A business person, a manager, has to make decisions every day that will help increase the profit of the organization. Industrial enterprises especially need qualified business managers. After all, it would seem that these are minor expenses, but they are the ones that reflect the sad reality in the annual report. The number of many small amounts, when added up, results in enormous damage in the inappropriate expenditure of company funds. In order to prevent the loss of a large sum, you have to keep a daily report, which is why you even seem too stingy among your colleagues.

Industrial infrared heater IR

All this is justified and brings the desired results, for which we have to increasingly look for methods to limit costs. Optimization is something that industrial organizations regularly practice in their activities; its goal is the economical use of resources while maintaining maximum efficiency.

There is no point in saving if in the future there is a risk of losing money on replacing or repairing this or that equipment. To do this, you need to carefully weigh all the positive aspects and take into account possible negative factors, so increasing the arguments in favor of the first will help the team of specialists make a decision.

Types of infrared heaters: gas, electric 380V

Among the emitters of infrared heat flow, the following two types are distinguished, if we focus on the heating method:

- Gas heaters.

- Electric heaters.

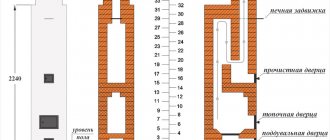

Fuel consumption of gas equipment is reduced by 50-85% in contrast to electrical appliances . The payback of such installations is noted already in 1 or 2 seasons, subject to their constant operation. The operating principle of such devices is to use gas fuel mixed with oxygen inside a special device - a burner. Combustion temperature from 800 to 1000 degrees Celsius . Combustion products are discharged through a special channel.

Electric heat emitters are widely used in industries both inside and outside buildings. The space can be heated locally (spotwise) and be an addition to the main heating system. These installations can be used in areas where there is a high level of industrial dust, fire risks, and where paint and varnish products are stored . They are also used for industrial purposes - as equipment for drying something, heating metal, being used in anti-icing systems, floor heating, and more.

Buyer mistakes

When choosing products, buyers make the mistake of not paying attention to the thickness of the anodized coating of the heat-radiating plate, indicated in the accompanying documents. It becomes covered with a “web” of cracks with a thickness of less than 25 microns, and budget models with layer thicknesses of less than 15 microns last 2–3 years, turning into a regular stove after the layer burns out.

It is preferable to choose models with a protective mesh or screen if there is a possibility of subsequent contact with the electrical appliance by children and animals.

Infrared household appliances have undeniable competitive advantages. While oil radiators and convectors heat up after being plugged in after 30 minutes, the thermal effect from infrared units is felt almost instantly. Despite the higher cost compared to analogues, infrared product items will be a profitable purchase for those buyers who value high efficiency, directivity and speed of heating, and quiet operation.

Gas: dark, light emitters

Among gas equipment that emits heat in the infrared spectrum, heaters are divided into the following two types according to the intensity method:

- Light emitters . The main feature is the bright reddish-orange color of the heating devices when they are incandescent. Variations of this class are capable of heating their metal tubes (heating elements) to a bright, intense color-light, without overheating.

- Dark emitters. The main difference is the muted color of the hot heating devices - metal tubes. They do not become red hot, which is why they are conventionally called “dark” heaters.

Light infrared heating devices are used to heat space in a room with a height of at least 4 meters from floor to ceiling . Their performance is always higher than those with lower heating intensity. Installing such devices follows a simple calculation: for every 20 cubic meters. m. it is required to install one heater with a power of 1 kW. If we take into account large areas of premises, then for every 100 sq. m. of space you will need one device with a power of 5 kW.

Dark ones are designed to heat the space in a room with an installation height of 3-3.5 m . Gas is burned in this case at temperatures from 350 to 400 degrees Celsius. These units are significantly heavier in weight than light type equipment. Therefore, this factor should always be taken into account during installation. To select this or that equipment, you need to look at the height of the ceilings in the room, the type of activity of the enterprise and the current ventilation.

Electrical: long wave, short wave

In addition to the numerous advantages of electric infrared heaters, they also have their disadvantages. The main disadvantage is the high cost. Cost reduction is carried out through the additional installation of auxiliary devices - thermostats, also of an industrial level.

Based on the type of radiation, IR can be divided into two groups:

- Long wave. They can be used where people work; these devices are not harmful to their health.

- Shortwave. Most often they are used for drying wood, but are not used in rooms where people are constantly present.

In addition to these types, there is also a gradation according to the type of installation - wall or ceiling heaters. Some modifications are provided for any type of fastening. In addition, there are stationary devices, and there are mobile (portable) ones. No flammable objects, furniture or animals should be placed near such installations.

Warehouses

For an industrial enterprise, it is important to constantly monitor the supply of raw materials and components, as well as the shipment of finished products. For surveillance in the warehouse, either outdoor cylindrical video surveillance cameras with IR illumination or dome surveillance cameras are used. Depending on the distance from the installation site to the surveillance area and the importance of monitoring details, you can choose either IP cameras with a standard video resolution of 1 MP (1280*720) or with a high video resolution of 2 MP (19820*1080). More detailed information can be found in our separate article “Video surveillance for a warehouse” .

Largest producers

The largest manufacturers of infrared heaters are the following companies:

- "EcoLine";

- "IcoLine";

- "Infra";

- "Peony";

- "Frico";

- "Mr. Hit";

- "Ballu"

- "Bilux";

- "Zilon"

- "Helios";

- "Starprogetti";

- "Hyundai".

If we rely on reviews from users or those companies that constantly use IR equipment for their production purposes, then “Peony” is considered the best among mobile installations. Each has its own advantages, the main thing is not to buy a fake device.

News

- 19.08.2013

Certification of scaffolding means according to GOST-24258-88

Dear consumers, we inform you that our products in the “Scaffolding Means” direction, intended for organizing workplaces at height, have again successfully passed the procedure...

more details

- 18.04.2013

Scaffolding in Izhevsk, market trends.

Since our specialization is the production and sale of scaffolding, towers, installation platforms and other construction equipment, I would like to highlight the most interesting...

more details

- 26.02.2013

TOP 3 gas infrared heaters

Gas dark IR heater Condor TRP24

- Power – 21.3-23.6 kW.

- Jet of heat – 4.5-8 m.

- Electricity consumption – 220 V.

- Premises area – 213-236 sq.m.

- Gas inlet pipe – 3/4 inch.

- Installation - horizontal.

- Weight – 110 kg.

- Heat transfer – 90%.

- Warranty – 2 years.

- Price – 78,350 rub.

- Manufacturer – France.

Gas IR heater Pakole Zenit U12

- Power – 50-58 kW.

- Jet of heat – 5.4-5.8 m.

- Electricity consumption – 220 V.

- Premises area – 500-580 sq.m.

- Natural gas consumption – 5.29-6.14 cubic meters/hour.

- Propane consumption – 1.72-1.99 kg/hour.

- Installation - horizontally, can be tilted.

- Weight – 128 kg.

- Efficiency – 90-92%.

- Warranty – 2 years.

- Price – 125,701 rubles.

- Manufacturer: Hungary.

Gas IR heater Pakole Zenit L18 / M with modulation burner

- Power – 34-58 kW.

- Jet of heat – 4.2-5.4 m.

- Electricity consumption – 220 V.

- Premises area – 340-580 sq.m.

- Main gas consumption is 3.6-6.14 cubic meters/hour.

- Cylinder fuel consumption is 1.17-1.99 kg/hour.

- Installation - horizontally at an angle of up to 30 degrees.

- Weight – 88 kg.

- Heat transfer – 90%.

- Warranty – 2 years.

- Price – 118,806 rubles.

- Manufacturer: Hungary.

TOP 3 electric infrared heaters

Short-wave electric IR heater Helios Titan EHT1-15 1500 W IP25 (white)

- Power – 1.5 kW.

- Heating area – 25 sq.m. maximum.

- Dimensions – 455x130x90 mm.

- Protection – not afraid of rain and moisture.

- Installation is possible both indoors and outdoors.

- Recommended installation height is 3.5-4 m.

- The wire for powering from the socket is 1.5 m.

- Kit - grille and fasteners.

- Cost – 15,225 rubles.

- Production - Italy.

Ceiling electric heater IK "Bilyuks" B1350, AOX 1300

- Power – 1.3 kW.

- Power supply – 220 V (50 Hz).

- Heating area – 26 sq.m.

- Dimensions – 1500x160x40 mm.

- Weight – 3.4 kg.

- Cost – 3300-3500 rubles.

- Production – Russia, Moscow.

High temperature IR heater Frico IR6000

- Power – 6 kW.

- Power supply – 380 V.

- Heating coverage area – 120 sq.m.

- The heating element is heated up to 700 degrees.

- Dimensions – 1800x358x83 mm.

- Weight – 14.1 kg.

- Cost – 42,100 rubles.

- Production - Sweden.

Electrical equipment is more expensive in terms of money than gas equipment if you use main gas fuel . Dark units are heavier in weight and should be mounted on special brackets or hanging mounts, while light IR units are much lighter. Without preliminary calculations, it will be extremely difficult to arrange such a system so that it works optimally. It will be necessary to take into account the parameters of the room, special production conditions, the use of heaters, as well as their characteristics. If the heating area for which the device is designed is small, you should simply install several of the same ones.

How the heating system is built

The heating system should be made from infrared heaters in such a way as to take into account the parameters of the devices themselves. It is necessary to think over a whole network of such devices. For example, in what quantity should they be used for a particular room, at what height from the floor should they be mounted, at what distance from each other should they be placed, and what should they be powered with. Gas installations serve well both with bottled and main fuel supply. It’s easier with electrics - heat emitters are connected to the electrical network with a preliminary calculation of the load on it.

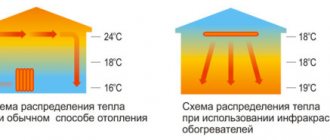

During work, people who are indoors under the influence of thermal infrared heating can receive heat not only from directly operating devices, but also from heated objects. The temperature of reflected radiation from heated surfaces will be felt by a person to be 1-2 degrees higher than from the heater itself . This suggests that for workers to feel comfortable, it is possible to reduce the power of the main heating device to +15 degrees.

Process monitoring

Video surveillance in the industrial premises sector is of paramount importance. Violation of technological processes and failure to comply with safety regulations can not only lead to injuries and even death of workers, but also affect the quality of products. That is why it seems appropriate to use IP CCTV cameras with high video resolution 2 MP (1920*1080) and ultra-high video resolution 4 MP (2592*1520), both with a fixed 2.8 mm lens and a wide viewing angle for general monitoring of the situation , and with a lens with variable focal length 2.8-12 mm for detailed control of particularly important areas. Different parts of the production process require different degrees of control. To monitor a group of packers or territory cleaners, a regular camera is sufficient, while the work of an engineer soldering expensive microcircuits requires much more attention.

A video surveillance camera can also help in the investigation of an emergency , for example, to find out whether a worker received a chemical burn with acid as a result of safety violations, or whether the plant's technologists were negligent while setting up equipment.

By combining both types of cameras, you get the opportunity to observe the situation as a whole and control key links in detail . For example, a camera with a lens with an adjustable focal length will display on the monitor screen a detailed picture of the work of the operator of a woodworking machine and turning blanks for furniture, and a wide-angle camera with a 2.8 mm lens will show you whether all workers are present at work places, whether the requirements for cleaning the premises are being met, everything whether the machines worked properly during the last shift, and so on. Depending on the height of the ceilings, the distance from the walls and other parameters, you can use dome CCTV cameras with ceiling installation and cabinet CCTV cameras that are mounted on the wall.

An alternative approach is to combine a panoramic dome camera to capture the overall view and a high-speed PTZ camera to monitor specific areas of interest.

The high-speed PTZ camera, thanks to its controllability and optical magnification, will allow you to observe each conveyor worker and the entire process as a whole: how the first worker solders the power supply board, the second mounts it into the case, the third performs technical control operations, and the fourth packs it into a box.

Please note that if there is a risk of explosion or fire, you can place the camera in a special explosion-proof or fire-resistant enclosure.