanical screw equipment. The difference between production is the simultaneous use of high pressure (up to 1100 bar) and thermal firing. The resulting “logs” have edges and a characteristic dark brown color.

- The washers are similar in structure to Pini&Kay, have four or six edges and a radial hole in the center. The length of the briquette is only a few centimeters.

- Coniferous briquettes flare up quickly and create a high temperature in the firebox, but quickly burn out due to the large amount of resin released. Heating with pine briquettes is not profitable due to high fuel consumption, but it is advisable to use them to light the boiler.

- Pressed hardwood slabs have a high calorific value, are difficult to ignite and burn out slowly. The average consumption is 10 kg for 6-7 hours.

The briquette production technology used affects the quality and cost of fuel. Pini&Kay have the highest calorific value; they are resistant to moisture and mechanical stress, and also burn longer when fired.

Briquette consumption in the boiler

Solid fuel for boilers in briquettes is made from various types of wood. The burning time and fuel consumption depend on the type and type of wood:

Another type of briquettes that has not found widespread use are slabs made exclusively from bark. This type of fuel burns hard, but during combustion it has practically no flame and smolders slowly. At the same time, the temperature is maintained until the slabs burn out. The average burning time is 12 hours.

Cost of wood briquettes

It is economically profitable to use fuel briquettes due to their high calorific value and low content of non-combustible residue.

Step-by-step manufacturing instructions

The process of creating a heating device is quite simple and takes place in several successive stages.

First, the body of the structure is made:

- Two large diameter pipes (50 and 45 cm) are inserted into each other and connected using a metal ring.

- A circle of metal with a diameter of 45 cm is cut out of a pre-prepared sheet, which is used to weld the bottom of a smaller pipe located inside the structure. As a result, we get a barrel with a diameter of 45 cm, with a welded hot water jacket-contour 2.5 cm wide.

- A rectangular hole is cut at the bottom of the “barrel”. Height - up to 10 cm, width - about 15. It will be used as an ash pan door. A hatch is welded in, a door with attached hinges and a latch is installed.

- A rectangular hole is cut in the upper part of the circuit to supply solid fuel. The size is selected individually, the main condition is the convenience of loading firewood. The hatch is welded. A door equipped with hinges and a latch is installed. It is made double: an asbestos layer is laid between individual metal sheets, and the contact areas are sealed with asbestos cord. Thanks to such manipulations, heat loss from the boiler is reduced.

- At the upper level, an exhaust pipe is installed that discharges exhaust gases into the chimney.

- In two places (top and bottom) of the water circuit, pipes with a diameter of 4–5 cm are welded, which are necessary to connect the boiler to a further heating system. The thread is cut, for which a groove is used.

- Checking welding seams and, if necessary, eliminating flaws.

After creating the metal body of the solid fuel boiler, you can begin to manufacture and install the air distributor:

The air distributor can be made in the form of a pancake with welded channels

- A metal circle is cut out. Its diameter should be several centimeters smaller than the internal one on the boiler. A round hole is cut in the center of the circle, the size corresponding to the air distributor pipe (5–6 centimeters).

- A metal tube is inserted into the cut hole.

- Channels or corners arranged in the form of blades are welded onto the “pancake” from below. If the thickness of the blades is suitable, an impeller from a fan is sometimes used.

- A small loop is welded on top. With its help you can raise and lower the distributor. A damper is also equipped to regulate the intensity of air supply to the fire zone.

- Installation of the air distributor to the housing. A circle is cut out of a metal sheet, the diameter of which is equal to the outer body. A 6–8 cm hole is cut in the center. The lower part of the air distributor is inserted into the boiler, the upper part is threaded through the hole. After this, the circle is welded to the boiler and subsequently functions as a top cover.

This is one of the simplest ways to make a solid fuel boiler. There are complicated circuits used in industrial and household models.

How to properly heat a boiler with wood briquettes

Pressed fuel contains a minimal amount of sulfur, a non-combustible residue, therefore, there is no negative impact on human health. If everything is done correctly, the bars burn with an even flame without sparks, crackling, etc.

Is it possible to use briquettes for a wood boiler?

Fuel briquettes burn, releasing small amounts of sulfur and soot. Unlike firewood, the same temperature is maintained throughout the entire burning period, which has a beneficial effect on the condition of the heat exchanger.

Briquettes are suitable for the following types of boilers:

- Classic units.

- Pyrolysis models.

- Boilers with automatic fuel supply, subject to the use of a “washer”.

Almost all solid fuel equipment can operate using wood fuel briquettes. It is optimal to use those models whose technical documentation clearly indicates the possibility of using compressed fuel.

Calculation of the minimum required power

Correct calculation of power will allow you to survive any frost without worries and always have warm water in sufficient quantities. The minimum required power is calculated at the rate of 1 kW per 10 m2 of heated area for a standard house with 2 bricks and a ceiling height of no more than 2.7 meters.

According to the technology, calculations are carried out separately for each room, but in practice the total area is often divided by 10 and multiplied by 1 kW. Then losses and calculation inaccuracies are added to increase the received power by 20%; if a DHW circuit is also planned, it is necessary to add another 20% reserve.

Excessive power results in underutilization of the boiler, but retains the opportunity to expand its use in the future. An error in lack of power promises a loss of comfort and an inevitable rework of the heating system.

This is largely an approximate calculation; for an accurate calculation, you can involve a heating engineer or, based on SNiP 2.04.01-85, you can recalculate the hot water consumption in accordance with the standards, but you will still have to take into account the safety margin, and such an estimate will have little effect on the choice of a specific model. For a private house up to 400 m2, in more than 90% of cases the simple calculation given above is sufficient.

How to calculate the required boiler power Individual calculation, formula and correction factors

Choosing a wood briquette boiler

Choosing a long-burning boiler using pressed wood briquettes can be difficult due to the large range of products offered. Models manufactured in Russia, European countries and neighboring countries are offered on the domestic market.

To facilitate the selection of equipment, all offered boilers for burning briquettes can be divided into several categories, based on territoriality - country of manufacture:

- Germany – Bosch Solid.

- Czech Republic - ATMOS, Dakon (the company is owned by Bosch), Wattek.

- Russia – Nibe Viking, Zharstal Dobrynya, Dragon.

- Türkiye – Radijator.

- Poland – Heiztechnik.

- Italy – Ferroli.

Comparative market analysis

The following table shows data on different types of stoves.

Table 1. Comparison of different types of ovens

| "Swede" | brick | 140 — 160 | 40 000 — 60 000 | Suitable for heating and cooking. |

| Stove-fireplace | brick | 145 — 175 | 42 000 — 63 500 | Open firebox. |

| Two-level | brick | 240 — 250 | 110 000 — 180 000 | Heats two floors. |

| "Russian" | brick | 145 — 165 | 90 000 — 250 000 | Equipped with a sun lounger. |

| "Chevron" | steel | 50 | 9 000 — 10 000 | Compact model weighing about 9 kg. |

| "Indigirka" | steel | 50 | 50 000 — 55 000 | Equipped with thermoelectric generator (12 V, 60 W) |

| "Hydraulic engineer" | steel | 670 | 30 000 — 32 000 | Boiler for connecting water heating. |

| Ferlux LAWA | cast iron | 250 | 38 000 — 42 000 | Decorated with artistic casting elements. |

A luxury ceramic stove is expensive

Types of pressed fuel briquettes

Heating units operating on pressed briquettes are easy to maintain and do not require equipment for storing fuel and its automatic supply. Briquettes can replace other types of solid fuel without upgrading the boiler.

The use of briquettes obtained by pressing as fuel significantly simplifies the supply of fuel to the firebox; there is no dirt and dust, and too frequent removal of slag is not required.

The main types of such fuel:

Wood fuel briquettes are produced by pressing crushed dry wood waste: wood chips, bark, sawdust. They have a cylindrical or rectangular shape, weight - 0.5-2.0 kg. Recently, a new technology for the production of this pressed fuel makes it possible to obtain short cylinders - washers that can be loaded into the boiler automatically.

The raw material for the production of coal briquettes is fine coal, which is not suitable for burning in a firebox due to the fact that it spills through the grate. To obtain durable products in the shape of a cube or cylinder, resin, protein, molasses, soda and other binding components are added to fine coal.

Among solid fuel heating units that use, among other types of fuel, pressed briquettes, Dakon units are very popular among consumers.

Conclusion

An automatic solid fuel boiler is an excellent alternative to a gas or electric heater. A special loading mechanism can significantly improve the ergonomics of its use, and the innovative pyrolysis method of fuel combustion makes it possible to use energy resources more economically.

You just need to select the appropriate fuel for the installed unit. The video below will help you with this.

Did you like the article? Subscribe to our Yandex.Zen channel

Pellets

Pellets have become widespread. They are granules whose size does not exceed a few centimeters. For their production, waste of various wood species is used.

One of the disadvantages of pellets is the need for special long-burning boilers to burn them. In classical equipment with uncontrolled access of oxygen, they will burn out very quickly and are unlikely to bring the expected benefits and benefits.

Representing hexagonal cylinders, Pini&Kay heating briquettes are the most technologically advanced among the above varieties. They have a round hole in the center. Thanks to the additional distribution of air flows inside it, it was possible to achieve uniform combustion.

Pini&Kay briquettes are widely used for burning in fireplaces. They have the most beautiful aesthetic appearance, being a source of beautiful and even fire.

Video review of Pini Kay

The average cost is approximately 8,000 rubles. per ton

The most common are RUF briquettes. They can be made from small particles and even dust, which are pressed into rectangular or square shapes.

RUF briquettes have many advantages, including:

- Ease of use

- Easy to stack and store

- High thermal conductivity

- No harmful binding additives in the composition

Briquettes of this shape and structure are able to smolder the longest in classic solid-state boilers. Due to their high density, they can be stored in high humidity conditions for an unlimited period of time. Even despite their higher cost compared to other types, their price per unit of heat is lower. Average price 6,000 rubles per ton

NESTRO fuel briquettes, unlike other varieties, are made exclusively from large sawdust, which is tightly pressed mechanically. They are the cheapest among the varieties considered, as they do not require the use of special equipment during the production process.

Among the shortcomings are noted:

- Easily disintegrates if improperly transported

- Burn out quickly

- Can only be stored in low humidity areas

Video of the combustion process

NESTRO briquettes may be similar in appearance to Pini&Kay and have a similar hole in the center. However, during the manufacturing process they are not treated with high temperatures, as a result of which they do not allow for an even fire over a long period of time.

The average cost is approximately 7,500 rubles. per ton

Wood burning stove design

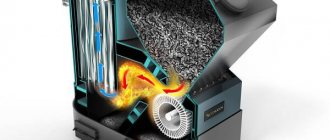

Let's take a closer look at the design of a wood-burning stove using the example of the structure of a cast-iron boiler-stove.

The name boiler refers to various furnace units whose walls are not made of brickwork. The design of the bath heater consists of two main compartments:

- Combustion chamber (furnace);

- Stone backfill chamber.

The chamber filled with stone is open inside the steam room. The stones are heat accumulators that heat the air inside the steam room. Their temperature in a heated space can reach 600 ºC. Water is poured onto hot stones to create steam.

A cast-iron wood-burning stove produces good steam only during the heating process; after it is finished, it begins to cool down and high-quality steam is not produced.

The stones are heated through the surface of the cast iron firebox. The geometric shape of the internal space of the firebox is made with a dome-shaped top, this ensures the rise of heated air masses upward, circulation and transfer of heat to the walls of the furnace. The size of the internal space of the combustion chamber determines the capacity of the firewood and the heating rate of the bath.

The exit from the chamber where the wood is burning is arranged in a rest room or in a utility room. This structure is called an elongated firebox; it eliminates the possibility of carbon monoxide poisoning and the formation of smoke in the internal space of the steam room. The chimney is led upward, its height ensures the draft and quality of combustion of wood inside the firebox.

At the bottom of the firebox there is a cast iron grate through which ash spills out. One door closes the firebox space, firewood is thrown through it, the second closes the ash pan (ash collection area under the grate of the combustion chamber).

Additional arrangement of a stone chimney in the wall of the bathhouse, with one or more surfaces opening into the interior of the steam room, will heat the steam room. Radiation of heat from heated stones will provide the main heating of the bath.

A convenient addition to the two main chambers can be a water heater that will heat water for the shower.

A firebox door made of heat-resistant glass will be a beautiful, spectacular addition, a living decoration of the bathhouse. Glass material will allow you to admire the fire and burning wood.

The modern construction market provides a wide selection of cast iron stove designs of various designs. The best models of sauna stoves are made from cast iron material.

Water jacket

The principle of operation of a solid fuel boiler implies the presence of double walls in its firebox: in the interval between them they are filled with coolant. This design is called a water jacket. As the fuel burns, the liquid in the water jacket heats up. This leads to the appearance of heat flows that lift the hot coolant to the upper part of the container. From here, hot water flows into the heat pipe. After the liquid passes through the entire heating circuit and gives off heat to the home, it returns back in a cooled state. For these purposes it has a lower pipe.

To speed up the circulation of water inside the heating system, special pumps are installed on some solid fuel boilers. However, most models are produced for open heating systems. This refers to schemes where the coolant moves not due to a running pump, but due to a slight slope of the pipeline. This is explained by the simplicity, reliability and efficiency of inertial systems. In addition, they are completely independent of the availability of electrical energy. Thanks to this, they can be used in remote areas deprived of the benefits of civilization.

Rating of the best manufacturers

Due to the complexity of the design, the likelihood of an automatic boiler breaking down is higher than a classic one.

Taking into account the fact that such an event complicates the operation of the unit and threatens the destruction of the heating system due to freezing of the coolant, the issue of choosing the brand of the unit deserves special attention. Users consider boilers from the following companies to be the most reliable:

- “Thermorobot”, “Zota Stakhanov”, KAZ Kordi, TIS Eko, Altep, Faci (Russia).

- Roda, Buderus (Germany).

- Metal-Fach (Czech Republic).

- Pereko, Galmet, Heiztechnick, Defro, Stalmark (Poland).

- Vulkan (Ukraine).

- Termodinamic, Emtas (Türkiye).

High-quality boilers with a drum hopper (without feeder):

- "Auto-30".

- "Ugleavtomat"

- "Master."

- "Prometheus".

- Carborobot (Hungary).

Russian boilers, which are not inferior in quality to imported ones, are more profitable to purchase due to their cost and speed of repair.

About some important points

Typically, long-burning stoves are made of metal. The optimal metal thickness is 4 mm (more is possible). It is better to make the chimney consisting of several parts to make it easier to clean in the future. The chimney also needs a fairly thick metal - this will extend the service life of the element.

On a note! If you work in the garage often and for a long time, then do not skimp on materials!

For the body, you can use a piece of large pipe, a gas cylinder or an old 200-liter barrel; or, alternatively, it can be welded from pieces of metal. You need to make a hole on top of the body to install the chimney (its diameter should be about 15 cm); another hole (10 cm in diameter) will be required for air flow, without which the wood will not burn.

You will also need a load - it will put pressure on the fuel. This should be a heavy iron circle with a diameter slightly smaller (several millimeters) than the diameter of the body. The circle should have a small air duct through which oxygen will flow.

Preparatory work

Rolled steel must be cut into blanks. Of course, you can do this on your own - using a grinder, but a more rational way is to order cutting in some workshop equipped with guillotine shears and a gas cutter. The work will be done faster and better. And it won’t cost much more than manual cutting, because grinder wheels also cost money.

Drawing: front and side sections of the furnace

Drawing of a homemade stove

Steel sheets must be cut into parts, the list of which is shown in the table.

Table: quantity and dimensions of steel sheets

| Length and width of workpiece (mm) | Quantity |

| Steel sheet 3mm thick | |

| 440x420 | 1 |

| 420x210 | 1 |

| 900x500 | 2 |

| 900x400 | 1 |

| 500x400 | 3 |

| 350x140 | 1 |

| 390x350 | 1 |

| Steel sheet 4 mm thick | |

| 360x170 | 1 |

| 400x70 | 4 |

| 400x50 | 1 |

| 150x70 | 2 |

| 900x360 | 1 |

| 900x460 | 2 |

| 500x360 | 1 |

| 360x150 | 1 |

| 360x360 | 1 |

It is also necessary to make nozzles from pipes and grate parts from corners.

It is clear that with a weight of 150 kg, moving the finished stove will be difficult. Therefore, it should be assembled directly at the place intended for installation. It also needs to be prepared:

- The location is chosen so that the stove is at least 1 m away from the walls. If the walls are decorated with non-combustible material, for example, vermiculite plaster, the specified distance can be reduced to 0.85 m.

- A stand is constructed from any non-flammable material, extending 300 mm beyond the boundaries of the stove in each direction. The easiest way is to lay it out of brick.

A basalt or asbestos lining is laid on the floor on the side of the fire door, and on top of it is a steel sheet with a thickness of at least 1.5 mm. The dimensions of this fireproof coating are selected in such a way that the floor is protected within a radius of 1.2 m from the axis of the combustion door.