Recent studies have shown that the world's population will increase steadily in the coming decades, despite the deteriorating environmental situation and the depletion of fossil fuels. And where the population increases, the need for new, more affordable, higher-quality building materials grows at the same pace. At the same time, the materials must meet environmental standards and be easy to handle.

Today, ecowool is increasingly used as a material for thermal insulation of premises. This is a durable material that is capable of providing high quality and almost any external conditions to ensure high insulation of a room from heat exchange with other rooms or the external environment. The production technology of ecowool is such that the output is a product of any shape and size. However, installation methods make it possible to evaluate the thermal insulation properties of ecowool per unit of its mass. That’s how they sell it – by weight. Installation of this material is a rather labor-intensive process that requires knowledge, training and specific equipment.

Very skillful hands

It was said above that the need for ecowool will only increase. Therefore, a logical question arises: “Is it possible to start producing ecowool yourself, with the prospect of creating your own profitable business?”

What should we do and where should we start creating ecowool production?

To begin with, you should understand some details regarding ecowool itself, its impact on the real estate market, as well as its equally important contribution to the preservation of the environment.

Why is ecowool good for production? The answer to this question is quite simple: it is popular. Both on the domestic market and on the Western market. There are no fools there either. It is popular, first of all, for the cleanliness of its production and high performance indicators. The very name ecowool, or rather the particle “eco-”, says that it is based on materials that are not harmful to the environment, one of which is cellulose. The naturalness of the constituent materials allows us to speak with almost one hundred percent confidence about ecowool as a material to which the vast majority of people do not have allergic reactions.

Last but not least, the high popularity of ecowool is influenced by the complete absence of seams, which greatly facilitates installation, since the insulation can be laid in voids of any shape. The structure of the material is flexible and porous, which allows it not only to restrain heat transfer, but also to dampen sounds - resulting in good sound insulation.

Procurement of raw materials

Wood raw materials themselves can be purchased almost free of charge: disposal of shavings and sawdust is a headache for woodworking enterprises. Another question is how high-quality and suitable material they can offer you, because no one will sort the waste. There are several rules for procuring raw materials:

- You should choose wood species with minimal resin content - that is, predominantly deciduous.

- Sawdust is only suitable for making floor filler; for walls you will need shavings or wood chips.

- The raw materials must be homogeneous, free from fragments of bark, twigs and various debris.

- Raw materials containing fragments with traces of blue or gray mold should be avoided. Drying and mineralization do not guarantee sterility, and the use of antiseptic additives leads to an unjustified increase in the toxicity of the material.

For the manufacture of insulation, illiquid residues from peeling veneer, waste from planing processing are best suited; it is also a very good solution to use long sawdust remaining when dissolving large logs on large sawmills. Thus, the collection of wood waste must be carried out independently, and immediately at the exit from the woodworking workshop, and not in general dumps. In some cases, it makes sense to produce raw materials yourself, passing unmarketable lumber or small logs, cleared of bark, through a garden shredder with a disk or millstone cutting element.

Before preparing the insulation, the raw materials should be kept for a long time in the open air to reduce the humidity to 15–18%. The shavings should be stored on a waterproof mat in a layer of up to 40–50 cm, protected from precipitation and opened in clear weather. The mass should be stirred periodically, lifting the most moistened part to the top.

Demand

Great demand for ecowool has been generated by the naturalness of the materials from which it is made. Compared to other building materials, the use of which not only leads to poor health, but also significantly reduces life expectancy and, sometimes, leads to death. For example, asbestos, which is used to make slate or fill walls, is a carcinogen, that is, it causes cancer. Ecowool is harmless in this regard. Its antiseptic properties ensure that the growth of harmful bacteria inside the voids between the fibers is impossible, which means the risk of pulmonary infections and intoxication is reduced.

Ecowool is cheap. This is especially evident when comparing its heat and sound insulation characteristics with glass wool. Low cost and high quality guarantee, according to experts, high quality repairs at low cost. Ecowool is a worthy choice for any room.

Do-it-yourself ecowool insulation

Cellulose insulation is sold in compressed form, so it must be loosened before installation.

To do this, you need to take a capacious container and fill it with Ecowool about a third. After this, install a mixer attachment on the electric drill, which is used to prepare mortars, and begin loosening.

Installation of ecowool using blow molding equipment

Ecowool insulation is carried out in several ways:

Manual filling or do-it-yourself installation

This method is used for small amounts of work. The material is simply poured onto a horizontal surface (for example, an attic floor) or filled into a cavity - in a wall or roofing pie. The packing density in the wall should be at least 60 - 70 kg/cu.m. m, on the floor slab - at least 35 - 40 kg/cu.m. m.

Dry mechanized backfill

Used for large volumes of work and only for filling cavities. Ecowool is supplied by a blowing unit. At the same time, it quite tightly fills all the cracks and other hard-to-reach places, so that dismantling of building structures before insulation is not required.

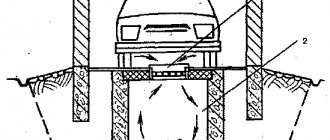

When insulating floors, a cavity is created by stretching a waterproofing film, in which a hole is left for inserting a hose. If you try to apply Ecowool on an open area in this way, it will simply be blown away by a stream of air.

Factory-built blow molding machines are equipped with an opening agent and can convey material up to 200 m horizontally or lift it to a height of up to 40 m.

Wet or wet-adhesive mechanical spraying

During wet spraying, a water suspension is supplied to the flow of Ecowool moving through the hose using a special pump.

Thanks to the lignin present in cellulose, the moistened thermal insulator adheres to the insulated structure like construction foam.

Thus, wet spraying allows you to insulate open areas with Ecowool, which are also located vertically or with a slope.

After drying, the applied layer resembles papier-mâché in its structure. Protrusions and sagging can be trimmed with electric roller shears.

If you add glue to the water at the spraying stage, the heat-insulating layer will adhere better, be more flexible and deform less when drying.

The simplest installation for laying ecowool

To install the insulation, you will need a blowing machine for ecowool.

You can make a blow molding machine for mechanical laying of ecowool with your own hands using a garden vacuum cleaner with the function of regulating the suction force.

The engine of the unit must develop a power of 2 kW.

The procedure is as follows:

- To increase suction power, disconnect part of the suction hose by moving the terminals from it to the main base.

- Using wire cutters, cut off the plastic teeth in the pipe leading to the dust container (it is important not to damage the housing). If the teeth are left, they will become clogged with heat insulation.

- A corrugated tube for laying electrical wiring with a length of 7 m and a diameter of 63 mm must be inserted into the hole for the dust collector. If the teeth were cut cleanly, the tube will go in easily, after which it will need to be secured with tape.

- When dry laying, a fabric strip should be wrapped around the corrugated tube to seal the hole through which the tube is inserted into the cavity. This measure will help prevent dust from entering the room. Please note that the tube will be removed as the cavity is filled, so the O-ring should move fairly freely on it.

To carry out wet spraying, you will have to purchase a water pump and a flat spray nozzle with a 25-degree whisk angle. It is very important to set up the system correctly so that the humidification is not excessive. Otherwise, the ecowool will not be able to stay on the structure and will fall off. The degree of moisture should be such that when squeezing, only a few drops of water can be squeezed out of the heat insulator.

When spraying onto vertical surfaces, glue may not be added. It is used only when insulating ceilings or inclined surfaces such as a roof slope.

There are many thermal insulation materials for home insulation, but each of them is selected depending on the type and purpose of insulation. How to insulate walls from the inside in a private house and what material to choose, read on our website.

An overview of traditional and innovative insulation materials for thermal insulation of a house is presented in this article.

Safety

At first glance, it may seem that using ecowool closer than a hundred meters from electrical wiring or open fire is madness. After all, it contains cellulose fibers, that is, it should, in theory, flash brighter than sparklers from any spark. However, making it burn is not a trivial task. Why?

The thing is that cellulose fibers are surrounded by a special substance that prevents fire - a fire retardant, which is sodium tetrabonate, or borax. It is completely safe for humans, as it does not have any chemically hazardous impurities. Sodium tetrabonate is a crystalline hydrate, that is, a crystalline substance (sodium is a metal) that contains water molecules in its crystals. Typically there are up to ten molecules per crystal. This kind of “impregnation” of the fibrous structure of ecowool reduces the possibility of fire of the material to almost zero, which allows the insulation to be used in any type of room - from a children’s room to a foundry workshop.

Fire resistance

Borax is sodium tetraborate. This chemical compound belongs to the category of fire retardants - compositions for fire retardant impregnation. The molecules of the substance are crystal hydrates. When exposed to fire, they separate into several water molecules, allowing the flame to die out. Therefore, cellulose wool can resist flame for quite a long time.

Ecowool from different manufacturers has different fire resistance. The best product is considered:

- G2 – moderately flammable (GOST 30244);

- B2 – moderately flammable (GOST 30402);

- D2 – moderately smoke-generating (GOST 121044).

The smoke released when burning ecowool does not contain toxic substances.

Ecowool is smoldering

Mechanism of action of borax

If a source of high temperature occurs near the insulation, the sodium crystals lose their stability and bend, thereby releasing the water they contain. Water takes on excess heat and slows down the spread of the fire further. For example, polystyrene foam, another popular insulation material, burns completely differently. During a fire, polystyrene foam heats up unevenly and has internal, hidden fires, which impedes extinguishing. Even completely blocking the access to oxygen with fire foam does not save the situation.

How to determine the required insulation thickness

The thickness of the insulation depends on the thickness of the wall and the climate of the region. Each wall is a pie consisting of many layers: interior decoration, insulation, exterior cladding. Each layer is characterized by a certain indicator of heat transfer resistance. How to calculate it:

- The thickness of the insulation is determined for each layer. To do this, the thickness of the layer must be divided by its thermal conductivity coefficient.

- The sum of the obtained values is calculated.

- Subtracted from the heat transfer resistance characteristic of a given region.

- The resulting value is multiplied by the thermal conductivity coefficient of the insulation.

Independent creation of ecowool

The following tips and explanations will allow you to better understand the mechanisms of creating ecowool not in a large-scale industry, but at home yourself.

The process of creating ecowool is quite simple and does not require any super-high investments. It can be recreated in the conditions of individual home production, thereby creating a small profitable business. The basis of everything is the processing of secondary raw materials. So first you will need this very secondary raw material - waste paper, and equipment for crushing and processing this raw material. Equipment for recycling waste paper works on a similar principle to a coffee grinder.

Some experienced eco-washers recommend using an old activator washing machine as a grinding machine.

Video description

Pouring polyurethane foam using a household installation.

Insulation of attics and attics

You may have the impression that to pour polyurethane foam you definitely need space between two vertically erected planes, but this is not so. If you have the right equipment, liquid thermal insulation can be poured onto exposed vertical and inclined planes, as shown in the top photo. After all, in essence, laying the foam substance here is no different from applying polyurethane foam, only there is no such powerful expansion effect. Therefore, to insulate an attic or attic, polyurethane foam is applied to the walls, roof and floor, and after drying it is covered with facing materials. When the foam hardens on the floor between the beams, you can even walk on it to lay the floor.

Note: pouring polyurethane foam for insulating houses has one drawback: this will require special equipment, and the foam itself must be ordered in containers, based on the volume of voids to be filled.

How is it suitable for the production of ecowool?

Structurally, the activator washing machine consists of a body, insulated disks on which the blades are attached. The latter will be used to shred paper. To do this, instead of the activator, a system of knives is fixed. If the machine is equipped with a motor of insufficient power, it must be replaced with a more powerful one. In this case, you should be careful and select the engine according to the design dimensions of the mount and connection to the screw.

From the above it is clear that almost everyone can afford to make ecowool at home. But this method also has a downside: quality. Made by hand using a converted washing machine, ecowool is of very low quality, even relative to the cheapest, but industrially manufactured samples. Do not forget that the buyer now knows much more about the item of purchase, and therefore selling home-made ecowool is a disastrous business. No one will buy it if there are better quality samples at an affordable price. This means that such insulation can be used exclusively for personal purposes.

Release form

Ecowool is produced in the form of a heap of cellulose fibers and is a loose mass. When carrying out industrial work on insulating buildings, the material is pre-moistened and then sprayed onto a previously prepared surface. Ecowool can also be applied dry, driving it into the frame using special equipment. To insulate a small building (garage or cottage), the material can be laid manually. This method will naturally require an increase in the amount of material and additional time.

Start

Theoretically, the profitability of ecowool production is one of the highest, since it does not require any expensive and unique equipment. However, you will still have to spend money. You can start if you have at least two or two and a half million rubles. Only such a minimum capital can guarantee at least some profitability of production.

In order for a product to enter the market, it must be certified, that is, it must be certified for compliance with minimum requirements by state control authorities and, if necessary, by commercial control authorities.

Necessary equipment

The basis for do-it-yourself ecowool production is the following machines:

- shredder;

- dispersant;

- packaging and fan installations.

In 2005, in Omsk, the production of all the necessary equipment for the production of cellulose heat insulation was mastered (Ekovata Omsk Engineering, Teplograd).

You can order a line with a capacity of 250 to 700 kg/h, and it will be equipped with an automatic packaging unit and dispensers for boric acid and borax, also operating in automatic mode.

What do you need?

After passing certification and receiving a certificate confirming quality, supply opportunities will increase significantly, previously inaccessible markets will open, and with them income will soar.

As mentioned above, ecowool for personal consumption can be produced using homemade equipment. In this case, there is no need for any professional devices and machines. But this is not suitable for an industrial scale. A professional needs to purchase machines that meet his level of ambition and means. There is no way without this.

Ecowool is produced using mass production. The line will require a number of specific equipment, including:

- shredder: what do you need to cut the raw materials with? Needed in any case;

- dispegator: in it, the material, hitting the blades, is crushed under the influence of centrifugal forces - dispersed;

- packaging machine;

- blowing machine.

The line created from this equipment using manual labor allows us to produce ecowool

Before starting work, the chemical composition of the future ecowool should be determined. GOST of this insulation will help with this. According to it, the future insulation should include cellulose (about 80%), borax (about 12%) and additionally boric acid (about 7%).

The raw materials for ecowool are waste materials from cardboard and paper production. It is not without reason that the production of ecowool is welcomed in many countries and regions, as it allows you to get rid of waste and thereby saves forests from being cut down. The raw materials are pieces of cardboard, paper containers and many other types of waste paper, which are industrial waste.

Following the general trend of reputable professionals, you should not use raw materials from newspaper types of waste paper. It is very heterogeneous in composition, which can affect the quality of the final product. In addition, newspaper waste paper is usually heavily contaminated with various impurities, which are designed to reduce the cost of production, and toxic ink. You should immediately look for direct paper suppliers. And customers will be happy, and they won’t have to spend money on repairing worn-out or broken equipment.

Advantages

Before talking about the advantages of Ecowool, we should tell you more about it itself.

Under this name lies only shredded waste paper, to which boric acid (antiseptic) and borax (fire retardant) are added.

The mass ratio of the components is, respectively, 81%, 12% and 7% (for some manufacturers - 80/10/10 percent).

Here are the advantages of this heat insulator:

- It's very cheap.

- Extremely easy to make.

- In terms of thermal resistance, it is not inferior to the best modern insulation materials: the thermal conductivity coefficient lies in the range of 0.037 - 0.042 W/m*C, like that of polystyrene foam and mineral wool.

- Provides good noise insulation effect.

- It is very light: the volumetric weight ranges from 28 to 60 kg/cu. m.

- Just like polyurethane foam (polyurethane foam), when applied it fills even the most inaccessible places and forms a seamless coating.

- Surpasses polymer insulation in terms of environmental friendliness. The biofire retardant additives available in Ecowool are considered low-toxic and moderately harmful.

- The top layer can retain up to 20% moisture, while the main part fully retains its heat-insulating properties.

- After getting wet, it dries very quickly (moisture evaporates well due to the capillary effect) and at the same time completely restores its thermal insulation properties.

Ecowool does not cause corrosion of metals because it does not exhibit chemical activity (pH ranges from 7.8 to 8.2).

Costs and profitability

Expenses

A significant part of the costs will be the purchase of equipment to create production. All mechanisms, machines, equipment and apparatus will cost about one and a half million rubles. Separate expense items include the delivery of equipment and its installation in accordance with all the rules - an additional approximately half a million rubles.

You should take care of the rented premises in advance. The minimum area should be fifty square meters.

Since the production will not be small, it is unrealistic to service all the processes alone - a staff of workers is needed. Another item will be the staff salary fund.

In total, to start you need to have about three million rubles.

Is it worth it?

Profit

As practice has shown, the creation of ecowool on an industrial scale can bring, in addition to purely intellectual satisfaction, also significant financial satisfaction. Experience in doing business in this area has shown that the costs of equipment, rent and staff salaries can be recouped in about a calendar year, provided that a revenue of three hundred thousand rubles is received monthly. And provided that all created products undergo certification by state control bodies.

Common Mistakes

Do-it-yourself insulation contains simple components, but a lot depends on the dosage, the mixing technology, and additional factors:

- Sawdust in its pure form is not used as thermal insulation. First of all, you need to treat the shavings with a composition of antiseptic and fire retardant. This is done to keep the house safe from fire.

- Over time, the resulting blocks sag significantly from the dry wind and the action of the sun. You will have to monitor the condition of the insulation, add it in time or lay it on top of another heat-insulating material.

- The mixture of sawdust and cement should not be too liquid.

They check it this way - take a lump in your palm and squeeze it. If water does not run out of the lump, it remains in the same shape, then everything is correct.

- Work on laying insulation is carried out in dry weather to avoid the blocks getting wet and premature disintegration.

- The mixture is prepared in small portions. To prevent the liquid from evaporating, the composition did not turn out to be too dry and friable.

- The blocks are dried for about 2 weeks in a well-ventilated area. This is necessary to acquire the properties of frost resistance and strength of the material.

- Layed blocks are never covered with plasterboard without waterproofing. Without a layer of waterproofing film, the blocks will quickly become unusable.

No processing

Kraft paper

Let's start by getting to know one fairly popular type of cellulose product.

Kraft paper is a very durable material that is made from long fibers of kraft pulp. Raw materials - wood; wood chips are boiled in an aqueous solution of sodium sulfide and some other substances.

It’s interesting: the process is extremely technological, since it allows the use of wood of any species. In addition, the chemicals used are recovered and can be reused. Yeast, soap, turpentine, rosin, methyl alcohol and many other useful products are obtained from by-products.

Everyone is familiar with kraft paper in this capacity.

How is thin and thick kraft paper useful in terms of insulation?

Of course, not as a thermal insulation material.

- The classic design of a frame house is a frame made of timber, sheathed inside and outside with clapboard, OSB or plywood . The space between the outer and inner skins is filled with insulation. It is often used mineral wool, polystyrene foam and other modern materials for insulation; The heat-insulating material is protected from blowing and moisture saturation by special polymer films. This scheme has two disadvantages:

- The materials used are of artificial origin and often continue to saturate the air in the house for many years with phenolic resins, styrene or fine mineral fibers that irritate the eyes and respiratory organs.

- They are by no means cheap.

Meanwhile, many decades ago, a very simple and incredibly cheap to implement scheme was used for insulation: the space between the inner and outer wall cladding was simply filled with sawdust - free waste from sawmills. The kraft paper served as a vapor barrier and a windproof membrane: it prevented the sawdust from becoming damp and protected the wall from the wind.

- The cheapest way to insulate a ceiling or interfloor ceiling is the same sawdust, expanded clay or slag. Bulk insulation. Kraft paper is the cheapest material for laying under insulation, which will prevent it from falling on the heads of the home owners.

Useful: kraft paper is sold and is more than inexpensive. Its price is from 25 rubles per kilogram. However, it often ends up in waste in the form of paper bags or corrugated cardboard. Small-sized bags or fragments of packaging are not suitable for the role of wind protection, but they can easily be used as a lining under backfill thermal insulation.

Cardboard

Corrugated cardboard, however, can also be used as an independent thermal insulation material. Of course, cardboard insulation can be obtained only when laid in a thick layer - no less than 5 - 10 centimeters.

The cellular structure of corrugated cardboard should protect the packaged goods, but it will also be insulated.

However, the time spent on installation is compensated by the fact that the material will cost exactly the cost of its transportation: any large base will be only too happy to get rid of the packaging material, the removal of which it usually has to pay.

How to use cardboard insulation? The instructions are very simple: it fits tightly inside the wall frame and is sewn up from the inside. It is clear that the outer covering of the walls must reliably protect the cardboard from precipitation.

There is one nuance associated with installation. To prevent the walls from being blown through, sheets of packaging material are laid layer by layer with the joints between them offset. Fixation with a stapler is possible.

Advantages and disadvantages

They are common to both kraft paper and its derivatives.

- Cheap, cheap and once again cheap. Insulation costs will be minimal.

- Environmentally friendly. Paper does not emit harmful substances into the atmosphere.

- Easy to use. As a wind barrier, the paper is fastened with a regular stapler; Insulating walls with corrugated cardboard also won’t make you rack your brains and look for a complicated tool.

- Material is flammable. However, in a wooden house, its fire hazard will not change the overall picture.

- Rodents make passages in paper and cardboard without any problems; Moreover, mice also appreciate the thermal insulation properties of cellulose and willingly use it to insulate their nests.

Mice will treat the new insulation without much trepidation.

- Paper is hygroscopic. If it gets wet once, this will not create problems, but constant dampness will worsen the thermal insulation many times over.

Insulation made from waste paper

Building materials are expensive, but you can save money if you make your own insulation from materials you have at home. The simplest and most affordable option for insulation is made from waste paper. Cardboard, regular A4 sheets, newspapers and other types of paper products can be used. If you decide to insulate the floor, collect all the newspapers in the house - they can become an excellent basis.

Anyone can make insulation from waste paper; it’s not difficult. First, gather all the paper you have and make sure there is enough to create blocks for an entire wall. Then follow the instructions:

- Choose a large container - preferably a cylindrical bucket.

- Shred the paper. You can tear it into small pieces or use a shredder if you have one at home. Try to make the pieces as small as possible.

- Install the frame on the wall, you will stuff it with paper. Use wooden beams to create it. Cover the wooden structure with a special vapor barrier film and begin pouring paper into the gap between the wall and the film. Compact the filler tightly so that it does not sag in the future.

Newspapers are best suited for such insulation, but if you don’t have them, or have them in small quantities, you can also use plain paper.

Try to grind the paper so that it resembles ordinary dust in appearance. Only in this case will the thermal conductivity indicators increase. Make sure that during work no excess moisture gets on the workpieces.