Types of boilers Don

Gas boiler Don-20

The production uses machine equipment from well-known concerns TRU M PF and Amada. Boiler parts are distinguished by high dimensional accuracy and quality. Don units operate reliably in different operating conditions and operate for 15 to 18 years.

Types of boilers produced:

- gas;

- solid fuel.

The heat exchanger has an original design and provides for repair or replacement of the heating element.

Gas

Boiler models are equipped with a burner that uses gas. The unit is used in closed and open heating systems. The Don 16 gas boiler does not require regular addition of firewood or pellets. There is no problem of storing fuel reserves and cleaning up combustion waste.

The unit works effectively if main gas is supplied to the house; connecting cylinders is not recommended if there is no gas tank. The gas does not produce soot when burning and does not clog the chimney or heat exchanger. The discharged products have a temperature lower than the emission from solid fuel, so condensation does not form on the walls of the structural elements.

Solid fuel

Solid fuel model

The heating unit is made of steel, cast iron, and the heating element is made of copper. Manual or automatic fuel supply is provided, as is the extraction of combustion products (ash). Coal, peat, firewood, coke or fuel particles - pellets are used. Electronic coordination systems make the equipment reliable and energy-dependent; the device can operate in a single-circuit and double-circuit heating system.

Floor-standing solid fuel boilers Don require regular cleaning to remove scale and soot deposits. Scale causes the metal to overheat and leads to damage. Soot reduces the heat exchange between pipes and combustion products, which prevents the energy carrier from heating up to the required temperature levels.

Recommendations for use

For stable and high-quality operation of the system, the following several points must be taken into account:

- The units must be used in open systems (with expansion tank). In addition, you should not allow the liquid in the tank to sink to the bottom.

- If water hammers occur in the system (knocks are heard), you must immediately turn off the boiler, add liquid to the system and start the device again.

- When the system is operating, it is necessary to monitor the heating of water; its maximum heating should be 95 °C.

- Remember that when operating a solid fuel unit, it is prohibited to use only the water heater when the heating is turned off.

- When in winter you need to stop the boiler for more than a day, then it is worth draining the liquid from the pipes to prevent failure of the system.

- Before you start igniting the unit, you need to ventilate the combustion chamber for ten minutes.

If you are thinking about organizing a heating system in your home, but do not want to invest a lot of time, money and effort into boiler equipment, then you should consider the Don solid fuel boiler. This is a reliable and effective device that is popular among consumers and is gaining more and more positive reviews. Thanks to the large model range, you can choose the most suitable heating equipment option for you.

It just so happened that a DON16 solid fuel boiler was purchased for heating, which honestly worked out its low cost for two seasons using wood (sometimes damp). A serious drawback of this, and all domestic boilers, is the complete absence of at least some kind of automatic combustion temperature control. After surfing the forums, I discovered that Czech solid fuel boilers DAKON are able to regulate the air supply to the firebox themselves. Having called several companies selling DAKON boilers, I discovered that the thermostatic valve for them can be purchased separately and it is quite suitable for DON 16 boilers with minor modifications. I show what happened in the photo.

2Nikolasd and how does it burn now?

It became a little easier with adjustments. It’s not a bad idea to run to him every 20 minutes. While the antifreeze is cold, the ash door is open; when it heats up to the desired temperature, it closes. Accordingly, the air supply and antifreeze temperature are reduced. It’s too early to say whether it’s better or worse, it’s only been working with the thermostat for 2 days.

In general, of course, you need to look towards the Czech DAKON. At the time when the Czechs bought DON 16, it seemed expensive and they did not have a second circuit for hot water, which helped us out this winter until the Termex storage water heater was installed.

Nikolasd wrote: In general, of course, you need to look towards the Czech DAKON.

I think that there is no need to look in his direction so clearly. Your Don is no worse (looking at the photo), and overpaying is not economical.. ( ) I’m installing an old KChM for myself (I saved 500 euros for the vaunted abroad)

Well, adjusting the blower is only one of its big problems; there is another one that is not as easy to deal with as the blower. The problem is this. The combustion process in the DON 16 boiler, as in other similar boilers, occurs throughout the entire volume of its firebox, which means that the wood does not burn evenly, that is, first when it flares up from below, then evenly throughout the entire volume of the firebox and gradually burns out downwards. The result is surges in generated heat and rapid fuel burnout for 3-4 hours.

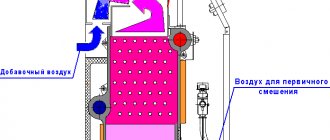

In the new generation Czech boilers with wood loaded not from the side but from above, the wood burns only in the lower part of the firebox. The combustion occurs not vertically, as in DON16, but horizontally. This apparently ensures high uniformity of heat transfer. Gradually burning out, new, untouched firewood is lowered to replace the burned-out ones, and so on until the load is completed. Combustion and heat transfer with this approach should be much more uniform than in DON 16.

Specifications

Characteristics of boilers

In some models, the temperature is regulated by a traction gearbox. The automation kit includes a supply fan and an operating mode controller.

Characteristics of coal-gas boilers:

- productivity – from 16 to 50 kW;

- heats rooms from 160 to 500 m2;

- The efficiency of gas models is 82 – 90%, for solid types – 75 – 80%;

- operating pressure of the energy carrier in the coil is 0.6 MPa, in the boiler – 0.12 MPa;

- The coolant heats up to +95°C;

- internal dimensions of the smoke extractor – 202 x 96 and 252 x 97;

- Boiler sizes range from 0.7 to 0.85 m in length, from 0.47 to 0.7 m in width, from 1.18 to 1.43 m in height.

Gas units consume from 2 to 6 m3/hour depending on productivity. The combustion products removed contain carbon monoxide (no more than 119 mg/m3) and nitrogen oxide (less than 240 mg/m3).

Weight

The mass of the boilers ranges from 140 to 270 kg.

Weight of some models:

- KS-T-16 – 153 kg;

- KS-TVm-16 – 190 kg;

- KS-TG-16 N – 155 kg;

- KS-TGVm-16N – 188 kg;

- KS-TGVm-16/20N – 200 kg

- KS-TV-31.5 – 266 kg;

- KS-TGV-31.5/40 N – 259 kg;

- KS-GV-50 N – 266 kg

The weight of the boiler depends on the dimensions, the number of plates in the heat exchanger and productivity.

Boiler structure

Construction of Don boilers

The water jacket of the Don furnace is made in such a way that the energy carrier is distributed throughout the entire body of the unit. The heat exchanger and housing are insulated with low thermal conductivity material, so energy is stored inside and the box remains cool. The firebox and body of the boiler are made of 3 mm thick steel.

The Don brand provides the opportunity to replace the copper coil in the water heating system. In hard water, the element quickly fails; replacement will extend the life of the equipment. The forced method of removing combustion products allows you to make a horizontal chimney. The manufacturer provides a warranty on the boiler for 12 months from the date of sale or 15 months from the date of manufacture if there is no sales stamp.

Floor-standing gas boilers Conord

The Russian company Conord, whose head office is based in Rostov-on-Don, has been producing heating equipment for about half a century.

An analysis of the development trends of modern heating technology and Russian operating conditions led Conord engineers to a completely different understanding of the tasks of heating equipment.

Unlike Western manufacturers, who rely on increasing functionality and the presence of additional systems, Russian technologists have tried to simplify their gas boilers as much as possible, eliminating all insignificant components and parts from the design.

As a result, a number of floor-standing energy-independent boilers were obtained, optimal for use in Russian conditions. They are reliable and stable, the lack of additional functions has not somewhat deteriorated performance, but, on the contrary, has increased the demand and preference of users.

Conord floor-standing gas boilers do not need to be connected to the power supply. This means that the use of fans or pumps is eliminated.

The combustion chamber of all units is of an open type (atmospheric), circulation of liquids occurs either naturally or using an external circulation pump.

The fundamental difference in design is only the functional features:

- Single-circuit boilers designed for heating.

- Double-circuit, capable of preparing hot water for household needs simultaneously with heating the coolant for the heating system.

In addition, there are differences in the design of the heat exchanger:

- Steel heat exchangers 3mm thick.

- Cast iron components with increased efficiency.

In addition, there are different types of control automation. These are mechanical gas supply and adjustment units.

Exist:

- Italian SIT nodes. In the boiler marking they are designated by the letter S.

- Thermohydraulic elements. They are designated by the letter N.

Recently, American-made components have been installed in some boiler models, which expands the range of boilers. In the marking they are designated by the letter M.

Advantages and disadvantages

The casing is made of galvanized steel, which prolongs the service life of the housing and gives it an impeccable appearance.

Don units have the following advantages:

- high quality of work;

- wide possibilities of service and repair;

- attractive design;

- reasonable combination of quality and cost;

- resistance to sudden changes in pressure in heating circuits;

- fuel efficiency.

Products are certified by a document of quality compliance with the international form ISO 9001 - 2011. The products have received many prestigious prizes and awards.

The disadvantages include the shallow depth of the firebox in the latest models and the absence of an electric heating element in the sales kit.

Features of operation and scope of application

When installing and operating boilers, you must strictly observe safety precautions.

During operation, you must not allow the water in the tank to evaporate to the very bottom. When starting, it is recommended that the filling rate be no more than 8 l/min; the energy carrier is supplied until water appears in the overflow tube on the expander. The automation is set to a maximum temperature of up to +95°C.

It is not permitted to use the connected boiler if the heating is switched off. In winter, the liquid from the circuits is drained if the unit remains idle for more than a day. The heater is placed below the boiler piping if the system is based on a gravity circuit.

The boiler power is selected 30% more than the calculated one if the unit will operate in harsh conditions of a poorly heated room or house without external insulation. When choosing, the device’s dependence on electricity is taken into account. If the model does not have electric ignition, you do not need to connect it to the network.

The wall or floor option is selected depending on the size of the heated area; heating capabilities depend on the ability to connect several circuits and hot water supply. Models with a closed firebox are used in apartments and houses where there are no traditional chimneys.

Installation and connection to heat supply and hot water systems

There are practically no special features during installation. The boiler must only be installed on the floor. The base must be durable and non-flammable. This is especially true in cases where the boilers will operate on solid fuel. The size of the pre-furnace non-combustible sheet must be at least 0.5 m². It can be made of steel or simply have a concrete base over a larger area than the boiler itself.

The heating system is connected using threaded connections. For more efficient use of the boiler, you can install a circulation pump on the return pipeline through a bypass. With a closed heating system, to ensure safe and trouble-free operation, install a safety group on the supply pipeline.

The hot water supply circuit is connected as follows. The water supply is also connected from the water supply to the coil at the inlet via a threaded connection, and a pipe is connected from the inlet to the mixer. This hot water supply system has one big disadvantage: it only works when the heating equipment is running. In the warm and summer months, the issue of hot water supply must be resolved in a different way.

Model range of boilers Don

Don Eco

You need to know the meaning of the letters in determining the brand of the unit in order to select the right model.

The letters stand for:

- K - the letter is present in all brands, it says that the device belongs to the category of boilers;

- C – made of steel;

- G – runs on gas;

- B – it is possible to connect a boiler;

- m – modernized version;

- N – thermostatic automatics are installed.

The numbers in the model name indicate the power of the unit.

Don 16

This modification is available to serve one or two circuits. The Don 16 boiler will heat a home with an area of about 160 - 400 m2 well. There are models with a power of 16/20 or 30/40 kW (solid fuel/gas). The device consumes 1.3 – 2.5 m3 of gas per hour.

The most popular model is convenient and economical, works without interruption in difficult conditions, and efficiency reaches 90%.

Don 20

The line of devices is characterized by energy independence, reliable design and simple maintenance. The units operate on any type of fuel; connection to a water heating circuit is provided. There is a copper removable heating element. The set includes a thermostat.

On wood it shows an efficiency of 75%, gas gives an indicator of 85%. The highest pressure in the system is 1.2 atm, the diameter of the smoke outlet channel is 140 mm. Floor-standing boiler with an open combustion chamber.

Other models

Don Stail

KS-T-11 is a non-volatile steel unit that heats small objects. The built-in regulator reduces consumption by a third. The firebox is made of carbon anti-corrosion steel, the insides are adapted to work with hard water. Heats buildings with an area of up to 110 m2, while consuming about 2 m3 of gas per hour. Available in a floor-standing version.

Don Eco is an economical compact option. Characterized by efficient heat transfer and built-in automation made in Italy. Can work with a flow-type boiler. Heats a house with an area of up to 120 m2, efficiency is 90%, the open type of firebox serves 1 circuit.

Don Stail – new equipment for working on gas. Powerful boilers are characterized by increased productivity and fit harmoniously into different interiors. There are single and double-circuit models with a power of 12 kW and an efficiency of 92%; the devices heat an area of up to 120 m2. Floor-standing units include an open firebox and a high-strength steel heat exchanger. The model has piezo ignition, the body is painted white. The manufacturer provides a 3-year warranty for this line.

Advantages

- Energy independence

- The boiler allows the use of several types of fuel (solid fuel and gas), which allows it to be very convenient in everyday life

- The boiler is specially designed for Russian operating conditions

- Excellently protected by 8 mm thermal insulation, which allows for more efficient heat retention and does not allow the surface of the boiler to heat up, which will prevent burns, etc.

- Thanks to 3mm steel, the KS-T boiler is very durable

- The KS-T Don boiler is adapted to our operating conditions - this is hard water, for example

- A replaceable coil will significantly extend the service life of the boiler and the secondary circuit as a whole.

- The design of the boiler is very successful and allows, if desired, to easily transfer the boiler from one type of fuel to another

- Long burning (up to 8 hours) from one load

- Provides you with comfortable and warm conditions in your home

- The KS-T boiler passed all tests and received all certificates in the Russian Federation

List of sources

- MyAquaHouse.ru

- www.teplogidromash.ru

- masterotopleniya.ru

- vashslesar.ru

- stroyka.radiomoon.ru

- mr-build.ru

- iobogrev.ru