Gas autonomous heating is the best option for a private home, as it is cheap, reliable and efficient. However, sometimes the equipment begins to malfunction, and as a result, the home may find itself without heat at the height of the cold season. Therefore, we will analyze why a gas boiler does not turn on, what are the characteristics of the main problems - poor draft, pressure drop, electronic malfunction - and how to correct them correctly in order to quickly restore the functionality of the heating system.

Only professional diagnostics can quickly find the exact cause of a gas boiler breakdown Source eurosantehnik.ru

Primary diagnostics of a gas boiler

First of all, you need to understand why the gas boiler does not turn on. Modern models help a person quickly find the answer to this question. They are equipped with an internal diagnostic system, which signals a breakdown with a code or icon on the control panel. All you have to do is look at the meaning of the message in the instructions. And do the repairs yourself or call a specialist.

For older models or those that do not have self-diagnosis, you will have to determine why the gas boiler does not heat in another way. All faults can be divided into external and internal.

External faults include:

- Low pressure.

- Chimney problems.

- Voltage drop.

- It's cold inside.

- Constant drafts.

Internal faults, when we can say that the gas boiler is broken, include:

- Problems with the sensor.

- Wiring fault.

- Failure of parts - pump, heat exchanger, etc.

Accelerated wear of parts

Its cause is frequent boiler cycling. Clock is understood as turning the unit on and off depending on the operation of the heating network. That is, it is a cycle during which the boiler turns on, heats up the antifreeze, turns off and waits for the coolant in the batteries to cool down, and then, at the command of the automation, turns on again and fills the system with warm liquid.

There is nothing wrong with clocking a boiler that does not blow out at all. It depends on how quickly the heating system cools. If the coolant cools down in it in a short time, clocking is very frequent. It is clear that constantly turning the boiler on/off leads to wear and tear on the igniter and other components that are needed to ignite the gas. After some time, the igniter or other component breaks down earlier than expected and an emergency shutdown of the boiler occurs.

To avoid accelerated wear of the igniter, as well as other components, it is necessary to make the boiler clock less. Most often this is done in two ways:

- Installation of a modulating burner with a good igniter. Its power should vary within wide limits (4-20 kW). The method is a partial measure of clock reduction.

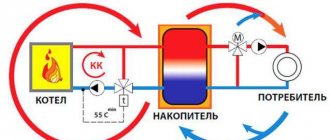

- Using a heat accumulator.

Also, to reduce the clock frequency, it is worth inviting experts who can diagnose the heating system and also carry out its modernization. These specialists can also perform maintenance, thanks to which the question of why the boiler blows, goes out or leaks will not arise at all.

Solving ventilation problems

The reason why a gas boiler does not turn on is often hidden in the ventilation system. This is especially true for models with an open camera. Since there will be no flame without an influx of oxygen from outside.

What you need to do: think about the ventilation in the room. Install special valves on the windows or simply open them.

If the gas boiler does not heat water, check if there is draft. Light a match and bring it to the window or outlet. When everything is in order with the draft, the flame tends to the side. If there is a problem, it burns straight. We need a chimney inspection.

How to repair a gas boiler chimney?

If you have reached the point of diagnosing the chimney, then there is a problem with the draft. It can be expressed in excess, deficiency or reverse thrust. As a result, the wick goes out and that’s why the gas boiler automatically turns off.

Reverse thrust or attenuation may well be due to weather - wind, pressure surges. Therefore, when installing a chimney, you should carefully calculate the height:

- For a flat roof 50 cm is enough.

- If it is 1.5 meters from the ridge of the roof, it should be 50 cm above the ridge.

- At 1.5-3 meters - exactly with the skate.

If you leave this distance, then there will be no difficulties, as well as the fact that the gas boiler does not heat well.

Excessive draft can occur when the hood in the kitchen works too well, which is detrimental. Then you should turn off the hood while the boiler is running.

The gas boiler turns on/off - this is not the only problem that can be due to low or high draft:

- Blockages . Relevant for stationary chimneys. It is necessary to clear the chimney of leaves and any other debris. In addition, during the cold season, the chimney may freeze. And with the smoke, steam escapes, causing condensation to appear, which also freezes. The pipe should be insulated.

- Pipe damage . There is only one way out - a new chimney.

Filling pipes with water

The initial start-up of the equipment is aimed at testing the operation of the heating system. After the Viessmann gas double-circuit boiler is installed, the unit should be connected to cold water.

Fill the heating system of a double-circuit boiler with water as follows:

- at the junction of the boiler with the pipes (at the bottom of the structure) a valve is found, which is moved to the open position, not unwinding it completely, in order to avoid stuck air in the pipes;

- then observe the pressure indicator (pressure gauge) and turn off the injection pump when the needle reaches 2-2.5 atmospheres;

- On each heating device, the air is bleed using Mayevsky taps (the valve is kept open until water appears and closed).

When bleeding air, the pressure should be within 1.5-2 atm, which is the optimal indicator for the operation of a unit such as a Ferroli gas wall-mounted boiler or equipment from other companies.

Be especially careful when filling the system with water in winter. The room is first warmed up to a warm state and the coolant is heated to 20 degrees.

An important point in the operation of all boiler units is fluid pressure. To control this parameter, all boilers are equipped with pressure gauges

To improve the operation of the system, install a filter designed for rough water purification. The device prevents the equipment from becoming clogged with debris formed when metal interacts with water inside the radiators. This is an important point that cannot be ignored, otherwise the device will quickly fail! Installation is carried out in the pipeline pipe using the winding method, making sure that the arrow points in the direction of the boiler.

A shut-off valve is installed on the return line of the unit, which eliminates the need to vent the system in the event of a breakdown. To be able to disconnect the shut-off valve from the heating system without cutting pipes, it must be equipped with detachable connections.

Gas boiler pressure

Does a double-circuit gas boiler not heat water? It may be worth paying attention to the quality of the fuel supply. Because of this, the burner may not ignite immediately. First check:

- Is there a leak ? Cover the line with soapy water. If you see bubbles forming, there is a leak. Immediately turn off the gas, open the window and call the gas service.

- What about the counters ? When meters fail, their readings stop updating and there is noise near them. You won’t be able to change the equipment yourself; you need to call a specialist.

If there are none of these malfunctions, then you need to wait until the fuel supply improves. At the same time, the problem that the gas boiler does not heat the water well will go away.

Why doesn’t the gas boiler turn on when you previously turned it off for a long time? Try antifreeze. He is not afraid of the cold, and also turns on the equipment without problems after a break in use.

UNIT EMERGENCY STOP

- There are the following cases of boiler emergency stop:

- interruption of electricity supply;

- damage to gas fittings or gas pipeline;

- in case of failure or incorrect operation of safety valves;

- if the water flow through the water heating unit has decreased below the minimum level line;

- in case of defective operation of the steam valve;

- in case of automation malfunction;

- when the flame in the furnace goes out when burning fuel;

- at elevated water levels;

- if the feed pumps do not work;

- when pressure rises or falls relative to normal;

- in case of mechanical damage to the unit, or pipe rupture;

- if cracks or gaps are found in the welds;

- when atypical sound signals appear (crackling, noise, knocking, blows), etc.

In order to restart the system after an emergency shutdown of the gas boiler, it is necessary to fill the radiators and pipes with water. Before this procedure, you need to check the pressure level on the sensor, which is located on the front panel of the boiler

Stopping heating units involves actions depending on the type of boiler.

The emergency stop procedure for a gas-fired boiler involves the following manipulations:

- Reducing the gas supply to the burner.

- Reduced air supply level (draft limitation).

- Closing a valve (faucet) on a gas pipeline.

- Closing the valve on the air pipeline.

- Checking the firebox for absence of combustion.

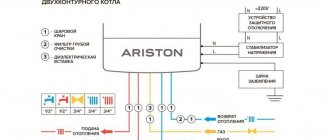

The operating instructions for an Ariston or other brand of boiler contain the information necessary to stop the device in the event of an emergency. It is important to carry it out step by step and monitor the correct execution of the actions.

Other malfunctions of gas boilers

To look for other answers to the question: why a gas boiler does not work, you need to have a good knowledge of its structure. But, despite the differences between the models, all of them can break down:

- Pump . It may cause the gas boiler to not heat. If there is noise or the flame goes out, then this is a reason to check the gas boiler pump, find out that it is not working, and replace it.

- Igniter . If the pressure is too low or too high, the flame will break off. And then the protective mechanism turns on and for this reason the gas boiler turns off. You should adjust the pressure in the line.

- Burner . If a double-circuit gas boiler does not turn on, the burner nozzles may be clogged. Clean them and the sensor, and then

A gas boiler can often turn on and off due to a breakdown of the thermocouple or sensors, then the problem unit needs to be replaced.

Also, if the equipment does not turn on, simply look at the control panel. Maybe it's time to buy new batteries. Look at the control panel, if there is something wrong with it, then you should test the controller.

Please note that there may be a problem with heating due to the gas boiler not working if it is connected to the network. And when power surges appear and the device turns off, you should additionally buy a voltage stabilizer.

There are many reasons why a gas boiler does not heat water. It's easier when the error code appears on the panel. But if this does not happen, then a good diagnosis will follow, which will require more knowledge. If you are not confident in your abilities, it is better to immediately call a specialist and entrust him with both inspection of the equipment and repairs. And remember that a problem is easier to prevent than to fix. Carry out maintenance once a year.

Video description

Video example of finding and correcting problems with a gas boiler:

Features of pressure recovery

Why the Baxi, Navien and their analogues often turn off due to a drop in pressure was discussed above, but this is not enough to solve the problem - you need to know how to raise it to normal. There are several features of this procedure:

- When the unit is first started, the pressure always drops and then recovers.

- When filling with ordinary water, a lot of air enters the system, which will require further effort to remove bubbles in the future.

- Air is bled from the system using both automatic air vents and special manual taps.

- Before performing the pressure restoration procedure, it is necessary to check the tightness of the system.

On a note! The heating unit may turn off not only due to a lack of draft or a drop in pressure, but also due to an electronic malfunction. This could be failure of protective fuses, penetration of water onto the board, burnout of a varistor or power supply, or failure of the display board. Correcting them will require professional diagnostics.