Equipping temporary country houses with a full-fledged water heating system is a waste of money. This option works only if the system operates in “anti-freeze” mode in the absence of the owners, maintaining a constant +5°C. In other cases, heating units are used that can quickly warm up the room. For example, you can install a long-burning fireplace stove for your summer cottage. When installing a heating device of this type, you can not only warm up the room, but also admire the flames.

We make “bubafonya”

If you are making a stove for heating premises for household or technical purposes, you should pay attention to the stove under the slightly funny name “bubafonya”.

It has a simple but original design that provides a lot of thermal energy. It works as follows:

- The lid is removed, firewood is loaded (small chips are placed on top);

- Kerosene-soaked rags are placed on top of the firewood and in the spaces between them;

- The rags are set on fire and the wood is set on fire;

- A piston is installed in the oven, the lid is closed - the unit begins to generate heat.

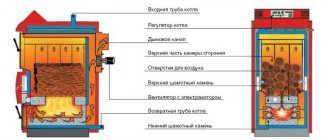

In order to understand the essence of this unusual long-burning stove, you just need to look at its diagram. The unit consists of three main parts - a body, a chimney, a heavy piston and a cover.

This picture clearly demonstrates the scheme and principle of operation of the “bubafoni”.

“Bubafonya” is simple to make; the easiest way is to build it from two whole metal barrels (without holes) with a volume of 150-200 liters. Thick steel is not particularly needed here, since due to the limited supply of oxygen, combustion will be slow and low-temperature. Let's see how to make such a long-burning stove with your own hands. Here are step-by-step instructions:

- We cut off the lid from the main barrel and prepare the combustion chamber;

- We weld a piece of pipe with a diameter of 100-150 mm into the side wall of the combustion chamber (in the upper part, according to the figure) - this will be the chimney;

- We prepare the top cover - we make a hole 40-50 mm wide in it, through which the piston pipe will pass. Bend the edges of the lid outward with gentle blows of the blade, tamp the edges of the barrel (combustion chamber) inward - the lid should fit tightly onto our barrel;

- We are preparing the piston of our long-burning furnace - we take a pipe with a diameter of about 40-50 mm (it should fit into the hole in the lid), weld the lid from the second barrel to it from below, and you cannot weld the pipe itself - air will pass through it. We weld pieces of a thick L-shaped channel to the bottom of the piston cover so that the piston itself is as massive as possible. The diameter of the piston itself must be such that it can be easily inserted into the combustion chamber (there should be gaps about 5 mm wide between the walls and the piston, through which combustion products will escape).

Our self-made long-burning stove is ready - all that remains is to install it on a non-combustible base and test it. How this stove is set on fire is described a little higher.

Some models of these long-burning stoves operate on one load of firewood for up to 20-24 hours or more, generating a large amount of heat.

Installation features

In order to control the combustion area, an air distributor is used. Oxygen is supplied through a pipe leading through the top cover. The unimpeded movement of the distributor is achieved due to the difference in diameters.

The thickness of the burning layer depends on the height of the impeller. It is recommended to pay special attention to this parameter. If the blade height is too high, the fuel will burn very quickly. It has been experimentally established that the optimal height should not exceed 50 mm.

The diameter of the air channel is selected to be at least 60 mm. A distributor opening size of more than 20 mm is considered excessive, since oxygen supersaturation increases the combustion intensity, which is unacceptable for a unit of this type. For a mixer for a warm water floor, read our article.

Types of long-burning stoves

Based on these instructions, various types of stoves are made - they all work on the principle of long burning, but have some differences.

- The Bubafonya stove is made and works on the same principle, only instead of a barrel, a gas cylinder is often used for the base.

- A furnace with a water circuit is made of a metal pipe. In addition to warming up the utility room, it also warms up the water, which is used for washing hands or other needs.

- The exhaust furnace runs on both liquid fuel (oil, diesel fuel) and wood.

Stoves based on a metal barrel or cylinder don’t look very nice; you don’t want to put one of these in a residential building, so they are installed in garages, workshops or greenhouses. And in a country house they build a long-burning brick stove.

Long-burning brick stove

The principle of operation here is somewhat different, as is the structure of the entire structure. An entire air supply system is built inside the masonry. After lighting the fire and sealing the fuel chamber, the flame is regulated using a damper, and the gases wandering inside the stove provide additional heat.

Dimensions are also calculated depending on the area of the house. The construction of a brick kiln always begins with laying the foundation, after which, observing the exact order, the bricks are laid. To work you will need the following tools:

- Plumb to ensure evenness of the structure

- Building level

- Yardstick

- Drop-shaped trowel

- Container for mixing cement

- Chisel and hammer to break the brick into required pieces

Before starting work, consult a professional stove maker. If you are doing the masonry yourself for the first time, without the help of a specialist, errors may occur that will affect the operation of the stove and accelerate wear.

Furnace foundation

Since heating of bricks in a kiln of this type occurs quickly, the foundation should be located no less than 70 cm from the base of the house. The resulting void is filled with sand to reduce the fire hazard.

- Dig a pit 70 cm deep. The diameter of the hole should be 10 cm larger than the future stove.

- The bottom of the pit is covered with waterproofing made of bitumen sheets and covered with a layer of sand (10 cm).

- Crushed stone is placed on top so that the foundation cement adheres better.

- Cement and sand are diluted (1 to 3).

- After creating the foundation, a sheet of asbestos is laid on it so that the heated brickwork does not prematurely destroy the foundation.

Chimney and reflector

reflectors will be needed

If a long-burning boiler will be installed in a room where people are constantly present, the issue of ensuring the safety of the installation should be considered. Lining the stove with brick will solve this problem.

To create a stove chimney, you can use a pipe with a diameter of 20 mm. The diameter of the combustion chamber must exceed the straight section of the pipe by 10 cm. It must be led outside with a minimum of kinks. Optimally - two bends at an angle of 45 degrees.

A few other features:

- When creating a stove chimney, its structure should be made collapsible. In this case, it will be possible to remove and clean its walls from soot during the season;

- sections of the chimney must be connected in the direction opposite to the movement of gas;

- objects and structures that are easily flammable under the influence of open fire must be moved some distance from the installation.

We are building the foundation

The base for the boiler can be made of burnt brick or rubble stone can be used. These materials do not crack when exposed to high temperatures. If a solid foundation is required, then in this case you will have to pour a solid monolithic slab. The equipment is installed on legs. Using a channel, they can be easily welded. You can hide them from view behind brickwork.

Using the boiler

Air must be supplied to a long-burning boiler in a certain quantity. This can be achieved only if it is filled in full, without leaving any free cavities. In addition to firewood, peat and sawdust can be added to the furnace firebox.

Adding fuel to the boiler should be carried out according to the following instructions:

- first you need to remove the lid and remove the regulator from the tank;

- then fuel is densely packed into the chamber;

- it is necessary to spray a flammable liquid on top of the stored fuel;

- after installing the regulator, the tank is covered with a lid, and then the damper is opened;

- After this, a splinter is thrown into the air pipe. When the smoldering process begins, the damper can be closed.

What is the difference between a homemade stove and a purchased one?

The pyrolysis process is implemented in different designs, and the choice of manufacturing a stove for a greenhouse is a decisive moment that affects its profitability. So, despite all the attractiveness of heating devices made of bricks (they act as energy accumulators, releasing the heat accumulated during the day at night), it is very difficult to build them with your own hands - it is not for nothing that good stove makers have always been valued in villages.

Stoves with metal bodies are much easier to install. For the pyrolysis version of the “potbelly stove”, any round container made of metal with a thickness of 4–6 mm is usually used - it is easy to ensure smooth operation of the gas distributor. However, homemade craftsmen also adapt available materials for their own purposes - old barrels, gas cylinders, rectangular metal boxes, etc.

Heating stove using sawdust from a barrel

In addition to the shell material, long-burning boilers are classified according to the type of fuel used - liquid or solid.

Indeed, there are devices that can even operate on used oil, and their installation is quite simple. But there is a nuance that significantly limits their use, namely, the explosion hazard of such a furnace - the slightest ingress of moisture into the firebox with hot oil will lead to instant ignition.

Waste oil furnace diagram

This is in fact a highly efficient and easy-to-use unit, but from the point of view of manufacturing “on the knee”, its design is complex and requires precise adherence to dimensions and proportions, as well as a large number of welds and the quality of their connection.

And finally, the last of the do-it-yourself long-burning stoves suitable for greenhouses is quite quick, it can be adapted to any fuel, and it burns for a very long time. In addition, there are no strict restrictions on sizes - for assembly you can use what you have on hand.

At first glance, a homemade long-burning stove differs from a purchased one only in price, but in reality everything is more complicated. In factory models, everything is thought out to the smallest detail, so if you do not have experience in this area, it is better not to take risks and purchase a finished product. This way you will protect yourself from possible metal burnout, poor chimney draft and other unpleasant problems that will only complicate the process of operating the finished stove.

Moreover, the parts at hand are not always highly compatible, so you should not count on the fact that different elements of a homemade device will be able to fit together well. However, if you have already prepared the necessary tools and materials, and also have experience in welding, it is worth trying to make a stove yourself, especially since using the diagram of the finished product, there will be no difficulties in inventing a fireplace during testing.

Advantages and weaknesses

Slow-burning wood-burning stoves significantly outperformed outdated designs, which had the following indicators:

- low efficiency, not exceeding 85% under good conditions;

- constant presence of a person to control combustion and lining the material every 3-4 hours;

- impossibility of automating various processes, etc.

The main advantage of the structures will be that the combustion process will change. Since the access of oxygen is limited, the firewood only smolders. During the process, pyrolysis gas is released, which subsequently burns in a remote chamber, increasing efficiency by 15-20%. As a result, instead of 4 hours, the lining of firewood occurs after 8-9 hours. Also, one should not forget about the automation of the combustion process.

Review of the best models

Zota Mix

A simple and easy-to-use device that runs on coal, wood, electricity and natural gas. Equipped with an X-shaped heat exchanger, an additional removable door in the front panel area and an ash collection box. The body is painted with heat-resistant paint.

- Power - 20 kW;

- dimensions - 580x425x1060 mm;

- combustion chamber volume - 35 l;

- price - 39,200 rub.

Termofor Gidravlik Engineer with heating element 12 kW

Structural steel is used to manufacture the furnace body parts; the door is made of cast iron and has a glass insert for visual monitoring of the fuel combustion process.

The coolant is heated in convective pipes from the heat generated during the combustion of flue gases and fuel. The furnace is equipped with a thermomanometer, which allows you to control the level of pressure and temperature of the water circuit.

Characteristics:

- Power - 26 kW;

- heating area - up to 250 m²;

- dimensions - 440x800x920 mm;

- combustion chamber volume - 122 l;

- price — 29705 rub.

Teplodar Cooper model OVK-10

An economy class device, equipped with a hob and a built-in heating element for 220 kW. The door is sealed with a special gasket made of silica material.

- Power - 10 kW;

- heating area - up to 100 m²;

- dimensions - 340x500x740 mm;

- combustion chamber volume - 18 l;

- price — 20166 rub.

Teplodar Cooper OVK 18

Kotoya is equipped with complete flame extinguishing in the tube sheet and an additional heat exchanger for hot water. The furnace performance can be adjusted manually or automatically.

- Power - 18 kW;

- heating area - up to 100 m²;

- dimensions - 745x422x645 mm;

- combustion chamber volume - 20 l;

- there is a hob;

- price — 24780 rub.

Dobrynya 18

A small stove designed for heating and heating hot water. Efficiency of at least 75%.

- Power - 18 kW;

- heating area - up to 180 m²;

- dimensions - 460x830x810 mm;

- combustion chamber depth - 50 cm;

- price - 20580 rub.

Teplodar Cooper Carbo 18

The stove is equipped with built-in heating elements, a thermostat and a pressure sensor, a cast iron grate, and a convenient ash drawer.

- Power - 18 kW;

- heating area - up to 180 m²;

- dimensions - 855x495x715 mm;

- Efficiency - 80%;

- price - 35930 rub.

Termofor Gidravlik Student with heating element 9 kW

The oven body is made of structural steel, the door is cast iron with glass. The equipment of the device includes a tubular electric heater and an ash box; the walls of the firebox are shielded.

- Power - 16 kW;

- heating area - up to 150 m²;

- dimensions - 370x720x770 mm;

- combustion chamber volume - 70 l;

- price — 22995 rub.

Cooper PRO 22 Teplodar

The stove is a combined type, capable of operating on one load of firewood for up to 8 hours, then the temperature is maintained using built-in heating elements.

- Power - 22 kW;

- heating area - up to 220 m²;

- dimensions - 855x485x670 mm;

- Efficiency - 85%;

- price — 25464 rub.

Breneran AQUATEN AOTV-19 t04

A powerful and practical unit connected to an open heating system with natural circulation.

- Power - 35 kW;

- heating area - up to 1000 m²;

- dimensions - 1500x800x1700 mm;

- combustion chamber volume - 200 l;

- price — 56650 rub.

Zota Master 20 KOTV (Zota Master 20)

The boiler runs on coal or wood and is additionally equipped with heating elements or a gas burner.

- Power - 20 kW;

- heating area - up to 200 m²;

- dimensions - 8200x440x760 mm;

- combustion chamber volume - 40 l;

- price — 28775 rub.

Review of popular models

Table 2. Overview of popular models and their characteristics

| Appearance of models | Characteristics |

| Bavaria series stove from EcoKamin | This Russian manufacturer has been presenting its products for only a decade and a half, but this was enough to establish its high-quality and aesthetic products on the market. In particular, steel and combined stove-fireplaces from the Bavaria series with a power of 9-11 kW are very popular. The photo shows an option with a steel body, cast iron stove and tiled cladding, which is capable of heating 110 m³ of premises. Burning duration is 5 hours, firewood consumption during this time will be 7-7.5 kg. |

| Fairway Gunther | Another Russian manufacturer specializing in the production of compact cast iron fireplaces and stoves, which are ideal for country use. In particular, the GUNTER model is presented here, capable of heating a house with an area of 140 m² with very modest dimensions of 750*750*560 mm. Its power is 14 kW and can operate on both wood and wood briquettes. |

| JOTUL oven, model F 3TD BP | Fireplace stoves from the Norwegian company Jotul (which has been in this market for 150 years) are known and loved all over the world. A huge range of models covers a variety of consumer needs. The rating presents a modest power (7 kW) and very compact (dimensions 577*707*484 mm and weighing only 106 kg) cast iron model for a summer residence. It provides secondary combustion of fuel, self-cleaning glass and the ability to connect a chimney both from above and from behind. Can heat a room with a volume of 60 m³. On a note! This manufacturer gives a 10-year warranty on its stoves, while Russian-made models have a maximum of 5 years. |

| Tim Sistem, model Alma Mons | The Serbian manufacturer of metal furnaces Tim Sistem is well known not only in Europe, but also beyond its borders. In our rating, we present the ALMA MONS model (R - with red lining, but there are options with black and white design), capable of heating up to 180 m³ of living space. It has not only a hob, but also an oven. The top and door of the firebox are cast iron, but the body is made of sheet steel painted with heat-resistant enamel. The hob has three burners and a convenient drawer below for storing firewood. By removing or installing an additional grate, the volume of the firebox can increase or decrease accordingly. This stove is intended not so much for heating as for cooking, therefore it has increased dimensions of 925 * 800 * 550 mm with a power of 6 kW. Weighs only 80 kg. |

| GreiVari, model 1.100 Screen | Another model from a Russian manufacturer, designed not only for heating, but also for cooking and heating food. Made of steel, it has a power of 10 kW, which makes it possible to heat up to 130 m³ of room air. It provides different heat transfer modes - not only intensive, but also economical. It can operate on all types of wood fuel, and if the firebox is fully loaded, it operates continuously for up to 5 hours. |

| Termofor Germa | The Germa steel stove from the Russian manufacturer Termofor, with dimensions of 450*645*1080 mm, is capable of heating at least 250 m³ of air volume. The hob is small in size, but there is a recess in the form of an open oven, in which a kettle or dishes with food can remain hot for a long time. The stove has a large, spacious firebox with a volume of 125 liters and an impressive power of 13 kW. |

Here is a far from complete list of manufacturers of fireplace stoves whose products are present on the Russian market. Among them there are many domestic brands that produce models that are quite worthy in terms of characteristics and external design. And everything would be fine. But buyers are alarmed by the ridiculously short warranty period of one year, which is determined by some of our manufacturers. For Chinese teapots there is a longer guarantee.

Stove heating of a private house

There are a huge variety of stove options. Here are just a few of them:

- cast iron stoves for heating;

- cast iron stoves for heating and cooking;

- cast iron stoves based on fireplace design;

- brick kilns "Shvedka";

- brick ovens for heating and cooking food;

- Russian stoves;

- brick fireplace stoves;

- Dutch brick stoves.

All these types have their advantages and disadvantages. Each stove for heating a home is good in its own way. Below is an example of a classic brick oven.

A carefully made stove will perfectly complement the interior of the house. Source zen.yandex.ru

Advantages of the stove heating method

In order to understand the need to install a stove for heating a private home, you need to know a number of its advantages:

- absolute autonomy

work and independence from external factors, such as turning off water, gas or electricity;

- brickwork is capable warm the room for a long time

, even if the fire in the firebox has already gone out;

- simultaneously with heating the rooms, the stove can use for cooking

;

- efficiency

in terms of the purchase of fuel and the need to pay bills for the general supply of gas, electricity and water, the availability of firewood, compared to peat or coal;

- absence

overheated and dry air;

- just a pleasant atmosphere in the house;

- Ease of operation: no high-tech electronic equipment required.

The advantage of a brick oven is that it can be designed according to your wishes and preferences. Source pinterest.com

Disadvantages of stove heating

Along with the advantages, stoves also have negative qualities.

- Enough long heating time

. This happens because bricks take a long time to heat up.

- Some usable space is lost

, since the larger the house, the larger the stove will have to be installed.

- Heavy weight

. If the stove is very large, you will have to build a separate foundation for it.

- Uneven heating

of all rooms, that is, the further the room is from the stove, the more time it will take to heat it; warm air will reach it last.

What is taken into account when choosing

Choosing which stove to install is not so easy. Stoves are made of brick and metal. Usually cast iron is used as a metal: it holds heat the longest.

When choosing the dimensions of the furnace, its shape, and material, several factors should be taken into account:

Number of heated rooms. For one or two rooms, a small metal stove is sufficient. For larger houses with more rooms, a brick oven should be installed. It can be supplemented with a water circuit that stretches through all the rooms. This option allows you to increase the efficiency of the stove, as well as heat all rooms more quickly and efficiently.

An example of the location of a stove in a small one-story houseSource lestorg32.ru

- Room dimensions

. It is logical to assume that a large brick stove will simply take up the entire space of a small room.

- The type of fuel on which the future furnace will operate. It can be gas, firewood, peat, coal. Combined devices are often used, but they have their own design and this must be taken into account.

In the old days, stoves were installed in the center of the house. They went out on each side into all the rooms, heating each of them. Massive stoves take a very long time to cool down, so after lighting you can be sure that all rooms will be heated. During installation, you will need to additionally cut a hole in the roof for the pipe to exit. In general, a place for a stove should be laid out at the stage of building a house. A well-chosen location is the key to effective use of the stove’s functionality, because it can not only heat, but also cook.

When designing a house, you can plan the location of the stove and design a pipeline for heating distant rooms and heating water. Source luchtepla.ru

When choosing a stove for a country house, you will have to think through the following points:

- where the stove will be installed;

- what size will it be;

- how the chimney will exit: through the wall or through the roof;

- if the stove is brick, you will have to cut through the floor and prepare an additional foundation for it;

- provide fire safety measures;

A flooring made of non-combustible material is always installed near the stove. Source rmnt.mirtesen.ru

Advantages of long-burning fireplace stoves

The main feature of a modern fireplace stove is the regulated combustion process of solid fuel, which occurs in the main chamber with a certain lack of oxygen. In this mode, firewood does not flare up with a bright flame, but smolders for a long time. At the same time, a temperature sufficient for pyrolysis is maintained - the decomposition of high-molecular compounds to the simplest gases, including CO. They completely burn out at the exit from the furnace, where additional air enters in the required quantities. As a result, the maximum amount of heat is released and no harmful emissions occur.

As is known, the intensity of the fuel combustion process depends on the amount of oxygen supplied. If there is enough fuel, the fuel burns intensely, releasing a large amount of heat, but the fuel burns quickly. With limited air supply, combustion can enter the smoldering stage, in which even flames are not always observed.

In principle, any furnace can be switched to a long-burning mode by manipulating the valves. Another thing is that not all of them are designed for this mode. Conventional stoves with closed valves can even be dangerous - in smoldering mode they can become a source of smoke or carbon monoxide. So it’s better to look for a fireplace stove for a summer house whose characteristics include the line “long burning” and the maximum burning time for one bookmark. This could be 6-18 hours.

How to determine whether a stove supports long burning or not

One of the characteristics by which you can distinguish a long-burning fireplace stove for a summer residence from a conventional heating stove is its sealed design. After all, you need to make sure that air flows in the right quantity. No more and no less. The second sign is the presence of several adjustable dampers.

The tightness can only be checked during combustion, but the presence of dampers can be monitored visually and how tightly they block the access of air, you can also see how well they move. In some models, the air supply is adjusted through the ash drawer. In this case, you need to look at how well it “moves” and how tightly it blocks the air supply. Although the ash box cannot be airtight, it should not leave large holes either. You can also track the presence of a seal on the door, a gate on the pipe. All these are criteria by which you can determine whether a given fireplace stove supports long-term combustion.

With afterburning of gases

How else do long-burning stoves differ from conventional ones? The fact that they can be used to burn gases that are formed during the combustion of wood. In conventional furnaces, these gases escape into the chimney, since their ignition requires a special regime - high temperature and limited access of air. In long-burning furnaces, the fuel chamber can be divided into several parts. In one firewood burns, in the rest there are gases that were formed during the decomposition of fuel. Such furnaces are also called gas generators, since it is in the smoldering mode that the largest amount of gases is formed. What is characteristic is that most of them have a calorific value higher than that of the fuel during the decomposition of which they were formed. So when using conventional ovens, a significant portion of the heat is lost. That is why it is believed that a long-burning fireplace stove is more profitable for a summer house or home, since it requires less fuel.

The downside is that a long-burning fireplace for a summer house or home costs a lot of money. The price tag for models that support long-term combustion starts from $400-450, if it is a Russian manufacturer and the body is made of structural steel. Domestic stainless steel costs twice as much, and cast iron costs twice as much. Imported fireplace stoves with a long-burning function, with the same characteristics, are approximately 70-100% more expensive.

The difference between a classic open fireplace and a fireplace stove

A classic open-type fireplace is only an additional source of heat that cannot heat a room in cold weather. It gives heat in small quantities, it spreads only during the combustion of the fuel, and immediately before the firebox. This type of heating device is good for a damp summer or autumn/spring day. In winter, it is not able to provide enough heat for the entire room, since its operation requires good draft, which “pulls out” most of the heat.

The fireplace stove has different characteristics, a closed firebox.

Such a unit can heat the room independently (with correctly selected power). And a long-burning fireplace stove for the country house and home also does this economically, as it uses fuel energy to the maximum. Date: September 25, 2022

Recommendations for selection

When choosing, you should pay attention to the power: heating 10 m2 requires 1 kW of thermal energy. You should not calculate power with a margin of area, as it will be hot. Furnaces are made from cast iron, steel, or a combination of both.

The materials differ:

- By weight. Cast iron is much heavier than steel.

- Corrosion resistance. Steel structures are susceptible to oxidation, but cast iron structures are not. This point is important for frequent and regular use.

- Resistant to high temperatures. Cast iron models do not allow the walls to burn through.

- At a price. Steel models are half the price of cast iron ones.

The best option in terms of price and quality are combined models, in which only elements susceptible to corrosion are made of cast iron.

According to their functional purpose, boilers are divided into the following types:

- Heating.

- With a water heating tank - there is a hot water supply function.

- Heating and cooking units include a hob for cooking.

- Multifunctional, include either all of the above types or some of them.

Furnaces are classified not only by material and purpose, but also by location of installation. There are corner and wall ones. Some models are topped with tiles and ceramic tiles, which increases the heat capacity of the stove.