Here you will learn:

- Disadvantages of other devices

- Infrared heaters - operating principle

- Advantages and disadvantages

- Types of infrared industrial heaters

- Scope of application

- Popular models of IR heaters

Heating industrial and industrial premises is a bit of a problem - not every heating device can effectively heat large volumes, including those with high ceilings. The way out of the situation is industrial infrared heaters, optimal for use in large rooms. Let's look at what these heaters are, how they work and what their advantages are.

Operation of infrared heaterscolor

The operation of infrared heaters

is the order of operation of heat-generating devices that convert consumed energy into heat, which is transferred to objects through infrared radiation.color>

Operating principlecolor>

The operating principles of infrared heaters are significantly different from any other types of heating devices. Its functioning is associated with the generation of thermal energy in a wide spectrum of infrared radiation. Moreover, the maximum value of the radiation intensity in this spectrum falls on a wavelength proportional to the heating temperature of the radiating body. Thermal energy is delivered to the required location by electromagnetic waves at a speed of about 300,000 km/sec. In this regard, infrared heating differs from other types in that the delivery of infrared heat occurs almost immediately after the heater is turned on. Conversely, the effect of heat rays stops when turned off. There is no fundamental difference: turning on or off a light source or a heat source in a room.

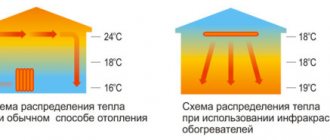

The operation of infrared heaters is based on the fact that infrared radiation primarily heats objects that are in its path. The air practically does not directly receive heat from the infrared ray; it passes it through itself. Objects, gradually heating up by convection, transfer heat to the air. With this heating method, objects located in the zone of infrared radiation will always be 2 - 3 ° C warmer than the air. The effect of infrared heaters is that the thermal energy generated by them is 90% spent to heat objects and only 10% is directly absorbed by the air mass, so they have high efficiency. All other types of heaters spend the bulk of the energy consumed on heating the air and only from it do all other objects heat up. Due to the fact that the infrared ray is almost not absorbed by the air and does not reduce the oxygen content in it, comfortable conditions for human stay are created. At the same time, he does not experience such sensations as lack of oxygen, headache, general malaise and fatigue, which are inherent in staying in a room heated by convection heaters.

Features of applicationcolor>

This type of heater is widely used in creating local heating zones for workplaces in industrial enterprises and is the only way to heat a person in rooms with large ceilings and heat losses. The use of infrared heaters makes it possible to create a local heating zone with a spot diameter approximately equal to (2 * h), that is, equal to two heights of the emitter suspension. At the same time, the heat transfer area is much larger than that of conventional heaters, which means the heating time is reduced. Reducing the heater operating time leads to energy savings. Therefore, infrared heaters today are the most efficient electric heating devices, allowing energy savings of about 50% of the calculated power. They have found wide application in heating houses, cottages, garages, industrial premises, etc.

IR gas heater

Gas-powered infrared heating systems have many advantages that attract potential buyers. The main advantage of use is considered to be the high efficiency of the device. If we compare it with other systems operating on gas, then fuel consumption in IR is 80% less. Provided that infrared is actively used, industrial heating equipment pays for itself within two seasons.

Gas infrared heater

Types of infrared heaters for large rooms

The most common infrared heaters are gas and electric, each of which has several types. The main advantage of all infrared heaters is their efficiency.

Compared to a conventional heating system, infrared heaters will be twice as economical, and when installing a new infrared

equipment, it pays for itself in 1-2 heating seasons.

Gas IR heaters

IR gas heaters are mounted on the ceiling and run on gas. They are divided into two types: light and dark. The selection and calculation of power is based on the volume of the heated room, the presence of air flows and the required heating temperature. The disadvantages for gas IR heaters are: the presence of a gas pipeline system, additional installation of an air vent, and a ceiling height of at least 4 meters.

Electric IR heaters

Infrared heaters with ceramic emitters can be installed both on the wall and on the ceiling. They can be used in any type of premises, including outdoors, which is convenient for short-term work outdoors. IR heaters are mounted in any convenient place and connected to the mains.

The advantages of IR heaters are that they can be used in rooms with a high fire hazard, in dusty and damp rooms, they are mobile and can be reconnected within 5-10 minutes. Infrared heating is safe and economical. IR type heaters can be found in hospitals and educational institutions. They are economical and multifunctional.

You can calculate the power of infrared heaters yourself or with the help of a heating specialist from the Infratorg company.

Advantages of gas emitters

Experience in using gas emitters has made it possible to discover several key advantages that set the equipment apart from its analogues:

- possibility of local heating of the room;

- reduction of heat consumption;

- payback in a short time;

- no costs for maintaining boiler house workers;

- the ability to turn off the device in winter and instantly warm up the unheated area if necessary.

The technical characteristics of industrial infrared heaters do not allow their use at home. The minimum ceiling height of the room required for safe use is from 3 to 4 meters.

What is an infrared heatercolor

Infrared heater

– - a heating device that uses infrared radiation in its operation and is used for primary or additional heating of premises, as well as local areas of outdoor space or workplaces in the workshop.color>

Heaters are usually used for heating rooms. Depending on the method of heat transfer, they can be convective or radiant. Convective ones work on the principle of mixing cold and hot air, and the difference in temperature of the air mixture on the ceiling and floor can reach large values. Radiant ones transfer heat mainly due to infrared radiation; they are placed above the heated area or on the ceilings and walls of the room.

Air, if it is not saturated with water vapor, almost completely transmits radiant energy. This energy directly heats any objects in its path, and they, in turn, give off heat to the air. Which gives a significant economic effect compared to convection heating, which uses part of the generated heat to heat the under-ceiling space where it is not needed. In addition, infrared radiation is felt by a person immediately after it is turned on, which eliminates the need to preheat the room and can significantly reduce heating costs.

Infrared heater devicecolor>

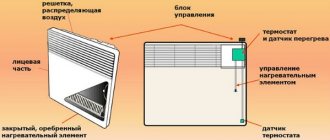

The main design element of an infrared heater is an emitter that generates infrared radiation. In order to ensure directional radiation and protect the housing from overheating, a reflector made of a heat-resistant element is placed behind the emitter. The reflector on the reverse side is covered with heat-insulating material, which further protects the housing from exposure to high temperatures. If the heater is used in places where people or animals are located, the emitter is covered with a metal mesh to prevent involuntary burns or electric shock.

Infrared wavelengthcolor>

Infrared Wave Range

is an electromagnetic wave located in the emission range from 0.74 microns. up to 2000 microns.color>

Infrared heaters are heating devices that provide heat transfer from a high-temperature emitter to bodies with a lower temperature through electromagnetic (infrared) radiation. Infrared radiation is absorbed by surfaces encountered in its path, turning into thermal energy, and the air is heated from these surfaces. This allows you to significantly save energy on space heating compared to convection heating. The wavelength of the infrared radiation range depends on the heating temperature of the emitters installed in infrared heaters. It is in the range from 0.74 microns. up to 2000 microns. The dependence of the wavelength of infrared radiation on temperature expresses Wien's displacement law. A graphical representation of this law for various temperatures is shown in the figure. It can be seen from the graph that the surface area under the curve relating to a certain temperature is proportional to the amount of radiant energy, and it increases greatly with increasing temperature. In addition, we can conclude that the wavelength λ

at which the maximum value of the curve is determined shifts by smaller values with increasing temperature.

Advantages and disadvantages of electric heaters

Many people cannot get enough of infrared heaters due to their striking advantages:

- ideal for working in dusty and dirty rooms, as well as for buildings with a high level of fire hazard;

- the possibility of use not only as a general and partial heating system, but also as special equipment for drying;

- a spot heater is used in paint and varnish production, for heating steel before processing, and arranging an anti-icing system for the floor;

- Electric heaters are actively used in educational and medical institutions.

We recommend: How to install infrared ceiling heating?

The downside is the high price of electricity. You can slightly reduce heating costs by installing industrial temperature sensors.

Infrared heating systems system based on infrared emitters

The basis of an infrared heating system is infrared heaters. The principle of their operation is based on the fact that the energy of burned gas or electricity is converted into thermal radiation energy.

Advantages: the ability to target heat to the desired zone and heat individual local zones on a large scale.

Disadvantages: if it is necessary to warm up the entire volume of air in the room, the efficiency of the devices is greatly reduced; radiating surfaces heated to high temperatures are located directly in the heated room, which can lead to a fire; emitters running on natural gas require a complex and extensive gas supply system, which greatly increases the cost of the entire project; Gas-powered emitters burn oxygen from the room, which leads to the need for ventilation; emitters running on electricity consume a lot of electricity, which is uneconomical; Possible deterioration in the well-being of personnel exposed to direct radiation.

Emitters are effective only when in a large volume room it is necessary to heat up several local working areas in a targeted manner; the effectiveness of their use for heating the entire volume of the room as a whole is extremely low.

The IR heater for industrial premises has the following design:

– heating element – ceramic IR emitters;

– body – stainless steel;

– connection – heat-resistant wire and terminal box;

– protective grille and other elements on request.

Local heating of the workplace is much more effective than general heating of the building. The infrared heating device begins to emit heat immediately after switching on, so there is no need to leave the device on for a long time.

Industrial infrared heaters IkoLine.

IkoLine infrared heaters with a power from 2.0 to 4.0 kW are conventionally called industrial

. because most often they are used in various industrial premises, workshops, car service centers, warehouses and other premises with ceiling heights from 3.3 to 12.0 meters.

There are, of course, residential premises with high shelves where it is advisable to use more powerful industrial infrared heaters, but such cases are rather the exception.

If you want to create comfortable and economical heating for your production, workshop or warehouse, then IkoLine industrial infrared heaters are the best choice for you. IkoLine industrial infrared heaters are also successfully used in gyms, indoor tennis courts, concert halls and stages, and train stations. In addition to being very efficient and economical, IkoLine heaters are also very easy to use and durable. And of course, an important factor is the low cost of these heaters with high quality. The warranty period for industrial infrared heaters IkoLine is 5 years! Service life 25 - 30 years!

“Is there a fireplace in your house? No, our owner saves on buying firewood.

. take a blanket and sit by the window on the sunny side"

A production facility is a structure that has an area that can rarely be designated in square meters by a three-digit number. Usually this is a four- or sometimes five-digit figure. The height of industrial premises usually starts at 6 meters, reaching 25 meters or more. How to heat an industrial building. with this question, we are usually interested in the heat in the lower part of the room. That is, where people work and production equipment is located. Conclusion: in most cases, thermal comfort is required at a height of 2-3 m from the floor level.

Warehouse heating using fan heaters

Implementing a heating system for warehouses and workshops using water fan heaters is a fairly popular and effective solution. This is practically the same as water heating, when the heat generator is a boiler and the coolant is water, but instead of radiators and convectors, water heaters (fan heaters) are used. Their design is based on a tubular heat exchanger with a fan. Hot water is supplied to the heat exchanger, the fan drives air through the heated heat exchanger, as a result, hot air masses are pumped into the room.

Warehouse heating with fan heaters has a number of advantages:

- Rapid heating of the object. Thanks to powerful fans, these devices provide air circulation, due to which the room warms up faster than with radiators, radiators, or convectors.

- Uniform heating of the object. It is also a consequence of forced air circulation.

- Energy efficiency. Heaters use electrical power only to operate the fan. The fuel can be any energy carrier that is beneficial to the customer - you can set up a system with a heat source in the form of a gas boiler, liquid fuel boiler or even central heating.

Fan heaters are installed on the walls and under the ceiling.

Air heating installation

Heating of production workshops

Having a clear plan for the location of components and assemblies of the system, it is very easy to carry out installation work by the company’s employees. However, if you wish, you can contact specialized companies

When installing it yourself, first of all, you need to pay attention to the completeness of the delivery. Manufacturers supply air ducts, dampers, inserts and other standard elements to order

In addition, you can additionally purchase the following materials:

- flexible lines

- aluminum tape

- insulation and mounting tape

Insulating some areas is very important because it helps prevent condensation. For this purpose, a layer of foil insulation on a self-adhesive base is laid on top of the pipeline walls.

Its thickness may vary. The most in demand are materials with a thickness of 3-5 millimeters.

Depending on the geometry of the premises and the design solution, rigid or flexible lines are installed. Individual sections are connected to each other using reinforced tape, plastic or metal clamps. All installation work boils down to performing the following set of actions:

- installation of warm air supply lines

- installation of distribution sockets

- installation of a heat generating unit

- laying a thermal insulation layer

- installation of additional equipment

Air heating in warehouses. production and utility rooms is a complete heat supply system. It is characterized by efficiency and high efficiency.

Warehouse water heating

When using centralized water heating systems for a warehouse, heating occurs due to hot water, which is supplied through a system of water pipes and heats the radiators. The water comes from the central heating system, where it is heated to operating temperature. Depending on the conditions, heating is possible in the boiler room, if there is one, as well as using special electrical appliances - boilers.

Warehouse water heating is used only in small areas with low ceilings. Otherwise, hot air will rise to the top, and the air masses below will remain unheated. Due to the high altitude, the air will not circulate evenly and the temperature separation will be significant.

Also, the water heating system for a warehouse is not very popular due to the complexity of installation, as well as the large amount of space occupied, which does not allow the warehouse space to be used with maximum efficiency, since the same rack cannot be placed close to the wall and more space will have to be left for the passage of equipment.

The coolant in a water heating system can be water or water-based antifreeze. For small rooms, you can install a circuit with natural circulation. The pipes are placed at an angle so that the water moves under the influence of gravity. This makes installation cheaper and easier, since there is no need to install a pump. For large warehouses, such a solution will not be effective; installation of pumps is required. Forced circulation systems have high efficiency, but require electricity.

Water heating of warehouses is often chosen by owners as the most optimal option. In those places where it is possible to connect to a centralized heating system, the task is simplified. If this is not possible, the calculation of warehouse heating should include the selection of a boiler and the installation of a separate room for the boiler room. The aesthetic component is cited as a disadvantage of such a system - the pipes along the walls do not decorate the warehouse.

The advantage of water systems for warehouses is uniform heating of heating devices, the air does not dry out, and optimal conditions are maintained for a wide range of goods. But water heating for warehouses is not recommended for use in terminals above five floors. This is because warm air rises and accumulates at the top, increasing heat loss through the roof and leaving ground floor areas cold.

In warehouses with high ceilings and hot water heating, professionals install ceiling fans to improve efficiency. The rotation of the propellers in the winter ensures the circulation of warm air throughout the entire volume of the warehouse, and in the summer it provides some coolness.

There are two types of water heating for warehouses:

- single-pipe,

- two-pipe.

For single-pipe warehouse water heating systems, it is impossible to control water heating. In two-pipe water heating networks, such regulation is possible using thermostats and parallel radiators.

The boiler itself can be liquid and solid fuel, gas, electric and combined - depending on the type of fuel used. Gas boilers are used, as a rule, only if there is a possibility of connecting to the gas main. They provide good heating with little labor, but their maintenance is very expensive - mainly due to the ever-increasing prices of gas and the need for regular and frequent testing of the equipment.

Liquid fuel boilers are explosive and require additional isolated storage space for fuel. Since fuel is consumed quickly, this also means high maintenance costs.

Solid fuel ones are the most economical for the implementation of water heating of a warehouse, but they provide extremely little heat - they are used only in small rooms and require considerable labor costs during maintenance (loading fuel, cleaning the firebox and chimney, etc.). There are also automated models, where manual labor is practically not required and there is the ability to regulate the temperature, but their price is quite high.

An electric boiler is perfect for water heating of small warehouse spaces, but use in larger spaces is not economically justified due to the high energy consumption.

Criteria for selecting contractors for the development of a heating system for industrial premises

The right choice of a contracting organization that can quickly and efficiently cope with such a difficult task as organizing optimal heating of production is 99% of success.

One of the fundamental criteria is formal – the Contractor’s membership in a specialized SRO (self-regulatory organization).

Such non-profit partnerships were created within the framework of legislation in 2009. Previously, the obligatory basis for carrying out work was the presence of an appropriate Rostechnadzor License.

Now such a criterion is membership in one of the SROs

If the Contractor is included in it, it means that he has the appropriate legislative framework, human, material resources and production base necessary to carry out contract work even on such a scale as heating factories professionally and on time. Often this factor is not given attention, and yet an organization that is not a member of the SRO does not have the right to take on such contracts

The second criterion can be called the company’s experience, both in the engineering market in general and in the segment under consideration in particular. Even the presence of all permits and qualified specialists does not guarantee high quality results.

As we have already written, this topic has many specific nuances. Inexperienced companies may simply not know about them or imagine them by hearsay, and have a superficial knowledge of the topic.

Everyone gets into trouble at some point... But you want them to be “hit” not on you, right?

Another important parameter is the number and structure of the company, as well as the qualifications of its employees. If the company is a member of the SRO, it meets the minimum requirements

But when we are talking about such an important and large-scale project as industrial heating, the minimum acceptable level is, as a rule, not enough. Therefore, it is advisable to familiarize yourself with the potential capabilities of the future Contractor in advance.

The next significant criterion is the presence of a clearly structured system for performing work and a model for managing it. Its influence on the result, it would seem, is less obvious than the parameters indicated above, but, nevertheless, many cases are known when experienced companies with competent technical workers, who approached the task quite conscientiously, “failed” the Object.

The main reason is the lack of a systematic approach to performing this work, insufficiently effective management of business processes, and the lack of a quality control system.

Finally, the level of business and personal contacts of the company with suppliers and subject knowledge of the equipment used are also important. It is no secret that, for example, heating factories is a very resource-intensive and expensive project, so the success of the result depends on how high-quality and appropriate the equipment is selected and supplied, how quickly it is delivered and installed. Overlays in this process are fraught with high costs.

In addition, the possibility of further service also plays an important role, which also depends on the level of the contractor’s relationship with suppliers and manufacturers of heating equipment.

The price level for equipment from a company with established business connections will always be lower than that of a newcomer to this business. This is due to the size of the discounts provided by manufacturers and distributors. Accordingly, a company with large discounts can offer better conditions to its Customers.

We, as a member of a specialized SRO, have been working in this area since 1999. Our structure has a powerful engineering staff, a qualified design department, as well as experienced installation teams. The staff of specialists is divided into those who work in the industrial segment and those who deal with the domestic segment - heating country houses.

Each Object is assigned an experienced manager-coordinator. The work is carried out through multi-stage control at all stages.

Our established direct contacts with manufacturers of equipment and materials allow us to complete Objects quickly and at attractive prices.

Are you looking for a reliable Contractor for heating industrial premises and workshops? We guarantee that our cooperation will be pleasant, free of headaches, and mutually beneficial!

Conclusion

Electrical equipment is more expensive than gas equipment if you use main gas fuel.

Dark units are heavier in weight and should be mounted on special brackets or hanging mounts, while light IR units are much lighter. Without preliminary calculations, it will be extremely difficult to arrange such a system so that it works optimally. It will be necessary to take into account the parameters of the room, special production conditions, the use of heaters, as well as their characteristics. If the heating area for which the device is designed is small, you should simply install several of the same ones. Date: September 25, 2022

Types of heating devices

Today's realities show that infrared heating is in sufficient demand, so equipment manufacturers are trying to approach the manufacturing issue carefully. Depending on the purpose, the types of heating devices powered by infrared healing can be divided into the following types:

- heaters. Almost everyone is familiar with a device with a lamp, often equipped with an additional support. Such devices are good for gatherings on the terrace or in the gazebo. They can also be used to heat private buildings and even greenhouses;

- lamp devices. Lamps with IR radiation are not much different from heaters, except for the installation method. They are attached to the ceiling at a certain angle. Thus, large production premises and workshops are heated;

- panels. Panel equipment powered by infrared radiation is probably the most reasonable solution for heating a home. A beautiful smooth surface, sometimes with a chosen design, fits perfectly into the overall interior and does not create any special problems for residents;

- film. There is also a film type of device. This is an indispensable basis for obtaining heat in the house based on the “warm floor” technology. But when installing equipment, it is quite acceptable to place it on the walls of the room.

In general, infrared heating has a number of advantages. It operates silently, does not create dust or deposits on surfaces, and does not take up storage space.

Infrared heater

Largest producers

The largest manufacturers of infrared heaters are the following companies:

- "EcoLine";

- "IcoLine";

- "Infra";

- "Peony";

- "Frico";

- "Mr. Hit";

- "Ballu"

- "Bilux";

- "Zilon"

- "Helios";

- "Starprogetti";

- "Hyundai".

If we rely on reviews from users or those companies that constantly use IR equipment for their production purposes, then “Peony” is considered the best among mobile installations. Each has its own advantages, the main thing is not to buy a fake device.

Advantages and disadvantages

The air heating method has undeniable advantages:

- The efficiency reaches 93%. When organizing heating, the installation of intermediate heating devices is not required.

- Heating systems of this type can be fully integrated with ventilation systems. This allows you to constantly maintain an optimal microclimate inside production complexes.

- Very low level of inertia. Immediately after activating the equipment, the air temperature in the room begins to rise.

- High efficiency has a positive effect on the economic performance of production and reduction in production costs.

Along with this, air heating also has obvious disadvantages:

- Constant technical maintenance of the active elements of the system is required. It is quite difficult to modernize already operating installations.

- To avoid interruptions in heat supply, a backup power source is required.

Automatic protection system

Unburned fuel in a sauna stove sometimes causes an explosion of the gas-air mixture. Therefore, monitoring the flame of a working nozzle is necessary for your safety. This can be done visually or using automation with modern photocells sensitive to light.

The burner protection system automatically provides the following functions:

- power regulation;

- fuel and air supply;

- completeness of gas combustion.

It is necessary to take into account the increase in dimensions of the modernized design. Especially with small bathhouse sizes. If device size is an important criterion for you, then all automation can be placed outside for compactness.

You can add automatic schemes for working with simple elements. Compact placement will save usable space in a small bathhouse

To control the combustion process, you can use an automatic factory-made installation such as SABK-8-50S. It provides a high level of security thanks to four levels of protection. The operation of furnace gas equipment with such a device will automatically stop in the event of a dangerous emergency mode.

Choosing a system for heating industrial premises

Heating of industrial premises is carried out using different types of systems, each of which requires detailed consideration. Centralized liquid or air systems are the most popular, but local heaters can also often be found.

The choice of heating system type is influenced by the following parameters:

- dimensions of the heated room;

- the amount of thermal energy required to maintain the temperature regime;

- ease of maintenance and availability of repairs.

Each system has its pros and cons, and the choice will primarily depend on the compliance of the functionality of the selected system with the requirements that apply to it. When choosing the type of system, it is necessary to calculate the heating system of an industrial building in order to have a clear understanding of how much heat the building needs.

Gas heating of warehouses

In gas heating systems for warehouses, gas air heaters or boilers are used as a heat source. This is a fairly simple and economical heating method, especially if there is a central gas main.

Special equipment is also inexpensive, but the installation of gas heating requires approval from regulatory authorities and the preparation of a competent wiring project. Each gas boiler must have its own supply pipe and a separate chimney.

The best option is a combination boiler - although it is more expensive than all its analogues, it is completely autonomous and does not depend on the central heating system, gas and electricity supply. It is equipped with several burners for any type of fuel; Depending on their types, the following types of boilers are distinguished:

- gas-wood;

- gas-diesel;

- gas-diesel-wood;

- gas-diesel-electric;

- gas-diesel-wood-electric.

Such gas heating of a warehouse will be more versatile and practical, since it will allow you not to depend on any one type of fuel and choose the most economical and cheap option in case of seasonal fluctuations in energy prices.