The trends in interior design are such (unless, of course, it is an industrial style in its purest form) that all communications should be hidden - in grooves, behind cladding or suspended structures. Electrical wiring hidden in baseboards is a solution that has already become almost a classic. However, not everyone knows that you can do the same with water heating pipes stretching from radiator to radiator, if you want to make them invisible, but at the same time accessible for inspection

The main advantage of laying pipes in plinth channels is the absence of labor-intensive and dirty installation processes

(no need to strip walls or cut leads in false structures). Matched to the tone of the floor covering, wall decoration or door material, such floor framing gives the interior a finished look and only eats up a little more usable space than conventional baseboards.

Since hot coolant flows through the pipes, the material used to make skirting boards must meet a number of requirements. First of all, it is heat resistance, that is, the ability to hold its shape and maintain linear dimensions under the influence of heat. The second is environmental safety, expressed in the absence of harmful volatile substances and chemical odors when heated. In addition, it is necessary that the material is impervious to moisture and does not warp both during leaks and during normal wet cleaning. And finally, its resistance to scratches and impacts that may be inflicted on it, for example, when washing floors or rearranging furniture, is important.

Decorative design of the heating pipeline

If it is not possible to hide the heating pipeline, then choose one of the ways to decorate it:

- finishing with prefabricated universal covers-boxes;

- decoration.

Universal cases-boxes

Prefabricated universal covers for pipes are made of metal, plastic or valuable wood and are a structure mounted on the wall using special brackets and, depending on the design, accommodating one or more parallel pipes.

The material used to make such pipeline casings must have a sufficient degree of heat resistance so as not to deform or lose aesthetics under the influence of heat from the heating circuit. To more evenly distribute heat flows throughout the room, the decorative lining on the pipes may have perforations or slots that ensure heat exchange between the pipeline and the room air, but this design of the elements makes it difficult to clean them from dust.

The decorative overlay on the heating pipe also performs a protective function - it eliminates the possibility of getting a burn from direct contact of the body with the circuit.

When choosing a universal casing in a store, you should give preference to types whose installation is not accompanied by damage to the existing finish of the room, and disassembly, if necessary, will not take much time.

You can also hide heating pipes with boxes of your own making. A frame is mounted from a CD profile, which is covered with plasterboard or plastic.

Decoration of heating pipes

Those who want to go beyond the template and fit the heating system into the interior of the room are looking for non-standard ways to design the pipeline, of which there are as many as there are room design options. You need to start by analyzing the existing finish and color scheme so that the design of the outline fits into the tone of the cladding or, on the contrary, contrasts effectively with it. Let's give a few specific examples.

The vertical riser of the heating circuit can be finished to look like a bamboo trunk. To do this, select a piece of bamboo wood of the required diameter, which is split longitudinally on two opposite sides. Then the transverse partitions are removed from the inside of the halves to obtain two longitudinal halves of the shell pipe. PVA glue is applied to the splitting surface, the halves are applied to the riser and aligned in their original position, after which they are pulled together with nylon clamps until the glue dries. After the clamps are removed every other day, the yellow dry bamboo can be painted green.

A vertical pipe can also be decorated to resemble the trunk of a birch or other tree, if you cover it with bark or paint it artistically - the temperature of the coolant is not so high as to threaten these finishing materials with ignition.

Horizontal sections of the heating system, as a rule, have a smaller diameter than vertical risers, and for their design you can use sesal or manila twine, which is wound onto the pipe in tight coils with inserts of decorative elements - flowers, leaves, etc.

Which way is better

The choice of method is determined by the material of the heating system pipes. If it is a copper alloy, stainless steel, i.e. durable materials that serve regularly throughout the entire life of the building, they can be walled into the wall under a layer of plaster.

A good option for masking pipes made of any materials is to install screens. They are simply irreplaceable in rooms where metal risers extend a long distance from the plane of the walls.

The advantage of this method of decorating heating pipes will also be a wide color palette and a variety of screen shapes, from which you can choose a copy that is in harmony with the style of any interior.

It is easy to install and does not interfere with heat transfer, which is very important both for private houses and apartments with centralized heating. https://www.youtube.com/embed/1ixU3Fp6-74

Purpose

Skirting heaters can serve as both the main source of home heating and as an addition to the existing heating system. Depending on the type of heating elements, they can be installed in private houses, apartments, loggias, garden houses, garages, winter gardens, and industrial premises. Electric cable skirting boards, for example, are used where placement of other heating systems is impossible. Baseboard heating pipes protect the wooden parts of the house well from dampness.

Heating baseboards work effectively in rooms with panoramic windows. Thanks to the rising warm flow, the rooms are heated completely and evenly, large windows do not fog up.

Ways to hide heating system pipes

Any pipeline, even the most modern design, does not decorate the room, since there are no pipes whose production design would be universal for any interior. One way to remove the visual presence of a heating system in the interior of a room is to hide the pipeline, which is done in several ways.

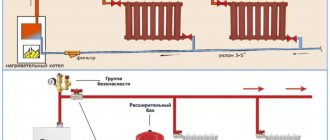

Installation of the pipeline in wall grooves under the molding

When making major home repairs, linear markings of the future heating circuit are made along the walls. Then, parallel cuts are made in the plaster layer of the partitions and load-bearing walls using a grinder and a concrete disc at a distance of 3-5 cm from each other.

In partitions, the depth of the cut can be increased, but taking into account the thickness of the wall, since, without experiencing external loads, it is still a self-supporting structure, the weight of which is significant.

The plaster layer between the cuts is removed with a hammer drill with a chisel attachment. Brackets are attached to the resulting groove-groove and the pipeline is installed, which, depending on the depth of the resulting channel, turns out to be completely or partially recessed into the wall, but not walled up in it.

This position of the contour makes it possible to neutralize linear deformations of the pipeline, as well as displacement of building structures in the event of uneven settlement of the building.

On top of the channel with the pipeline, decorative plastic or metal moldings of a suitable size, color and profile (flat or convex) are attached to the wall with self-tapping screws.

This method allows you to hide steel or PVC wiring of a heating system with a diameter of up to an inch, while maintaining the possibility of its inspection and maintenance after simple dismantling of decorative trims.

Hiding wiring with a false wall

If the room is spacious enough, and reducing its length or width by 5-10 cm is not important, then the wall on which the existing heating distribution is located can be completely hidden behind a light partition - a false wall made, for example, of plasterboard.

Work begins with marking the frame, which can be made of wooden blocks, a rectangular steel profile or a special CD profile for GC sheets. The frame design must include inspection hatches for access to shut-off valves and the ability to monitor the condition of the circuit.

To increase the functionality of the gypsum board partition, the wall can be covered with foil penofol before installing the frame, which will be an additional means of thermal insulation of the room.

Sheets of plasterboard are laid on the mounted frame and secured with self-tapping screws, on top of which one of the types of decorative finishing is performed.

Tree

Wooden skirting boards fit perfectly into the interior.

Natural wood skirting profiles are a separate category of products that can be made to order in carpentry or furniture workshops according to individual sketches and sizes. Of course, from the point of view of environmental friendliness and aesthetics (and cost too), such a solution is unrivaled. But wood is a living material, extremely sensitive to operating conditions, and with constant heat exposure (essentially, with continuous drying), it can become fragile, begin to delaminate and twist. So these phenomena will have to be prevented with the help of periodically updated impregnations that preserve the structure of the wood. Moreover, both external and internal surfaces of the profile must be processed. Attach wooden baseboards to brackets screwed to the wall.

To reduce the thermal load on wood, applying through threads to the profile or creating special slotted holes in it to remove heated air will help. And if you arrange internal lighting in such a plinth, you can simultaneously get an interesting decorative effect

How to close heating pipes in a private house

When choosing which method of masking heating pipes in a private house to resort to, it is worth taking into account the design features of the building. If the floor in the house is concrete, then the pipes can be connected to the heating system. But this option requires a mandatory screed; it is also necessary to insulate the base and lay a layer of expanded polystyrene.

If floor heating does not play a significant role for you, then you can make grooves in the floor and place pipes with thermal insulation in them. This way you will be provided with an efficient heating system.

Location of pipes in walls

This masking method is well suited if you are installing a new heating system. You will need to do the following:

At the very first stage, you need to draw up a pipe laying diagram. To do this, you need to know the diameter of the pipes (this must be taken into account), thermal insulation and the thickness of the wall layer that will be sealed. Then a recess (groove) is made in the wall, running along the entire length of the pipe placed in the wall. The grooves are made using a wall chaser or a hammer drill. Also, special attention should be paid to those areas where bends and tees will be located

It is important to place them in such a way that access to them is free. Thermal insulation is put on the pipe itself and it is placed in the groove. In order to install pipes in the wall, you need to use brackets

For them, you need to drill holes in the wall, and place dowels in them, which are designed to fix the pipes. At the final stage, the pipes need to be tested and sealed with mortar.

Location of pipes in the floor

Thermally insulated heating pipes in a concrete floor groove

- in the case of the floor, as with the walls, the first priority is to draw up a pipe laying diagram, taking into account their thermal insulation and diameter;

- a groove is made in the floor into which pipes are placed;

The top of the pipe should be below floor level.

Next, you need to put thermal insulation on the pipe and lay it in the cutouts of the concrete floor; Be sure to test the pipes for possible leaks.

The screed on top of the pipes should be thick enough. This is necessary to ensure that it does not accidentally break and the pipe does not become deformed.

This method of pipe arrangement has one drawback. It lies in the fact that if there is a leak, the gate will have to be broken and repaired.

Installation

All work is divided into stages, the sequential implementation of which achieves an effect that allows you to feel most comfortable in the room.

Preparation

This process involves preparing sources for connection. In the case of central or individual heating, this is the correct pipe layout, and when choosing an electric heater, this means free access to an outlet, which it is advisable to transfer to a separate machine. A detailed installation diagram is drawn up.

Marking and fastening the mounting strip

The process begins with preliminary marking, which is done using a cord and a level; it is necessary to obtain the exact location of all elements. The rear mounting strip is applied to the drawn line, drilling is done along the existing holes and dowels are driven in. The element takes its place on the wall.

Attaching the mounting plate

The remaining fragments are installed in strict sequence

It is important to ensure that they are located in the same plane, without distortions

Installation

Brackets for fastening the main part are installed on a fixed bar; all elements of the system are connected in series.

Connecting heating elements to each other

Thermostat location

The thermostat is installed at a distance of 2 meters from any heating element. The optimal height above the floor is 1.3–1.5 m. All work is carried out according to the connection diagram. The system is being tested.

Thus, a warm baseboard can be installed with your own hands without much effort. The main thing is to ensure that all the necessary components are available.

Baseboard heating systems

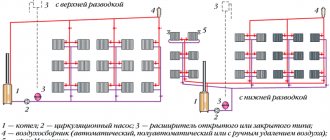

Depending on the coolant, baseboard heating systems are divided into:

- Liquid. The system consists of copper pipes where hot water or antifreeze moves.

- Electrical. Electrical energy transformed through wire and air heating elements is used as a heat source.

- Infrared. They emit thermal energy from special tapes attached to the base of the walls.

Water system

A baseboard heating system, where water or glycol flows through copper tubes, is called water or liquid. Flat parts made of copper or aluminum are mounted on the pipes.

The coolant in the tubes heats up to 85 °C. The optimal heating temperature is considered to be 65 °C. The degree of heating is adjusted automatically or manually. The efficiency of the circuit decreases when the length reaches 12.5 m.

The water version of the baseboard with heating pipes can be powered by solid fuel, electric and gas boilers, solar collectors, and heat pumps.

Electric cable

The basis of the electric baseboard is an electric heating cable. It can heat up to 100...120 °C. This is significantly higher than in a conventional heating system. The decorative casing heats up to 50...60 °C.

The design is installed in modules 1 and 2 m long. They can be connected into one circuit, the entire system operates from a regular 220 V outlet. Power consumption is quite small: on average 0.150 kW per linear meter.

The operation of the heating baseboard is controlled automatically; the set temperature is maintained by a built-in thermostat. According to calculations, 5 meters of electric heating is enough to heat a room of 20 square meters.

Infrared heating

The heat source in infrared baseboard heating is an infrared tape. It is fixed above the floor and closed with a decorative box made of plastic or plasterboard.

By analogy with the electrical cable system, the structure is equipped with heat sensors and a measuring apparatus with an information display is installed.

Installing the system is very simple, its operation is absolutely safe for humans.

Varieties

Currently, it is customary to distinguish two main groups of these products. Belonging to one or the other variety depends on the heating source, which can be electricity or coolant in the form of water.

Electric baseboard

Warm electric baseboard is a relatively simple system that allows installation in a shorter time. The general principle of the structure is that air heating elements with a power of 200 W are built into the radiator. They are mounted in one of the copper tubes of the structure, the second tube is used for laying wires.

This option is suitable for heating almost any object. The only caveat is that it cannot be used in areas with high humidity.

The installation principle is quite simple; the design does not require the creation of special connections or the use of additional parts.

Electric baseboard

Currently, an infrared baseboard has appeared on the market, which is a type of electric baseboard. This model exceeds its predecessors in terms of heat transfer by more than 4 times, while it has an even smaller size - the thickness is only 20 mm. The weight of one element does not exceed 2.5 kg, and the rated power of the system is 150 W.

The structure is fixed to the surface of the walls, using a simple connection. Due to infrared radiation, high heating of adjacent surfaces is achieved, which provides complete protection from cold air. In addition, the products do not contribute to disruption of the indoor microclimate.

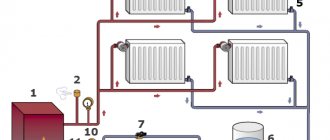

Water baseboard

The other group is made up of warm water baseboards. Its system includes the following elements:

- A collector responsible for the distribution of coolant. It consists of steel tubes through which water is supplied and returned.

- Plastic tubes placed inside each other.

- Radiator made of a box with copper heat exchanger tubes. Lamels are attached to them, providing the necessary thermal conductivity.

Water baseboard

A heater based on liquid coolant is more difficult to install than an electric one. The fact is that it is necessary to carry out the correct piping and joining of all components.

Due to the fact that the product is not always installed in places convenient for constant maintenance, all parts are made with maximum reliability. The tube coatings are resistant to various salts, which ensures a long service life.

Products for heating pipes

There is another variety that has a slightly different purpose - this is a plinth for heating pipes. It represents elements that hide the laid communications. Such products are made of plastic and are characterized by increased flexibility. They are used for laying systems consisting of one or two pipes, subject to a maximum diameter of 22 mm.

Skirting for heating pipes

What is

Baseboard ducts for heating pipes are installed around the perimeter of the room. The structures contain heating elements, from which warm air rushes up the walls and spreads throughout the room. Heating skirting boards are designed to completely replace conventional heating radiators, providing the opportunity to free up additional living space.

The contents of the channels (pipes, radiators) are covered with a decorative platband of a special design with longitudinal holes at the bottom and top. In this case, the decor can be made of plastic or metal parts.

The dimensions of skirting boards for heating pipes do not exceed 13.5 cm in height and 3.6 cm in depth (width).

Advantages and disadvantages of baseboard heating

Before you refuse to buy skirting boards for heating pipes, you should know about the following advantages:

- thermal energy is evenly distributed throughout the room, and the peculiarity of infrared radiation is such that only translucent objects are heated;

- uniform heating of air masses is observed, which is difficult to achieve in the case of convection;

- the human body perceives infrared radiation as natural;

- the ceilings have a temperature approximately equal to body temperature, and therefore there is no imbalance during interaction;

- the walls and ceiling are dry, and therefore there is no condensation effect;

- installation of such a system is very simple, and the plinth for hiding heating pipes is very suitable: various elements are not visible during visual inspection and in the photo, which is very aesthetic;

- It is also very easy to carry out repairs on baseboards under the heating system;

- when using baseboards, the system allows the use of special thermostats that maintain a certain microclimate in the room;

- the average temperature of the coolant does not have a negative effect on the efficiency of the system, but on the contrary, it allows you to save up to 30-40% of the energy spent on heating it.

Of course, such a system has disadvantages:

- the heating circuit under the baseboard cannot be longer than 15 meters in order to maintain the efficiency of the system. In large buildings, it is necessary to use distribution manifolds that allow you to combine several circuits within a building or room;

- cracks in the baseboards should not be allowed to be blocked so that heat flows are distributed evenly, and infrared radiation warms up the entire room without obstacles. Naturally, it will not be possible to completely abandon the furnishings of the room, therefore it is necessary to designate enough space on each of the walls, evenly distributing such areas;

- On the floor plinth for heating pipes, it is unacceptable to install various decorative overlays that worsen heat transfer performance;

- since the radiators of the heating system will be adjacent to the wall ceilings as tightly as possible, the use of materials in the walls that are not resistant to the formation of cracks, other deformations and subsequent destruction is unacceptable;

- the cost of such a system is quite high, because The design uses expensive materials, the refusal of which will affect the efficiency of operation.

Kinds

Currently, the Rehau company produces a considerable number of different models of heating pipes.

Experts include the most common samples:

- Rautitan;

- Stabil;

- Flex;

- Pink;

- His.

Rautitan

This model of Rehau pipes is universal. Often such a sample is used for radiator heating (for installing an internal heating network). According to some experts, the quality of the Rautitan product not only meets the European standard, but also significantly exceeds it.

Rautitan pipes are durable products that consist of cross-linked polyethylene and black sleeve fittings.

Stabil

This option is also considered universal. Most often, pipes of this model are used for installing hot and cold water supply systems. They consist of heavy-duty cross-linked polyethylene with special reinforcement inside. The diameter of such a sample is most often 16 mm.

It should be said that Rehau Stabil pipes can easily withstand even severe freezing. In addition, they have a special oxygen-protective layer. Many experts and consumers note that the service life of these building elements is at least 50 years.

Flex

This model is focused exclusively on heating systems. Moreover, it is suitable for both standard radiator heating and modern heated floors. The Flex sample is a one-piece pipe that consists of cross-linked polyethylene. The thickness of its walls is 3-8 mm, so it is quite flexible, but at the same time durable.

Rehau Flex pipes are coated on the outside with a special wear-resistant protection layer. It is designed to avoid various scratches, damage and abrasions on the surface of the product. The maximum operating temperature for this model, as a rule, is at least 80 degrees. The diameter of such a sample is most often 16 mm.

Pink

This type is also created by manufacturers exclusively for the installation of heating systems. Rehau Pink pipes have increased temperature characteristics. So, they can easily withstand fluctuations up to +130?. The diameter of this model can reach 20 mm.

Such pipes are made from special molecular cross-linked polyethylene with a protective layer. Thanks to this material, the products are quite strong, reliable and durable. The Rehau Pink model has a characteristic pink color.

His

Often, the His pipe model is used to install heating systems. It consists of polyethylene cross-linked using the peroxide method. It should be said that if you choose just such a sample, then you will have to buy additional branded components, without which it will be impossible to fasten the parts.

It is important to note that the Rehau His model comes in a variety of sizes. So, the diameter of such a pipe can vary significantly (from 20 mm to 60 mm)

The wall thickness can also be different (from 2.2 mm to 8 mm). According to most experts, this sample has increased resistance to corrosion, high impact resistance and wear resistance, which is why it is often used for various plumbing systems.

Features of baseboard heating

From its invention to the present day, heating has been divided into two types - convection and panel radiant. In the first case, the air is first heated from the hot surface of the heating device (radiator battery, convector), after which it circulates in the room and gradually heats it up.

In the second case, objects in the room are initially heated, and the air is heated from them by useful infrared radiation, which does not dry out the air or remove oxygen from it, and this process is secondary.

Among the old examples are stoves in village houses, tiled stoves in ancient mansions, in a modern interpretation - heated floors, but what about baseboard heating and what type of heating does it belong to?

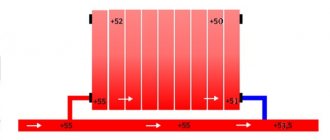

Heating a room using a warm baseboard allows you to ensure a uniform supply of heat throughout the height and area of the room being treated

Let us turn again to the opinion of the manufacturers. They unanimously claim that the heat radiated along the perimeter rises from the floor to the ceiling along the walls, warms them evenly and creates a kind of curtain from the cold penetrating from the outside. Once warmed up enough, they themselves begin to give off heat.

In fact, the temperature of walls at different heights fluctuates in the range of 26-30 ºС, and in order for heat to transfer from them, the surface must be heated much more strongly. Therefore, talk about the coveted infrared heat emanating from the walls is not so much the truth as a marketing ploy.

The planes of thermoplinths emit maximum heat at the level of the feet. It’s not just pleasant, but also optimal for well-being and health (+)

It is more correct to say that thermal baseboards are also convectors with a high surface temperature. It’s just that the room is heated more evenly by warm air currents, both emanating directly into the room and ascending along the walls. Heated walls are a guarantee that you will not find dampness or mold anywhere on them.

It is also fair to note that as you move upward, the amount of heat decreases, and this is good. It is evenly distributed in the room in the lower and middle zones, reaching the ceiling to a lesser extent. For people, such a microclimate is considered the most comfortable - they do not freeze or feel chilly, but at the same time breathe fresh and cool air.

Advantages and disadvantages of baseboard heating

The advantages include:

- fast, and most importantly, uniform heating of the room, since in essence, the wall of the room is used as a heating surface for air;

- economical - thanks to the heating speed, the cost of heating rooms is reduced. In turn, the thermal curtain, which is formed by a flow of heated air near the walls, prevents heat loss through the wall partitions;

- With the best thermal insulation, the possibility of dampening the walls is quite high. Warming them up significantly reduces the risk of condensation accumulation, mold formation, and, therefore, destruction of materials;

- low inertia – thanks to their small size, the devices “start up” faster. This same feature allows you to easily adjust the temperature in a very short time;

- thermoregulation is possible individually for each room;

- fairly simple installation, do-it-yourself;

- decorative – the heating baseboard is not much wider than the usual floor one. The entire heating system is hidden from view and does not interfere with the placement of furnishings at all. The only rule that is recommended to be followed is not to place large pieces of furniture above the heating element, as this reduces its efficiency.

Flaws:

- the method is designed for a limited area - the length of the contour should not exceed 15 m;

- installation of the system is the last, simplest stage of work. Preliminary calculations and preparation require significantly more time and accurate calculations;

- the system is effective only if the house is very well insulated.

Rules for choosing a device

When choosing an electric type in-floor convector, the main thing is to evaluate the power and dimensions of the device. It is also advisable to decide on the type of convection, which can be natural and forced.

The choice of water heaters built into the floor requires taking into account many parameters of the functional features of the device.

Main characteristics of the convector

Initially, you need to select the size of the product, the presence of a fan, the material of the housing, fins, pipes

In addition, you need to pay special attention to other characteristics

When considering a built-in water-type convector as a home heating device, you should decide on the manufacturer.

Domestic and foreign manufacturers offer heating devices with a wide power range. By choosing this parameter correctly, you will ensure a comfortable room temperature

One of the most important characteristics of a convector is the type of heating system - single-pipe or two-pipe. Connection diameters are not the primary selection criteria, since adapters are available.

Heating system pressure

This is one of the most important indicators of a water device. Any model is suitable for heating a private house, two-story and three-story cottage, since the pressure in the general heating system is usually no higher than 3 bar.

Usually, for installation in multi-storey buildings, it is recommended to install convectors built into the floor, the operating pressure of which is up to 15 Bar

For high-rise apartments, it is necessary to take into account the pressure testing and working pressure. The operating organization should find out these indicators for your home by comparing them with the characteristics of the selected model.

Selecting a coolant option

When choosing the optimal model of an in-floor convector, it is necessary to take into account the type and parameters of the device. Any model is suitable for individual heating, since the owner of the premises can independently set and control the temperature and characteristics of the coolant.

Residents of high-rise buildings will have to adapt to the conditions and indicators of the water that flows in the sewer pipes. In this case, the following factors should be taken into account: temperature, amount of suspensions, Ph, oxygen content, optimal type of device connection.

Features of space heating

Research has proven that 99% of thermal radiation affecting the skin is absorbed by the human body. The most famous natural source of thermal energy is the sun. As for rooms, studies have shown another interesting relationship: a heated room with cold walls is considered less comfortable.

The reason is that the human body better absorbs thermal energy emanating from wall ceilings, because horizontally heated air interacts with a larger area of skin than in the case of heated floors.

Electric convector power calculation

When calculating the required convector power, you should adhere to the following rule. For every 10 sq. meters you need 1 kW of heat. Provided that the ceiling is about 2.7 m high. Ideally, each window should be equipped with a device of the same length as the width of the window opening. The second option for calculating power is the following ratio: per 1 cubic meter. meter of room should be from 35 to 40 W of heat, taking into account the heat losses that occur in corner rooms, rooms near the basement and attic. For such rooms you need to take devices with a power reserve. Otherwise, the heater will not provide the required temperature and, as a result, will work continuously.

Economy and the laws of physics

However, not everything here is as rosy as it seems at first glance. If your entire wall is heated, then heat loss from it increases.

This means that it must initially be made heat-intensive and strive for maximum heat resistance.

Here, for example, is the formula for calculating heat loss known from a physics course:

Where:

S - wall area

T = (Tinside - Toutside) - the difference in wall temperatures inside the house and outside

R – surface heat transfer resistance

From this formula it becomes clear what heat loss primarily depends on. R - both with batteries and with the baseboard you do not change. The wall is the same.

But the parameters in the numerator will be different. The greater the temperature difference (T), the greater the heat loss. Let’s say that when heated by batteries near a window, the wall will conditionally have t=20C.

The temperature along the wall from the radiator to the farthest point (in the corners) is distributed along a gradient. The sections of walls to the right and left of the windows do not warm up at all.

If the entire wall inside the house is heated with a warm baseboard, from the same boiler with the same coolant temperature, then the wall will warm up more. Conventionally, up to +25C, which means, according to the formula, the difference in the numerator will increase, and heat transfer through the walls will increase.

It turns out that the more heat you lose, the more you will have to replace it

It doesn’t matter how this heat is pumped into the room - radiators or thermal baseboards

As a result, there will be no significant savings and super energy efficiency here.

The same applies to the area - S. The surface heated by the baseboard is much larger than the surface located directly behind the radiator.

The situation can be improved a little if the heating baseboard is placed not only on the external walls of the house (as with radiators), but also on its internal partitions.

Most of the heat generated in this case will remain in the house, rather than trying to immediately escape outside. A little heating of the external walls is useful not only as a source of heating, but also for the building itself. Dampness as such completely disappears.

Considering all of the above, many therefore perceive such innovations with skepticism. There are long-proven and understandable methods - the same radiators under the windows, or heated floors in a screed.

All other tricks are too expensive either at the construction stage or during operation and repair.

For a room of 16 m2 you will need from 10 to 12 meters of plinth. Its price today averages 4000-5000 rubles per meter and more. And this is in addition to the cost of components. Add here the work itself (in Moscow they charge about 1,400 rubles per linear meter), all the rooms in the house and calculate your expenses.

Is it possible to fully survive the winter with such thermoplinths? Yes, definitely. If there is sufficient linear footage and appropriate coolant temperature.

And numerous reviews on the forums confirm this. To warm up the house on the coldest winter days, the temperature of the coolant extraction in the warm baseboards collector will need to be kept around 75C. On normal days, 50-70C is enough.

The higher the temperature, the more radiant energy you will receive. When it decreases to a level of 45C and below, the warm baseboard turns into a kind of mini-convector, which heats mainly with air flows.

Therefore, do not expect any unrealistic savings from thermal skirting boards. She won't be there. Warm floors are much more profitable in this regard.

However, the system has become widely used and some consumers actively use it both as the main and additional source of heating for their apartment or individual rooms in the house.

Decorative rosette

Decorative finishing of heating pipes passing through the floor becomes an acute problem when laying parquet. There are two methods for finishing heating pipes.

Decorative covers for heating pipes

The first method involves the following: The pipes are wrapped quite tightly, without leaving gaps, turn to turn, using asbestos-containing cardboard. This is done at the height of the future baseboard. After this, the area around the pipe is laid using a heat-resistant material with good elasticity.

To cover the cracks, use a simple cement mortar.

The second method is even simpler. The gap between the parquet and the pipe is filled with an elastic sealant that has good heat resistance. The place where the floor and the pipe meet is masked using a decorative rosette. Thanks to the wide range of sockets, they can be selected for pipes of any diameter. Sockets for heating pipes consist of two parts, and their connection takes place thanks to a spike. At the junction of the two parts, the sockets are coated with glue. After the glue has dried, the sockets are connected in a way that fits around the pipe, and then pressed against the floor as tightly as possible. Remove any remaining glue using a soft cloth.

Metal

Heating pipes are covered with a perforated metal box.

Perforated metal structures used to cover heating pipes serve rather to enclose them than to disguise them as an element of interior decoration. These are a kind of shell-screens, attached to the wall not only near the floor, but at any height where the pipeline fixed with holders will be stretched.

The products are made of stainless steel or aluminum and give them a smooth round or rectangular shape. Boxes for decorating risers are also constructed from perforated sheets.

The shells are light in weight and do not exert any noticeable load on the supporting base. To shield reinforcement units, a fragment of the required size is cut from a standard section; Metal plates are installed at the joints. With a simple paint job, the screens can be blended into any interior palette, and if they get dented, the metal can be easily straightened out and re-powder coated.

Interior decor

You can hide heating pipes by using them as a piece of furniture. For decoration, natural materials, artificial flowers, and curtains are used.

Options:

- Natural motives. The design of pipes to resemble a tree trunk, vine, or reed looks impressive. To do this, the pipe is lined with matting, wrapped with hemp or similar material of natural color and texture. Then they decorate with flowers, birds, ceramic dishes, etc.

- Stylization as a support or canopy for shelves, decorative interior elements of the corresponding style.

- In rooms decorated with tiles, pipes are masked with covers with pebbles, shells, and elements stylized in a marine style.

Note! Materials should be selected taking into account their heat resistance and naturalness. The use of decorative elements made of synthetics can provoke the release of harmful substances when they are heated