An automated heating control unit will help you solve two problems:

- ensure optimal temperature inside the building and

- reduce heating costs.

In our review of heating system control units you will learn:

- When is it advisable to install a weather control unit - examples and calculations

- How does the heating control unit work?

- The main advantages of installing an automated heating control unit

- How to install an automated heating system control unit

- Effective use of automated metering units

- conclusions

Automated heating control unit

How it works

The operating principle of the heating system control unit is very simple:

When the outside temperature drops, for example to -20 °C, the heating control unit supplies more heat to the rooms, thereby maintaining the indoor temperature at the required level, for example +20 °C.

And vice versa.

When the outside temperature rises, for example to +5 ° C, the weather control unit, as it is also called, supplies less heat to the premises.

Thus, heat consumption is reduced, and the temperature in the rooms remains at the level we need, for example, +20 ° C and does not increase to +28 ° C, as often happens during sudden warming.

The temperature does not rise to +28 °C

And scientifically speaking, the weather control unit is designed to ensure and maintain the required coolant temperature in the supply pipeline, depending on the outside air temperature.

Advantages

You can easily control the system with your own hands from any distance.

What are the advantages of using an automatic heating control unit?

A modern controller with a communication module allows you to get the following advantages and benefits:

- Fine adjustment of the system in real time allows you to achieve maximum savings at the appropriate level of comfort;

- You can achieve exactly the temperature and climatic parameters of the room that you want, and for this you simply need to set the desired temperature values;

- The instant notification system about emergency conditions and abnormal events significantly increases the reliability and safety of work;

- You have the opportunity to leave the house with the heating running and control its condition from a distance, as well as control operating modes, turn the equipment on or off remotely;

- A winter visit to a country house with the heating turned off requires entering a cold room, heating the unit and waiting several hours for the room to warm up. Now you can give the command to turn on in advance and not waste time.

You just need to take out your phone.

You can assemble and connect the control system yourself - no permits or approvals are required for this. The work is easy to do by following the manufacturer's instructions. The price of the kit can range from 4 to 40 thousand rubles, depending on the configuration and manufacturer.

Important! Most modules have connectors for connecting additional sensors, which can be used to control the opening of windows and doors, listening or surveillance, and other useful functions.

The main advantages of installing an automated heating control unit

As we have already said, the goal of this energy-saving measure is to optimize the consumption of thermal energy in the building, namely:

- significant reduction in costs for heat supply to buildings and structures,

- improving the quality and reliability of heat supply,

- automatic control of heat supply to buildings and structures,

- the possibility of remote control of coolant parameters and operating modes of heat supply equipment,

- the ability, without additional costs, to reconfigure the operation of the heating system, for example, after insulating facades, replacing windows, renovating a building,

- automation of the thermal energy consumption metering system.

As practice shows, an automated control unit (ACU) allows saving about 25% - 37% of thermal energy and providing comfortable living conditions in each room.

What does the elevator unit consist of?

- Jet elevator;

- Nozzle;

- Resolution camera;

In addition, the elevator unit includes the so-called “elevator piping”, consisting of control pressure gauges, thermometers, and shut-off valves. Recently, elevators have appeared equipped with an electric drive to regulate the diameter of the nozzle. Such an elevator allows you to automatically regulate the temperature of the coolant entering the heating system. However, such models are not yet widely used due to the low degree of reliability.

When is it advisable to install an ACU - examples and calculation of the payback period

Let's look at 3 examples of installing a metering unit and calculate the payback period for this event.

All examples are from real life and are based on energy surveys that we have carried out.

And so, we have three administrative buildings (offices):

- Building 1 with an area of 1300 m2

- Building 2 with an area of 4800 m2

- Building 3 with an area of 18,500 m2

All three buildings are located in Moscow.

Here are the main results of installing the heating system control unit:

| Area, m2 | Total heat consumption for the heating period before installing the ACU | Total heat consumption for the heating period after installing the ACU | Reducing heat consumption Gcal | Cost Gcal thousand rubles. (2018) | Savings during the heating period, thousand rubles. | |

| Building No. 1 | 1 300 | 340 | 266 | 74 | 2,0 | 148 |

| Building No. 2 | 4 800 | 550 | 418 | 132 | 2,0 | 264 |

| Building No. 3 | 18 500 | 4 400 | 3 720 | 680 | 2,0 | 1 360 |

As can be seen from the table, installing a heating control unit helped reduce heat consumption during the heating period by:

- Building No. 1 – 74 Gcal,

- Building No. 2 – 132 Gcal,

- Building No. 3 – 680 Gcal.

Such a significant difference in consumption reduction is mainly due to:

- size of buildings (area and number of storeys)

- number of operating hours,

- appointment.

The following table shows:

- heat savings during the heating period (based on the cost of 2 thousand rubles per Gcal)

- cost of installation and assembly of the heating control unit and

- payback period.

| Savings during the heating period, thousand rubles. | Cost of automatic control unit (equipment and installation) | Simple payback period years | |

| Building No. 1 | 148 | 1 556 | 10,5 |

| Building No. 2 | 264 | 1 856 | 7,0 |

| Building No. 3 | 1 360 | 2 000 | 1,5 |

The main conclusion that we can draw from calculating the payback period of an automated control system

It is advisable to install an automated heating control unit in buildings with significant consumption of thermal energy and in buildings with overheating.

In small buildings and buildings with low thermal energy consumption, an automated heating control unit will pay for itself for a very long time or may never pay off.

In small buildings, it is more advisable to inspect or install elevator units, as well as install a system of balancing valves on the main risers of the heating system.

Heating system control unit

Control unit "TR-102"

For example, consider one of the most popular modifications of GSM systems today. Its main purpose is to maintain temperature in 4 zones. It occurs in a cyclic mode thanks to the thermostat. This displays the current administration area.

It will not be possible to remotely control the simplest energy-independent heat generators that do not have electronic systems.

The TR-102 unit performs the following functions:

- blocking control of unnecessary areas;

- cyclical temperature control in 4 thermal zones;

- displaying information on an integrated indicator with LEDs;

- setting up the unit using a computer or keys on the front panel of the unit;

- transferring information about regulated zones to a computer via an open communication protocol;

- saving configurations after power failures or unauthorized logins;

The presented heating control unit does not depend on power outages. An additional advantage of this system is the bimetallic sensor for thermoregulation, which is user programmable.

Conditions for using the TR-102 block:

- storage is carried out at temperatures from -45 to +70 °C;

- operation is possible at temperatures from -35 to +55 °C;

In this case, the standard atmospheric pressure should be from 84 to 106.7 kPa, and the air humidity should be 30–80%.

Why is it more profitable to install ACU in buildings with high heat consumption?

The heating control unit costs approximately the same for large and small buildings (the difference in the cost of equipment and installation is 20%-30%).

At the same time, in a large building you can save 5-10 times more thermal energy than in a small building.

In our example we see:

- The heating control unit pays for itself in 10.5 years in building No. 1, with an area of 1,300 m2 and a heat consumption of 340 Gcal before installing the ACU.

- The same unit pays for itself in 1.5 years in building No. 3, with an area of 18,500 m2 and a heat consumption before installing an ACU of 4,400 Gcal.

Our analysis and calculation are not universal.

They only give you a basic understanding of which buildings make the most sense to install automated heating control units.

We recommend calculating the feasibility and payback period of the heating control unit individually for each building, based on specific circumstances and conditions.

Heating control devices

Programmers and thermostats

The key parts of the heating control system are thermostats and programmers. They are electronic devices, in some modifications equipped with a control panel, which helps control the operation of the boiler. In addition, such a device allows you to synchronously change the indicators in two connected components.

In addition, an additional function of the programmers is adjustment using SMS from a cell phone or commands transmitted via the Internet.

You can select a suitable modification of this device based on a set of basic characteristics, which may include:

Control via the Internet occurs in the same way, only through a different communication channel between the homeowner and the electronic unit in the house

- remote communication between components using radio transmitters;

- operation of radiators (depending on the settings) can be in comfortable, normal or economical mode;

- the number of connected circuits can be increased by connecting additional modules;

- heating control via mobile phone;

- data transfer via SMS, etc.

These functional features make the presented elements quite convenient and in demand.

Zone devices

Such heat supply control elements are installed directly on radiators and boilers. In this case, adjustment by the system is carried out via Internet connection. These devices are represented by electronic thermostats. They are capable of changing the water temperature in each individual battery or the system as a whole. The differences between these thermostats are their ease of installation and affordable price. At the same time, the complexity of setting up the system is reduced, especially since they do not require a separate control cabinet. Zone devices allow the use of several thermostats that are connected to one control unit.

Heating remote control modules

The function of remote control of the heating network can be provided by special modules included in the package with shut-off and control valves and programmers.

The number of additional functions of the devices is limited by the number of connected sensors and executive relays of the electronic heating control unit itself

Internet management

Control using the Internet block is as convenient as SMS control. It features the following features:

- installation of specific software systems into a smartphone, laptop or other gadget;

- simple interface that can be easily combined with Android or Windows OS;

- unlike SMS blocks, restrictions on the number of connected users have been removed;

- Parameters are adjusted where there is access to the Internet (you do not need to use roaming for this).

When traveling abroad, experts advise not to use roaming functions to regulate heat supply via the GSM system, as this can be fraught with large financial costs. In this case, the right decision would be to entrust control of the heating system to friends you trust.

The operation of heating radiators can be controlled using local devices, represented by mechanical temperature controllers. They cannot connect to electronic controls. Their only advantage is their low cost.

How to install an automated heating system control unit

There is no fundamental change in the building's heat supply scheme when installing an automated heating system control unit (ACU).

Unlike elevator units, which are installed on each section of the house, the ACU is installed, as a rule, one per building.

The control unit is connected after the thermal energy metering unit.

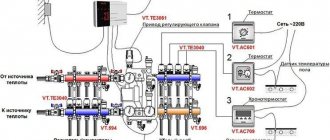

The weather control unit includes the following elements:

- control element,

- control valve with actuator,

- circulation pump,

- outside air temperature sensors,

- room temperature sensors.

The control element of the weather control unit allows you to manually change the settings that determine the operating mode of the heating system and allow you to maintain different temperatures in the building at different times.

For example, in administrative buildings on weekends and holidays, the air temperature inside can be reduced to +12 °C.

On weekdays the temperature can be increased to +18 °C.

The diagram and general view of the automated weather control unit are presented in the figures below.

The scheme provides:

- automatic switching between the main and backup pumps if one of the pumps fails,

- the possibility of introducing a flexible schedule for regulating indoor air temperature, taking into account night time, weekends and holidays for the entire heating season,

- mandatory control of the return coolant temperature,

- maintaining a temperature schedule.

The temperature of the heating system is regulated by changing the valve capacity and mixing network water using a circulation pump.

During operation, the controller:

- periodically polls the coolant temperature sensors, the indoor air sensor (if there is one) and the outdoor air sensor,

- processes the received information and

- generates control signals that command the actuator to open or close.

The control action from the controller changes the opening value of the flow area of the control valve.

In the absence of an indoor air sensor, the main control priority is maintaining the temperature schedule.

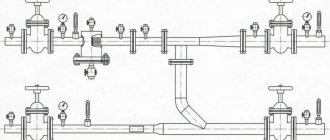

Operating principle of the elevator heating unit and diagram

With the help of an elevator, the temperature of the superheated water drops to the calculated temperature, after which the prepared coolant is sent to the heating devices. The operating principle of the elevator unit is based on mixing superheated coolant from the supply pipeline with cooled water from the return pipe.

The diagram of the elevator assembly below clearly shows that the elevator performs 2 functions at once, which makes it possible to increase the overall efficiency of the heating system:

- Works as a circulation pump;

- Performs mixing function;

Elevator unit diagram

The advantage of the elevator is its simple design and, despite this, high efficiency. Its cost is low. It does not require an electrical connection to operate.

It is worth mentioning the disadvantages of this element:

- There is no possibility of regulating the outlet water temperature;

- The pressure difference between the supply and return pipelines should not fall outside the range of 0.8-2 Bar;

- Only accurate calculation of every detail of the elevator guarantees its efficient operation;

Today, elevators are still widely used in heating units of residential buildings, since the efficiency of their operation does not depend on changes in thermal and hydraulic conditions in heating networks. In addition, the elevator unit does not require constant supervision, and to adjust it, it is enough to select the correct nozzle diameter. It is worth remembering that the entire selection of elevator unit elements should be trusted only to specialists who have the appropriate permits.

Elevator diagram

Effective use of automated metering units

The use of ACU is most effective:

- in large buildings with significant heat consumption,

- in houses connected to city heating networks,

- in buildings with insufficient pressure drop in the central heating system and where the installation of central heating pumps is mandatory,

- in buildings with decentralized hot water supply and central heating.

Elevator heating unit - what is it? Scheme and principle of operation

No one will argue that the heating system is one of the most important life support systems of any home, both a private house and an apartment. If we talk about apartments, centralized heating often predominates in them; in private houses, autonomous heating systems are most often found. In any case, the design of the heating system requires close attention. For example, in this article we will talk about such an important element as the elevator heating unit, the purpose of which is not known to everyone. Let's figure it out.