Heating needs vary at different times of the day. In the morning and evening, when everyone is at home, not only heat is required, but also hot water. At night, it is better to lower the temperature by a few degrees. Several standard heating programs can be “hardwired” into the memory - the user just needs to select the appropriate one. A standard heating program includes one or more comfortable and reduced heating modes alternating throughout the day, sometimes with different temperatures in each period. It often happens that on weekdays during working hours there is no one at home, and on weekends a different heating program is required. To avoid the hassle of reprogramming, many systems are able to “create” one or more “weekly” heating programs.

If weather-compensated heating is used, it is also necessary to adjust the temperature curve, i.e. program the required boiler water temperature (it is determined using a sensor installed at any point in the system, usually at the inlet or outlet of the coolant to the boiler) depending on the outside air temperature. Let's say the heating should be turned on when the air temperature is below 20 °C. This is the first point of the curve.

When the outside temperature drops, more heating is required, but how strong depends on the conditions, in particular on the heat loss of the building: the higher they are, the more intense the heat needs to be. Typically, several such curves are “hardwired” into the control module controller; the required one is selected based on specific conditions. After selecting the curve, the boiler water temperature is set at the point of the lowest air temperature for the given region. This completes the setup.

The heating on/off time and the temperature curve setting can be programmed either from the user or service level. Some systems allow you to create your own heating programs in addition to the standard ones.

Heating programs are convenient because they allow the system to operate effectively in automatic mode. For greater convenience, several more modes are provided. Most of them can be easily turned on manually from the control module.

The “winter/summer” mode is adjusted either manually or automatically (with weather-dependent control). If the system includes a DHW circuit, in “summer” mode energy is spent only on heating sanitary water in the water heater tank, and the boiler can be completely turned off. If you are away from home for a long time, it is advisable to turn on the “vacation” mode, in which a predetermined low temperature will be maintained, and the circuit

The DHW will turn off. Of course, the freeze protection program has priority over all others; it will not completely turn off the boiler, but fuel consumption will be much more economical.

Various manufacturers also offer some other preset programs, for example, temporarily turning off the heating for ventilation or a “party” mode, which, when turned on, extends the period of comfortable heating for some time. Other available control functions depend on the system configuration. If it has a hot water tank, you can set up one-time heating modes (when a large amount of hot water is needed at odd times) and thermal disinfection (periodic heating of water to kill bacteria in it).

All modes are usually turned on and off from the central control module. If the system has additional room regulators, some modes can be activated from them, but this depends on the settings. In any case, there is nothing difficult in setting the desired mode at the user level.

REMOTE CONTROL SYSTEMS

In addition to wired communication and, occasionally, radio communication between individual elements, many manufacturers are now developing devices capable of remote control, monitoring and control of heating systems. Such systems are especially appropriate for non-permanent residence, when the house is left unattended from time to time, and it is not important or unknown for how long. To do this, you will need to include a corresponding device in the system, most often a GSM module. In fact, this is the same mobile phone or modem with a SIM card.

There are several options here and they depend on the tasks at hand. The first thing that is required in this case from the heating system when the owners periodically appear in the house is the “ability” to turn the heating on or off on command. To implement this function, in principle, one channel with a pair of contacts is sufficient, when closed, a signal is sent to the control panel. Many controllers provide such a channel; the desired mode (“turn on” or “turn off”) is programmed in advance.

Then everything is simple: call (or send an SMS) to the module number - the controller receives the signal and turns the heating on or off. The functionality of such a system is not too great compared to other methods, but it is quite sufficient to ensure comfort and save energy.

Different manufacturers may have other methods of controlling heating equipment via a GSM channel or a landline telephone network. Sometimes with the help of such devices it is possible to regulate the temperature, and the modem will additionally transmit fault messages.

Much more possibilities are provided if you use the Internet for remote control. The easiest way to connect is mobile, using an appropriate module with a SIM card; alternatively, connecting via a landline network. Theoretically, there is no difference; in practice, a landline connection is more reliable: if the mobile network is overloaded or disconnected for various reasons, remote control becomes impossible. Here you need to look at the location of the building: if it is located next to special highways, special facilities, or simply venues for large-scale celebrations, the mobile Internet can be turned off without any warning and there will be no one to file a claim.

Of course, you will need to install the appropriate software on the control computer (or an “advanced” mobile phone). Control capabilities via the Internet are the same as from a conventional control panel; user and service levels are provided. At the same time, it is important that employees of service organizations will be able to remotely reconfigure equipment, monitor the system, and in some cases, even remotely troubleshoot problems. However, it is worth considering that constant monitoring of equipment condition by a third-party organization is a paid service.

Elements of a gas boiler control circuit

The electrical circuit of a gas boiler includes blocks of electronic boards and their radio elements. You can consider an example of a diagram of a typical Ariston UNO 24MFFI unit, which displays the location of the boiler elements.

A – temperature regulator.

A11 – flame sensor.

B – button that allows you to clear the error and reboot the device (Reset).

C – on/off (Power).

D – switch to “Comfort” mode.

E – hot water temperature regulator.

F, G, H, I – LEDs that indicate faults or certain operating modes.

J – connector for connecting a thermostat.

K – pump power supply relay.

L – three-way valve power relay.

M – fan control relay.

N – gas valve relay.

O – remote control control connector.

P, Q, R, S – jumpers responsible for sparking, ignition, temperature selection and smooth ignition with maximum power.

T – two-wire connector for external thermostat and control of the set temperature.

U – power supply of the electronic circuit.

Connection CN301 terminal block, to which the gas valve, circulation pump, transformer and three-way valve actuator are connected.

The CN201 connector is connected to supply and return water temperature sensors, a chimney sensor, and a water flow sensor.

Connector CN102 in position A is responsible for setting the ignition power of the burner device. During the setup process, the red sensor will blink.

Jumper CN101 on A turns off the ignition delay, in position B it turns on the delay by 2 minutes.

CN104 – sets operation in different temperature ranges: A – 35-45ºC, B – 43-82ºC.

CN100 is responsible for setting the maximum power of the unit.

"SMART HOMES"

The concept of a “smart home” involves centralized control and interaction of several systems simultaneously. To create comfort in a room, temperature alone is not enough; you also need to take care of the ventilation or air conditioning system and air humidity. Some elements that involve the joint operation of heating with other systems can be controlled by some standard controllers, for example, when connecting window opening sensors, you can program the heating of rooms to be turned off when ventilating.

Elements of heating systems from different manufacturers communicate with each other using different protocols and using different buses - in short, they “speak different languages.” To integrate “smart heating” into a “smart home”, most likely, you will need an interface module (gateway) for the heating installation controller, connecting it with other systems not related to heating equipment. The advantages of simultaneous control of all home systems, and not just heating, are obvious; it all depends on the complexity of the system.

Ready-made devices that allow you to control your heating boiler via the Internet

Owners of heating systems are well aware that there is a fairly large selection of special room thermostats on sale. With their help, you can both maintain the desired temperature in the room and control the heating boiler via the Internet.

However, all these devices are quite expensive and cost a tidy sum, often exceeding 10 thousand rubles. Due to their high cost, these devices have not yet been able to gain a sufficient level of popularity.

The function included in these devices is very useful for owners of dachas and country houses. It allows, for example, to warm up a cold house before the owners arrive.

In addition, these devices allow you to keep the heating system in a non-freezing state. They make it possible to maintain a specified minimum temperature, at which the coolant is guaranteed not to freeze.

The described function is very useful. But not all home owners can take advantage of it. The reason for this is the high cost of the relevant equipment.

Below we will talk about how this function can be implemented without installing expensive equipment. The proposed system is not as perfect as ready-made analogues, but it is reliable and not at all expensive. It will cost about one and a half thousand rubles. And its versatility guarantees the ability to control any heating device. Its diagram is presented below.

How to connect and configure the unit

Regardless of the controller model, the principles of its connection and configuration are almost identical.

It is necessary to perform actions in the following sequence:

- Place the automatic unit in a place protected from overheating. The maximum distance depends on the length of the cables for connecting the pump, fan and required sensors. It can range from 2 to 10 meters.

- Install a blower fan to supply air at the damper location on the combustion door. If there are no mounting holes, pre-drill them.

- Install the temperature sensor using the clamp with thermal spacer supplied with the device. For this purpose, most boiler models have a special mounting hole with a depth of 60 mm and a diameter of 10 mm. If not, the sensor is mounted on a metal outlet pipe.

- Connect all necessary connectors. The block housing has terminals for the circulation pump, fan and all sensors. They must be connected in accordance with the instructions included with the device.

- The final stage is setting basic settings: temperature, air volume, etc.

After configuration, the system is connected to the power supply and a test run is performed.

How to use automation, watch the video.

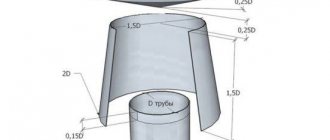

Requirements for a boiler room in a separate building

The advantages of a separate boiler room are increased safety, reduced noise levels and the ability to use the freed up space for other purposes. The disadvantage will be that the heating system will become more expensive, since it will be necessary to install an additional thermally insulated pipeline branch.

At the same time, the requirements for such boiler houses are as follows:

- separate foundation ;

- concrete base for the boiler;

- forced ventilation , which should provide three air exchanges within an hour;

- fulfillment of requirements regarding the size of the boiler room;

- no more than two heating devices can be installed in one room

- doors to the street should open outwards;

- wall surfaces and ceilings are made of non-combustible material;

- the presence of a window with a transom for daylight and emergency ventilation - the area of the window opening must be suitable for the volume of the room (0.03 m2 per 1 m³);

- presence of a chimney , if it is needed for the device being installed (for wall-mounted devices with a capacity of less than 30 kW, a coaxial pipe is allowed to exit through the wall).

A sewer pipe is also connected to the boiler so that water can be drained from the system when it is replaced.

How to choose a GSM module, what should you take into account?

Devices running on the Gsm platform can be purchased both in city stores and on well-known trading platforms such as Aliexpress. Before buying such a module, you should decide what capabilities are expected from it? For example, whether the length of the antenna cable to be connected is important, as well as how many telephone numbers can be used at the same time. When choosing a module, you should consider the following factors:

- number of control zones;

- availability of outputs for connecting sensors of different purposes;

- the ability to expand functionality by updating the device’s firmware;

- the presence of a relay through which feedback is provided;

- ability to monitor temperature and send readings to a mobile phone

A good module has adjustable temperature modes and response thresholds.

With its help, you can remotely control the operation of the boiler and make changes to the temperature. A high-quality device will make it possible to change power indicators, and will also instantly send an SMS notification about the activation of emergency sensors.

Maintenance Recommendations

The operation of heating equipment leads to wear and tear of its components. You can extend their service life by following the maintenance recommendations given by the manufacturer. In addition to those specified in the passport, you must follow the recommendations common to all types of boilers. They are as follows:

- Carrying out a routine inspection. The procedure must be carried out every year.

- The equipment must be checked by a technician twice a year. This is done after the end of the heating season and before it begins.

During the inspection the following activities are carried out:

- Visual inspection of equipment for damage. If any damage is detected, the parts should be replaced. To do this, it is recommended to call a specialist.

- Checking the input panel. There should be no melted elements.

- Checking safety devices.

- Monitoring of sensors, thermostats, relays and other components responsible for the operation of the boiler.

- Replacement of filters and other cleaning elements.

The internal parts of the boiler are inspected by a master.

It is important to carry out the inspection with the equipment disconnected from the network.

Smart heating boilers are equipped with a self-diagnosis function. The device independently analyzes its state and, if errors are detected, corrects them automatically. If an error requires the participation of a specialist, its code will be displayed.

Frequently encountered problems and their solutions

A smart heating system is able to function independently without human intervention. But there are mistakes that only a person can correct. The most popular problems include:

- Crackling noise during operation, periodic system shutdowns . The main reason is poor contact with electrical power. It is worth checking it and, if necessary, replacing it with a functional one.

- Insufficient heating at high temperature setpoint. Associated with possible third-party thermal influence on the sensors. They need to be visually inspected and removed from sources of thermal influence.

- The required temperature conditions are not provided. Associated with a malfunction of the thermostat. It needs to be replaced with a new one.

- LED flashes. Due to a broken temperature sensor that needs to be replaced.

- No connection when using the GSM module. It may be due to insufficient balance on the SIM card or lack of network. You should top up your account and wait for the network to appear. If the problem is not fixed, you need to change the SIM card.

- The device does not turn on, although it is connected according to all requirements . The main reason is a malfunction. You need to call a specialist for further diagnostics.

Preparatory stage

You need to set up a single-circuit or double-circuit gas boiler after:

- Montage.

- Setting fire.

- Long break.

After the equipment is installed, it is necessary to test the sensors, fuse, and components. In this case, the initial connection is performed by employees of the company with which you have a maintenance contract.

Five steps for installing and setting up an Ariston gas boiler:

- Heat the boiler.

- Open the gate.

- Adjust the heat to maximum power.

- At the same time, turn the valve until the yellow flames are removed.

- Test all positions and automation.

The steps will also apply to equipment from other manufacturers.

Don’t forget that a floor-standing gas boiler not only needs to be adjusted, but also cleaned. Especially if you don’t use it for a while, insects appear in the chimney.

Inspect the pipe and fan and take care of them. Including removing carbon deposits, ice, and soot as a combustion product, otherwise there will be problems with ignition.

It doesn’t hurt to remove debris from the insulator where the wiring leading to the combustion chamber is located. Can be cleaned with a soft cloth. If there is already a lot of debris, a solvent will help. And before starting the boiler again, wait until the insulator dries.

After setting up a wall-mounted gas boiler, clean the heat exchanger from scale. If you notice that the equipment has become poorly heated, flush its circuit. Pour in hot water along with descaling agent. Finally, test how the flow sensor works. Fine? The boiler can be used.

Setting up boiler and pressure automation

The automation needs to be specially configured if it starts to operate randomly. This problem is also called clocking. The reason is often the high temperature of the coolant.

There is a backup method - remove the tap in front of the device. But you need to understand that when fuel does not burn completely, more harmful substances are released.

It is better to adjust the temperature of the gas boiler. To do this, you need to move the thermostat to a cool place, if possible, or reduce the temperature where it is. And also make more coolant. You can also replace the burner if the issue arises due to its high power.

The most common reasons for interpretation:

- The tension has changed.

- The wind extinguished the burner.

- Problems with pipe patency.

- The pressure dropped.

In order to improve the operation of a gas boiler, you can configure the automation as follows. Turn the knob to "Spark". The burner will light. Next, leave it on “Iskra” for another half a minute, then turn it to “Off.”

Boilers are manufactured with regulators that can be used to set the time in the program for a period of 24 hours or for a whole week. When the equipment heats up to tedious degrees, it turns off on its own.

To adjust the pressure in the gas boiler, use the automatic block. The boiler keeps the temperature at a level and shuts off the gas when danger arises.

Some models have a knob that you can turn and select one of seven modes. You need to select the first one, remove the cover and tighten the screw under the handle on the left side. It is better to turn the handle clockwise so that the feed is gradual.

You can also set the maximum. Set the knob to the seventh mode and tighten the screw at the bottom of the equipment. And now turn counterclockwise. As soon as the flame becomes less intense, the pressure will drop.

On the automatic unit, it is correct to understand the sides when setting up a gas boiler. Where the handle is, let it be on the side. Or, depending on how the boiler was installed, this may be the top. Be careful and check the screws.

The pressure needs to be reduced if:

- The flame lights up but quickly goes out.

- You hear a popping noise during ignition.

- The flames extend beyond the designated area.

- The fire is red or red-orange.

Typically, blood pressure becomes high during cold weather. Gas companies increase it to 280 mm. Install a pressure regulator or reduce the flow by lowering it manually.

Remote control of the boiler using multifunctional thermostats

When the house has an outdated heat supply system without any hint of the ability to connect electronic units, there are no three-way valves and other automatic equipment - you can buy universal thermostats on the market that can easily be combined into a branched system into many zones with the ability to control heating via the Internet.

The kit of such equipment includes an electronic controller, where all settings for each zone take place.

It doubles as a WI-FI transmitter-receiver and through this channel “communicates” with electronic thermostats installed on each battery.

Remote control of the boiler using a Vaillant programmer

It has a separate channel connection with the boiler shutdown unit. Heating parameters can be changed either on the controller itself manually or via the Internet.

Some remote heating control systems of this type allow you to control up to 8 zones, each with 6 thermostats.

Sources

- https://oteple.com/upravlenie-gazovym-kotlom-rabota-sxemy-i-stykovka-so-smartfonom/

- https://domsgazom.ru/gazovye-kotly/upravlenie-gazovym-kotlom-cherez-smartfon

- https://delta-instrument.ru/kotly/upravlenie-gazovym-kotlom-cherez-smartfon.html

- https://mastack.ru/utilities/heating/blok-upravleniya-gazovym-kotlom-kontroller-chto-eto-za-ustroystvo-i-kak-ono-rabotaet.html

- https://sovet-ingenera.com/otoplenie/kotly/upravlenie-gazovym-kotlom-cherez-smartfon.html

- https://ProUteplenie.com/otoplenie/upravlenie-kotlom-po-gsm-cherez-smartfon-i-cherez-internet-wi-fi-podklyuchenie

- https://expo-sib.ru/upravlenie-gazovym-kotlom-cherez-smartfon-kak-pravilno-organizovat-distancionnyj-kontrol/

- https://teplowood.ru/gsm-upravlenie-kotlom-otopleniya.html

- https://future2day.ru/gsm-upravlenie-gazovym-kotlom-s-telefona/

- https://allremont59.ru/inzhenerka/otopl/kak-upravlyat-kotlom-cherez-internet.html

Which heating systems can be controlled remotely

There are practically no system restrictions on the types of heating equipment in order to implement GSM boiler control. The only restrictions are related to the fuel on which the unit runs. This control model is suitable for gas, liquid fuel and electric boilers that have the technical ability to establish a 100% level of automation. Units operating on solid fuel, due to the inertia of thermal processes in the furnace, do not yet have such a level of regulation.

Modern country houses are most often heated using a closed two-pipe heating circuit with floor and room heat control. This is achieved through the use of a circulation pump and a hydraulic boom. The heat supply complex is equipped with a reliable protection module that works with several emergency sensors: gas pressure, flame separation from the burner, unacceptable coolant temperature, pressure limit in the heating and gas mains.

Heating control via GSM - control systems provide:

- Standard temperature operating conditions, maintaining sanitary temperature in the house;

- zone heating: children's room, bathroom, bedroom, living room, kitchen, utility room;

- standby heating to preserve pipes with a water medium from hypothermia during the cold season;

- pre-heating of the facility before the arrival of residents or their guests;

- mode with a daily breakdown of heating quality, which is more preferable: night-day.

Principle of operation

Operating principle of a solid fuel boiler

If in older models of solid fuel units, to regulate the air supply, it was necessary to open or close the ash door manually, and monitor the temperature visually using a thermometer, then in new boilers an automatic draft regulator is installed. This device is energy-dependent; its functions include opening and closing the ash pan damper depending on the temperature of the water in the container.

Taking into account the inaccuracy of the settings and the dependence of the operation of the unit on natural draft in the chimney, instead of an ineffective thermostat, a fan was installed to supply the required volume of air to the combustion chamber. And the operation of the fan is ensured by a controller that receives information about the state of the coolant from the sensor.

The controller consists of a screen and a control panel, designed to set the required coolant temperature. Models that do not have such a kit can be equipped with it; the fan is installed on the mounting plate, but you must first disconnect the ash door.

The coolant temperature is adjusted regardless of external conditions.

To maintain the temperature in the room taking into account street conditions, you can install an additional automatic system with an expanded range of capabilities: remote temperature controllers, outdoor air sensor.

Both wired and wireless methods are suitable for connecting them. Thanks to the information received from the sensors, the selected temperature regime in the house is maintained. This is the most rational method.

Safety valve

Modern automatic models have an ignition system, flame control, and continuous fuel supply. For ignition, an electric incandescent element is provided, which turns on after the pellet screw container is fed into the burner.

A stable flame, recorded by a photosensor in the form of a pulse transmitted to the controller, is a signal to turn off the electric ignition. During operation, granules are fed into the auger from a bunker, the volume of which is capable of providing heat to the room for several days, without human intervention.

Solid fuel units with an automatic control system, in addition to the above devices, are also equipped with safety devices, in particular, a safety valve.

It is necessary to discharge water from the boiler tank in case of overheating, to stabilize pressure, and also provides reliable protection of the casing from destruction. The boiler can be equipped with an overheating sensor, which signals if the temperature is exceeded at the initial stage.

So, boilers can be equipped with:

- Traction control sensor.

- Water level sensors in the jacket.

- Fan - smoke exhauster.

- Pressure recorders.

- Circulation pump.

- Fuel and water consumption sensor for domestic hot water.

- Sensors for the level of pellets or coal in the container.

All these devices are interconnected with a controller that performs control and signals emergency situations. The most sophisticated devices have a remote control function, where you can control automation via the Internet and mobile applications.