How to light a flame on a gas boiler

When you purchase and install gas equipment, the first question that arises is how to light a gas boiler. The first start-up of a gas boiler is carried out by a specialist, from whom you can get recommendations on the use of the equipment. During subsequent starts, you can also set the required temperature using the coolant heating level control knob.

Read more about the procedure for starting gas equipment in the material: Starting gas into a private house. Primary requirements

At the same time, the circulation pump is connected. Excessive noise indicates stagnant air in the pump. To release it, you need to remove the boiler cover, then unscrew the pump cover. When water appears from under the lid, screw it back on. As soon as the pump starts, automatic ignition occurs and the boiler operates normally.

The feed tap is of great importance for the operation of double-circuit boilers. Due to it, pressure is maintained so that the equipment operates without interruption.

Main points

The boiler goes out when its automatic mechanism responds to the following violations:

- Reduction or disappearance of draft in the chimney.

- Drop in fuel pressure in the supply pipe.

- Flame extinguishment in the burner.

They arise from internal problems or the influence of external factors.

The simplest solutions are implemented if you have a floor-standing device installed, for example Danko, Zhitomir or Aton. They have a primitive design inside. And the answers to the dilemma of why a floor-standing gas boiler goes out are usually: powerful wind and other external influences.

Wall-mounted models are similar in design to a small autonomous boiler room. And there are more versions of turning them off:

- There is no coolant circulating in the heating circuit. This is indicated by the flow indicator.

- Air is supplied in weak volumes or its supply has been stopped. The pressure switch reacts here.

- Voltage surges.

- Power outage.

If the gas boiler does not ignite the first time

In order to determine why the gas boiler does not turn on, you should pay attention to the following important points:

If your device's piezo element runs on batteries, try replacing them. As a rule, they last for 6-8 months, then a lack of power appears, which leads to the fact that the burner on the gas boiler does not light. The “syndrome” of low batteries sometimes manifests itself in such a way that the gas boiler does not light up the first time, but lights up on the second or third attempt. In modern gas boilers, batteries are practically not used to ignite the gas burner, and the problem when turning on can be of the same nature. Below we will look at the reasons.

Recommended reading: Why does a gas boiler often turn on and off?

Malfunctions of all Neva models

Why doesn't the burner light up? There may be other reasons for this.

- In the model with piezo ignition, the button was not held sufficiently. Press the key for at least 10 seconds.

- Insufficient water pressure in the system. You need to wait for the supply to be restored and also check the filter in front of the column. It could become clogged with small debris. To do this, remove and rinse it under running water, you can use a brush. Adjust the pressure knob on the panel.

- Poor ventilation. Then overheating occurs and the device turns off. After installing Euro-windows, a similar problem may arise. The solution is to install a ventilation valve.

Error E1 in Neva Transit

Decryption: ignition error. What is the reason:

- Check for draft, open the gas valve all the way. To check, hold a burning match to the window on the panel. If the flame deviates to the side, then everything is in order with the draft.

- The fuel pipe is too long, the gas does not have time to reach the required quantity. Restart.

No spark

Main problems and ways to solve them:

- The batteries in the automatic model are low. Check that the batteries are installed correctly. It is recommended to install alkaline batteries. They have sufficient charge for stable operation of the equipment. Also inspect the contacts; they need to be cleaned periodically.

- No traction. The main reason is a clogged chimney. From the street, leaves and debris can clog the hole. During combustion, soot is formed on the walls, which also reduces cross-country ability. Then the traction sensor is triggered - protection against the accumulation of carbon monoxide. Clean the chimney from your side; call utility services for cleaning from outside.

- Leaks at pipe connections. The connections are sealed with gaskets, and nuts are screwed on top. Over time, the gaskets lose elasticity and wear out. If you notice a leak, unscrew the nut and replace the seal.

- Problems with water pressure. If after some time the pressure has not resumed, clean the filters and pipes that lead to the device.

- The membrane has failed. The element is located at the entrance to the water block. What could happen: loss of elasticity, wear; damage, deformation; scale clogged. The part must be dismantled for inspection and replacement. We wrote how to disassemble the block in the article “Water unit of a gas water heater”.

- Damage to the electronic unit. Specialist intervention is required.

There is a spark, but the burner does not ignite

This happens when there is a blockage in the system.

The heat exchanger is clogged with soot and scale . When soot accumulates, traction deteriorates, which leads to the activation of the safety system. Remove the top casing and clean the radiator with a vacuum cleaner or brush.

Scale is formed when magnesium and calcium salts settle on the parts of the heat exchanger. It creates a thermal insulation effect. As a result, the water takes longer to heat up, the pressure decreases, but gas consumption increases. We will tell you how to clean the unit at home.

- Remove the radiator.

- Place it in a container that is ¼ full of water.

- Prepare a solution of citric acid 150 g per 750 ml.

- Using a watering can, pour the solution into the heat exchanger coil and leave for 15 minutes.

- Place the container on the stove and boil for a few minutes.

After the procedures, rinse all radiator tubes with running water. The remaining scale should come out. Dry the assembly and reinstall.

The burner is clogged with soot . The holes and jets are cleaned with a wire brush. To check connections for leaks, use a soap solution. If foam bubbles somewhere, turn off the gas supply and contact a specialist.

The mixer filter is clogged . It is necessary to disassemble and clean the part from contaminants.

- Set the temperature to no more than 55 degrees. It is better not to dilute hot water with cold water - this leads to scale formation.

- Use purifying water filters. They make it “softer”, after which the equipment works for a long time and stably.

- It is better to connect powerful devices through a stabilizer to avoid voltage drops in the network.

- Carry out a preventive examination once a year.

Ready to start renovating? Don't forget to turn off the gas and water valves. Now you know not only how to fix it, but also how to prevent it from breaking.

What to do if a gas boiler with automatic ignition does not light up

Reason 1. Reduced network voltage

If the gas boiler does not start, then the problem may lie in the power supply from the household network. It is recommended to install a voltage stabilizer, which can significantly reduce the risk of consequences of power outages.

It protects the electronic component of the boiler during power failures. A decrease in voltage may affect the operation of other elements of the gas heating system. First, check the serviceability of the outlet and inspect the condition of the electrical wiring.

Reason 2. The ignition unit has failed

When the equipment does not want to ignite, check how the ignition unit works. To do this, you can take a multimeter. Switch it to ohmmeter mode. Measure the resistance at the output of the contacts of the electronic unit, which are responsible for ignition. A level of 650-750 Ohms means that the unit is functioning normally. If the value is different, the tester will show an open (the electronics will show a value of 1) or a short circuit (the electronics will show a value of 0). Replacing the part will solve this problem.

Reason 3: Gas valve malfunction

Gas burners tend to let debris into the valve, as a result of which the valve fails because the inductor burns out. And she is responsible for the operation of the valve. To check this malfunction, you can also use an electronic tester in the “ohmmeter” mode. To do this, be sure to first turn off the power to the boiler. Readings of 80-90 Ohms can be considered normal. If the value is different, the gas valve must be cleaned. First you need to unscrew the side of the housing in which the valve is located and clean it inside. If the equipment has fasteners with a rarer head profile, you will have to select a suitable screwdriver or sharpen the one that is available.

Reason 4: Flame electrode needs cleaning

Another reason when the gas boiler does not turn on and there is no heating is contamination of the electrode. The soot remaining after fuel combustion causes the flame control electrode to malfunction. Cleaning with fine-grained sandpaper will help. If the gas boiler still does not turn on, you need to turn off the heating and wait until the circulation pump stops. Next, you need to turn off the instrument panel, remove the plug from the socket, and turn it 180 degrees. Then insert it into its original place and turn on the boiler. This rephasing helps restore the sensitivity of the gas ions necessary for normal operation of the system.

Why does the gas water heater pilot light go out?

There are several reasons why the pilot light goes out:

- There is no draft in the chimney.

- The thermocouple is worn out or burnt out.

- The wick is clogged with dust.

- Flame separation.

- The traction control sensors have failed.

- There is poor contact between the control unit and the sensor.

- The ionization sensor is located outside the flame range.

The most common reason for the pilot light going out is a thermocouple malfunction. When the pilot light goes out, there is a lack of heat because there is no fire, the thermocouple detects it and turns off the gas. A thermocouple is an element that is designed to turn off the gas if the gas water heater operates intermittently. But after long-term use, the thermocouple may burn and its tip will become friable from prolonged exposure to fire. This is what causes the pilot light to go out.

If there are any air currents from the outside, they can blow out the igniter. If the device has improper ventilation, then air currents may come from it, which extinguish the igniter. But many people confuse this problem with a lack of traction. Therefore, during repairs, you need to correctly identify the problem.

The gas control system includes solenoid valves. They are located in geysers. When ventilation stops functioning, carbon monoxide begins to enter the room. And the solenoid valves shut off the gas supply and the igniter goes out.

Over time, black soot settles on the heat exchanger and the area around the igniter. This is another reason why the pilot light goes out. As a result of incomplete combustion of gas, soot is formed. Accumulated soot often causes problems with the air ventilation system. As a result, the igniter goes out.

There is no spark and the flame does not light up on boilers with semi-automatic mode

The gas supply system is not adjusted

This problem on heating devices can lead to the following consequences:

- When fuel is supplied at low pressure, the system may experience constant malfunctions. The gas boiler may turn off, and the automation will not allow it to ignite when the coolant temperature drops and will generate an error. The consequences of low gas pressure, especially in winter, can be detrimental to the entire heating system. If the device generates this particular error, check the gas supply valve, as well as the fuel supply pipes at their connections for leaks. Call your gas company to see if they have reduced the pressure due to any work. If the cause cannot be determined, contact a specialist.

- gas pressure too high. This can lead to increased fuel consumption and rapid wear of all equipment. Check the gas supply valve, you can close it a little.

However, first, contact the gas workers and find out if there were any failures on their part. accompanied by movement of the coolant along the system circuit. To resolve the issue, it is recommended to contact a specialist.

Read more: How to properly set up and adjust a heating boiler

The emergency electrical circuit is broken

The emergency electrical circuit includes connecting wires and bimetallic sensors in the chimney, which are triggered when 75-80 degrees Celsius are reached. The circuit also includes a thermocouple that produces a voltage of 10-20 mV, a draft breaker and an electric valve, which consists of an inductor, a rod and a valve.

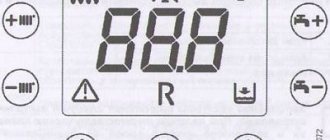

If the emergency circuit is broken, the electric valve does not open, which may be the reason why the gas boiler does not ignite. A special multimeter tester will help you check all elements of the circuit. A value of 0.3-0.5 Ohm is considered normal. There should be no oxidized or loose contacts. If there is no such device, we adjust the temperature to about 0 and at the same time connect the piezoelectric element. The pilot light should light up. Release the temperature control button.

If it goes out, you need to carry out the entire cycle again, closing the contacts of the traction breaker in order to check the integrity of the installation and boiler sensors. If the pilot light is on, it is due to poor contact in the circuit or one of the sensors is not working. The thermocouple may also be faulty. Non-working elements require replacement.

The piezoelectric element has failed

This part is usually mounted next to the temperature setting, but is sometimes located separately. To check whether the piezoelectric element is working properly, try disconnecting the wire through which the generated voltage flows from the electrode and bring it 4-8 mm closer to the valve body.

After that, click on the launch element button. When a spark appears, the piezoelectric element is working, you need to check the electrode itself (its body is made of ceramics, it must be dry and clean). Remember that the fastening nut must be tightened by hand.

The valve or torch tube is clogged

This problem often occurs in the summer when the boiler is rarely used. In summer, the valve and flare tube become filled with insects, which prevent further gas movement. Also, the reason that the gas boiler does not turn on may lie in rust and the combustion products themselves. The tube and valve must be cleaned to continue proper operation of the equipment.

How to deal with problems

If the boiler goes out and does not light up again, check the quality of ventilation in the room. This is a common cause of problems for atmospheric models “Proterm”, “Navien”, “Ariston”, “Bosch” with an open combustion chamber, because they take combustion air from the room.

- Organize high-quality ventilation in the room;

- Install ventilation valves on sealed window packages;

- Open the window in the boiler room for air flow.

Check the presence of draft in the boiler chamber. To do this, light a match and bring it to the control window or chimney outlet. If there is draft, the flame will deviate to the side. If not present, it will burn evenly. In the latter case, a chimney inspection is required.

Problems with the chimney part

This is excess, deficiency or backdraft. All this leads to the fading of the wick and automatic shutdown of the equipment.

Backdraft or blowing out occurs due to weather conditions: strong winds, pressure changes lead to the burner extinguishing. During installation, take into account the requirements for the height of the chimney:

- The height of the pipe on a flat roof is at least 50 cm;

- With a distance from the roof ridge of 1.5 meters - from 50 cm above the ridge;

- At a distance of 1.5–3 meters - level with the ridge.

Compliance with these parameters will help to avoid blowing and backdraft.

Excess air flow occurs with a powerful kitchen hood or ventilation. The solution is to turn off the hood while the boiler is operating.

Lack or absence of traction provokes:

- Blockages. Occurs in stationary chimneys. Clear the mine of leaves, debris, and construction debris. Fixed and coaxial pipes can become covered with ice in winter. Along with combustion products, hot steam escapes into the street, condensation forms, which freezes on surfaces. Insulate the chimney.

- Damage, burnout of the pipe. Only replacing the chimney will help.

Line pressure drop

Does the dual-circuit device “AOGV”, “Beretta” or “Vailant” turn off and not turn on? This is possible when the fuel supply is unstable. For the same reason, the burner does not light the first time. First of all, check:

- Pipes and joints for gas leaks. To do this, lubricate them with soap foam. If bubbles appear, there is a leak. Then turn off the valves, open the window and call the gas workers.

- Counter. If there is a breakdown, the meter readings do not change; noise and crackling are heard. You can’t fix the problem yourself—you need a specialist.

If everything is fine, wait until the gas supply is restored.

Does your equipment not start after a long shutdown? It may be worth using antifreeze as a coolant. It does not freeze when the temperature drops and allows you to safely start the system after a long period of inactivity.

Fan fault

All boilers with a closed combustion chamber - such as Buderus, Wolf, Danko, Lemax - are equipped with fans. They forcibly discharge combustion products into the street. If you hear strong noises when the blades rotate or do not hear operating sounds at all, carry out diagnostics and replace the element if it breaks.

The flame does not ignite (general faults)

Pipe burnout

To organize the safe operation of the chimney, a steel pipe is used. However, it can overheat when interacting with combustion products and burn out. To avoid this problem, it is recommended to use a sandwich pipe, which will protect against overheated gases.

Chimney problems

There may be several problems associated with the chimney design. So, fallen leaves, snow can get into it, and the mouth can freeze over (in this case, the frequency of occurrence depends on the deflector, umbrella or other end). This requires cleaning the chimney or reshaping its fungus to allow smoke to escape unhindered. Below in the picture are options for “fungi” deflectors.

In addition, if the chimney is poorly insulated, the gases in it can form an air lock, since the cooled, cold gas is more dense and does not allow hotter gases to escape freely.

If the chimney is not insulated, strong condensation may settle inside it and freeze up during the cold season. Insulating the chimney will help solve the problem.

If foreign objects (house, tree) interfere with the mouth of the chimney, you will need to increase its height, cut off interfering branches, or otherwise remove the obstacle to the exit of smoke.

Weak supply ventilation

Organizing normal supply ventilation is very important for the proper operation of gas equipment. Thus, combustion requires oxygen, and combustion of 1 m3 of gas uses 10 m3 of air. If this air is not enough, then backdraft may form in the chimney, and ventilation will not be enough. The exhaust hood in the kitchen also contributes to weak supply ventilation if the boiler is installed in this room. Also, due to plastic windows there may not be enough air. The problem needs to be solved by proper installation of gas equipment and proper ventilation.

Signs that the igniter (wick) is not working properly and why does it go out?

In columns with piezo ignition, the igniter must burn constantly, because when the hot water tap opens, it must ignite the main burner. The extinguishing of the igniter disconnects the column from the gas supply so that gas does not accumulate inside the device.

The pilot light may go out if:

- It is clogged with debris or dust.

- A flow of air acted on him from outside.

- The thermocouple has burnt out or worn out.

- There is no draft in the chimney.

- The traction sensor has failed.

- The solenoid valve is broken.

- No air access.

The most common cause of igniter extinguishing is a faulty thermocouple. Its main function is to block gas access to the column if the device is operating unstable. As soon as the pilot light goes out, the thermocouple detects the lack of heat and gives a signal to turn off the gas. However, if the thermocouple itself is damaged, it causes the wick to fade.

An equally common situation is when dust or some kind of debris gets into the igniter nozzles. Their diameter is very small, so even slight contamination can prevent the igniter from burning, resulting in the thermocouple not heating up enough.

The color of its flame indicates that there are problems with the igniter and it may go out at any moment. A normally functioning wick will have a flame that is 90% blue and may include some red flecks, and the tip may be yellow. If the pilot flame is predominantly yellow or orange, the wick is not working properly and the thermocouple will not heat up enough, causing the burner to go out.

For other possible reasons for the igniter fading, see the following video.

The principle of operation of a gas burner

It consists of the following: air and fuel are mixed, and the combustion products must go through the entire combustion process.

We can conditionally distinguish three tasks in the operation of this element of the system:

- preparing air and fuel for combustion by determining temperature, speed and direction;

- mixing these elements;

- combustion, that is, oxidation of combustible elements with the help of oxygen, combustion due to the nozzle at the end point of the tube.

The reasons that the burner does not light up must be sought in the principle of its operation.

The burner itself is essentially a metal tube that is hollow inside and has several holes called nozzles. The gas burns in it, heading towards the combustion chamber. The mixture of combustion products is discharged outside. And if the air is collected by natural injection, then the gas is distributed and directed inside thanks to the system of indicated holes.

If the gas boiler does not ignite, it means that the combustion conditions are not met: there is no gas, no air is supplied, and combustion products do not come out. Understanding the cause of problems allows you to eliminate them in a timely manner and restore system operation. When lighting a gas boiler, be careful. This equipment requires special care.

What you can do yourself

The sequence of first actions is the same in all cases:

- The boiler is disconnected from the power supply, and the gas tap is completely closed.

- A visual inspection is carried out to check for possible blockages and mechanical damage.

- If the combustion chamber is open, you can simply light a match or lighter and hold the flame near the holes through which air is supplied to the burner. If the draft is not clogged, the tongue will immediately deflect towards the holes, and the flame will burn evenly. If the flame deflects weakly, then there are large blockages.

- You can also draw conclusions based on the operation of the boiler. If it hums quite loudly, and the color of the flame is closer to colorless, then the draft is too strong - it needs to be reduced.

Excursions on models and brands

The indicated reasons may apply to boilers of different modifications and brands. Below are some examples of specific models.

First: Why does the AOGV 2321 gas boiler go out? As a rule, the wick goes out with a characteristic metallic click. Most often the reason lies in poor traction.

Second. The Zhukovsky boiler goes out. This unit has old automation. The problem lies in the oxidation of the contacts on the EMC and the burnt-out thermocouple. The valve is thoroughly cleaned in the connecting areas of the copper tubes. It is better to replace the thermocouple.

Third: If the Zhitomir-3 boiler goes out. The most common problem is that it only works briefly after startup.

The reason for this was the thermal breaker, which was poorly screwed into the EMC. There was weak contact between them by default. During the season of work it got even worse. After tightening it a little, the boiler stopped turning off.

Fourth: The Conord device goes out after 5 minutes of operation. After cleaning the igniters, pipes, and chimney, it functioned without failure for 2 days. Then the problem repeated itself. After a thorough investigation, the true reason was found out: the hole for air intake to form a combustible mixture was clogged. Brushing with a toothbrush solved this dilemma.

Fifth: the Danko 158 gas boiler goes out. Most often, attenuation occurs due to strong winds and blockages in the conductive pipes. The dilemma is solved by cleaning the pilot tube, diffusion hole, burner, and installing a draft sensor and deflector. You can also change all the jets.

Sixth: KSG focus 12.5. When ignited, the main burner burns brightly, but goes out after 20-30 seconds.

In such a situation, the circuit contacts are diagnosed. The pilot burner is carefully removed and cleaned. The ignition burner is adjusted - the fuel pressure on it is reduced. It is necessary to check and, if necessary, improve the draft to the pilot burner, since there is not enough air to ignite the main burner.

The seventh is a Dani boiler with two circuits and automatic 630 EUROSIT. When the burner starts, it lights up actively, but after 10-15 seconds it turns off.

The procedure is carried out as in the sixth example. The thermocouple and draft sensor are also checked.

If there is a lack of air, the burner mechanism is removed, it is cleaned, the jets and heat exchanger are washed.

Inclusion rules

Connecting an open or closed type gas boiler is not as simple as it might seem, since this is not only a high-tech device, but also a dangerous one. There are too many connection options and circuits. The installation method and the order of connecting the highways are all individual. For this reason, it is recommended that the connection process, start-up and commissioning of gas equipment be carried out by an authorized service center.

In addition, if you connect a double-circuit or single-circuit gas boiler of an open or closed type yourself, this will void the performance warranty. However, situations are different. You should proceed as indicated in the instructions.

The algorithm for how to light a gas boiler will depend on the method of installation of the boiler. So, you can connect a wall-hung gas boiler correctly by proceeding as follows:

- Connect the device to the electrical network;

- Unscrew the gas valve and press the start button (the type with the name of this button is indicated in the operating instructions);

- Select the operating temperature using the plus and minus buttons.

Burners running on electricity are connected automatically after they have been switched to the hot water heating mode. The piezo type of ignition occurs by short adjusting the flame and pressing a special key.

Note! Switching on is blocked when air accumulates. It is enough to press the restart button and the boiler will be able to start working.

As for how to turn on a floor-mounted double-circuit or single-circuit open or closed boiler, this can only be done after the boiler room has been completely ventilated. The rest of the connection process is simple. First, you need to set the temperature selector to off mode, open the gas supply valve, and set the selector to piezo ignition. Then hold down the key for 5 seconds, press the piezo button and adjust the temperature.

Important! To prevent rupture of pipes and freezing of the system, you need to set the minimum indicator values before starting the boiler.

How to start a boiler - step-by-step instructions

It is necessary to start a single-circuit or double-circuit domestic or foreign gas boiler only if the integrity of the system with threaded connections, taps, valves and expansion tanks has been checked. If water is used as the coolant, then the heating system can be filled at above-zero temperatures to avoid the formation of plugs.

It is also important to remember about the absence of prolonged drainage, since untreated and hard water forms scale and settles inside the system. It is better to use soft water or give preference to distilled water.

In an open type heating system, it is enough to fill the coolant using an expansion tank until it is filled to the extent it should be. In a closed system, the media is filled using a specially designated drain and fill valve. As a rule, in modern units the carrier is already installed in a certain place. It is indicated in the instructions and operating instructions.

When filling the carrier, you need to take into account that the pressure there is high, for this reason the opening of the refill tap should be gradual and not full. It is necessary to stop filling the liquid when the pressure on the pressure gauge reaches the operating range. Usually it is 2 bar. It differs depending on which model, for this reason the exact values are always indicated in the manual.

It is also necessary to take care of the air exhaust system, pressure testing and flushing before lighting the boiler.

Note! Modern wall-mounted models already have an automatic air vent, which is located inside: at the top above the heat exchangers or at the bottom in the circulation pump. If there are no automatic air vents in the system, then the air is released using a Mayevsky valve. To do this, you need to take a small plate, place it under the radiator, unscrew the tap a little until the air comes out and hisses. Wait for 5 minutes and close the tap. In modern domestic and foreign advanced models, this is not required, since the air itself comes out through the expansion tank

.

As for the pressure testing procedure, this is an optional step, but necessary for the safe start-up of the boiler. In case of depressurization of the heating system, there will be a lot of hassle if pressure testing is not done. This is done using a suitable pressure testing pump. To do this, the operating pressure is set and the system is run. If the pressure drops, there is a leak somewhere.

Solving problems with boiler attenuation

If the flame goes out not due to malfunctions of the boiler itself, but to other external reasons, you can try to fix the problems yourself. Some models of simple boilers can even be cleaned from soot and soot yourself, but this is a topic for a separate article.

Restoring traction

You can figure out what is clogged - the boiler or the chimney - by disconnecting the corrugated pipe of the exhaust system from the boiler itself. If there is draft in the pipe, then we solve the problem with the boiler by calling a technician. Otherwise, you will have to climb on the roof and look into the pipe. If a blockage is detected, you need to remove those foreign fragments that interfere with the passage of smoke.

Cleaning the chimney is a mandatory procedure to prevent its contamination

If ice is found on the head, it must be carefully chipped off so as not to damage the chimney itself. Be sure to check the cleaning hatches. A sign that cleaning needs to be done is a large amount of soot and soot extracted from the inside of the channel.

You can still reconcile with the blowing of the channel due to strong wind if it happens once or twice during the entire heating season. But if winds are a common occurrence in your area, you should take measures:

- First, you can try to extend the pipe. The high altitude will prevent the wind from pushing the air back with force.

- Secondly, a competent configuration of the head can help out, which will cover the hole on the side from which the winds predominantly blow.

If the electricity goes out

A non-volatile boiler in conjunction with a circulation pump does not consume much. It can be adapted for DC power and switched to battery operation. But this is not suitable for powerful boilers. The only way out is to connect the boiler to an alternative source of electricity, for example, a gasoline or diesel generator.

If the gas pressure decreases

The first thing you need to do is check the gas pipeline at the place where it branches off from the main line. The joints where there are traces of welding, as well as valves and taps, are carefully checked. The specific odor imparted to natural gas at distribution stations will help detect leaks.

The only option is to write an appeal to the appropriate authorities. Contact your neighbors - they most likely have the same problem. Completing a collective petition will help speed up the decision-making process for the natural gas supplier organization in your area.

Boiler bimetallic plate

Natural gas heating systems are high-risk devices and therefore include various condition monitoring sensors. So, the main safety element is the traction sensor. It determines the correct direction of exit of combustion products, that is, from the combustion chamber towards the chimney. This prevents carbon monoxide from entering the room and poisoning people.

The main component of the draft sensor is a bimetallic plate for a gas boiler. Its operating principle is similar to any bimetal, and the dimensions and parameters of the material are calculated in such a way that exceeding the temperature of 75 degrees in the channel leads to deformation of the plate and operation of the gas valve.