The Breneran or Buleryan stove is a highly efficient small-sized heating device produced by Canadian, German and Russian companies. It vaguely resembles a classic potbelly stove, but has its own improved characteristics and high efficiency. Furnaces of this type are mass-produced; the model range differs in power and design. You can make a Breneran stove with your own hands. The choice of product depends on the area of the room and its purpose, the space allocated for the oven, the budget and the necessary functions.

Description of the Breneran furnace

Buleryan is a German company, Breneran stoves are manufactured under license. The

Buleryan stove is a development of the German company Bulerjan, which produces heating equipment. The name Breneran refers to the same devices, but created by Russian companies under license.

Characteristics:

- There is a flat platform at the top. Used to heat food.

- The shape is cubic instead of the usual cylindrical.

- There is an ash pan, as well as a grate.

- Convection heat exchangers are recessed into the housing.

Initially, the product was conceived as a stove with an air heat exchanger, but its feasibility is not justified. The heat capacity of such a device is low, which reduces the efficiency.

To preserve heat, owners use various storage devices for convection pipes. They can also be placed in brickwork, forming something like a fireplace. This is a version of the Breneran sauna stove.

The Breneran stove can be used for cooking, including

Currently, the Breneran boiler is actively used in the following areas:

- heating of cottages and houses;

- production workshops;

- garages;

- baths;

- cafes and restaurants;

- administrative buildings in small settlements.

When choosing and installing a boiler, power, dimensions, installation location and other parameters are taken into account. They affect the efficiency and uniformity of heating of the room.

Firewood, bark, wood chips, and shavings are used as fuel. It is not recommended to choose coal as a raw material in an original furnace, since the high temperature may cause deformation of the body. You can get around this ban by upgrading the device. It is necessary to make a collector at the bottom of the heat exchanger and supply air using a blower.

There are two varieties: a Breneran boiler with a water circuit and a Breneran gas generator stove. The first type operates from water heating of the house, and the second - from gas. Also, gas generating devices often have a place for cooking.

Where to buy high-quality oven equipment?

To purchase Breneran heating stoves in Moscow, the region and regions of the Russian Federation, contact the specialists of our online store. We offer:

- Prompt delivery throughout Russia. Shipping to remote regions is carried out 1-2 days after payment for the equipment.

- Low prices. We work directly with suppliers, eliminating markups from intermediaries, which allows us to make the best offer on the market.

- Warranty from 2 years.

- Quality control and compliance of equipment with domestic and foreign standards.

To buy a Buleryan stove or get advice, contact the company’s managers by phone or leave a request for a call back.

The manufacturer that produces long-burning stoves, Breneran, has accumulated impressive experience in the production of such equipment. These products have decent demand on the Russian market. The company gives a 2.5 year guarantee for the reliability and safety of its products.

The production company Laotherm has been present on the Russian market since 1993. Previously it produced equipment under the Buleryan brand. Since 2005, the products received a modern brand name - Breneran. This company also produces more budget models - Buran stoves. They are in no way inferior to their predecessor.

Design features and operating principle

Structural components of the Buleryan stove

The Breneran stove from Canadian specialists has a long-burning convection boiler design. They enlarged the combustion doors, made a different shape for the blower in the form of a pipe, and installed a throttle inside to regulate the air level. To control the power of the furnace, a lever is used that controls the throttle.

The firebox is a metal cylinder that has tubular heat exchangers on both sides. They are curved like knees. Due to the location of most of the pipe in the body of the stove, the air receives up to 70% of the heat from the wood. This allows air to be heated to 100°C at an oven temperature of 60°C.

The firebox is divided into three chambers. A grate or metal tray is installed in the lower part. A metal sheet is mounted under the arch of the firebox. Volatile compounds are burned out in the upper chamber.

Combustion products are discharged through a special hole in the afterburner chamber. At the beginning of the chimney there is a damper with a 90° sector. To select the correct rod, a gap is made around the metal plate that adjusts it. It is equal to 10-15% of the chimney diameter.

The original furnaces also have a device for pyrolysis combustion of gases - an economizer. It is installed near the outlet opening on the horizontal section of the chimney. In order for the combustion products to have time to cool, the pipe must have an optimal height.

Unit design

Breneran is a successful design that runs on solid fuel. It has many advantages:

- The housing serves as a forced convector through which all the oxygen in the room passes. In this case, air exchange is carried out naturally - due to the different densities of heated and cool air.

- You can burn peat briquettes, logs, waste from the paper and woodworking industries.

- High efficiency of the stove - it reaches 80%.

- Drawings of this heating device are widespread and can be found without much difficulty on the World Wide Web.

- The materials and equipment for installing the product are quite simple and are not very expensive. You will need a welding machine, a pipe bending device, metal sheets and stainless steel heat exchangers.

- The installation of the equipment itself, as well as the principle of its operation, is quite simple.

Disadvantages of the design

Buleryan has no visible negative sides. These devices are called “furnaces without flaws.” But if you understand the design well, you can still find negative aspects:

- Burning coal in a stove may damage the device. The use of flammable liquids and gases is also prohibited.

- The operating principle is based on the combustion of wood and paper. In this case, reaction water is released, which is formed during the breakdown of molecules of living organisms.

Modern design Sellers, when advertising Breneran, say that when burning, wood does not form ash, but it is present in the wood initially. Therefore, ash particles fly into the chimney pipe.

The resulting water after the reaction precipitates as condensate. Moreover, this is not just a contaminated liquid, but a mixture of ash particles and a thin film rolled into a lump. The resulting toxins fall into the sump and have an unpleasant odor. This “water” always needs to be taken out somewhere, because it cannot be poured into the garden - otherwise the soil will be poisoned. In connection with this not very pleasant phenomenon, a heating device is often used in greenhouses, where the soil must be renewed annually.

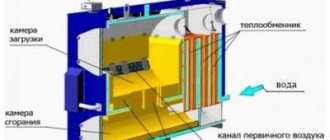

Device diagram

The product is based on the design of a slow-burning steel convection-tube air boiler. Sometimes it is called a furnace-heater type device.

Buleryan consists of the following parts:

- Fireboxes. Heat exchangers are recessed into its walls by 2/3 of the diameter. In this case, 70% of the heat released in the firebox during smoldering is transferred from the air to the tubes. And 10% is distributed throughout the oven and heats the air.

- Doors that close tightly.

- Blower type pipe.

- Throttle. Using it, you can regulate the power of the device, and when it is closed, the oven goes out.

- Grate bars made of cast iron. When installing the product, they are placed below at a level slightly more than half of the firebox.

- Partitions located horizontally. It is welded from the top to a quarter of the height of the firebox and at the same time reaches the front side by a fifth of the entire size of the firebox. This jumper has holes with a total area of 7%.

Advantages and disadvantages

Firewood must be prepared in advance so that it is completely dry.

The positive aspects of Breneran include:

- Mobility. The product has compact dimensions, so it is convenient to transport.

- Compactness. The configuration of the furnace allows the device to be installed in small temporary buildings.

- Safety. This is achieved due to the tightness of the working chamber and the use of a single-door design. There are also obstacles to accidentally touching hot metal parts.

- High performance. The room is heated in the shortest possible time due to forced convection.

- Possibility of long-term operation. The Breneran sauna stove can operate for several hours on one load of fuel.

- Easy to use and highly reliable.

The disadvantages include achieving high productivity only when using completely dry firewood. Humidity more than 10% reduces combustion intensity and reduces efficiency. The oven also doesn't hold heat well. After the fuel burns out, the temperature in the room decreases. To improve operating efficiency, it is also important to provide additional thermal insulation to the chimney.

Drawings and diagrams of buleryan for making it yourself

Despite the fact that manufacturers keep the exact parameters and drawings of the convection ovens they produce secret, taking dimensions from the finished product is not difficult. Thanks to passionate people, today we have an almost complete set of design documentation. It must be said that when making a buleryan it is important to observe the ratio of the sizes of all parts of the unit, so you can adapt the drawings presented below as an example to your conditions.

Drawing of the buleryan door

Buleryan's drawing

Buleryan's drawing

Buleryan's drawing

Oven operation and maintenance

Once a year, you need to clean the chimney so that the stove does not fill with smoke.

In order for the Breneran stove to work efficiently, it is necessary to comply with the operating conditions and properly maintain the heater.

Basic advice given by experts:

- You can only heat with dry, finely chopped wood. Place paper or cardboard under them.

- It is not recommended to preheat the oven for more than 30 minutes with the damper fully open. Breneran is designed for smoldering fuel, which can cause some of the thermal energy to escape.

- After the wood has completely burned out, the stove switches to gasification mode. To do this, you need to close the gate and throttle.

If the potbelly stove fills with smoke, one of the following errors can be judged:

- Low chimney height. Optimal performance is ensured by a pipe 5 meters high.

- The slide valve is closed.

- The smoke channel is clogged with soot. It needs to be cleaned. Preventive cleaning is carried out once a year.

Contamination of the furnace impairs its draft, which reduces heat transfer. For cleaning, you can seek help from specialists.

How to install it yourself

Installing it yourself is not so easy. The furnace, like all other metal furnaces, produces harsh thermal radiation. Therefore, it is necessary to adequately evaluate where exactly to place the stove so that there are no fire hazards. The average weight of a Breneran stove is 105 kilograms - this fact must be taken into account during transportation and installation.

There is no need for a monumental foundation for the Breneran furnace, but it is advisable to make it higher than the floor level to a maximum of 20 centimeters. Heating elements must be protected, as they are hot metal. For this stove, it is advisable to choose stainless steel pipes so that they last longer and are of better quality.

Popular models

Model range by power for the home, garage and bathhouse.

At the moment, there are several popular models of the Breneran brand:

- Breneran AOT-14. This is one of the largest stoves, capable of heating an area of 400 sq.m. Made from steel. Can work for 10 hours. Used for heating cottages and country houses.

- Aqua Breneran. Heating is carried out by circulating the liquid and heating it. Suitable for heating large areas, workshops, workshops. Operating time from one fill of fuel is 6-8 hours. There is a water tank.

- Breneran AOT-08 type 005. Allows you to cook food and heat the house. A gas generator stove is suitable for heating small rooms.

- Aquaten. This is a unique stove with a different design. Its pipes are connected to heating radiators, through which coolant flows. Made of high strength steel. Instead of fuel, a heating element with a power of up to 1 kW can be used to operate the Aqua Breneran boiler.

The choice of a suitable model depends on several criteria: room area, which affects power, type of fuel, dimensions, required functions.

If you have the skills and professional equipment, you can create a stove yourself according to the instructions. Also, a home craftsman can upgrade it with his own hands.

The ingenious design of the Breneran stoves

The unit is a solid metal structure containing many welded pipes, which are necessary to create forced convection. This structure allows the air to heat up quickly and be distributed evenly. The design of the Breneran stove is very impressive.

The body of the heater stove is made of steel 2-3 mm thick. There is a heat-resistant firebox made of 5 mm thick steel and a compartment where stones are placed. The kit also includes a stainless steel water tank.

The operating principle of this brand of oven

The quality of the firewood you use, the height of the chimney, the operating mode of the stove and the features of its installation will determine how quickly the room will warm up after the first fuel supply.

Of course, everyone is interested in the economical use of heating materials, so such factors are important to take into account. If everything is done correctly, the stove can heat perfectly for about 7 hours with one load of firewood.

Skilled bath attendants can achieve 12-hour operation of the stove, which is confirmed by numerous reviews, but the heat will be moderate.

The operation of Breneran furnaces is very similar to the principle of operation of a gas generator. The technology is this: a flow of hot air circulates at the top, and cold air rises from below. The air in each pipe instantly warms up to 60-150 degrees. After solid quality fuel is burned, the gas enters the ejectors, where it is completely burned. Due to this, a high efficiency of the furnace is achieved - 80%. The peculiarity of the model is that it is capable of operating in 2 modes - “gasification” and “fast heating”. In this way, two tasks are performed: instant heating of the air and maintaining the optimal temperature.

Adjusting modes

Using the switch, which functions for the “Russian bath” and “Finnish sauna” modes, you can adjust the heating temperature and humidity level in the steam room. This device is located near the door through which firewood is supplied to the firebox.

Switching modes occurs according to the following principle:

- If it is necessary to create a dry sauna atmosphere in the steam room, the valve of the device opens, allowing cold air to pass through. The air flow moves through the pipes and, already heated, enters the heater. The temperature of the stones increases, which warms the surrounding space and dries out the air in the room.

- If you want to have a good steam in a bathhouse with a broom, you need to close the valve tightly. Thus, air access is blocked and the heater is heated from the hot stove body. To create wet steam, the stones are poured with liquid.

Almost always, the Buleryan heating device for a bath includes a water tank installed on top of the structure. The liquid heated in it is usually used for washing. Wooden strips connected to each other serve as protection against contact between a person and the hot stove body.

Operational moments

When starting the Breneran unit, you need to slightly open the vent and carefully burn a small amount of paper or wood chips in the firebox. After the flame burns, you can add firewood. Until the required temperature is established in the steam room, the oven will operate continuously. In just 45 minutes the room will warm up to 100 °C. Then you can cover all the holes through which oxygen enters the firebox. This reduces the intensity of the flame in the fuel combustion device, but the stove is already so hot that the heat emanating from it heats the water and stones. When the cobblestones are heated sufficiently, the steam room receives a high temperature that can last up to two hours.

Breneran stove range

There are six main variations of Breneran stoves. When choosing suitable equipment, you should take note of its characteristics, which are indicated by the manufacturer in the technical documentation.

| Model | Characteristics |

| AOT 19 | The design has 8 pairs of convection pipes. Stove power 35 kW. The equipment copes with heating rooms with a volume of 1000 m³. The total weight of the fireplace without firewood is 240 kg. The combustion chamber can accommodate up to 200 kg of fuel. This is a Breneran wood-burning gas generator stove with long burning time, perfect for heating a home with several floors and rooms. |

| AOT 16 | This is another model that is suitable for heating rooms up to 600 m³. The weight of the equipment when the firebox is empty reaches 190 kg, so a foundation will be required during installation. AOT 16 is well suited for industrial purposes. Based on the model, air heating of several rooms isolated from each other is installed. |

| AOT 14 | There are two types of equipment here, which differ in the presence of a fireproof glass door. The model is necessary for installation under brickwork, with imitation under a fireplace or Russian stove. The productivity can be 18 kW, this is enough to properly warm up rooms with 180 m² or a volume of up to 400 m³. |

| AOT 11 | More suitable for domestic rather than industrial conditions. The compact dimensions of AOT 11 made it possible to reduce the weight to 100 kg, while maintaining a high efficiency of 11 kW. The stove is capable of heating one large room or hall with a volume of 200 m³. By creating an air duct system for certain rooms, a boiler of this modification is capable of heating the entire house with an area of about 100 m². |

| AOT 08 | Model AOT 08 is a compact but efficient stove; it is ideal for heating cold rooms: cottages, garages, greenhouses. Weighs only 70 kg when the firebox is empty. For efficient circulation of warm air, there are seven convection channels on the body. The range includes models with and without glass doors. The maximum productivity is 8 kW, the volume of the heated room is 140 m³. |

| AOT 06 | The Breneran AOT 06 stove is a long-burning household solid fuel air-heating boiler using wood. Designed for efficient and fast heating of rooms with a total volume of up to 100 m³. The model is successfully used for heating individual rooms. The furnace power is not enough to connect the air duct system. The series includes modifications with glass and all-metal doors. |

In conclusion, we suggest watching a video with a review of the Breneran stove.

PVC installation

If in a country cottage it is planned to install water heating from a brick stove (wood-burning), the heat exchanger is designed individually, for a specific stove. Such a device is practically beyond repair, so for installation a specialist stove specialist is hired who can professionally perform all the work:

- Make a heat exchanger and double check its quality - before and after installation.

- Install the heat exchanger at the required stage (after completing the foundation), then continue laying, observing certain rules. When installing the heat exchanger, compensation gaps are left, leaving 1-1.5 cm to the walls of the combustion chamber. Gaps that take into account thermal expansion are also needed when installing pipes.

- When installing a heat exchanger with pipes and for insulation, use only heat-resistant seals.

Steel pipes for the manufacture of a heat exchangerSource 36doors.ru