How to choose a heat storage stove-fireplace

Thus, based on the main characteristics of the facing material, it is advisable to select heat-storing stoves-fireplaces taking into account thermal parameters. Let us remind you that these are the following parameters:

• heat transfer time from 20 to 48 hours

• estimated area of the heated room

• energy intensity, efficiency, chimney class and its location, amount of firewood.

According to the thermal characteristics, storage stoves and fireplaces can be divided into several types:

• stoves for a small heated area (heat transfer time up to 22 hours, heated area from 20 to 75 sq.m. with energy intensity up to 58 kW/h and efficiency up to 80% with the amount of firewood used 16-18 kg.)

• stoves designed for a large heated area from 40 to 100 sq.m, with a heat transfer time of up to 32 hours, an energy intensity of 77 kW/h and an efficiency of 83%, wood consumption of up to 22 kg for one firebox).

Lightweight models of interior fireplaces can be installed directly on the foundation slab on the floor. The foundation is equipped on all sides of the fireplace, thereby eliminating the possibility of sparks and ignition.

In addition, upon completion of installation of the heat storage furnace, it is recommended to ensure that the base of the structure can support the weight.

Naturally, in addition to thermal and operational characteristics, one should take into account the overall dimensions of the fireplace stove, the overall design and type of door

Modern models from the Finnish company Tulikivi

Modern fireplace stove Tulikivi

The modern interior is well complemented by fireplaces made in original Scandinavian design. The line is represented by a large number of models in several colors, various shapes and configurations. Also, modern Finnish fireplace installations are distinguished by increased functionality - the possibility of integration with a water heating system has been realized.

The Valkia Aalto model has an original textured surface and can be made in two colors: dark gray and white. There is nothing superfluous in the decoration, there is a cast-iron firebox in the middle, one door made of fire-resistant glass, and a compartment for storing firewood at the bottom. This version of the fireplace will perfectly complement any modern interior in the style of hi-tech, minimalism, and modernism. Characteristics:

Heat storage stove-fireplace SONKA

- heat transfer – up to 32 hours;

- Efficiency – 84%;

- dimensions – 1120*520*1530 mm;

- weight – 1320 kg;

- maximum load – 15 kg of firewood;

- heating area – up to 90m2.

The most advanced Finnish Tulikivi technologies are embodied in the Sonka model; it is made of natural stone, gray in color, and can be installed in any interior style.

The fireplace is distinguished by its impressive size, and can be used to heat the entire house, the maximum area is 120 m2. You can connect a water heating system to it and install heating elements that will ensure maintaining the required temperature in the house during absence or at night. Characteristics:

- heat transfer – up to 35 hours;

- Efficiency – 87%;

- dimensions – 1324*600*1530 mm;

- weight – 2250 kg;

- maximum load – 20 kg of firewood.

The model is equipped with a glass door, which is made of fire-resistant glass and has a special coating that prevents the formation of soot and contamination.

Choosing a Finnish wood-burning stove for a sauna

Stoves from Finnish manufacturers can be considered synonymous with quality. These units combine traditional solutions and the latest technologies. The production uses metal that has good thermal conductivity. The stoves produce soft heat that lasts for a long time. This increases the efficiency of the equipment and its cost-effectiveness.

Stoves provide gentle heat

The equipment is characterized by a long service life. Their minimum service life (if used correctly) is at least 10 years. Among other things, Finnish equipment has an attractive appearance.

Original design of a Finnish stove

The operating principle of a Finnish stove (most models) looks like this.

- The combustion chamber is made of heat-resistant steel (cast iron fireboxes are not often found in Finnish stoves) with a thickness of 4...10 mm. For stoves from Finland, it is located in the lower part of the body. Firewood is placed in it and ignited. Above this compartment there is a blower. The firebox door is usually made of heat-resistant glass, which makes it possible to observe the combustion. Burning wood produces heat.

- Thermal energy rushes upward. Typically, Finnish units are equipped with two independent fuel combustion channels. Stones placed in a heater that holds 20...110 kg are heated.

- The chimney, located in the center of the stove, additionally heats the stones.

- Water is poured into the heater through a special funnel.

- The steam, passing through a pile of stones, dries and enters the steam room in the form familiar to a Russian bath.

- To be able to splash herbal infusion on the stones, the heater usually has a door.

- Some models are equipped with a tank for heating water, which is mounted on the chimney or on the side of the unit. Often the firebox is remote, then the steam room is heated from the next room.

Not all models have a water tank. Some models of Narvi stoves

When deciding to purchase products from Finnish manufacturers, it is useful to have an idea of the important characteristics that you need to pay attention to. What are the benefits of modern metal stoves?

What are the benefits of modern metal stoves?

- The thermal power of the devices is of decisive importance. For wood-burning equipment, it depends on the capacity of the heater (the mass of stones placed there determines the amount of heat and steam released). There is a simple rule: for heating 1 cubic meter. m steam room requires about 1 kW of power. You should not purchase a unit with a large performance margin. This is fraught not only with unnecessary costs, but also with possible deformations of the cladding. A unit that is less powerful than required will not last long (you will have to increase the load, constantly maintaining the fire) and will not be able to provide the conditions necessary for staying in the steam room. Typically, manufacturers indicate the performance of the furnace when operating under ideal conditions (the room must be well insulated, heat loss must be minimized). However, as a rule, a small reserve of power should be provided in case not all the heat remains in the steam room.

- Preference should be given to products from a company whose quality has been tested by time.

- The presence of a water tank allows you to obtain hot water for the needs of those in the bathhouse.

- A remote firebox helps save space in the steam room and create comfortable conditions in the adjacent room.

- The grate, which protects the bottoms from temperature influences and is necessary for removing ash, must be made of heat-resistant steel or cast iron.

How to choose a Finnish sauna stove

The products of Finnish stove makers are distinguished by their performance properties and attractive design. Despite the fact that domestic manufacturers try to develop analogues, they do not always manage to achieve similar characteristics.

Device

The main task of a home stove is to accumulate heat and release it slowly over half a day or a day. Therefore, making a good sauna stove is not so easy. Let us remember that they started heating the Russian bathhouse stove earlier. In order for the stove to quickly heat the room, it should ideally be made of metal, since a better heat-conducting material than metal cannot be found (see article “Do-it-yourself iron stove for a bath - knowledge is power”). We remind you that brick itself is a heat insulator. It heats up slowly and releases heat slowly. Therefore, in many designs of sauna stoves, space is provided in their body for cast iron or steel blanks.

Of course, when building a sauna stove, it is necessary to provide for heating the water. Thus, Finnish sauna stoves even at the stage of thinking and design turn into a rather complex heating device. Due to the fact that a certain number of people cannot do without bathing procedures, simple washing has turned into a ritual, which entrepreneurs have slowly but surely turned into business.

Since there is a wide range of Finnish sauna stoves on the market, the question arises, how to choose a stove for a bath or sauna? Having reviewed the appearance, price tags and design features, the dry steam lover comes to the conclusion that “for that kind of money!” You can also make Finnish sauna stoves yourself. There will also be funds left over for small expenses.

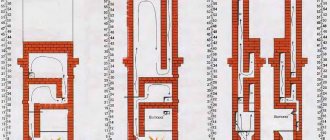

Fuel gas flow diagram

The figure shows the movement of flue gases in a metal furnace. Finnish wood-burning metal stoves themselves do not differ in any design features. If you have electric welding skills, making such a sauna stove is no problem. It should be taken into account that low carbon metal will burn out over time. Therefore, the wall thickness must be at least 3 mm. It is even better to line the firebox with refractory bricks. People's lives depend on the quality of welds. When the furnace is fired, carbon does not burn completely and forms carbon monoxide CO. Carbon monoxide forms a strong compound with hemoglobin in the blood, thereby blocking the transport of oxygen in the body. Carbon monoxide is deadly.

Installation tip

To prevent condensation from forming during operation, when installing a stainless steel pipe, you need to seal the joint between the ceramic and steel elements with ceramic fiber tape, sealing the seam with a heat-resistant sealant.

Before installing the main protection, you need to take a sheet of mineralite, cut a hole for the pipe and use it to sew up a box at the bottom for the passage of the rolled metal product. After this, it is necessary to fill the structure with fine expanded clay.

In the future, to clean the chimney, one pipe will be removed, and the second, leading to the ceramic block, will be fixed in its previous position. To make this process more convenient, during installation the first pipe must be inserted deeper into the chimney, and then the second product will be removed much easier.

Heat storage stoves-fireplaces Tulikivi

Tulikivi heat-storing fireplace stoves are the traditional embodiment of a home. Stoves made of natural soapstone create a comfortable climate in one or more rooms. Their weight can reach several tons. And while the fire is burning in the firebox, the stones accumulate the thermal energy of burning wood. And then, up to two days later, soapstone gives off the accumulated heat in the form of warming infrared rays. A heat storage stove-fireplace is a healthy microclimate in the house and an original decoration for the living room. The Tulikivi collections include wall and corner stoves, as well as double-sided fireplaces with a through firebox. Such models zone the room, conditionally dividing the space.

Tulikivi corner stove in an apartment

What's a cottage without a fireplace?

It has been noted that a private home will acquire real comfort if a fireplace or a heat-storing stove is installed. Any heat-storing stove provides an optimal microclimate in winter and home decoration.

Naturally, to choose a fireplace stove model, you need to focus on the characteristics of the room, namely the foundation and the presence of a ceiling. Of course, fireplace stoves, photos of which you can look at for hours on the Internet, are intended for any consumer:

• fireplace stoves with ovens

• lined stoves-fireplaces

• models created according to individual orders.

But each fireplace-type stove is a proven technology, installation by experienced craftsmen and an attractive design.

Counterflow oven

A good heat transfer effect is precisely those furnaces through which the combustion gases pass through the entire mass of the furnace. In engineering terminology, this coefficient is abbreviated as efficiency.

Please note: the classic model of the Finnish oven is necessarily equipped with a bread chamber.

A Finnish stove - fireplace is called that way if it has a transparent glass door. And vice versa, they call a fireplace with a door a stove.

Simply put, any heating element in a room equipped with a heat transfer system in several “elbows” is a stove. The design feature of the Finnish counterflow stove was created by the best stove makers in Finland with the support of the government.

Their main task was to create a heating device with a high level of efficiency, efficiency and heat capacity.

Important advantages of such stoves - fireplaces:

- All models of stoves with bottom heating. Thanks to the channels throughout the entire area of the heating device, heating begins from the second row.

- Firewood burns only in the firebox, and the smoke circulation system is designed in such a way that fuel combustion occurs smoothly with minimal soot deposits in the system.

Fireplace stoves have a fireproof core. This feature ensures measured heating of the outer cladding material. Plus, the heat capacity of the structure is generally higher than that of similar stoves.

The oven is almost ideal due to the heating of absolutely all its surfaces evenly. There are no cooled areas or zones, corners or planes in the fireplace stove. Flue gases transfer heat through the smoke channels as much as possible, and this process is non-aggressive. When firing a Finnish stove, soft heat is generated. The classic model can be equipped with additional doors and stove fittings. The counter-flow system has no drafts, thanks to which heat is retained for the room and cooking.

A Finnish fireplace stove is the best option for the budget construction of a wood-burning heating system in a room for permanent residence. Beginner stove makers can create this model with their own hands, knowing the order and order of laying all the elements.

Wood burning stoves Harvia

Harvia Legend is one of the most successful wood-burning sauna stoves from Harvia. Legend furnaces are mesh furnaces that are designed for a large volume of stones, due to which a large part of the hard radiation from the hot walls is absorbed by the stones. At the same time, the rate of heating of the room remains high. In summer, the required temperature can be “caught up” in just two hours, sometimes even in an hour. But Finnish stoves are still stoves for dry-air saunas. And if you are going to achieve the atmosphere of a classic Russian bath, then you cannot do without a protective brick screen erected around the stove. It will accumulate and soften heat. It is unlikely that it will be possible to achieve the ideal conditions of a Russian steam room (50-60°C and almost 100% humidity), but close ones are quite possible

Thus, it will fall on well-heated stones and evaporate. Then, bypassing the stones located on top, the steam is additionally heated and dried. In this way it will be possible to obtain well-heated and fairly light steam.

Finnish sauna stoves Legend150

If you want to use Finnish heaters for a sauna, you need a different approach. For quick heating and dry air, you need to use only a large fraction of bath stones (at least 15-20 cm in size), and also lay them sparsely. This way the air will heat up faster.

There are several modifications of the Harvia Legend wood stove. Each modification is designed for a certain volume of steam rooms, it is made of heat-resistant (alloy) steel, which is coated with a special heat-resistant paint, in addition, all models have an option - “remote firebox”, which allows you to heat the stove from the next room.

Models of wood-burning stoves Harvia for small saunas (6 - 13 m³)

- Legend 150 and Legend 150 SL – has a new grate design. Part of the air is transferred to the upper part of the firebox, thereby ensuring more efficient use of wood combustion energy. The SL modification has an extended remote firebox, which allows you to put firewood into the stove from an adjacent room.

- M1, M3 and M3 SL - a classically shaped wood-burning sauna stove "Harvia" with a heater (30 kg of stones), can be supplemented with a water tank for the pipe and a protective fence - the temperature of the walls is high, which can lead to burns. The SL modification has an external firebox.

- Finnish wood-burning stove from Harvia: Classic 140, Classic 220 Duo, Classic 220 - an open heater with a classic design, reliable and efficient. Adjustable legs allow you to set the stove to the desired position. Various modifications will allow you to select the unit of the required power, as well as choose the type of firebox and door.

Medium-sized sauna stoves (8 - 24 m³)

- Premium and Premium VS – Finnish wood-burning stove with an outer casing made of stainless steel. The VS modification has a water tank (30 l) on the side. The upper part of the firebox is made of sheet steel 10mm thick.

- wood-burning heater Legend 240, Legend 240 SL, Legend 240 Duo - the design is similar to the Legend 150, but is designed for large volumes of steam rooms and has slightly larger dimensions (600*830*600 mm) and holds 200 kg of stones.

- 20 ES Pro and Pro S – a stove with a built-in 20-liter tank for heating water. In the Pro S modification, the outer casing is made of stainless steel.

- 20 SL Boiler and 20 Boiler - a heater with a boiler, with the ability to heat either from the same room or with an external combustion chamber.

- 20 Pro, 20 SL, 20 Duo - a classic Finnish wood-burning sauna stove with different door shapes - a remote firebox and a wide-format glass "fireplace" type.

The Harvia 20 Duo stove is an excellent option for saunas with a volume from 8-20m3 to 14-36m3. This model has a remote firebox and a large door with fire-resistant glass. Additional equipment is provided with a hanging stainless steel water tank.

Based on reviews from owners, we can conclude that the Harvia 20 Duo is capable of heating a steam room to 100°C in 50 minutes, if the room volume is 6.8 m3, the stove does not deform during heating, and is easy to clean, because the ash spills into a special tray through the grate.

Harvia 20 Duo oven. Photo and installation diagram

Why accumulation

- Schmid Feuerungstechnik GmbH & Co.KG

- Tulikivi

- HAAS + SOHN

- Spartherm Feuerungstechnik GmbH

Heat from a fireplace or stove spreads in two ways - convection and radiation. In the first case, energy is transferred by a flow of air flowing around a heated surface, in the second - through electromagnetic waves of the infrared spectrum. As a rule, the heater provides a combination of these two methods.

An ordinary fireplace with a closed firebox heats the air and also radiates heat directly from the flame through the glass. Such a device is capable of quickly heating a room, but after the firewood burns out, the heat release will also stop quite soon.

Closed fireplaces can operate in a long-burning mode (with limited air flow into the firebox), but this leads to a decrease in performance and is only possible during periods that are not too cold or with the support of other heat sources. In addition, such operation causes contamination of the viewing glass (if there is no special protection) and the entire gas path with products of incomplete combustion of wood. So, in order to extend the time between stacking firewood and uniformly maintain the temperature in the heated room, regardless of the combustion cycle, it is advisable to provide for heat accumulation.

You can store heat for future use by using a fairly massive fireplace stove, fully or partially (for example, in the lining) made of heat-intensive material, equipping the fireplace with built-in storage devices, combining it with additional heat-intensive structures, heating water with heat transfer to the storage tank of the heating system. All these methods are implemented in home solid fuel heaters.

Note that energy can be accumulated in the fireplace design with or without heat transfer to the facing material. In the second case, the casing in which the fireplace insert is placed is made heat-insulating, and the heat accumulated by the structure is transferred to the circulating air. This method may be preferable under certain conditions. But heating the facing material ensures that “radiant” heat enters the room - much softer than from the flames of wood burning in the firebox, and without convective currents that can carry dust and be perceived as a draft.

Long burning versions

The specifics of these modifications are as follows:

- Positions of convective channels. They allow optimal accumulation of heat from the combustion chamber. Cold air ends up inside the housing, passing through special outlets at the bottom of the device. The air masses are rapidly warming up. And warm air fills the room within 2-5 minutes from the start of the kindling.

- Heating of adjacent rooms. Long-burning wood-burning air-heating modifications can be used as a heating base for an entire house. With prolonged combustion, warming up a building with an area of no more than 350 - 400 sq.m is enough. The connection of air ducts is possible due to the design of the housing. Pipes are distributed throughout the building. Each pipe ends up in every room that needs heating.

Some modifications have a compartment in the body where you can store the required amount of firewood. With it, the stove can work for several days.

Fireplaces and stoves from a trusted manufacturer

If you want to buy a fireplace or stove, please contact. The Finnish manufacturer guarantees first-class product quality, and the products also have other advantages:

1. Excellent heat accumulation. The products guarantee first-class heat output (at least 2 days). This guarantees maintaining optimal temperature in the room and significant fuel savings.

2. Product safety. The use of natural materials in production significantly reduces the risk of burns when touching a hot structure

3. Unlimited service life. The company provides a 5-year warranty on all fireplaces.

4. Large assortment. The manufacturer has developed different fireplaces, both in style and color. This guarantees the opportunity to choose original solutions for each home.

Stove or fireplace, which is better - you can only answer this question based on your own preferences and needs.

Finnish stoves and fireplaces: advantages, service life and operating features

Finnish stoves and fireplaces for use in the home or country house embody the functionality of proven and popular heating devices.

Let's look at what they are in this article.

For heating

These models of heating devices have proven themselves due to their good level of heat transfer, as well as ergonomic characteristics.

Their advantages include the following:

- The peculiarity and uniqueness of the housing design. Modern Finnish stoves are made of cast iron or steel.

- Occupied area of the device.

- Unpretentiousness in finishing. It is easy to choose any finishing material for this type of heating device.

- Cost-effective and high heat transfer.

Tulikivi (Tulikivi) from soapstone

This Finnish brand has long been heard by many owners of private houses, however, few people know that Tulikivi is the largest European company that processes stone for heating devices.

Several hundred models from the range of fireplaces and stoves, lined with environmentally friendly materials of natural origin, are available to the buyer. It's no secret that the birthplace of the sauna is Finland.

Therefore, there is a wide demand not only for stoves - fireplaces from Tulikivi, but also for sauna heaters for steam rooms and modern saunas. Any model from six collections of stoves, fireplaces and heaters from this company does not create harmful emissions during operation.

You can read a review of wood-burning stoves for summer cottages in this article.

The indicators for electricity consumption are also met, which is very attractive for the European buyer.

Counterflow oven

Finnish brick fireplace stoves are an ideal solution for a room where people live all year round.

A good heat transfer effect is precisely those furnaces through which the combustion gases pass through the entire mass of the furnace. In engineering terminology, this coefficient is abbreviated as efficiency.

A Finnish stove - fireplace is called that way if it has a transparent glass door. And vice versa, they call a fireplace with a door a stove.

Simply put, any heating element in a room equipped with a heat transfer system in several “elbows” is a stove. The design feature of the Finnish counterflow stove was created by the best stove makers in Finland with the support of the government.

Their main task was to create a heating device with a high level of efficiency, efficiency and heat capacity.

Important advantages of such stoves - fireplaces:

- All models of stoves with bottom heating. Thanks to the channels throughout the entire area of the heating device, heating begins from the second row.

- Firewood burns only in the firebox, and the smoke circulation system is designed in such a way that fuel combustion occurs smoothly with minimal soot deposits in the system.

- Fireplace stoves have a fireproof core. This feature ensures measured heating of the outer cladding material. Plus, the heat capacity of the structure is generally higher than that of similar stoves.

- The oven is almost ideal due to the heating of absolutely all its surfaces evenly. There are no cooled areas or zones, corners or planes in the fireplace stove.

- Flue gases transfer heat through the smoke channels as much as possible, and this process is non-aggressive. When firing a Finnish stove, soft heat is generated.

- The classic model can be equipped with additional doors and stove fittings.

- The counter-flow system has no drafts, thanks to which heat is retained for the room and cooking.

You can read how to cover a stove so it doesn’t crack in this article.

A Finnish fireplace stove is the best option for the budget construction of a wood-burning heating system in a room for permanent residence. Beginner stove makers can create this model with their own hands, knowing the order and order of laying all the elements.

Bread chamber

The semicircular door of the chamber at the top is the flap above the firebox for cooking, including baking. Having such a compartment in your oven gives you excellent options for alternative cooking.

You need to know how to cook in this chamber. For proper heating, it is necessary to place the dishes not in an open space under a live fire, but on the so-called “teeth”. These elements are designed specifically for cookware.

Timing and operation

A Finnish fireplace stove with a double casing, built according to all the rules, will last more than 25 years without major repairs. The heat capacity and reliability properties of this model have been tested for several decades.

The presence of valves (latches) for summer and winter fireboxes is very important. However, the less metal in the overall masonry scheme, the more durable and holistic the structure.

Finnish fireplaces: less wood, more heat!

Finnish fireplaces from the Nunnauuni company are a real pearl in the collection of the Fireplace Center. Made from a unique material called soapstone, they will fill your home with a very special, soft thermal radiation. Compared to their brick counterparts, Finnish soapstone fireplaces heat up 10 times faster, retain 2.5 times more heat and release it twice as long. In addition, such models consume almost half as much fuel. In just a few hours, this “heat piggy bank” accumulates heat sufficient to heat a room with a volume of 40 to 120 square meters during the day. This is why many buyers choose Finnish fireplaces for their homes.

Finnish fireplaces of the Kaisa, Sandra, Silke series from Nunnauuni perfectly retain heat due to the layered structure of the outer walls. In addition, the material from which they are made is resistant to repeated temperature changes. Finnish fireplaces differ from others in the unique masonry mortar that is used in the manufacture of these heating devices. It is made from soapstone flour mixed with liquid glass. Therefore, the happy owner of a Finnish fireplace is not in danger of cracking of the masonry, which brings a lot of trouble to the owners of brick fireplaces. Finnish fireplaces made of soapstone are also distinguished by their original design and color scheme, combining mother-of-pearl and silver-gray tones.

Finnish fireplaces Mette, Meeri, Mona, Eva, Elena, Mari, Essi, presented in the Fireplace Center catalog, belong to the category of bakery fireplaces. Their combustion chamber can also be used as an oven for baking bread. After the firewood has burned out, all you have to do is carefully rake out the coals and put the dough in the mold in their place. The fact is that after heating in the oven for at least 3 hours, the temperature is maintained at 400 degrees C, which allows you to prepare delicious homemade bread and fragrant buns

Therefore, we heartily advise lovers of fresh baked goods to pay attention to Finnish fireplaces

It is not at all surprising that the most durable heating devices that survived several centuries later in Finland were Finnish fireplaces, made from soapstone using a special technology. They served their owners faithfully for about a hundred years. They also provided longevity to their owners, improving indoor air quality and providing soft solar warmth. Modern Finnish fireplaces are worthy descendants of these ancient heating devices. They are divided into 3 thermal classes. The Fireplace Center specialists will help you choose a fireplace of a suitable thermal class that will provide a comfortable atmosphere in your home. By purchasing a Finnish fireplace from Nunnauuni, you can be sure that the heat in your home will last for 100 years!

“Fire stone” TULIKIVI

TULIKIVI fireplaces and stoves are made of a unique natural stone of volcanic origin - soapstone.

Its uniqueness lies in the combination of several qualities. The first is environmental cleanliness. The stone contains two minerals in approximately equal proportions - talc and magnesite, but at the same time it contains almost no sulfur and other impurities harmful to human health, characteristic of many rocks. In addition, soapstone does not have the radiation background inherent in granite, marble and other minerals, which are often used to create building interiors. The absence of harmful impurities and background radiation in the stone from which TULIKIVI fireplaces and stoves are made is recorded in the relevant certificates. The second fundamental property of soapstone is its high heat capacity (its specific value is 0.98 kJ/kg °C), making it ideal material for fireplaces and stoves. Heat capacity is the ability to accumulate heat. In other words, the greater the heat capacity of the material from which the fireplace or stove is made, the longer it will take to cool and, accordingly, the longer it will take to heat the room. This indicator is considered in combination with the mass of the material. Thus, TULIKIVI fireplaces and stoves weighing 2500 kg, heated for 2-4 hours, retain heat for more than 24 hours: during this time the surface of the heating device drops from 70-80ºС to 40-50ºС, that is, only by 20-30ºС! And fireplaces and stoves weighing over 2500 kg are capable of heating a room for 36 hours. It is no coincidence that the word TULIKIVI translated from Finnish means “fire stone”! Note that the heat capacity of soapstone is 2.5-3 times higher than that of oven bricks. This means that, in comparison with brick products, TULIKIVI fireplaces and stoves cool down much longer. High heat capacity is combined in soapstone with another important quality - high thermal conductivity (6.4 W/mK). Talkomagnesite perfectly transmits temperature through its thickness, due to which TULIKIVI fireplaces and stoves quickly warm up after kindling. Compared to brick stoves, this process is accelerated by 2-2.5 times: while the brick stove is slightly heated, the fireplace or TULIKIVI stove is already fully heating the house. Let us add that the excellent performance of soapstone magnesite in terms of heat capacity and thermal conductivity is the result of the layered structure and high density (2980 kg/cub.m) of the material. The melting point of this stone is over 1600ºС. Another advantage of soapstone magnesite as a material for creating fireplaces and stoves is that, due to its high talc content, it cannot get burned when operating a heating device. However, not every soapstone magnesite has the listed properties. Its composition depends on the place where it is mined. There are deposits of soapstone magnesite in America, Europe and Asia. But the stones extracted from the depths in the town of Nunnalahti in the eastern part of Finland are considered to be among the best in their composition from the point of view of furnace making. This is where the stone from which TULIKIVI fireplaces and stoves are made is located - stone with an optimal combination of talc, magnesite and other substances, which ensures its excellent performance in terms of density, heat capacity, thermal conductivity, and environmental friendliness. Moreover, the high talc content of the stone quarried in Nunnalahti makes it easy to process. And due to the high content of magnesite, this material turns out to be denser and harder than soapstone from other deposits. Please note: today on the market there are fireplaces made from another natural stone - soapstone, mined in Russia. Sellers of products made from this material claim that its properties are identical to Finnish soapstone.

This is wrong. The composition of soapstone, in addition to the minerals themselves - talc and chlorite, contains many impurities, in particular quartz inclusions, which make the material brittle and short-lived under constant exposure to high temperatures.

Which is better: a fireplace or a fireplace stove?

If you are undecided whether a stove or a fireplace is better, then you should take a closer look at the stove-fireplace option. The combination of these two structures is an advantageous solution that guarantees “fast” heat.

The following options for fireplace stoves are available:

1. Standard, made of cast iron material. This is a hybrid version of the potbelly stove, characterized by a large firebox and an auxiliary door.

2. Miniature models. The design differs in that it has an open firebox with a massive glass door. There is a large window for storing firewood, which also allows you to observe the process of burning the flame.

A casing is mounted around the hearth, air circulates inside. These designs work perfectly in smooth combustion mode.

Multi-level floor

To zone the space, craftsmen install floors at different levels. They advise installing a podium to separate the kitchen and dining room. This option is considered one of the most practical because, among other things, the owners have additional free space where they can hide something.

It is convenient to use boxes or crates for this. Wicker baskets will look good. But such space can remain free.

However, such a design should not be made if there are small children in the family, since the podium can become an obstacle for him. In addition, various floor coverings can be used. They will zone the space between the living room and the kitchen and protect the podium from damage. For example, tiles are laid in the kitchen area, and laminate flooring in the dining room. The main thing is to choose colors and textures and combine the finishes correctly.

Criteria for choosing a fireplace stove

The choice of a heat-storing fireplace stove must be made according to the following criteria:

• furnace lining material

• volume and location of the combustion chamber

• type of fuel route and air supply method.

European heating equipment manufacturers have a hot season. It is necessary to solve the problem of increasing the heat-accumulation properties of fireplace stoves, eliminating the increase in equipment power. A traditional fireplace, equipped with a closed firebox, is known to produce and radiate heat from the flame through the glass.

The fireplace quickly heats the room, but as the wood in the firebox burns out, the heat transfer quickly stops. In heat-accumulating fireplace stoves, the time interval between adding firewood and maintaining the heating temperature is increased. Energy accumulation is carried out by transferring heat from the material with which the fireplace is lined. In addition, the casing is involved in the accumulation process.

The firebox of such a fireplace, placed in a casing, is also thermally insulated, while the accumulated heat safely follows the path of the heated circulating air. A successful combination of a closed fireplace insert and factory-made heat-insulating cladding ultimately gives a good result. For example, fireplace stoves from the German company Schmid, equipped with massive cladding, evenly release heat into the room for 4 hours.

But Finnish fireplace stoves are of particular interest. The air supply system to the firebox ensures not only wood pyrolysis, but also high-temperature combustion of gases.

Correct application and use of the properties of the crystalline structure of facing soapstone and soapmagnesite allows thermal energy to be distributed in an oriented manner in the design of a fireplace-type stove.

Finnish heat storage stoves - fireplaces are able to maintain temperature for a long period of time (up to 36 hours).

Naturally, a bright future and a prosperous old age are guaranteed with Finnish stoves.

The Finnish fireplace stove Tulikivi can confidently be called the best.

Advantages of soapstone

Installations made of soapstone

- The use of soapmagnesite ensures the absence of temperature jumps, so that structural elements do not become unusable due to high temperatures on an open fire - this ensures a long service life of heating equipment.

- Fuel consumption is economical: by heating the stove once, you can keep the house warm all day long.

- When heat spreads from heat generators, infrared radiation is used. But at the same time, uniform heating of all objects in the house occurs, which in turn also begin to distribute horizontal IR radiation into the space surrounding them. With this heating method, the air does not dry out, as when heating with convection heating systems. Convection heating is contraindicated for allergy sufferers, while there are no restrictions for stoves from the Finnish brand Tulikivi - they are completely harmless.

The Finnish company Tulikivi provides consumers with complete freedom of choice - customers can choose exactly the fireplace that fits perfectly into your design. They have a fairly large lineup, including more than a thousand options. In addition, you can order a unique model from specialists, the design for which the customer can develop independently. When ordering a fireplace from the Finnish company Tuliviki, you can be sure of its efficiency, environmental friendliness and uniqueness.

Construction of a Finnish wood stove for heating a house

Any Scandinavian stove consists of a large firebox that occupies the entire area of the unit, and a roof covering it with a hole in the rear for smoke removal.

Hot gases enter the wells and drop almost to the floor, giving off heat to the brick walls, then rise and go into the pipe. The number of such smoke circulations can be from 2 to 8.

To retain heat, a view is used on the last bend of the chimney. The access of oxygen is regulated using the ash pan door - the ash pan. Advantages of the Finnish stove:

- Ease of manufacture. If you have a drawing, you can build it yourself.

- Inexpensive and relatively light.

- Good technical characteristics (traction, thermal output, high efficiency).

- It heats up quickly and begins to provide heat immediately due to the large open firebox.

- The heat from the walls does not dry out the air; the device can simultaneously heat 2-3 rooms.

- Safe and environmentally friendly.

- Excellent appearance, with high-quality masonry it becomes a decoration of the house.

A Finnish stove is placed in the center of the heated room, and they try to place the firebox so that it is convenient to observe the flame in the living room. Sometimes such ovens are called bread ovens because of the built-in oven in which you can cook a wide variety of dishes.

Bathroom and outdoor Finnish stove

Now on sale there are compact stoves made of cast iron, soapstone (a natural material) and brick. The last option is the most affordable and easiest to make yourself.

Finnish stoves for baths are most often made of metal and have a built-in heater. The top heating of devices of this type will quickly heat a small room, and the stones will accumulate heat.

For greater efficiency, the side walls of the structure are lined with soapstone or natural slate. This measure will help protect against burns and soften the heat in the bathhouse or sauna.

The outdoor Finnish stove is somewhat different from the home design. In such units they try to combine the functions of a barbecue, hob and kebab maker. The simplest version can be built over a weekend.

Making a brick device using wood with your own hands

When choosing a stove for heating, you need to take into account the area of the heated room, the frequency of stay in the house, the size and heat transfer of the structure itself. Let's consider the design of a simple device for heating a house with a power of up to 3.5 kW per day and dimensions of 110 by 80 cm and 200 cm in height.

Materials, tools and drawings

For construction you will need the following materials:

Two types of brick. Ceramic - for cladding and making side walls. The firebox core and dome are made of refractory (fireclay) material. The number of bricks for construction is about 800 pieces (of which 70-80 are fireclay).

Attention! Hollow bricks cannot be used

- As a mortar for masonry, special fireclay clay or a mixture of ordinary red clay and river sand is used (1 part clay to 2.5 parts sand). You can buy a ready-made solution and dilute it according to the instructions.

- Furnace fittings - grates, valves, doors, soot cleaners, steel strips and binding wire.

- Chimney pipe, if you do not plan to build a brick pipe to the ridge of the house.

Tools for bricklaying - a plumb line, a tape measure, a grinder with a stone disc, a trowel, a level and containers for mixing mortar.

Photo 1. Drawing of a Finnish stove: front and side views. The masonry of the first four rows is also shown.

Photo 2. The second version of the drawing with the arrangement of a Finnish brick stove. The dimensions of the device, its front and side views are indicated.

Description of masonry with order

For convenience, the entire construction of the furnace can be divided into several stages:

- Construction of the foundation. The brick finca is massive, so it is best to install a monolithic base at floor level. The foundation slab can be poured on top of a block base or other solid support. The distance to the edge of the combustible floor is 3-5 centimeters.

- The first 5 rows are laid out from ordinary bricks. A hole is left in the center for the collector. The 6th and 7th rows are made of refractory bricks - the construction of the finca core begins from this level.

- Now a bevel is formed under the stove. It can be made of brick placed on edge, with a sawn corner, or from two rows of brickwork to form a step. Along the bevel, the coals will fall onto the grate better and will be burned more efficiently.

- The walls of the firebox are erected with a height of 4 refractory bricks on the edge. At this stage, verticality is carefully controlled using a plumb line and level.

- A metal jumper is installed from a corner measuring 40x40 or 50x50. From this moment, the firebox begins to be covered with rows of fireclay bricks. Each subsequent row is located stepwise above the previous one. By the 5th row of overlap there should be only a hole left for the smoke to escape - hilo, and the sixth row forms the bottom of the oven.

- We continue to lay out the oven, its height is from 3 to 6 rows of bricks. The back wall of the oven near the fire channel can be made of brick, ceramic or cast iron.

- Now all that remains is to lay out the side smoke channels. For them, it is permissible to use ordinary stove bricks, but you can continue laying them with fireclay material. The main purpose of the ducts is to take the maximum amount of heat from the smoke and release it into the room. To do this, instead of two channels, 4 or 6 can be arranged. Their walls are made 3-4 bricks higher than the core of the furnace.

- The installation of the device is completed by installing the floor slab on the mortar and installing doors, grates and other fittings.

Photo 3. Option for ordering a Finnish stove, which includes 32 stages in total. Red color in the diagram indicates ceramic brick, yellow - fireclay brick.

Finally, the structure is optionally faced with brick.

Possible difficulties

During the construction process, certain difficulties may arise, which can be resolved using the following recommendations:

- The solution does not adhere well to the brick; you need to soak it in a bucket of water until the release of air bubbles stops.

- The first row must be laid out as accurately and evenly as possible, especially horizontally. A slight deviation at the bottom will lead to noticeable distortions at the top. If the building moves away from the vertical, then you can sharpen each subsequent row a little with a grinder from one edge until the horizontal reaches “zero.”

- Brick can chip when hewn with a hammer; it is much more convenient to cut it with a grinder. With its help, the surface is brought to the tightest possible fit of the rows. You can make technological cuts to attach the door and view.

- When laying the upper rows, mortar and brick fragments may get inside the chimney. This problem is solved with a simple piece of polystyrene foam wrapped in a damp cloth. It is inserted into the hole and gradually moves up.