Russian stoves came to the current user from time immemorial. Modern interpretations are somewhat different from the ancient ones, but in general they repeat all the architectural and functional aspects. The effectiveness of a structure with a bench and a cooking stove is beyond doubt. The only question is whether to make such a stove with your own hands or order the project drawings (as well as masonry and test run) to specialists.

Materials

During the construction process, materials will be required to build a foundation for the device, laying the structure of the furnace and chimney pipe itself, as well as metal cast iron elements in the following quantities:

| No. | Name | Unit measurements | Quantity |

| Furnace design | |||

| 1 | Red burnt solid brick M-200 | Thousand PC. | 1,85 |

| 2 | Fireclay brick ShB – 8 | Thousand PC. | 0,02 |

| 3 | Oily clay | kg | 250 |

| 4 | Coarse river sand | kg | 300 |

| 5 | Blower door | PC. | 1 |

| 6 | Cleaning hatches “DP-1” | PC. | 8 |

| 7 | Grate “RD-6” | PC. | 1 |

| 8 | Fire door 25x28cm “DT-4” | PC. | 1 |

| 9 | Cast iron two-burner stove 70x40 cm | PC. | 1 |

| 10 | Gate valve | PC. | 2 |

| 11 | Strip steel | m | 20 — 25 |

| 12 | Angle steel | m | 1,5 |

| 13 | Steel wire | m | 20 |

| 14 | Sheet steel 5 mm thick | m² | 0,5 |

| 15 | Asbestos cord | m | 15 |

| Foundation | |||

| 1 | Portland cement | T | 0,65 |

| 2 | Construction sand | m³ | 3,5 |

| 3 | Crushed stone | m³ | 4,5 |

| 4 | Ruberoid | m² | 16 |

| 5 | Edged board 40 mm thick | m³ | 0,5 |

| 6 | Nails | kg | 1 |

| 7 | A1 fittings with a diameter of 12 - 14 mm | m | 90 |

| 8 | Steel knitting wire | m | 30 |

| 9 | Bitumen | kg | 10 |

Modern Russian stoves: what are they?

May vary in size and functionality. Traditional options have dimensions: length - 2.5 meters, width - 1.5 meters. Products can be of different sizes:

- small (178*124 cm);

- medium (213*147 cm);

- (231*160 cm).

In rare cases, furnaces can be built to non-standard sizes.

But few people were satisfied with the old ones - unattractive appearance, the ability to cook only inside the hearth, limited capabilities. Thanks to the work of craftsmen and changes in designs, Russian stoves have regained popularity. They have everything you need to heat your home, cook food and more.

Modern version

So, the latest additions:

- equipped with a cooking floor. Such designs are multifunctional and can replace any hobs and stoves;

- with fireplace. This option is a new trend. Its peculiarity is that the rear wall of the firebox structure is led into another room through the wall. Thus, it turns out that one design combines two: a fireplace with a flame effect and all the magnificent sounds of crackling wood, as well as a classic Russian stove that heats the house, has a firebox for cooking and a stove for cooking;

- with a bed. In the classic versions it was very large. Three people could fit on the sun lounger. An analogue has a sunbed, but only smaller. It is enough for one person to live comfortably. However, this disadvantage can be easily compensated for by an attached trestle bed.

According to fire safety rules, all furniture and equipment must be at a distance of 1 meter from the firebox!

Such designs are multifunctional

Pros and cons of designs

In addition to beauty and warmth, they have some advantages:

- uniform heat transfer and accumulation;

- high level of efficiency;

- bottom heating The classic versions were devoid of this. Only after some time, builders modified the stoves, making them more practical to use. This feature makes it possible to heat the room as a whole;

- high security. Since all structures are made of brick, the walls of the furnace do not heat up to such a temperature as to cause a fire or burn;

- built-in stove. Enables housewives to prepare food in their usual way;

- long service life. A properly made structure can last more than 30 years.

Minuses:

- you will have to stockpile solid fuel for the winter;

- the firewood will have to be dried, since wet wood cannot be placed in the firebox;

- When heating a house with a Russian stove, excess waste from the fuel occurs.

Warm and cozy sleeping place

The Russian stove cannot be called an ideal device - it has positive aspects and shortcomings. For example, in order to learn how to cook in it, housewives will have to go through a long training phase. For ignition you will need firewood, which will have to be prepared. These are, of course, not the electric or gas boilers that everyone is so used to. But the Russian stove also has a lot of positive aspects:

- there is an opportunity to cook excellent dishes. They turn out very tasty and differ from those cooked on stoves;

- depending on the design features, the Russian stove can be equipped with a sun lounger, allowing you to relax comfortably during the cold season. It can also have shelves;

- and finally, the effect of the flame, the sound of crackling logs and flickering fire - no device can replace this.

Staircase to the second floor in a private house. 290+ Photos of Options (wooden, metal, concrete)

Tools

To lay a Russian stove with a stove and a stove bench, you will need to assemble a set of tools consisting of:

- trowel - for applying oven mortar;

- hammer - pick - for splitting bricks into smaller parts;

- ordering - control of seam thickness;

- jointing - design of seams on the facade;

- rules - for smoothing the surface of the foundation;

- building level, plumb line, square, tape measure;

- measuring strip for measuring the width of masonry joints;

- two containers for the production of concrete and clay-sand mortar;

- shovels - for loading and mixing the components of the masonry mixture.

Installation process

If you nevertheless decide to lay the furnace with your own hands, then familiarize yourself with the features and technology of carrying out the main work. This will help you complete the process correctly and avoid mistakes during installation. According to experts, many are able to complete all stages of construction without outside help.

Foundation and foundation

It is very important to take care of constructing a reliable foundation for a brick structure. It must withstand heavy loads and not sag under them.

The lower part of the oven is reserved for baking and remains free. It is convenient to store household supplies and kitchen utensils there. Concrete slabs or steel beams in combination with brick are chosen as the floor for the oven.

Due to the high fire danger, the use of wooden supports is not recommended, but is not prohibited. If you still cannot replace such material with anything, do not forget about antiseptic wood treatment. Otherwise, the ceiling may be damaged by insects.

It is also necessary to pay attention to the seams and their correct processing. They should look neat after applying the cement mortar. External walls are plastered with conventional mixtures intended for interior decoration.

Preliminary work

Masonry mortar

The process of preparing a mortar for laying a furnace is much more complicated than a conventional cement-sand composition. The main component in it is fatty clay. First of all, it is cleaned of large foreign inclusions. Then soak for at least 24 hours. When the clay particles swell, it is rubbed through a metal sieve.

Another component is washed river sand, which it is advisable to calcinate before adding it to the mixture.

On average, for 2 parts of clay you need to measure 1 part of sand, but the percentage of fat content of clay is always different, so it is better to determine the correct proportions experimentally. To do this, mix a solution with different amounts of components in three small jars and roll them into flat cakes.

Comparison of solutions

After 3 days, they look at which of the samples has fewer cracks - this means that the entire masonry mixture must be mixed in these proportions.

Making the foundation

Such a massive structure, such as a Russian stove with a stove bench and stove, must have a reliable support underneath it, not connected to the foundation of the main structure. Therefore, installing the device in an already built house is much more difficult than at the stage of its construction.

The most reliable support for a Russian stove is a monolithic reinforced concrete slab. It is constructed using standard technology. The depth of its base must correspond to the level of the base of the foundation of the internal wall near which the device is installed.

There should be a gap of 5 cm between the walls of these structures, which is filled with sand. The upper plane of the slab should be 15 cm below the floor level. If a place is chosen for the construction of a Russian stove near the outer wall, under which there is a deeper foundation, then the foundation structure for the stove must be expanded.

Foundation diagram

The process of making the foundation itself is as follows:

- mark the dimensions of the oven;

- tear off the pit 25 - 30 cm wider from the intended lines on each side and 25 cm deeper than the future support;

- level and compact the bottom of the pit;

- pour a sand cushion 10 cm thick with water and layer-by-layer compaction;

- lay a 15 cm layer of crushed stone and also compact it thoroughly;

- install formwork;

- roofing felt is attached to the inner walls of the formwork;

- the reinforcement frame is knitted along the entire height of the support. The mesh is laid parallel in two rows in the lower and upper parts of the base and fastened together with transverse reinforcement rods;

- pour the concrete mixture into the formwork. Concrete should be laid in layers of 20-25 cm and thoroughly compacted with vibrators. This is done to prevent the formation of voids in the body of the structure. The upper plane is leveled using a rule or a regular board;

- the formwork is dismantled a week after the concrete has set and gained its initial strength;

- to protect against the effects of soil water, after 22 - 25 days the side walls of the structure are coated with hot bitumen, and the top surface is covered with two layers of roofing felt.

Construction of a Russian stove

Russian stoves may differ in size, shape and design features.

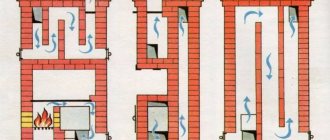

According to one definition, these are heating and cooking structures with 2 fireboxes, intended, in addition to heating functions, to also prepare typical dishes and bake bread. The process of burning firewood in the main firebox occurs as follows: the gases generated during the combustion of logs enter the 1st section of the hearth chamber, then through special holes - undercuts - enter the 2nd section. After this, they move to the upper cooking chamber, from where to the collection channel and into the pipe.

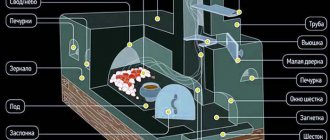

Diagram of the Russian stove. The main firebox is necessary for winter heating, the small one is used for cooking at any time of the year

When burning wood in a small firebox, combustion gases first enter the main firebox, and from it into the chimney. Here you can use not only dry logs, but also bark, wood chips, branches and other waste.

The Russian stove has a lot of advantages, but has one noticeable drawback: heat is released at the level of the hearth, that is, approximately 0.9 m from the floor, which prevents heating of the lower part of the room

The basis for the structure is a foundation, usually 0.1 m larger than the dimensions of the lower part of the Russian stove. Here, below, there is a storage area - free space for storing a poker, grip, spatula and other equipment.

The main part is considered to be the crucible - a cooking chamber with a hole (mouth) on the front side. The mouth can be rectangular or arched. Through it, fuel (logs) is placed inside the crucible and dishes with food are placed

For laying the cooking chamber, and in particular for the vault, the most fire-resistant, selected bricks are selected. The thickness of the walls determines how long the heat will last.

The thin walls of the cooking chamber heat up very quickly, but cool down just as quickly. Standard thickness is 1 or ¾ brick. The front wall is thinner - ½ brick, like the partition in front of the furnace.

At the bottom of the cooking chamber there is a floor for which a strong, smooth brick is suitable. Often it is laid dry, without using a solution, on a backfill of coarse sand, to which crushed stone, gravel or broken glass is added. The floor is laid with a slope of 3-5 cm towards the mouth.

The shape of the vault affects the degree of heating and the complexity of the masonry.

For example, semi-circular vaults heat up slightly under and reflect gases unevenly, but are considered easier to construct with your own hands

Gentle vaults are more difficult to lay; steel ties must be used to distribute the load. However, with this design, the underfloor heats up more.

The technology for laying the roof of a Russian stove may differ, but the following rule is often followed: lay it out on both sides simultaneously and finish in the middle. A castle brick is laid in the center, and a clay solution is used to coat it.

The cooking chamber is arranged so that the fuel can be placed close to the mouth - in this case, combustion occurs more efficiently. Pots and baking trays are also placed on the underside near the mouth

If they are baking bread, then they clear the floor - they scoop out the ash, and sweep away its remains.

There is still a way to bake bread without baking sheets or molds, when it is placed on a special shovel, lightly sprinkled with flour, and then “put in the oven” - simply dumped with a sharp movement onto the floor.

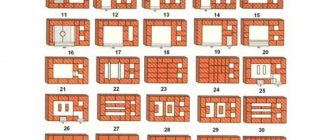

Order and description of masonry

Arranging a Russian stove with a stove bench and stove

The laying of a Russian stove with a stove bench and stove is carried out according to the order (in the photo above), which clearly shows where each brick needs to be placed in rows and at what stage the stove fittings should be installed.

Description of masonry in rows:

- The 1st row is laid solid in the following order: first, the brick is laid around the perimeter of the structure, and then the middle is filled. This row determines the evenness of the entire structure, so it must be well aligned;

- in the 2nd row they begin to form under. To do this, bricks are placed on edge;

- in the 3rd row, install a blower door and continue to lay out the bottom of the cooking section with bandaging of the elements of the previous row;

- the laying of the 4th row is similar to the 2nd;

- The 5th row is the formation of a clearing passage and laying the foundation under the arched vaults;

- 6th row - they begin to narrow the cleaning channel and install the grate;

- 7th and 8th rows - installation of the combustion chamber door, placement of the steel sheet;

- from the 9th to the 11th row - formation of the firebox, installation of the stove;

- from the 12th to the 16th row - laying a niche on the hob;

- 17th and 18th rows - narrowing of the arches of the niche;

- from the 19th to the 21st row - completion of the laying of the bed;

- 22nd row - formation of a heil;

- from the 23rd to the 33rd - raising the chimney with the installation of valves and cleaning hatches.

When laying a stove, the seams are bandaged in each row, using bricks that are not full size. For proper dressing, you can also use the poke-and-spoon masonry technology, when the brick of the bottom row is laid flat, and in the next row - with the poke outward.

Ceramic products can draw water out of the joint material, so they are immersed in water for a few seconds before installation. Excess clay-sand mixture protruding on the internal surfaces of the parts of the device must be removed with special care.

Design of devices. Interesting design options

Since the stove was always located in a prominent place and occupied a significant part of the room, from ancient times it was ennobled: painted, coated, painted. Nowadays, a variety of materials allows you to decorate the hearth depending on your preferences and budget.

It is important to comply with the following requirements for finishing materials: fire resistance, high thermal conductivity, strength. Plaster, brick, tiles, ceramic tiles, stone have such properties.

- Plaster is one of the most budget-friendly and at the same time beautiful finishing options. It is applied in two stages, the second layer being made thicker. After drying, it is advisable to give free rein to your imagination: paint the device in a pattern or cover it with water-based paint of any color.

- Another simple finishing option is brick. The combination of bricks of different colors will make the device original. Unlike other types of design, facing with facing bricks is carried out simultaneously with masonry.

- Tiles are an ancient method of finishing. The material is made from refractory clay; the front part is decorated with an ornament covered with glaze. A stove lined with tiles turns into a work of art; each tile is hand-painted. This design is most often carried out by a master; this finishing method is considered expensive.

Photo 2. Russian stove, decorated with decorative tiles. The device is located in the corner of the room.

- An alternative and more budget-friendly analogue of tiles is ceramic tiles. Most similar to majolica tiles. Glaze is applied to it, under which there is a bright design. This material is durable, looks great, but cannot be used in wet areas. The most durable type of ceramic tile is clinker. The fact is that clinker tiles are made from highly plastic clay and fired in an airtight oven.

- Natural stone cladding is gaining popularity. It is fireproof, retains heat for a long time, and is environmentally friendly. Sandstone and shell rock are mainly used for finishing. This design of the stove looks quite unusual.

Types of finishes can be combined with each other.

Important! Before the device is registered, a month must pass from the moment of its laying. During this time, the solution will completely dry, and the structure itself will shrink a little

Drying

To dry a Russian stove with a stove bench and a hob, shavings, chips and small logs are used. The first combustion should be carried out with fuel in an amount of no more than 30% of the maximum volume. With each subsequent firebox, the volume of loaded firewood increases.

The drying time is influenced by the size of the oven, the degree of humidity of the brickwork and the temperature in the room. Typically, drying in the summer season takes a week; in the cold season, this period can last up to 25 days . All this time, the valves and combustion damper must be open.

You need to stop drying the oven at the moment when there are no damp spots left on its surface, as well as condensation on metal parts.

Variety of designs

A classic oven has an oven, and the lower part does not heat up. Polati, also called a couch, are intended for resting people, drying clothes and fruit. If you make them two-tiered, then the whole family can fit on them, for example, children can lie on the upper tier, and adults on the lower tier.

Water procedures are also performed on the beds, and to wash, water is heated in a vat. The heating unit is erected separately or in combination with other devices.

Trial fire

After drying is complete, perform a test fire in the following sequence:

- the combustion chamber is loaded as much as possible with dry wood, laying it in dense rows and set on fire. At this moment, the valve should be fully open, and the wellhead valve, on the contrary, should be tightly closed;

- after the first batch of firewood has burned out, the next portion of wood is loaded, but only 2/3 of the furnace is already filled;

- The intensity of fuel combustion is regulated using a valve;

- Complete closing of the valve is possible after all the firewood has burned out and the formed coals have gone out.

The next fire can be started only after the stove has completely cooled down.

Stove with stove - multifunctional structure

The stove is so useful, convenient and ergonomic that building a structure without it simply loses its meaning. Perhaps this is why all modern modifications of Russian stoves have cast iron stoves - with one, two or even three burners.

In fact, models with a stove do not contradict one of the main features of a Russian stove - they have two fireboxes. It is the small firebox that is responsible for heating the stove. Moreover, in simple stoves it has a separate chimney, connected at the top to the chimney of the furnace.

One of the popular options for placing the stove is right in front of the mouth of the furnace. Heating is carried out independently of the large firebox, through the lower heating

For more complex designs, there is the possibility of “summer” and “winter” fireboxes: in the first case, the small furnace (furnace) operates autonomously, and in the second, with its help, the walls and the large furnace are heated.

There is a third option for locating the flooding - in the main structure, but on the side or on the opposite side. This solution is not always acceptable - for example, if the stove needs to be located in a corner. In this case, it is more convenient if both fireboxes are on one side and located one above the other.

A successful engineering solution in which a small stove with a cast-iron stove is placed separately, but has a common wall with the main structure. Disadvantage - takes up more space

The advantages of the design with a hob are obvious:

- autonomous heating with a lower degree of heat transfer;

- fast heating process of cast iron and walls;

- cooking all kinds of dishes on the stove;

- the ability to heat or store food warm;

- economical fuel consumption - firewood;

- easy maintenance - cleaning the ash pan.

On the stove, when it is no longer hot, but has cooled down a little, you can dry household items. For the same purpose, stoves are used - small recesses in the walls of the stove, as well as a brick perimeter around the cast-iron surface.

For summer residents, the model with flooding is much more convenient, as it is used more often. A large firebox is usually used either in early spring or late autumn, when the cold season sets in and the entire stove needs to be heated.

Alexander Batsulin

Born in Moscow on September 7, 1976.

Graduated from the Faculty of Chemistry of Moscow State University with a degree in Chemical Kinetics. He has been involved in the furnace business since 2000. Interests: construction and design of stoves for heating individual houses. Traditional timber construction. Tel. 8 (915) 169 1733 8 (950) 259-6401 e-mail: sashbats (а) mail.ru and Marcus Flynn

Marcus Flynn

Born in England in 1961, lives in Montreal, Canada.

Member of the North American Stove Makers Association. He has been involved in the furnace business for more than 20 years and specializes mainly in the construction of Finnish counterflow furnaces in various versions. Area of interest: non-standard cladding made of antique bricks, Art Deco design, history of stove making. In filling its website, www.pyromasse.ca adheres to the “open source” policy. they put a Russian stove and a couch in the Russian outback,

and they are filmed by a hidden camera.

End of August 2009

Time passed, and at the end of February 2012, on the eve of Maslenitsa, inspired by our video about pancakes in a Russian stove, Channel One (ORT) made a short story for the Good Morning program with this stove.

26.01.2012

Author: A. Batsulin