A water tap is required to allow water to flow through the pipeline. This type of shut-off valve allows you to open and shut off the supply of hot or cold water. All stores selling these plumbing devices provide customers with a huge selection of equipment with different operating principles. In order for the faucet to be purchased correctly, it is worth knowing the types, functions and selection criteria for this device.

There are many types of water taps, the most important thing is to choose a design for specific purposes Source moscowsad.ru

Design Features

A water tap is an indispensable device in any home. These shut-off valves are installed in the bathroom, kitchen and other places where the use of water is required. Given a certain type, all products have different design features. The main elements that make up a water tap are as follows:

- coupling;

- connection pipes - located near the base of the mixer, and are required for supplying hot and cold water;

- cover nut;

- pipe branch;

- saddle;

- body - can be plastic, aluminum, cast iron, silumin, bronze, brass;

- cap - responsible for regulating the flow of supplied liquid;

- spindle;

- aerator at the tip - sprays liquid at the outlet;

- sealing washers - prevent leakage at pipe joints;

- spout is a piece of shut-off valves that is designed to supply water to a washbasin, bathtub or sink; it is made in different shapes.

Some models of water taps can be equipped with an instantaneous water heater Source ytimg.com

All types of water taps have a special device in their design that allows you to open or shut off the water supply. For example, in spherical products it is a ball of a special design, in valve devices it is a release ring and a silicone gasket, in sensor varieties it is a special valve, in thermostatic models it is a thermostatic device.

The second indicator is the nominal pressure PN.

It is measured in bars. Almost all taps have this indicator registered, except for the Giacomini tap. Pressure is also one of the most important parameters of shut-off valves, so the maximum number of points here is 4. After analyzing the samples, they can be divided into five groups.

- The Bugatti tap has the highest pressure value - 64 bar.

- It is followed by Itap, ICMA and FIV - 50 atmospheres.

- Then Giacomini - 42 atmospheres.

- Then again 4 brands with a reading of 40 bar. They receive 2 points.

- And in last place in this category is the HERZ crane. Its nominal pressure is 25 bar.

Classification based on purpose

All types of shut-off valves are conventionally divided according to the principle of their main purpose. In this case, the following groups can be distinguished:

- devices for the water supply system, mounted in it, when coupling products and, in rare cases, ball devices are usually used;

- products for household needs, when valve or ball equipment is used, installed at the end of a pipeline for water intake, irrigation, etc.;

- household appliances, known to many as valve and mixing types of taps.

A large assortment of water taps allows you to choose a model for any room interior Source info.sibnet.ru

For domestic purposes, it is important to both regulate the water pressure and monitor its temperature. Therefore, for this purpose, mixers are most often used, which are manufactured in a wide variety of variations.

Household appliances have been made simpler. They do not need to control the temperature of the incoming liquid. These devices only change the water pressure. Coupling products can only operate in the off/on position. They simply allow you to supply or shut off water.

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

What will we compare?

And in the end you will find out which crane is better - Bugatti or Giacomini, Itap or IVR. Or maybe some other brand comes first.

10 brands will participate in the comparison.

- Bugatti Oregon;

- Itap Ideal;

- General Fittings 7100;

- IVR Evermid;

- Giacomini R254;

- FIV Perfecta;

- RUB S90;

- HERZ KV2162M;

- Bonomi Tamigi; —

- ICMA 87351.

The comparison will involve two sets of information - passport data and real measurements. In total there were 10 categories.

- Maximum temperature,

- nominal pressure,

- throughput,

- throughput,

- materials,

- weight,

- guarantee,

- equipment and design,

- rod assembly

- and wall thickness.

The number of points for different categories is not the same. More significant categories received 4 points. For example - materials, pressure, wall thickness. Less significant categories received one and two points each.

In the event that real measurements differ for the worse from the passport measurements, the given sample will receive negative points. I described the eighth category in more detail so that there would be fewer questions. The maximum number of points that one brand can receive is 27.

And of course, in the end we will see who will take first place, which brands will be the top 3, and who will be at the bottom of the list.

Principle of operation

Different types of water taps have their own design features, but they have the same operating principle:

- if water supply is required, the user activates an external device for this, for example, in sensor devices it is necessary to bring your hands to the sensor, in valve structures special caps are used on the valves, in single-lever taps you need to raise the flag upward;

- after performing these manipulations, cold and hot water begins to flow from the pipes, which is mixed in the faucet structure itself, so at the outlet the user has a liquid of the required temperature;

For a kitchen sink, it is best to choose a long valve tap with a high curved spout Source kabel-house.ru

- to adjust the temperature, an external device of the plumbing fixture is again used: the flag is moved to the required side, the valves are screwed or unscrewed;

- touch and thermostatic taps contain a special element that independently regulates the temperature before serving, that is, the equipment can be pre-set to the required temperature.

How does a valve differ from a ball valve by type of installation?

Both types of fittings have a threaded and flanged type of connection to the pipeline. However, each has differences in the range of nominal diameters. For a coupling connection it looks like this:

- valves - DN from 15 to 300 mm;

- taps - DN from 8 to 100 mm.

At the same time, ball valves also have other types of installation:

- Wafer - DN from 15 to 200 mm;

- for welding - DN from 10 to 600 mm;

- combined - DN 15 to 200 mm.

Scope of use

The different structure of the crane makes it possible to install these devices in different areas. This type of shut-off valve is used for:

- soul;

- drawing water to the bathroom;

- combined use for washbasin and bathtub;

- bidet;

- kitchen sink.

Shut-off valves for the bathroom are distinguished by a low spout design; you can find products with short faucets that allow you not to touch the equipment when performing hygiene procedures. Options for the bathroom are often made with a shower head, which is equipped with a nozzle for it.

Taps for installation in the bathroom are miniature in size, which is very convenient when using them. Source vanna-prosto.ru

The main difference from a bathroom faucet is that the faucet does not have a spout, since the water moves into the shower itself. Products can be both classic and modern - with a set of different functional buttons and a display.

Attention! The dimensions of the required washing device must take into account its diameter, allowing the user to easily care for the sanitaryware. Today, there are products with a pull-out drain - they allow you to instantly clean the sink, and devices with drain equipment make it possible to instantly close the drain to fill the sink with water.

Combined devices for the washbasin and bathroom are no longer installed so often, but are still sometimes in demand. These plumbing fixtures are characterized by an elongated spout and the ability to rotate them in the required direction.

The kitchen faucet is most often installed with a single lever, so there is no need to rotate the valves all the time. The design of the kitchen faucet must be chosen with a high bend so that it is possible to wash deep pots.

Bidet faucets come in many designs, this one is considered a classic Source burlingtonbathrooms.ru

Models for bidets have a ball aerator, which is installed in a special hole; it is often also popularly called a “hygienic shower”.

Guarantees

I will say right away that it was extremely difficult to find information about the guarantee in official sources. In the end, I was able to find this information for all brands except FIV. Since this value was not indicated anywhere in official sources. Therefore, for this brand I equate the warranty period to the minimum - 1 year.

The most interesting fact about the warranty is that the manufacturer provides a lifetime warranty on Rub ball valves. I've never seen anything like this before.

These faucets receive the maximum score at this stage of comparison - 2.

Next come General Fittings and Giacomini - 10 years warranty and 1.5 points, respectively.

Hertz and Bugatti provide a 5 year warranty. Itap, ICMA, IVR - two years.

And Bonomi is 1.

By the way, for those interested, here is a table of passport data.

| Model | Max. Temp., eC | Pressure PN, bar | Passage | Kv, mH | Material housing | Weight, g | Guarantee, years | A country prod. |

| IDEAL-0930012 | 150 | 50 | Full | 15,65 | CW617N | 2 | Italy | |

| OREGON-03070051 | 185 | 64 | Full | 16,30 | CW617N | 187 | 5 | Italy |

| 7100M2N040400A | 120 | 40 | Full | 13,80 | CW617N | 178 | 10 | Italy |

| EVERMID- 191905008 | 150 | 40 | Full | 17,00 | CW617N | 2 | Italy | |

| R254X003 | 185 | 42 | Standard | 10,20 | CW617N | 10 | Italy | |

| Perfects - 8367R004 | 120 | 50 | Standard | 11,70 | CW617N | 151 | — | Italy |

| S90D26 | 170 | 40 | Full | 28,00 | CW617N | >50 | Italy | |

| KV2162M | 150 | 25 | Full | 17,00 | CW617N | 190 | 5 | Slovenia |

| Tamigi - 760700 | 120 | 40 | Full | 10,05 | CW617N | 1 | Italy | |

| 87351AD11 | 150 | 50 | Full | 15,50 | CW617N | 2 | Italy |

You can also do subtotals a second time now.

Intermediate rating 2

The first two places remained unchanged - Bugatti and Rub. Giacomini came in third place. Next come ICMA, Itap, Herz. The General Fittings crane moved up one position in the ranking. Behind it is IVR and Bonomi. FIV closes the list.

Types of cranes: technical characteristics, advantages and disadvantages

All types of water taps are classified based on their internal design. According to the method of their operation, mixers are distinguished: single lever, valve, ball, touch, thermostatic. A complete overview of all types of designs and the principles of their operation will allow you to better understand the differences between different types of shut-off valves.

Single lever

The operating principle of these devices is quite simple: the design includes a one-piece body and a cartridge for controlling water flows. The latter is located in the body and is secured with a single nut hidden by a decorative cap. The product is so simple that there are no unnecessary elements that could foreshadow the failure of the faucet.

Single lever taps are characterized by simplicity and durability of design Source krovati-i-divany.ru

Attention! Single-lever devices are mounted on a bathtub, shower, sink; they are characterized by ease of adjustment and control.

The main advantages of mixers:

- reliable design;

- long service time;

- high maintainability;

- simple controls;

- ease of installation.

Among the disadvantages, it is necessary to note the rapid failure of silicone gaskets, as well as the difficult adjustment of the water temperature on budget products. To avoid possible troubles, it is recommended to call a plumber every few years to replace the seals.

Valve

The faucet design can be one- or two-valve. The single-valve design consists of one cap without the ability to change the temperature setting, that is, you can only adjust the water pressure. The device works by pressing a silicone seal against the so-called “saddle”. In more modern models, manufacturing companies install a ceramic faucet axle box in the body - when the valve rotates, the plates coincide and water flow begins.

Installation of valve taps is popular due to the simple installation scheme and high maintainability Source postroika.biz

Two-valve products are one of the most popular types of water taps today. The liquid is supplied thanks to the operation of 2 shut-off mechanisms that supply water to the device, in which it is mixed, thereby achieving the required temperature.

The main advantages of valve taps:

- ease of pressure adjustment;

- ease of setting the temperature;

- ease of installation;

- affordable price.

Flaws:

- expensive price of ceramic valves;

- Silicone seals need to be replaced regularly;

- short service life - no more than 10 years.

Attention! Two-valve models contain an elastic silicone seal or a ceramic valve. The scope of use of these products is bathtubs, sinks, kitchen sinks.

Ball

The design of a ball valve for water resembles single-lever products, but has a slightly different operating principle. The body contains a ball of a special design, which performs the function of supplying liquid. When the flag is raised, it rotates, the holes coincide with similar ones in the “saddle”. The more coincidences there are, the stronger the pressure occurs.

The ball valve has a simple design and is very easy to repair Source eurosantehnik.ru

The operating principle of a ball valve allows this equipment to be installed under a bathtub, sink or shower. It makes it possible to shut off the water supply at the nodes described above. In this case, the device is divided into full-bore and reduced-bore - taking into account the diameter of the hole in the ball and the possibility of passing water.

The design of the ball valve determines its advantages:

- small sizes;

- affordable price;

- reliable shut-off of water;

- long service time.

Among the disadvantages, it is necessary to note the presence of long valves to shut off the flow of water and compliance with all operating rules to prevent leaks in the structure.

Tips for choosing

Almost the entire choice of the best ball valves for the home comes down to brass products - reliable, non-corrosive, durable, inexpensive and widespread. On polypropylene pipes, polypropylene structures are used to disconnect part of the system. Metal products are always placed at the input.

Leaking water systems are expensive, so you should buy products in fairly large stores, with a receipt and certificate. Do not focus on imported products - domestic manufacturers also produce good quality products.

The tap must be inspected - there should be no chips or cracks; the thread must have at least 4-6 full turns without nicks; the walls must be thick enough; it is necessary to inspect the inside of the faucet, check how the handle and the ball turn, whether there is a hole in the ball (and whether there is a ball - occasionally there are “dummies” in which the body is machined like a pipe, the handle does not turn, there is no ball in sight). In addition, you need to try to understand whether the body is silumin - the metal inside will be white, and the faucet will seem light - the density of silumin is less than that of brass (according to the standard - 8.5-8.7 g/cm³). You can’t buy silumin - sometimes it bursts during installation.

The handle is more reliable and practical than the butterfly handle, but when installing the faucet against a wall or in a cramped bathroom, you should consider whether there is enough space to turn the lever, or whether you should buy a butterfly handle. For the entrance, a faucet with threaded pipes of the “nut-fitting” type is most often chosen.

approximate price

Brass taps with running diameters of 15 and 20 mm cost from 150 rubles, polypropylene taps of the same diameters - from 110 rubles. A lever faucet for a kitchen will cost from 2,000 rubles (the simplest) to... there is no limit to perfection - there are faucets that cost tens of thousands, and for a shower they can reach up to 100,000.

The most common malfunctions

Mostly faucets used to supply hot water are subject to breakdowns. The most common causes of faucet malfunctions are:

- incorrect valve operation;

- abrasion of the threaded connection on the body;

- failed stuffing box;

- wear of seals.

In addition, leaks in faucets are often caused by foreign particles that settle between the seal and the valve seat, which leads to the destruction of the former. Also, the gasket is often damaged by very strong screwing of the device.

Recommendation! Due to breakdowns of faucets and drain tanks, water losses often amount to more than 30%. Therefore, it is necessary to get rid of leaks that appear in a timely manner.

You can change the seal for a water tap yourself, but it is still recommended to contact specialists Source ytimg.com

The most common cause of leakage is wear of the seal. If a breakdown occurs because of this, you need to urgently call a plumber who will perform the following work:

- the main valve shuts off the water in the house (most often it is located under the sink or in the toilet);

- unscrews the union nut using the appropriate wrench;

- then unscrews the handle with the spindle and takes out the seal;

- the gasket is replaced with another one - silicone is used for cold water, leather is used for hot water;

- the size of the seal must be approximately 1 mm larger than the diameter of the valve seat, this is quite enough for a tight fit and being in its seat;

- The edges of the installed seal are trimmed using scissors at 45 degrees around the perimeter.

Sometimes installing a new seal is not necessary, but repairs are still needed. Some residents of private houses are faced with the “roar” of pipes. In this case, too, it’s all the gasket’s fault. To get rid of extraneous noise, you need to disassemble the mixer and again cut the edges of the seal at an acute angle.

Marking

The following is applied to the body:

- Manufacturer's emblem.

- Nominal diameter - DN - in mm and inches, but for small bodies the "inch" symbol may be omitted.

- PN - working pressure in bars. A bar is equal to 1 atmosphere and 0.1 MPa.

Briefly about the main thing

After you have described what kinds of water taps there are, you need to determine the main purpose of the purchase - what exactly this or that model is needed for. Taking this into account, the shape of the product, material of manufacture, design and other important points are determined.

Recommendations for choosing a crane:

- Material of the body and internal elements. Today on the market you can most often find devices made of materials such as brass and bronze - these are the highest quality and most durable devices. Silumin products do not have a long service life, the same applies to the plastic filling of the faucet.

- Design. Double-valve products are usually chosen for classic interiors, single-lever ones are characterized by ease of use, and touch and thermostatic ones will appeal to connoisseurs of new products and comfort.

- Form. For the kitchen, it is best to choose taps with a curved spout; for the bathroom, short models. Medium-length items with a slight bend fit perfectly into the washbasin.

- Fastening method. Faucets can be floor-mounted, wall-mounted, mortise-mounted, built-in - this will depend on specific preferences and the location of future installation.

- Maintainability. The most durable are modern touch taps and products with a thermostat. It often happens that the valve on a two-valve device rotates, and on single-lever devices the silicone seals fail.

- Dimensions. Connecting elements are indicated in inches, so it is advisable to find out this parameter in the store. The diameter of the tip is also important - the liquid pressure will depend on it.

Attention! When purchasing, you also need to pay attention to the aeration nozzle - the more holes, the better the water is sprayed.

Today, faucets in stores are available in a huge assortment, this allows all customers to choose the model and design that best suits their specific needs. By following all the rules for operating shut-off valves, you can extend their operating time.

What materials are they made from?

There are many materials for the manufacture of ball structures:

- Carbon steel. The most commonly used steels are 20 and 09G2S (this steel can be used at temperatures down to -60°C). Steel products are inexpensive, strong, durable, but susceptible to corrosion - they are coated with chromium or nickel to protect them.

- Stainless steel, most often grade 12Х18Н10Т. Stainless steel products can be used in systems with aggressive environments, at low temperatures, they are strong and durable, but quite expensive.

- Brass is an alloy of copper and zinc. Brass is strong and ductile, does not rust, is durable, but loses strength already at 200°C. But in residential buildings such temperatures do not exist, and at the moment this is the most popular material for small-diameter taps in housing.

- Bronze is an alloy of copper and tin (varieties of bronze are alloys with aluminum, silicon, beryllium, lead). The quality of the products is similar to brass, the price is higher. They don't occur very often.

- Titanium. Lightweight, durable, expensive, not used in everyday life.

- Plastic. They are used for plastic pipelines, made of the same material (some are made of unplasticized PVC, polyethylene, polypropylene). Such taps have sufficient strength, are not prone to corrosion, and are chemically inert. Less reliable than metal products. In everyday life, they are used on water supply and heating systems, but not at the entrance to an apartment or house.

- Ceramics. New strong, durable material. Durable, non-corrosive, chemically inert. They are quite expensive and, despite their strength and wear resistance, they are fragile and resistant to shocks and falls.

- Cast iron. Archaism. Found in some old plumbing systems (not in households).

- Silumin. Aluminum alloy with silicon. In practice, we can assume that silumin fittings are fake. They don’t last long, they crack, the threads are cut off, and they start leaking at the most inopportune moment. In general - transfer of money.

Plastic or metal faucet

With the arrival of polypropylene pipes on the market, polypropylene taps began to be actively promoted. They are offered as a cheap alternative to brass. Any plastic under constant temperature influence can become unusable in a short time. This is important to consider when purchasing plastic taps. Often, polypropylene taps are connected to a pipe by welding. After the faucet fails, you will need to cut off the pipe and weld a new faucet into it. With metal taps everything is different. You need to unscrew one and install the other.

When choosing the best faucet, remember that a brass faucet is always more reliable than any plastic.

Installation subtleties

The installation location is determined based on the fact that the crane handle should rotate smoothly. After this, you need to rewind the thread and screw it to the end of the pipe. The tap must be screwed on with some force; this happens because the winding is pressed into the thread, thus preventing the formation of leaks. A similar operation is performed with the other end of the tap.

IMPORTANT! During installation, the use of KTR (gas) type wrenches is prohibited. For installation of these products, only plumbing tools are used.

Valves

The gate valve is a simple and reliable shut-off device designed to operate in energy mains with various working environments. According to the design and the material used, this element can withstand pressure in the system up to 25 MPa.

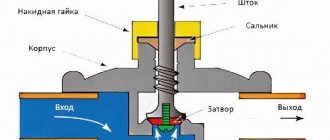

Structurally, the valve consists of the following parts:

- housing closed with a bolted lid;

- shutter;

- a spindle with a nut making up a screw pair;

- flywheel;

- wedge or damper (taking into account the design of the element).

Rice.

1. Valve diagram The cross-section of the channel with the working medium is blocked by a wedge or valve when the flywheel rotates, moving the spindle in the nut. Inside the body there are seats with mirror surfaces that seal the shutter. On shut-off elements for large pipeline diameters, a pneumatic, electric or hydraulic drive is installed, which automates the operation of the device. The drive mechanism is equipped with a gearbox that converts torque. The valve body parts are made of cast iron or steel (alloyed or stainless). The valve element is made of steel, selecting the material according to the properties of the working environment under which operation is expected. Typically, valves are used to operate in an open or closed state, without the function of adjusting the open cross-section of the line. Leaving the locking part in an intermediate position will result in deformation of the valve, resulting in damage to the device.