Today, many housing infrastructure facilities use autonomous gas heating for life support. If for city apartments this possibility is limited by technical limits, then for the private sector autonomous heating is one of the key aspects of housing comfort.

Gas heating equipment can provide high-quality and efficient heating of residential premises in autonomous mode. Water-heating gas boilers are exactly the type of heating equipment that allows you to create the necessary comfort and coziness not only in a private home, but also in mini-hotels, country houses and cottages.

The technical capabilities of this type of equipment can fully satisfy the needs for heating and hot water supply.

Conditions: centralized main gas

Industrial equipment operates on centralized main gas, which is supplied from central direct gas supply systems in the city or locality. Such installations are most often used in the premises of the following facilities:

- warehouses;

- workshops;

- utility central heating points;

- administrative buildings, offices, buildings;

- indoor training grounds, playgrounds and other wide areas of premises.

Gas fuel is considered the most inexpensive than all others, which is why the equipment is more economical than solid fuel or other installations. The device has a special gas burner that directly supplies gas, and also has a special heat exchanger made of high-quality copper.

The design also includes a pump for supplying water (steam) , a pressure gauge for measuring pressure indicators, a thermometer showing the optimal heating temperature and, most importantly, a tank into which the coolant liquid – water – is supplied. To this it is worth adding a security system, which is now supplied to almost all models of modern industrial gas boilers.

What you need to know to select a heater

You can’t just go to the store and buy a gas heating boiler. To choose a suitable model, you need to prepare a list of requirements for the unit - determine the thermal power, required functions, installation method and other initial data.

What items are included in the list:

- Calculate the amount of heat required to heat a cottage or apartment.

- Outline the range of tasks for a gas boiler - it should only heat the building or, in addition, serve as a water heater for household needs.

- Set aside a space for installing a heat generator. The rules allow the installation of gas-fired heating equipment in the kitchen (power up to 60 kW), attached boiler room, or in another separate room located near the outer wall of the home.

- Determine the method of installing the boiler - floor or wall. For apartments, only the hanging option is suitable.

- Consider the operating principle of your heating system. Under a gravitational scheme with natural circulation of coolant (so-called gravity flow), an appropriate energy-independent heater that operates without electricity is selected.

- Set the level of automation of the device according to your wishes. Examples of useful functions: maintaining indoor temperature according to a schedule or signals from an external weather sensor, remote control via the Internet, and so on.

- Estimate the prices of various boilers and find out how much you are willing to spend on purchasing a gas boiler.

Note. Rules for the placement and connection of gas-using installations intended for heating and hot water supply are set out in the publication on the installation of a double-circuit heater.

Before choosing a new one or replacing an outdated gas boiler for heating a private home, we highly recommend consulting the customer service department of Gorgaz (or another management company). Why is this needed:

- in addition to the general rules, regional offices have internal instructions that limit the use of gas equipment; these points are worth clarifying;

- a new or replaced boiler must be included in the project documentation, otherwise you risk incurring a fine for installation without approval;

- Our specialists will help you place the heat generator correctly in your home.

The boiler house design indicates the location of all heat generators with dimensional references to building structures

Clarification regarding internal instructions. Gorgaz often introduce their own restrictions, for example, they may prohibit the installation of an atmospheric boiler next to a forced kitchen hood. The reason is the lack of compensating air flow.

Another example: you want to remove a horizontal (coaxial) chimney from a room in an apartment building, but the office does not approve this decision, since the protruding pipe spoils the appearance of the facade. To understand all the intricacies, you will have to understand the existing types of gas heaters, but first...

Types of boilers: hot water, steam pyrolysis

Depending on whether the device will heat a hangar or a small warehouse, two heating supply options are provided - steam or hot water. To heat indoor production areas, hot water boilers are most often used. And the steam pyrolysis option is well suited for residential buildings and small premises. Which of them is more economical and which is more expensive should be calculated individually, based on the parameters of the area, principle and design of each model separately.

Heating boiler Protherm Bizon NO 100

Price

Water heating boilers are characterized by a fairly wide range of prices.

- boiler "Karakan 8-TPE" (power - 8 kW): 12,200 rubles;

- boiler "Sibir KVO 15 TPE" (power - 15 kW): 17,400 rubles;

- boiler "Hephaestus-15" (power - 15 kW): 21,570 rub. (combined, that is, it has a built-in heating element);

- boiler "Karakan 12-TGEV" (power - 12 kW, additionally equipped with a gas burner, heating element, water heating tank): 21,700 rubles.

Imported boilers are much more expensive, for example:

- boiler “BURNit WBS 25” (Bulgaria, 25 kW, can additionally operate on gas, diesel fuel and oil): RUB 86,250;

- Viadrus Hercules U22C-2 (Czech Republic, 11.7 kW): 44 thousand rubles;

Buderus Logano S111-2 (Germany, 12 kW) costs 53,440 rubles.

If there is no gas supply, owners of private houses have a choice - to purchase a solid fuel or liquid fuel boiler. A diesel fuel boiler has a number of advantages, which is why many people prefer this type of heater.

What is a distribution comb and how to install it correctly, read in this material.

Additionally: automatic boiler control, automatic fuel filling

The improvement of gas industrial boilers lies in the fact that they have automatic control, as well as automatic “filling” of fuel.

Automation consists of the following elements:

- Control block;

- elements that control the operation of the boiler - sensors, valves, control with a built-in microprocessor;

- elements safety system - warn of leaks, pressure drops, temperature increases, etc.

Thanks to this system, it is possible to control the supply of energy, shutdown, ignition of the flame, stability, and uniformity of pressure distribution in the system. And other. This also achieves significant savings in gas consumption.

Popular models

To conclude the material, we will consider the most popular brands of water heating devices from leading manufacturers that are in greatest demand in the plumbing market.

Beretta

An Italian company that produces all types of heating boilers produces high quality products. The performance of the equipment is checked during testing under extreme conditions, which help to identify the weak points of the devices.

Popular models:

- Compact;

- Ciao;

- City.

Ferroli

An international concern, originally created in Italy, specializes in the production of domestic and industrial boilers. Thanks to the quality of its products, it has been a leader in the heating systems market for many years.

Popular models:

- Domina;

- Arena.

Bosch (Bosch)

Reliable German boilers that can function in combination with a solar collector.

Popular models:

- Gaz 4000 ZWA;

- WBN6000-24C RN.

Advantages and disadvantages

The advantage of using industrial gas boilers in areas such as agriculture, production, administrative or residential buildings is easy installation and long-term operation without major repairs. But there are other advantages, which are as follows:

- The heat transfer coefficient is high , more than the consumption coefficient.

- The coolant in such boilers does not need to be brought to a boil, which eliminates the risk of compromising the integrity of the heating system itself.

- Work on different types of liquid energy without significant losses.

- Fluid movement is straight forward.

- Climate change regulators control the operation of the system.

- A control and measuring set of instruments is included in the boiler package.

- Perfectly mounted in a block-modular boiler system .

- There is protection against scale.

- Compact dimensions.

- Availability on the market.

- There is no need to connect to a power supply, which significantly reduces the cost of using the equipment.

The disadvantages of gas industrial installations are the following indicators:

- They consume fuel quickly and intensively.

- The price on the market is too high. You have to look for cheaper options from a direct supplier.

- Accidental extinguishing of the burner can lead to accidents and gas explosions. You need to choose a model with a built-in self-diagnosis and safety system - for example, thermostats that regulate the intensity of the flame.

Industrial heating equipment

Industrial gas hot water boilers, thanks to constant modernization, have the following advantages:

- The service life has increased significantly without repairs.

- Operating costs for routine maintenance of boiler equipment have been significantly reduced.

- Equipment performance has increased.

- The efficiency of boiler equipment has increased, thanks to the ability to automatically control and adjust the device load according to the air temperature.

- The reliability of the industrial boiler has increased significantly.

- There are comfortable conditions for the operator to work due to innovative automation, which is based on microprocessor circuits.

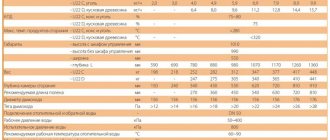

| Boiler brand KVA | KVA 0.4 | KVA 0.5 | KVA 0.6 | KVA 0.8 | KVA 1.0 | KVA 1.1 |

| Heating capacity, MW(Gcal/h) | 0,4 (0,34) | 0,5 (0,43) | 0,6 (0,5) | 0,8 (0,7) | 1,0 (0,86) | 1,1 (0,95) |

| Boiler efficiency, not less, % | 91 | 91 | 91 | 91 | 91 | 91 |

| Flue gas temperature | no more than 220 0 C | |||||

| Length, mm | 2500 | 2800 | 2800 | 2850 | 3400 | 3400 |

| Width, mm | 1200 | 1300 | 1400 | 1800 | 1800 | 1800 |

| Height, mm | 1900 | 1800 | 1900 | 1950 | 1950 | 1950 |

TOP – Description with characteristics and prices of three boilers (for an area of 1000 sq.m.)

We will describe the capabilities and main parameters of some industrial-grade gas boilers.

Floor-standing boiler Buderus Logano (2 boilers come in pairs)

- Heat exchanger – cast iron.

- The combustion chamber is closed.

- Power modes – 4 options.

- Control – intelligent, automatic.

- Burner type – atmospheric.

- Ignition - electric.

- Thermal power – 159-296 kW.

- Pressure – 4 Bar.

- Efficiency – 93%.

- Pressure thrust – 3 Pa.

- The chimney diameter is 250-360 mm.

- Manufacturer – Russia.

- Dimensions (LxWxH) – 1264x1420x1610 mm.

- Warranty – 2 years.

- Price – 776,550 – 950,000 rubles.

Gas industrial boiler VAILLANT atmoCraft

- Type of equipment – sectional.

- Installation - on the floor.

- Heat exchanger – cast iron.

- The combustion chamber is open.

- Control – LCD display, intelligent, automatic.

- Burner type – atmospheric.

- Ignition - electric.

- Thermal power – 157 kW.

- Pressure – 4 Bar.

- Heat transfer – 95%.

- Pressure thrust – 3 Pa.

- The chimney diameter is 250-375 mm.

- Dimensions (LxWxH) – 1145x1730x1012 mm.

- Manufacturer – Germany.

- Warranty – 2 years.

- Price – 550,000 – 750,000 rubles.

Industrial gas boiler PROTHERM NO-3500 Bison

- Heat exchanger and housing – steel.

- The combustion chamber is open.

- Association – cascade.

- Power modes.

- Control – intelligent, microprocessor-based.

- Burner type – atmospheric.

- Burners - there may be several variations.

- Different variations of energy carriers.

- Ignition - electric.

- Thermal power – 3500 kW.

- Thermal load – from 10 W.

- Heat transfer – 93-100%.

- Pressure thrust – 3 Pa.

- The chimney diameter is 250-360 mm.

- Dimensions (LxHxW) – 2146x390x1870 mm.

- Manufacturer – Russia.

- Warranty – 3 years.

- Price – 1.9-2.2 million rubles.

In conclusion, I would like to note that the selection of the optimal boiler model should be carried out with accurate calculations, and not approximate ones. Only in this case is its high level of functionality possible. A special formula is used for calculations: 1 kW (heating) per 10 sq. m. premises with excellent thermal insulation and a ceiling height of no more than 3 m. The boiler may have 1-2 circuits. You should also pay attention to the dimensions, weight and equipment of the equipment with all the necessary measuring instruments.

Principle of operation

This unit is a direct combustion boiler, that is, fuel is burned in it in the most common, uncomplicated way. The resulting ash is poured into the ash chamber, from where it must be removed periodically.

The most convenient to maintain are boilers in which the manufacturer has installed a pull-out tray in the ash chamber.

Fuel loading and ash removal are carried out traditionally - through the corresponding doors in the housing. The difference from conventional solid fuel heaters is the increased size of the firebox and the presence of a water heating tank. Note that boilers of this type are not double-circuit. Here, rather, we are talking about an indirect heating boiler (and partly direct), built into the boiler body.

Operating principle of the boiler

But indirect heating here is not entirely ordinary. As is known, in indirect heating boilers, heat is delivered to the heated medium using water or other coolant fluid (oil, antifreeze), which fills the heating circuit. In a water heating boiler, thermal energy is transferred using air: inside the water heating tank there are tubes connected to a heat exchanger installed in the firebox, and this entire system is essentially empty, that is, it is filled with air that circulates in it.

At first glance, such a solution may seem strange, because we are accustomed to seeing water as a coolant, the heat capacity of which is 800 times greater than the heat capacity of air. But everything falls into place if we remember that the intensity of heat transfer depends not on heat capacity, but on the temperature difference. Air, due to its low heat capacity, heats up faster than water, which means it will give off heat more actively. Since all components are located inside the boiler body, there is no heat loss, so there is no need to use a coolant with a large heat capacity.

The location of the tank affects the efficiency of the water heating system. The best performance is demonstrated by boilers in which the hot water tank is located above the firebox, and not on the side of it. This is explained by the tendency of heated air to rise.

Boilers equipped with a fan can operate longer on one load of fuel than those without one. This system works as follows:

- The user sets on a special panel the temperature that must be maintained in the water heating tank, after which he closes the firebox door (in such models it is sealed) and starts the fan installed in the air duct connected to the firebox.

- As soon as the temperature sensor detects the heating of the water to the desired temperature, it will send a signal to the controller and it will turn off the fan. In this case, the so-called gravity damper in the air duct will lower under its own weight (it opens only during operation of the fan - by the air flow), so that the oxygen supply to the firebox will be completely blocked. This will cause the fire to die out, but the coals will remain - the boiler will go into standby mode.

- When the water cools down, the sensor will signal the controller again and it will start the fan. The latter will fan the coals in the firebox and the fire will flare up there again.

Two-way VGK device.

VGK includes: flame pipe pos. 1, boiler body pos. 2, water supply pipe pos. 3, water drain pipe pos. 4, manifold pos. 5, pipe for safety valves pos. 6, smoke pipes pos. 7, anchor rods pos. 8, flue gas box pos. 9, burner pos. 10, thermal insulation pos. 11, housing support pos. 12, front door pos. 13, service platform pos. 14, hinges for transportation pos. 15, flue gas outlet pipe pos. 16, gas flow swirlers pos. 17, working fluid drain pipe pos. 18, condensate drain pipe pos. 19, inspection hatch pos. 20, adapter pos. 21, cover for cargo bolt pos. 22, shield pos. 23, cleaning hatch pos. 24, viewing window pos. 25.

The VGK is a body consisting of two cylindrical shells installed one inside the other: the inner one, which is the flame tube, and the outer one, which is the load-bearing shell. The shells, on the burner side, are connected by an end wall through which the smoke pipes pass. On the gas outlet side, the shells are closed with annular partitions connected to each other by anchor fasteners.

In the annular cylindrical volume, between the shells, which is a reservoir for running water, there are smoke pipes through which heat is transferred to the water.

The first stroke of combustion products takes place in the combustion chamber, and the second stroke in smoke pipes installed between the shells.

In the front part of the housing, on hinges, there is a front door on which the burner is fixed. This placement of the burner ensures tilting of the VGK door without dismantling it and the power supply lines, easy access to the combustion chamber and pipes for inspection and cleaning.

A smoke box is attached to the rear end of the housing, covered with thermal insulation and equipped with a smoke pipe in which a thermometer is installed. To clean smoke pipes, a special hatch is installed in the smoke box, and condensate is drained through a special pipe.

The thermal insulation of the VGK is made using mineral wool mats fixed to the body. A decorative coating is installed on top of the thermal insulation, providing its reliable protection from mechanical damage.

Where does pure hydrogen come from?

Note to the owner

“To attract attention to their products, some hydrogen boiler manufacturers make references to some kind of “secret catalyst” or to the use of “Brown gas” in their devices.” For example, you can extract hydrogen from methane gas, where there are as many as 4 atoms of hydrogen! But why? Methane itself is a flammable gas, so why waste additional energy to produce pure hydrogen? Where is the energy efficiency? Therefore, hydrogen is most often extracted from water, which, as everyone knows, cannot burn, using the electrolysis method. In its most general form, this method can be described as the splitting of water molecules into hydrogen and oxygen under the influence of electricity

In its most general form, this method can be described as the splitting of water molecules into hydrogen and oxygen under the influence of electricity

For example, you can extract hydrogen from methane gas, where there are as many as 4 atoms of hydrogen! But why? Methane itself is a flammable gas, so why waste additional energy to produce pure hydrogen? Where is the energy efficiency? Therefore, hydrogen is most often extracted from water, which, as everyone knows, cannot burn, using the electrolysis method. In its most general form, this method can be described as the splitting of water molecules into hydrogen and oxygen under the influence of electricity.

Electrolysis has long been known and widely used to produce pure hydrogen. In practice, not a single industrial hydrogen boiler, at least for now, can do without an electrolysis installation or electrolyzer. Everything would be fine, but this installation requires electricity. So, a hydrogen boiler must necessarily consume energy. The question is, what are these energy costs?

Electrolysis process diagram

All the talk about the “heat of combustion” of hydrogen takes us a little away from this issue, and yet it is the most important. So, a hydrogen boiler can be beneficial in the only case - the thermal energy it produces must be higher than that expended on the operation of the boiler.